Technical Contents

Engineering Guide: 3D Printed Model Parts

Engineering Insight Precision Imperatives for 3D Printed Model Parts in High-Stakes Manufacturing

In the realm of advanced manufacturing, 3D printed model parts transcend mere prototyping. They serve as critical validation tools for aerodynamic performance, thermal behavior, and assembly fit within complex systems. The precision of these models directly dictates the reliability of downstream production data. Tolerances exceeding ±0.1mm or surface deviations beyond industry benchmarks introduce unacceptable uncertainty, potentially cascading into costly redesigns, production delays, or field failures when scaling to final metal components. For sectors like aerospace, defense, and high-performance automotive, where safety and performance margins are non-negotiable, model fidelity is not optional—it is foundational to engineering integrity.

Wuxi Lead Precision Machinery operates at this critical intersection of additive modeling and precision metal manufacturing. Our engineering team possesses deep expertise in translating high-fidelity 3D printed models into certified production tooling and end-use metal parts. This capability is rigorously proven through mission-critical projects. We engineered and validated wind tunnel models for structural components used in the Beijing 2022 Winter Olympic venues, where aerodynamic precision directly impacted structural safety under extreme wind loads. Similarly, our models support defense contractors in thermal management validation for avionics housings, adhering strictly to MIL-STD-810 environmental testing protocols. These engagements demand absolute confidence in dimensional stability and surface characteristics from the earliest model phase.

Achieving this level of precision requires more than advanced printers. It demands integrated metrology, material science expertise, and a closed-loop manufacturing philosophy. At Lead Precision, every model undergoes stringent first-article inspection against the client’s master CAD dataset using calibrated CMMs and optical scanners. We prioritize materials with certified thermal stability and low warpage characteristics, essential for maintaining accuracy during post-processing and testing. Our process ensures the model you test is a true physical manifestation of your digital design, eliminating guesswork in performance prediction.

The following table outlines the precision metrics we consistently achieve for critical model parts, far exceeding standard prototyping benchmarks:

| Precision Parameter | Standard Prototyping | Wuxi Lead Precision Standard | Measurement Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.2mm | ±0.02mm | CMM (ISO 10360-2) |

| Feature Repeatability | ±0.15mm | ±0.015mm | Optical Comparator |

| Surface Roughness (Ra) | 12-25 μm | < 50 μm | Profilometer (ISO 4287) |

| Critical Feature Alignment | ±0.3° | ±0.05° | Laser Tracker |

This precision foundation directly de-risks your path to production. When your model parts meet aerospace-grade tolerances, the transition to CNC-machined or cast metal components becomes significantly more predictable. Lead Precision provides the engineering continuity—from validated model to certified metal part—ensuring your high-stakes projects launch on time, within spec, and without compromise. Trust in precision starts at the model stage; we deliver the accuracy your innovation demands.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries such as aerospace, medical, energy, and precision automation. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining platform, enabling us to produce complex 3D printed model parts with exceptional accuracy, surface finish, and geometric integrity. These multi-axis systems allow simultaneous movement across five planes, providing unmatched flexibility in machining intricate contours and undercuts that are common in prototype development and low-volume production runs.

Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent performance and minimal thermal deviation. This technology supports a wide range of metallic materials, including titanium alloys, Inconel, aluminum, stainless steel, and tool steels—commonly used in additive manufacturing validation and functional prototyping. The integration of 5-axis machining with digital CAD/CAM workflows enables rapid translation from 3D model data to precision-engineered components, reducing lead times and enhancing repeatability.

To maintain the highest standards of quality, every component undergoes rigorous inspection using our Coordinate Measuring Machine (CMM) system. The CMM provides full 3D metrology validation, capturing dimensional data with sub-micron resolution. This allows us to verify form, position, and profile tolerances in full compliance with ISO 1101 and ASME Y14.5 standards. Our quality control process includes first-article inspection reports (FAIR), production sampling plans, and full documentation traceability for every batch.

All inspection data is analyzed using PC-DMIS software, ensuring accurate alignment with customer-defined datums and geometric dimensioning requirements. This systematic approach to quality assurance guarantees that each 3D printed model part meets the functional and fitment criteria required for downstream testing, assembly, or certification.

The following table outlines the standard dimensional tolerances we achieve through our integrated machining and inspection workflow:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 500 mm length |

| Hole Diameter | +0.025 / 0 mm | +0.010 / 0 mm | Reamed or honed finishes |

| Positional Tolerance | ±0.03 mm | ±0.015 mm | Relative to primary datum |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Machined finish, optional polishing |

| Angular Tolerance | ±0.1° | ±0.05° | Verified via CMM |

| Flatness | 0.03 mm per 100 mm | 0.01 mm per 100 mm | Critical sealing surfaces |

These capabilities are supported by a lean manufacturing environment and an engineering team with over 15 years of experience in high-precision component production. Wuxi Lead Precision Machinery ensures that every 3D printed model part not only meets but exceeds the expectations of performance-driven clients worldwide.

Material & Finish Options

Material Selection for Precision 3D Printed Metal Model Parts

Selecting the optimal material for 3D printed metal model parts is critical for achieving functional accuracy, durability, and cost efficiency in high-stakes prototyping and low-volume production. At Wuxi Lead Precision Machinery, we understand that material properties directly impact prototyping fidelity, assembly validation, and performance under simulated conditions. This guide outlines key considerations for Aluminum, Steel, and Titanium alloys, alongside the essential role of anodizing finishes, ensuring your models meet rigorous engineering standards.

Aluminum alloys, particularly 6061 and 7075, offer an exceptional strength-to-weight ratio and excellent machinability post-print. These materials are ideal for lightweight structural prototypes, aerospace mock-ups, and consumer electronics housings where thermal management and ease of secondary operations are paramount. Their inherent corrosion resistance is sufficient for many indoor applications, though anodizing significantly enhances surface durability and aesthetic control. Steel variants, including 316L stainless and 17-4 PH, deliver superior hardness, wear resistance, and structural integrity. They are the preferred choice for functional prototypes subjected to high stress, pressure, or demanding mechanical environments such as hydraulic components, tooling fixtures, and medical device housings requiring biocompatibility. Titanium alloys, notably Ti-6Al-4V, provide the ultimate combination of high strength, exceptional corrosion resistance, and biocompatibility at elevated temperatures. While commanding a higher material and processing cost, titanium is indispensable for mission-critical aerospace, biomedical, and high-performance automotive prototypes where weight savings and extreme environmental resilience are non-negotiable.

Anodizing is not merely cosmetic; it is a vital engineering finish for aluminum model parts. This electrochemical process creates a dense, wear-resistant oxide layer that significantly improves surface hardness, corrosion protection, and adhesion for subsequent coatings or labels. Color-coded anodizing (clear, black, red, blue, etc.) streamlines assembly verification and part identification during complex prototyping phases. Wuxi Lead Precision Machinery applies precise Type II (sulfuric acid) anodizing with controlled thickness (typically 10-25µm) to ensure dimensional stability and consistent appearance, critical for client presentations and functional testing.

Material performance characteristics must align precisely with your model’s intended use case. The following table provides essential comparative specifications for common alloys used in metal additive manufacturing for prototyping:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Post-Print |

|---|---|---|---|---|

| Aluminum 6061 | 2.70 | 310 | Good | Excellent |

| Stainless 316L | 8.00 | 580 | Excellent | Moderate |

| Titanium Ti-6Al-4V | 4.43 | 900 | Outstanding | Fair |

Consult Wuxi Lead Precision Machinery engineers early in your design phase. We leverage extensive experience in metal AM and precision finishing to recommend the optimal material-finish combination, ensuring your 3D printed models deliver accurate performance data and accelerate time-to-market validation. Our integrated manufacturing capabilities guarantee seamless transition from digital model to physically validated prototype.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the production journey for 3D printed model parts begins with an intensive design phase, where engineering precision meets functional intent. Our team collaborates closely with clients to translate conceptual models into manufacturable designs, ensuring dimensional accuracy, structural integrity, and compliance with end-use requirements. Utilizing advanced CAD/CAM software and simulation tools, we conduct thorough design for manufacturability (DFM) reviews to identify and resolve potential issues before any material is cut or fused. This proactive approach minimizes iterations, reduces lead times, and ensures that every design is optimized for both additive and post-processing stages.

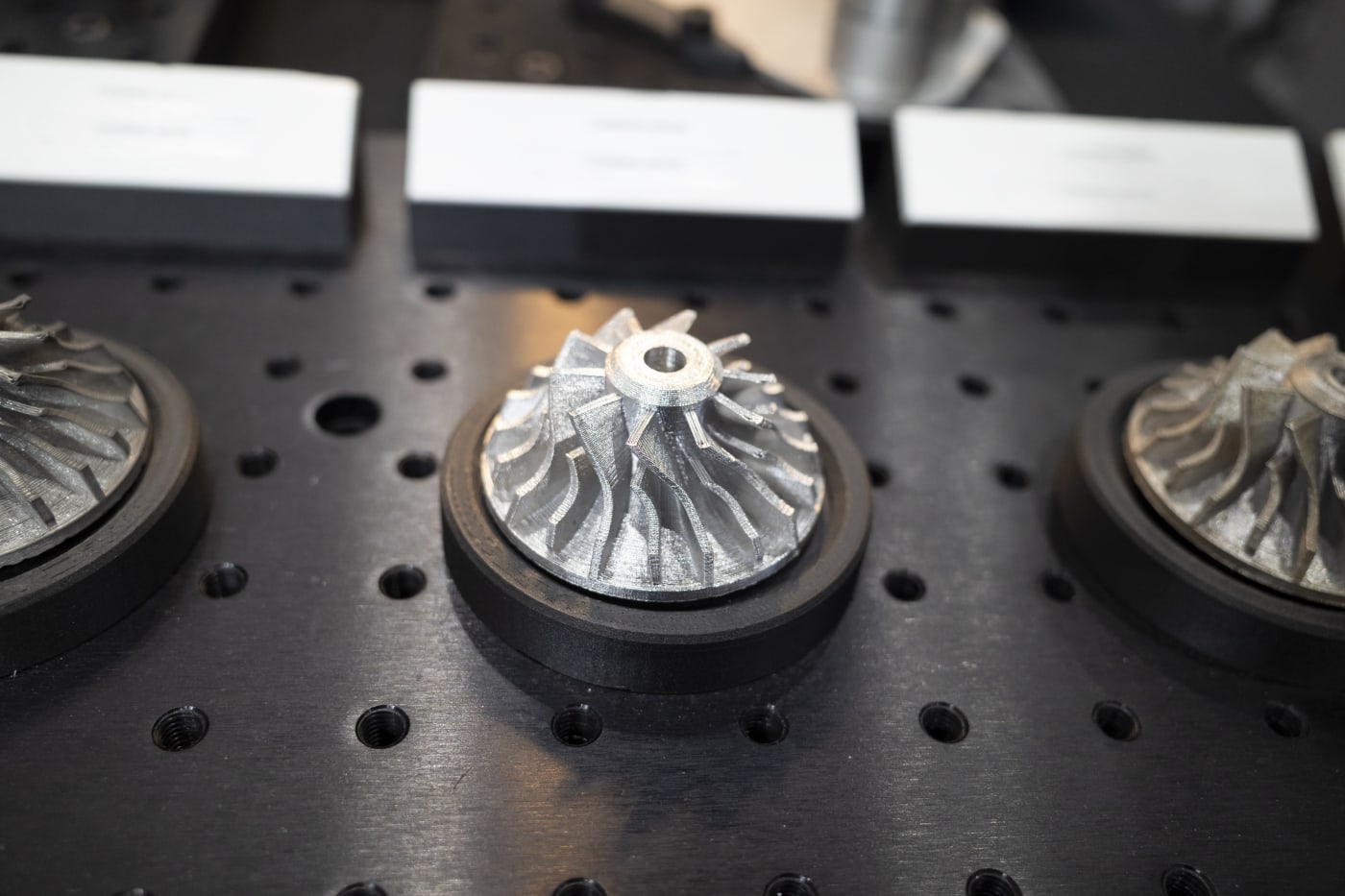

Prototyping: Validating Performance and Fit

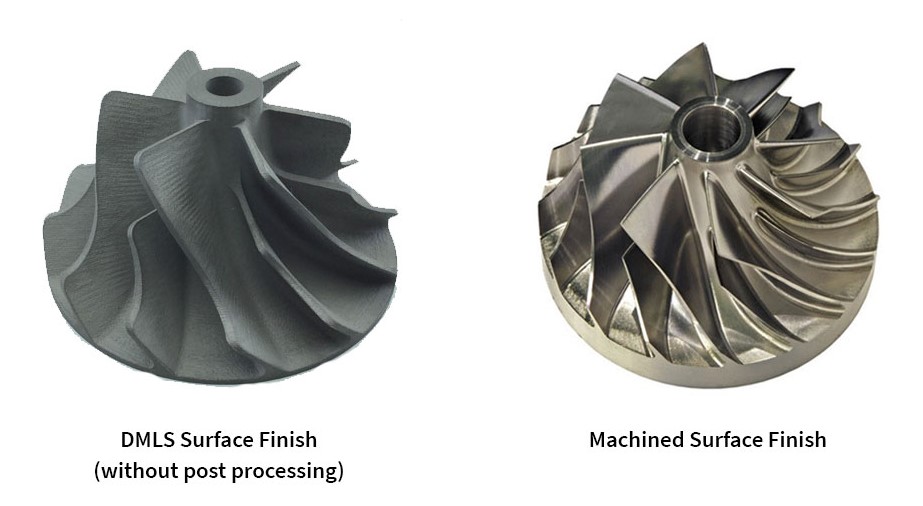

Once the design is finalized, we proceed to prototyping using state-of-the-art metal 3D printing technologies, primarily selective laser melting (SLM) and direct metal laser sintering (DMLS). These processes enable us to produce high-fidelity prototypes in materials such as titanium, stainless steel, aluminum, and Inconel, matching the mechanical properties of final production parts. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify geometric accuracy within tolerances as tight as ±0.02 mm. Functional testing, including stress analysis and fit checks in assembly environments, confirms that the prototype meets all performance criteria. This validation phase is critical to ensuring that mass production will proceed without deviation.

Mass Production: Scalable Precision with Zero Defects

With the prototype approved, we transition to high-volume production using automated additive systems integrated with real-time monitoring and in-process quality control. Our production lines are equipped with sensors that track laser power, build temperature, and layer consistency, enabling immediate detection and correction of anomalies. Every part is traceable through a digital twin system, ensuring full process transparency. Post-printing, components undergo precision CNC machining, heat treatment, surface finishing, and final inspection to meet exacting standards. Our zero-defect philosophy is enforced through a closed-loop quality management system certified to ISO 9001:2015, with 100% inspection of critical dimensions and non-destructive testing (NDT) as required.

Production Specifications

| Parameter | Capability |

|---|---|

| Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Aluminum (AlSi10Mg), Inconel (718, 625) |

| Layer Thickness | 20–50 μm |

| Build Volume | Up to 250 × 250 × 300 mm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processing Options | CNC Machining, HIP, Heat Treatment, Polishing, Passivation |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting, First Article Inspection (FAI) |

Through seamless integration of design, prototyping, and production, Wuxi Lead Precision Machinery delivers 3D printed model parts with unmatched consistency, reliability, and precision—ensuring zero defects and complete client confidence.

Why Choose Wuxi Lead Precision

Elevate Your Prototyping with Integrated Precision Engineering

When your 3D printed model parts require transition from concept to certified production component, generic additive services fall short. At Wuxi Lead Precision Machinery, we bridge this gap through engineered hybrid manufacturing. Our facility combines metal additive expertise with 5-axis CNC finishing, heat treatment, and metrology under one roof—ensuring your prototypes meet functional, regulatory, and lifecycle demands. Unlike standalone 3D printing vendors, we address the critical post-processing phase where 90% of high-stress prototypes fail validation. Our engineers collaborate from Day 1 to optimize part geometry for both printability and final performance, eliminating costly redesign loops.

Critical Specifications for Mission-Critical Model Parts

| Capability | Specification | Value to Your Project |

|---|---|---|

| Dimensional Accuracy | ±0.005mm after finishing | Ensures seamless integration with existing assemblies |

| Material Certification | AMS 4928, ASTM F136, EN ISO 2281 | Full traceability for aerospace/medical compliance |

| Surface Integrity | Ra 0.4μm to 1.6μm (as-printed to mirror polish) | Meets fluid dynamics and fatigue resistance requirements |

| Post-Processing | Stress-relieving, HIP, micro-machining | Eliminates internal voids and residual stresses |

| Lead Time | 15-22 days (complex assemblies) | Accelerates validation cycles by 30% vs. fragmented suppliers |

We specialize in resolving the hidden challenges of metal additive manufacturing: anisotropic strength in printed lattices, thermal distortion during support removal, and achieving repeatable surface finishes for sealing interfaces. Our ISO 9001:2015-certified workflow includes in-process CT scanning and coordinate measuring machine (CMM) validation at critical stages—data you’ll receive with every shipment. This isn’t just printing; it’s engineering assurance.

Partnering with Lead Precision means your model parts transition directly into production-ready components without requalification. Our clients in aerospace, medical device development, and energy sectors leverage our hybrid approach to compress time-to-market while exceeding AS9100 and ISO 13485 requirements. We handle material procurement, NDT testing, and first-article inspection so your engineering team focuses on innovation—not supply chain firefighting.

Your Next Prototype Cycle Starts Here

Submit your CAD file to Contact [email protected] for a technical feasibility assessment within 24 hours. Our applications engineers will provide a detailed manufacturability report highlighting cost-saving geometry adjustments, material recommendations, and a validated production timeline. For urgent projects, request our Express Validation Program—priority scheduling with 72-hour preliminary feedback. Wuxi Lead Precision Machinery operates from our 12,000m² facility in Jiangsu Province, serving global OEMs with uncompromised IP protection and strategic cost efficiency. Trust the partner that treats your prototype like a production part from the first layer.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.