Technical Contents

Engineering Guide: 3D Printed Sand Molds

Engineering Insight: 3D Printed Sand Molds and the Imperative of Precision

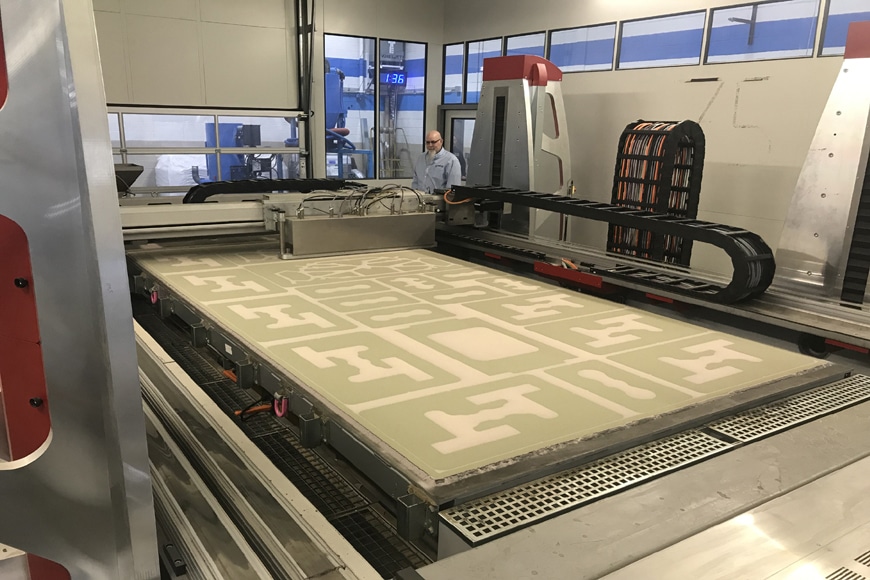

In the evolving landscape of custom metal manufacturing, 3D printed sand molds have emerged as a transformative technology, bridging the gap between complex design intent and high-integrity casting production. At Wuxi Lead Precision Machinery, we recognize that the true value of this innovation lies not just in its ability to produce intricate geometries, but in the precision with which those geometries are replicated in final metal components. Precision in 3D printed sand molds directly influences dimensional accuracy, surface finish, and the structural integrity of cast parts—factors that are non-negotiable in high-stakes industries such as aerospace, defense, and advanced energy systems.

Traditional mold-making methods often involve multi-part tooling, manual assembly, and inherent tolerances that accumulate across stages. In contrast, 3D printing enables monolithic mold construction with micron-level control, eliminating human error and minimizing post-processing corrections. However, achieving consistent precision demands more than just advanced printers—it requires deep metallurgical understanding, rigorous process validation, and a systems-level approach to material behavior during both printing and pouring phases.

At Lead Precision, our engineering team leverages over a decade of experience in high-precision casting solutions, including mission-critical components for Olympic-standard equipment and military-grade hardware. These applications demand zero-failure performance under extreme conditions, where even a 0.1 mm deviation can compromise functionality. Our work on titanium alloy structural supports for high-impact sports systems and corrosion-resistant housings for naval deployment units exemplifies how precision in sand mold fabrication translates directly into reliability of the final product.

We utilize state-of-the-art binder jetting technology with proprietary sand formulations to ensure optimal flowability, compaction, and thermal stability. Each mold is validated through in-process metrology and paired with predictive simulation software to anticipate shrinkage, distortion, and stress points before metal is poured. This proactive approach reduces scrap rates, accelerates time-to-market, and ensures repeatability across batches—key metrics for OEMs operating under tight regulatory and performance constraints.

Our commitment to precision is further demonstrated through our quality assurance protocols, which include full CMM inspection, 3D scanning verification, and traceability down to individual mold layers. This level of scrutiny is not standard across the industry, but it is fundamental to our philosophy: that advanced manufacturing must be as exacting as the applications it serves.

Technical Specifications: 3D Printed Sand Mold Capabilities at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Layer Thickness | 0.2 mm – 0.3 mm |

| Build Envelope | Up to 1000 mm × 600 mm × 500 mm |

| Dimensional Accuracy | ±0.2 mm per 100 mm (typical) |

| Surface Roughness (as-printed) | Ra 12.5 – 25 μm |

| Sand Material Options | Silica, Chromite, Zircon, and Resin-Coated |

| Binder System | Inorganic and Organic (low-ash) |

| Compatible Alloys | Iron, Steel, Aluminum, Bronze, Nickel-based |

| Post-Processing Integration | CNC core drilling, sealing, coating |

By combining cutting-edge 3D printing with disciplined engineering oversight, Wuxi Lead Precision Machinery delivers sand molds that meet the most stringent performance criteria. For manufacturers pushing the boundaries of design and durability, precision is not optional—it is the foundation.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration for 3D Printed Sand Mold Manufacturing

Wuxi Lead Precision Machinery delivers unmatched dimensional accuracy and surface integrity for complex 3D printed sand molds through an integrated digital manufacturing ecosystem. Our process begins with high-resolution sand binder jetting systems capable of producing intricate core and mold geometries up to 1,200 x 800 x 600 mm. However, additive manufacturing alone cannot achieve the tight tolerances required for critical metal casting applications. This is where our advanced subtractive capabilities become essential. We deploy state-of-the-art 5-axis CNC machining centers, specifically DMG MORI CTX beta 1250 and Hermle C30U models, to refine critical sealing surfaces, gating systems, and parting lines. These machines operate with sub-50μm repeatability and utilize high-speed spindles (up to 24,000 RPM) with dynamic tool compensation to eliminate micro-vibrations during fine finishing. This ensures perfect mold assembly alignment and eliminates flash defects in the final casting.

Rigorous quality control is non-negotiable. Every machined sand mold undergoes comprehensive inspection using Zeiss CONTURA G2 CMM systems equipped with VAST XXT scanning probes and CALYPSO software. Our inspection protocol validates geometric dimensioning and tolerancing (GD&T) against the original CAD model, focusing on critical features such as core pin locations, draft angles, and cavity wall thickness. Surface roughness is measured to ISO 25178 standards using portable profilometers, ensuring optimal metal flow and surface finish on the cast component. All inspection data is digitally archived and provided in a full FAI (First Article Inspection) report, offering complete traceability from digital model to physical mold.

The table below details achievable tolerances for machined sand molds, reflecting our operational standards under controlled workshop conditions (20±1°C). These values represent the combined capability of our 5-axis CNC machining and CMM validation processes. Tolerances are achievable on features with appropriate aspect ratios and material stability; complex thin-walled sections may require engineering consultation.

| Feature Type | Tolerance Range | Measurement Standard | Critical Application Example |

|---|---|---|---|

| Dimensional (Linear) | ±0.05 mm | ISO 2768-mK | Core box mounting interfaces |

| Geometric (Flatness) | 0.03 mm/m | ISO 1101 | Parting line sealing surfaces |

| Positional (Holes) | ±0.02 mm | ISO 5458 | Core pin alignment holes |

| Surface Roughness (Ra) | 1.6 – 3.2 μm | ISO 25178 | Casting cavity finish |

| Angular | ±0.05° | ISO 1101 | Draft angles on complex contours |

This precision engineering capability directly translates to superior casting outcomes. Reduced machining allowances on molds minimize sand inclusion risks, while exact geometric control ensures consistent wall thickness and eliminates costly casting rework. By combining additive sand printing with deterministic CNC finishing and metrology-grade verification, Wuxi Lead provides foundries with molds that deliver repeatable casting integrity, reduced scrap rates, and accelerated time-to-market for high-value metal components. Our China-based facility maintains Western engineering standards while offering competitive cost structures, making us the strategic partner for demanding aerospace, energy, and industrial pump manufacturers globally.

Material & Finish Options

Material Selection for 3D Printed Sand Molds in High-Precision Metal Casting

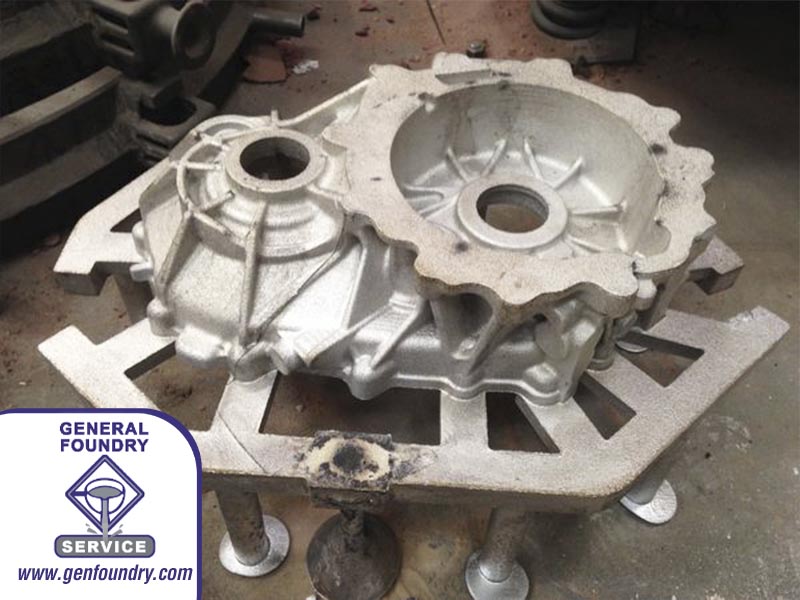

Selecting the appropriate base material and surface treatment is critical when utilizing 3D printed sand molds for custom metal manufacturing. At Wuxi Lead Precision Machinery, we specialize in integrating advanced sand mold printing with precision casting techniques to deliver high-integrity components in aluminum, steel, and titanium. Each material offers distinct mechanical properties, casting behaviors, and post-processing requirements that must align with the end application’s performance demands.

Aluminum alloys are widely used in aerospace, automotive, and industrial applications due to their excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. When cast using 3D printed sand molds, aluminum benefits from the mold’s high dimensional accuracy and complex internal geometries, enabling lightweight designs with integrated cooling channels or hollow structures. The low melting point of aluminum (approximately 660°C) reduces thermal stress on the sand mold, minimizing defects such as cracking or erosion. For enhanced durability and surface protection, anodizing is strongly recommended. Anodizing creates a controlled oxide layer that improves wear resistance, electrical insulation, and aesthetic consistency, especially in exposed components.

Steel, particularly low-alloy and stainless variants, is chosen for applications requiring high strength, toughness, and resistance to elevated temperatures. Casting steel in 3D printed sand molds allows for intricate part consolidation and reduced machining time. However, steel’s higher pouring temperature (around 1,500°C) demands sand molds with superior thermal stability and refractory properties. Our proprietary binder systems ensure mold integrity under extreme thermal loads, reducing the risk of burn-in or veining. Post-casting heat treatments such as quenching and tempering are typically applied to achieve desired mechanical properties. While anodizing is not applicable to steel, surface finishes such as passivation, plating, or coating are used depending on environmental exposure.

Titanium and its alloys are reserved for mission-critical applications in aerospace, medical, and defense sectors where exceptional strength-to-density ratios and corrosion resistance are paramount. Titanium casting requires strict atmospheric control due to its reactivity at high temperatures. Our process integrates vacuum-assisted pouring with specially formulated sand molds to prevent contamination. The result is a near-net-shape component with minimal material waste and excellent structural fidelity. Surface finishing often includes grit blasting or chemical passivation to remove alpha-case layers and enhance fatigue performance.

The following table summarizes key material and finish specifications relevant to 3D printed sand mold casting:

| Material | Melting Point (°C) | Typical Applications | Compatible Finishes | Mold Requirements |

|---|---|---|---|---|

| Aluminum | 660 | Aerospace, Automotive | Anodizing, Powder Coating | High resolution, low ash content |

| Steel | ~1,500 | Industrial, Energy | Passivation, Plating | High thermal stability |

| Titanium | 1,668 | Aerospace, Medical | Grit Blasting, Pickling | Vacuum-compatible, low reactivity |

Material and finish selection must be approached holistically, considering design intent, production volume, and lifecycle conditions. At Wuxi Lead Precision Machinery, we support clients through every stage—from alloy selection to final surface treatment—ensuring optimal performance and cost-efficiency in every cast component.

Manufacturing Process & QC

Precision Sand Casting Through Additive Manufacturing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we transform complex metal component requirements into flawless physical reality using industrial 3D printed sand molds. Our integrated process eliminates traditional pattern-making bottlenecks while guaranteeing the dimensional accuracy and structural integrity demanded by aerospace, energy, and heavy machinery sectors. This seamless workflow ensures zero defects from initial concept through high-volume manufacturing.

The process begins with rigorous digital design validation. Our engineering team conducts comprehensive Design for Manufacturing (DFM) analysis on client CAD models, optimizing geometry for casting feasibility and material flow. Advanced solidification and thermal simulation software predicts potential defects like shrinkage or porosity, allowing proactive mold cavity and gating system refinement. Only upon achieving virtual defect elimination do we proceed to physical prototyping. This critical phase utilizes our high-resolution binder jetting systems to produce exact sand molds directly from the validated digital file. Each prototype mold undergoes non-destructive testing (NDT), including CT scanning and pressure decay analysis, to verify internal integrity and surface finish against the original CAD. Rapid iteration based on prototype casting results ensures the final mold design meets all functional and dimensional specifications before committing to production.

Mass production leverages the same validated digital mold data, ensuring absolute consistency. Our automated foundry lines integrate seamlessly with the additive process, maintaining strict control over sand composition, binder saturation, and curing parameters. Real-time in-process monitoring tracks critical variables like mold density and dimensional stability at every station. Each production mold undergoes 100% automated optical inspection against the master CAD model, with AI-driven analysis flagging deviations beyond micron-level tolerances. This closed-loop system, combined with our ISO 9001-certified quality management protocols, guarantees every casting meets stringent zero-defect criteria. Material traceability and batch-specific documentation provide full auditability for critical applications.

Our additive sand casting capabilities deliver unmatched precision and reliability for complex geometries. Key production specifications are maintained consistently across all volumes.

| Parameter | Specification |

|---|---|

| Material Compatibility | All ferrous & non-ferrous alloys |

| Dimensional Accuracy | ±0.1% (min ±0.1mm) |

| Surface Finish (As-Cast) | Ra 3.2 – 6.3 µm |

| Max Mold Size | 1000 x 700 x 500 mm |

| Lead Time Reduction | 70% vs. traditional tooling |

| Defect Rate | < 0.25% (PPM compliant) |

This end-to-end digital workflow eliminates tooling variables inherent in conventional methods. By embedding quality at every stage—from virtual simulation through automated production inspection—we deliver castings that require minimal post-processing and consistently exceed customer specifications. Wuxi Lead Precision Machinery provides not just components, but certified manufacturing assurance for mission-critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printed Sand Mold Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision metal components through innovative manufacturing technologies, including 3D printed sand molds. Our expertise in custom metal manufacturing enables us to support industries such as aerospace, automotive, energy, and heavy equipment with unmatched accuracy, speed, and repeatability. When you partner with Lead Precision, you gain access to a vertically integrated production ecosystem that combines cutting-edge 3D sand printing, advanced metallurgy, and rigorous quality assurance—all under one roof.

Our 3D printed sand mold technology revolutionizes traditional casting by eliminating the need for physical patterns, reducing lead times by up to 70%, and enabling the production of highly complex geometries that are impossible with conventional methods. This digital approach ensures dimensional accuracy within ±0.1 mm, surface finishes down to Ra 6.3 µm, and full repeatability across production runs. Whether you require low-volume prototypes or high-volume serial production, our systems are designed to scale with your needs while maintaining consistent quality.

We operate state-of-the-art 3D sand printers capable of producing molds for a wide range of non-ferrous and ferrous alloys, including aluminum, ductile iron, and stainless steel. Our in-house foundry is equipped with automated pouring systems, real-time process monitoring, and full NDT inspection capabilities, ensuring every casting meets international standards such as ISO 9001 and IATF 16949.

Below are key technical specifications of our 3D sand printing and casting capabilities:

| Parameter | Specification |

|---|---|

| Maximum Build Volume | 1000 x 600 x 500 mm |

| Layer Thickness | 200 – 400 µm |

| Dimensional Accuracy | ±0.1 mm per 100 mm |

| Surface Roughness (as-cast) | Ra 6.3 – 12.5 µm |

| Minimum Wall Thickness | 3 mm (aluminum), 5 mm (iron) |

| Supported Sand Types | Silica, Chromite, Zircon |

| Binder Systems | Inorganic (no-bake), Phenolic (heat-cured) |

| Compatible Alloys | Aluminum, Cast Iron, Stainless Steel, Bronze |

| Production Lead Time (avg.) | 7–15 days (from CAD to finished casting) |

| Quality Standards | ISO 9001:2015, IATF 16949, NDT Certified |

By integrating digital mold making with decades of foundry experience, Wuxi Lead Precision Machinery delivers superior part performance, reduced material waste, and faster time-to-market. Our engineering team works closely with clients to optimize designs for manufacturability, conduct rapid prototyping, and ensure seamless transition into full-scale production.

For manufacturers seeking a reliable, technology-driven partner in Asia, Lead Precision offers competitive pricing, transparent communication, and on-time delivery—without compromising quality.

Contact us today at [email protected] to discuss your next project. Let us help you transform your casting challenges into precision-engineered solutions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.