Technical Contents

Engineering Guide: 3D Printed Replacement Parts

Engineering Insight: 3D Printed Replacement Parts – The Critical Role of Precision in High-Performance Applications

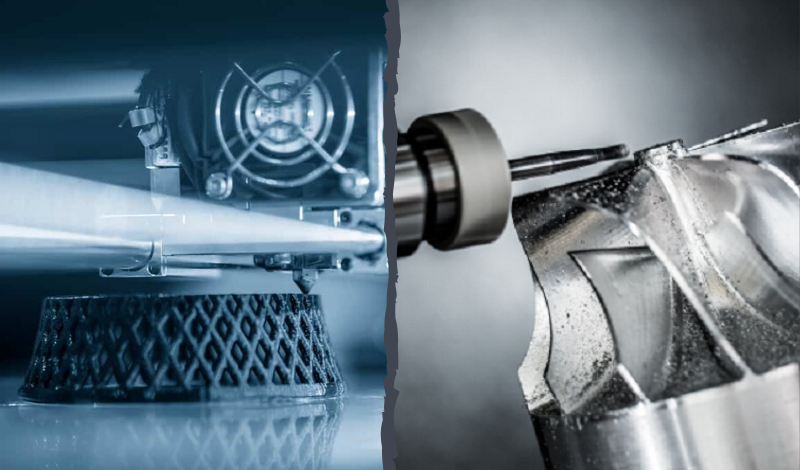

In the evolving landscape of industrial manufacturing, 3D printed replacement parts have emerged as a transformative solution for maintaining legacy systems, reducing downtime, and enabling rapid prototyping. However, the success of additive manufacturing in mission-critical environments hinges on one non-negotiable factor: precision. At Wuxi Lead Precision Machinery, we understand that producing functional, durable, and dimensionally accurate replacement components demands not only advanced equipment but also deep engineering expertise and rigorous quality control.

While 3D printing offers unparalleled design flexibility and reduced lead times, the technology alone does not guarantee performance. The transition from prototype to production-grade part requires meticulous attention to material properties, thermal management, post-processing techniques, and geometric accuracy. In high-stakes applications—such as aerospace, defense, and high-performance industrial machinery—micro-level deviations can result in catastrophic failure. This is where precision engineering separates viable solutions from experimental curiosities.

Wuxi Lead Precision Machinery brings over a decade of experience in custom metal manufacturing, with a proven track record in delivering components for Olympic-standard equipment and military-grade systems. Our involvement in these elite projects underscores our commitment to tolerances measured in microns, material integrity verification, and full traceability. When applying this expertise to 3D printed replacement parts, we integrate laser powder bed fusion (LPBF) technologies with stringent metrology protocols, ensuring every component meets or exceeds original equipment manufacturer (OEM) specifications.

Our process begins with high-resolution scanning of legacy parts, followed by intelligent reverse engineering to restore worn or obsolete geometries. We then select appropriate alloys—such as titanium Ti6Al4V, Inconel 718, or maraging steel—based on mechanical requirements and environmental exposure. After printing, components undergo stress-relief heat treatment, precision machining where necessary, and surface finishing to achieve the required fatigue resistance and dimensional stability.

The result is a replacement part that is not only functionally identical but often enhanced through optimized internal structures made possible by additive manufacturing. This capability is particularly valuable for clients managing aging infrastructure where OEM support has been discontinued.

Below are typical specifications achievable through our integrated 3D printing and precision engineering workflow:

| Specification | Capability |

|---|---|

| Layer Thickness | 20–50 μm |

| Dimensional Accuracy | ±0.05 mm for features under 100 mm |

| Surface Roughness (as-printed) | Ra 10–15 μm |

| Surface Roughness (post-processed) | Ra 0.8–3.2 μm |

| Build Envelope | 250 x 250 x 300 mm |

| Materials | Stainless Steel 316L, Ti6Al4V, Inconel 718, AlSi10Mg, Maraging Steel |

| Post-Processing | Heat treatment, CNC machining, HIP, polishing, coating |

At Wuxi Lead, we treat every 3D printed replacement part as a mission-critical component. Our engineering team collaborates closely with clients to validate performance through FEA, mechanical testing, and first-article inspection reports. Precision is not an afterthought—it is the foundation of reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration for Mission-Critical Replacement Parts

Wuxi Lead Precision Machinery delivers definitive solutions for demanding 3D printed metal replacement part requirements through the strategic integration of additive manufacturing and advanced subtractive precision. Our core strength lies in bridging the gap between complex additive geometries and the stringent dimensional stability demanded by industrial machinery. We recognize that replacement parts often serve in high-stress, safety-critical applications where tolerance compliance and material integrity are non-negotiable. Our approach ensures printed components meet or exceed original equipment manufacturer specifications, mitigating downtime risks associated with obsolete or failed machinery.

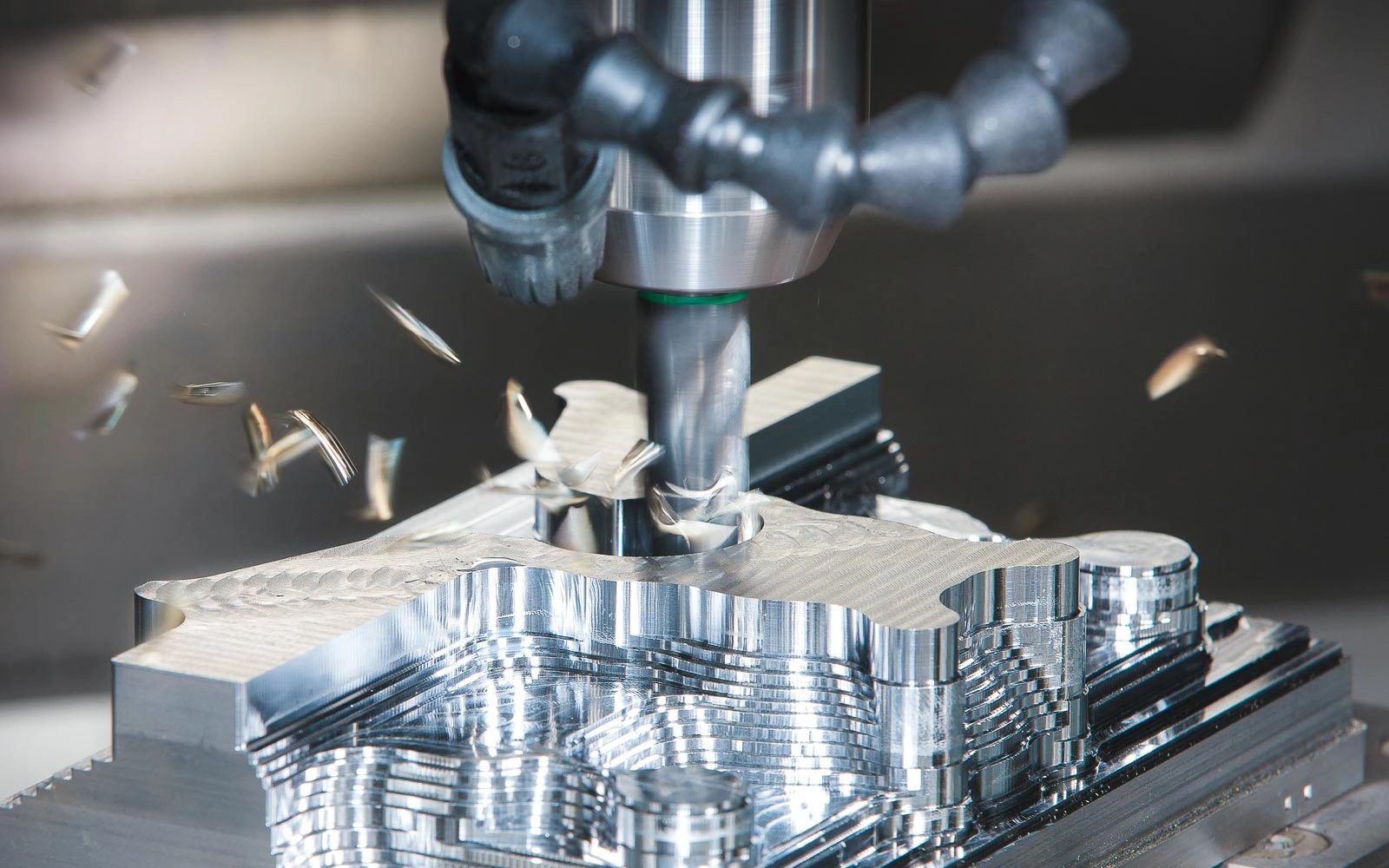

Central to our capability is a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems provide the necessary flexibility and precision for comprehensive post-processing of additively manufactured metal parts. Complex internal channels, critical sealing surfaces, tight-tolerance bearing bores, and precise datum features inherent in replacement components are reliably achieved through our multi-axis milling and turning operations. The simultaneous 5-axis movement allows for single-setup machining of intricate geometries, significantly reducing cumulative error potential and ensuring superior part-to-part consistency compared to sequential 3-axis methods. This is particularly vital for legacy part replication where original tooling is unavailable.

Rigorous quality control is embedded throughout the production workflow, culminating in comprehensive Coordinate Measuring Machine (CMM) inspection. All critical dimensions, geometric tolerances (GD&T), and surface finishes are verified against the approved engineering drawing using calibrated Zeiss and Hexagon CMM systems operating within an ISO 17025 accredited environment. Our inspection protocols include full first-article inspection reports (FAIR) and statistical process control (SPC) data for high-volume replacement programs, providing absolute traceability and confidence in every component shipped. Material certification and non-destructive testing (NDT) options further validate structural integrity for critical applications.

The following table details our standard achievable tolerances for post-processed 3D printed metal replacement parts, reflecting the combined capability of our additive processes and precision CNC finishing:

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 | ±0.0125 | Up to 150mm; tighter tolerances achievable over smaller ranges |

| Geometric (GD&T) | ±0.05 | ±0.025 | Includes flatness, perpendicularity, position |

| Hole Diameter (Reamed) | +0.025 / 0 | +0.0125 / 0 | Post-machined features only |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As-machined; polishing options available |

| As-Printed Features | ±0.1 | ±0.05 | Minimum feature size dependent on AM process |

This integrated capability—leveraging advanced 5-axis CNC for critical feature refinement and backed by metrology-grade CMM validation—ensures Wuxi Lead Precision Machinery produces replacement parts that function reliably within existing machinery assemblies. We transform the design freedom of metal additive manufacturing into certified, precision-engineered components that restore operational continuity with confidence. Our technical team collaborates closely with clients to define achievable specifications based on part function, material, and legacy requirements, guaranteeing a viable and robust solution for your most challenging replacement needs.

Material & Finish Options

Material selection is a critical step in the production of 3D printed replacement parts, particularly in high-performance industrial and aerospace applications where reliability, weight, and durability are paramount. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced additive techniques, enabling precise replication and enhancement of legacy or obsolete components. Our expertise spans key engineering metals—aluminum, steel, and titanium—each offering distinct advantages depending on operational requirements.

Aluminum alloys, particularly AlSi10Mg, are widely used in 3D printing due to their excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. These properties make aluminum ideal for aerospace, automotive, and consumer electronics applications where reducing component mass without sacrificing structural integrity is essential. Aluminum parts are also well-suited for post-processing techniques such as anodizing, which enhances surface hardness and wear resistance while providing aesthetic and protective finishes.

Steel, especially stainless steel 316L and tool steel, delivers superior strength, toughness, and resistance to high temperatures and corrosive environments. 316L stainless steel is frequently selected for marine, chemical processing, and medical equipment due to its excellent resistance to chloride-induced pitting and crevice corrosion. Its biocompatibility and ability to withstand sterilization cycles make it a preferred choice in regulated industries. Tool steel variants, such as H13 or maraging steel, are used when high hardness, impact resistance, and dimensional stability under thermal cycling are required, such as in injection molding inserts or high-wear tooling components.

Titanium, specifically Grade 5 (Ti6Al4V), stands at the pinnacle of performance materials for additive manufacturing. Its exceptional strength-to-density ratio, biocompatibility, and resistance to extreme temperatures and corrosion make it indispensable in aerospace, defense, and medical implant applications. Titanium’s ability to maintain mechanical integrity in aggressive environments—such as saltwater or high-heat exhaust systems—ensures long service life and reliability, even under demanding operational conditions.

Surface finishing plays a vital role in enhancing both the functional and aesthetic qualities of 3D printed metal parts. Anodizing, particularly for aluminum, is a controlled electrochemical process that thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paints or primers. Type II and Type III (hard coat) anodizing are commonly applied, with the latter offering superior durability for industrial use.

The following table summarizes key mechanical and physical properties of the primary materials we utilize:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–500 | 250–300 | 2.67 | 8–12 | Aerospace brackets, heat sinks |

| Stainless Steel 316L | 550–650 | 300–400 | 8.00 | 35–50 | Marine components, medical devices |

| Ti6Al4V (Grade 5) | 900–1000 | 800–880 | 4.43 | 8–12 | Aircraft engines, prosthetics |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on functional requirements, environmental exposure, and lifecycle demands, ensuring optimal performance of every 3D printed replacement part.

Manufacturing Process & QC

Zero Defects Execution in 3D Printed Metal Replacement Parts Manufacturing

At Wuxi Lead Precision Machinery, producing mission-critical 3D printed metal replacement parts demands an unwavering commitment to Zero Defects. Our integrated process transcends simple additive manufacturing, embedding rigorous quality assurance at every phase from initial concept to final delivery. This systematic approach ensures parts meet exacting operational demands, eliminating costly field failures and unplanned downtime for our industrial clients.

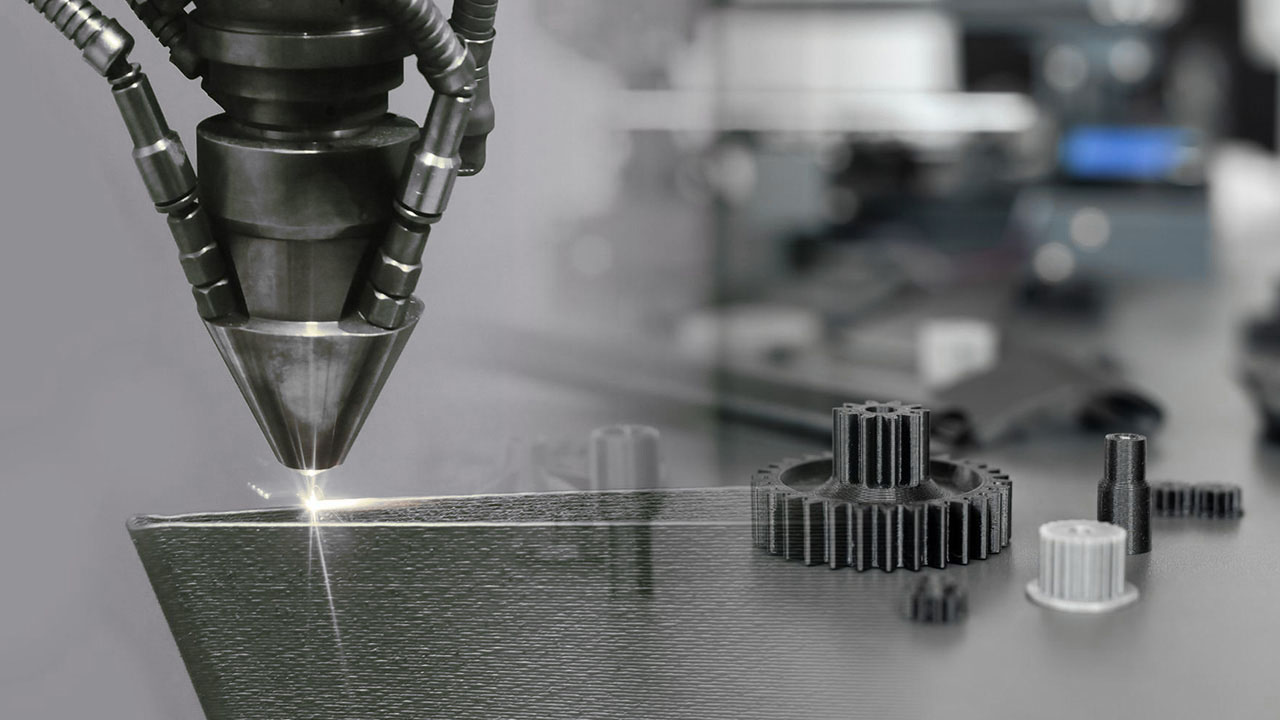

The process initiates with collaborative Design Engineering. Our team works directly with your engineering data or physical part scans, leveraging advanced simulation software to optimize geometry for additive production. Critical considerations include stress distribution, thermal management during build, and support structure minimization to ensure dimensional stability. Material selection is paramount we specify aerospace-grade alloys like Inconel 718 or Ti-6Al-4V based on your part’s operational environment, corrosion resistance needs, and mechanical property requirements. Every design iteration undergoes virtual validation against your functional specifications before physical production begins.

Prototyping is not merely a sample step it is comprehensive functional validation. We produce initial builds using our certified EOS M 400-4 Quad Laser systems under strict environmental controls. Each prototype undergoes full metrology, including CT scanning for internal integrity verification and coordinate measuring machine (CMM) inspection against the original CAD model. Material properties are validated through destructive testing of coupons built alongside the part, confirming tensile strength, fatigue resistance, and microstructure meet or exceed ASTM/AMS standards. Only after client sign-off on all performance metrics do we proceed to mass production.

Mass Production executes with industrialized precision and continuous monitoring. Production builds occur within controlled inert gas environments with real-time melt pool monitoring and layer-wise thermal imaging. Every build undergoes mandatory Hot Isostatic Pressing (HIP) to eliminate micro-porosity, followed by precision CNC post-machining to achieve critical tolerances and surface finishes. Final parts progress through a defined inspection sequence including 100% dimensional verification, dye penetrant testing for surface cracks, and final certification. Our integrated quality management system, certified to ISO 9001 and AS9100, ensures traceability from raw powder lot to finished part.

Key production specifications guaranteeing Zero Defects outcomes are maintained consistently:

| Parameter | Standard Specification | Verification Method |

|---|---|---|

| Material Density | ≥ 99.95% | Archimedes, CT Scan |

| Dimensional Tolerance | ±0.05 mm / 0.2 mm/m | CMM, Optical Scanning |

| Surface Roughness | As-built Ra ≤ 12.5 μm | Profilometer |

| Machined Ra ≤ 3.2 μm | Profilometer | |

| Internal Integrity | Zero detectable voids | CT Scan, Ultrasonic Testing |

| Mechanical Properties | Per ASTM/AMS Spec | Tensile, Fatigue Testing |

This closed-loop process, combining advanced additive technology with disciplined manufacturing science, delivers replacement parts engineered for reliability. Wuxi Lead Precision Machinery guarantees that every component shipped performs identically to the original specification, safeguarding your operational continuity through uncompromising quality execution.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printed Replacement Parts

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing solutions that meet the rigorous demands of modern industrial applications. As a trusted leader in China’s advanced manufacturing sector, we combine cutting-edge 3D printing technology with decades of engineering expertise to produce replacement parts that exceed performance, durability, and accuracy expectations. Whether you’re maintaining legacy equipment, optimizing supply chains, or requiring rapid turnaround on mission-critical components, partnering with Lead Precision ensures a seamless, reliable, and cost-effective solution.

Our state-of-the-art metal additive manufacturing capabilities enable us to produce complex geometries and high-integrity parts that are difficult or impossible to achieve through traditional machining methods. Using premium-grade materials such as titanium, stainless steel, Inconel, and aluminum alloys, we ensure every 3D printed replacement part meets exact OEM specifications while offering enhanced mechanical properties and corrosion resistance. Every project is supported by in-house design validation, finite element analysis (FEA), and full metrology reporting to guarantee dimensional accuracy and functional reliability.

We understand that downtime is costly. That’s why our agile production model supports rapid prototyping, low-volume production runs, and on-demand spare part manufacturing—reducing lead times and inventory burdens. From concept to certification, our engineering team works closely with clients across aerospace, energy, medical, and industrial automation sectors to deliver solutions that integrate flawlessly into existing systems.

Our commitment to quality is unwavering. We operate under ISO 9001-certified processes, with full traceability from raw material sourcing to final inspection. Every component undergoes rigorous non-destructive testing (NDT), including CT scanning and laser scanning for dimensional verification, ensuring compliance with international standards such as AS9100 and ASTM F2734.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic manufacturing ally focused on innovation, precision, and long-term value.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20 – 50 μm |

| Positional Accuracy | ±0.1 mm per 100 mm |

| Surface Roughness (as-built) | Ra 10 – 15 μm |

| Post-Processing Options | Heat Treatment, HIP, CNC Finishing, Polishing |

| Materials Available | Ti6Al4V, 316L, 17-4PH, Inconel 718, AlSi10Mg |

| Quality Standards | ISO 9001, AS9100, ASTM F2734, Full NDT Reports |

For engineering support or to initiate a project, contact us today at [email protected]. Let Wuxi Lead Precision Machinery power your next innovation in metal 3D printed replacement parts.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.