Technical Contents

Engineering Guide: 3D Printed Milling Machine

Engineering Insight: Precision Integration of Additive Manufacturing in CNC Milling Systems

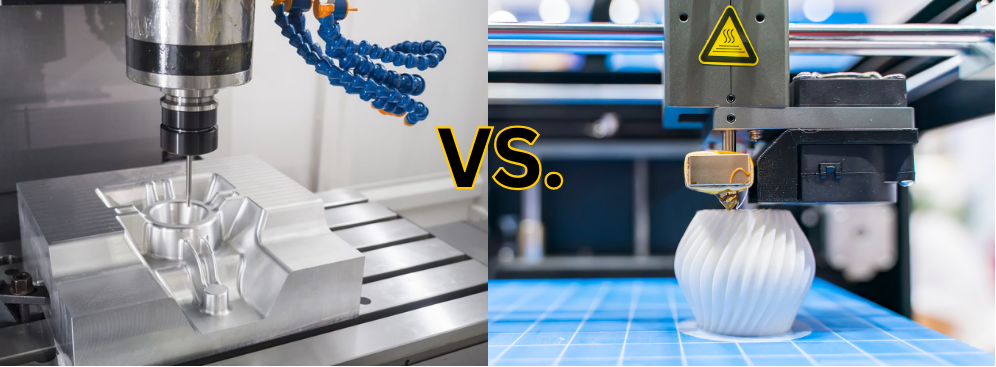

The term “3D printed milling machine” requires immediate technical clarification. Milling machines themselves are not fabricated through additive manufacturing (AM); their core structural components demand the rigidity, thermal stability, and micron-level geometric accuracy only achievable through precision subtractive processes like CNC milling and grinding. However, additive manufacturing plays a transformative, precision-critical role within advanced CNC milling systems, specifically for optimizing non-structural but functionally vital components. At Wuxi Lead Precision Machinery, we integrate AM not as a replacement for CNC, but as a strategic enabler to push the boundaries of what precision milling can achieve. This synergy demands exacting standards far beyond typical AM applications, directly impacting the final part quality our clients receive.

The criticality lies in component functionality. Conformal cooling channels within custom-machined mold inserts, topology-optimized lightweight fixture components, or complex internal coolant manifolds for high-speed spindles all rely on AM. A deviation of 0.025mm in a conformal cooling channel’s internal geometry can create turbulent flow, leading to uneven thermal dissipation, part warpage, and scrapped aerospace components. Similarly, a fixture bracket printed with insufficient dimensional stability introduces micro-vibrations during micron-level machining, directly compromising surface finish and geometric tolerances on medical implants. Precision in the AM process—layer adhesion, thermal management during build, and post-process stress relief—is therefore non-negotiable. It is not merely about the printed part’s standalone accuracy, but its precise integration and performance within the ultra-stable CNC environment.

Our experience delivering mission-critical components for Olympic timing systems and defense applications underscores this reality. These projects demanded absolute reliability under extreme conditions, where a single micron of positional error in a sensor housing (often incorporating AM elements for weight reduction and internal routing) could invalidate critical data or compromise system function. We developed rigorous internal protocols for AM component validation, including CT scanning for internal integrity verification and thermal cycling tests to ensure dimensional stability matches the machine tool’s base structure. This ensures AM elements enhance, rather than undermine, the machine’s core precision capability.

The true value emerges in the final machined part. Precisely integrated AM components within the milling system directly enable tighter tolerances, superior surface finishes, reduced cycle times, and the ability to machine complex geometries previously impossible. For the end manufacturer, this translates to higher yield, extended tool life, and components meeting the most stringent aerospace or medical standards. Understanding where and how AM integrates with precision CNC is not a technical footnote—it is fundamental to achieving next-generation manufacturing capability. Wuxi Lead Precision Machinery leverages this integrated approach daily, ensuring the precision our clients require is engineered at every level, from machine component to finished product.

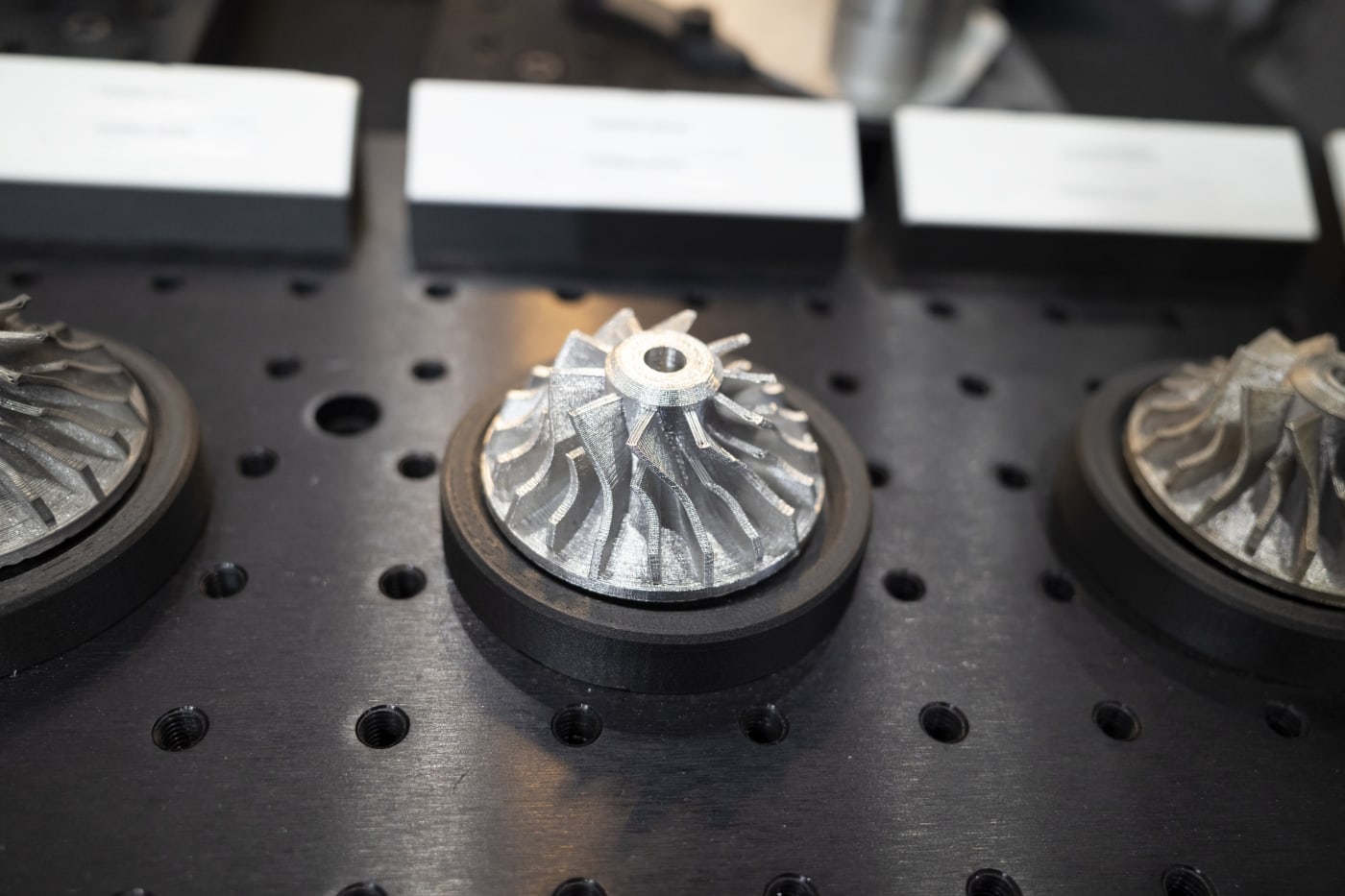

Key Additive Manufacturing Applications in Precision Milling Systems

| Application Category | Typical Material | Precision Requirement | Functional Impact of Precision Failure | Wuxi Lead Validation Process |

|---|---|---|---|---|

| Conformal Cooling Inserts | Maraging Steel (1.2709) | ±0.025mm internal | Uneven cooling, part distortion, scrap | CT Scan, Flow Simulation, Thermal Cycle Test |

| Lightweight Fixturing | Aluminum AlSi10Mg | ±0.015mm critical loci | Micro-vibration, positional error on workpiece | CMM Verification, Modal Analysis |

| Internal Spindle Manifolds | Inconel 718 | ±0.020mm flow path | Reduced coolant efficacy, thermal growth, tool wear | Pressure Test, Flow Rate Measurement |

| Custom Sensor Mounts | Titanium Ti6Al4V ELI | ±0.010mm datum faces | Signal drift, measurement inaccuracy | Vibration Test, Thermal Stability Check |

Precision Specs & Tolerances

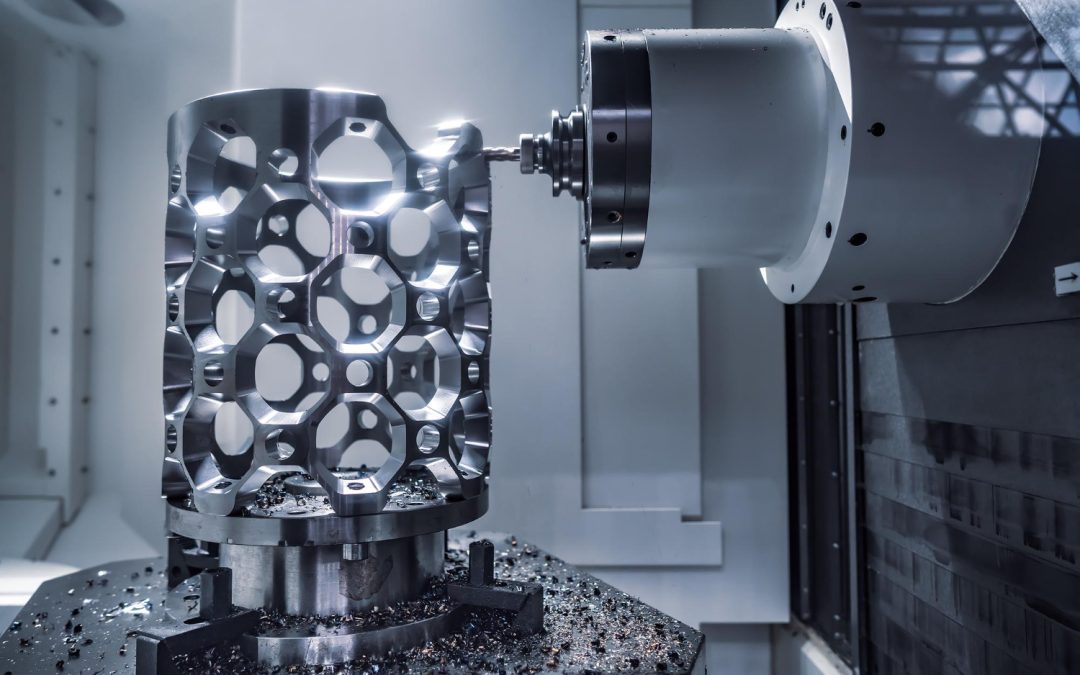

Wuxi Lead Precision Machinery stands at the forefront of advanced precision CNC machining, delivering high-performance manufacturing solutions tailored to the most demanding industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex, high-accuracy components with exceptional surface finish and dimensional consistency. These multi-axis systems allow simultaneous movement across five axes, providing unparalleled flexibility in machining intricate geometries that are often required in aerospace, medical, energy, and high-end automation sectors.

Our 5-axis CNC platforms are equipped with high-speed spindles, dynamic tool compensation, and real-time monitoring systems, ensuring optimal cutting performance and minimal thermal deformation. This level of precision is further enhanced through rigorous process control, adaptive machining strategies, and the integration of advanced CAM software that optimizes toolpaths for maximum efficiency and accuracy. As a result, we are capable of machining a broad range of materials—including titanium, Inconel, aluminum alloys, stainless steel, and engineering plastics—to exacting standards.

Quality assurance is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM system provides micron-level measurement accuracy and generates detailed inspection reports traceable to international standards. These reports are available to clients upon request, offering complete transparency and traceability throughout the production cycle.

In addition to advanced equipment and inspection protocols, our technical team comprises seasoned CNC engineers and machinists with extensive experience in high-precision manufacturing. Their expertise ensures that every project, from prototype to full-scale production, is executed with meticulous attention to detail and adherence to customer specifications.

The following table outlines the standard technical tolerances we consistently achieve across our 5-axis CNC machining operations:

| Parameter | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm |

| Positional Tolerance | ±0.020 mm | ±0.008 mm |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm |

| Circular Runout | 0.015 mm | 0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished finishes) |

| Angular Tolerance | ±0.05° | ±0.02° |

| Hole Diameter Tolerance | H7 (ISO 286-1) | H6 (ISO 286-1) |

These capabilities, combined with our commitment to continuous improvement and technological investment, position Wuxi Lead Precision Machinery as a trusted partner for high-end manufacturing challenges. Whether producing one-off prototypes or high-volume precision parts, we deliver performance, reliability, and consistency across every project.

Material & Finish Options

Material Selection for Hybrid 3D Printed Milling Components

Material selection critically impacts the performance, durability, and cost-efficiency of components produced through hybrid manufacturing combining 3D printing and precision CNC milling. At Wuxi Lead Precision Machinery, we prioritize materials that balance printability, machinability, and end-use requirements. Aluminum, steel, and titanium dominate high-performance applications, each offering distinct advantages under stringent machining conditions.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are preferred for lightweight structural components requiring high strength-to-weight ratios and excellent thermal conductivity. 6061-T6 offers superior weldability and corrosion resistance for aerospace brackets, while 7075-T6 delivers exceptional strength for high-stress automotive fixtures. Both alloys machine cleanly with minimal tool wear, though 7075’s higher hardness demands optimized cutting parameters. Steel variants like 4140 and 17-4PH stainless provide unmatched wear resistance and structural integrity for heavy-duty tooling and molds. 4140 excels in shock-loaded applications due to its toughness, whereas 17-4PH’s corrosion resistance suits medical and marine components. Titanium Grade 5 (Ti-6Al-4V) remains the benchmark for extreme environments, offering aerospace-grade strength at half the density of steel. Its biocompatibility and fatigue resistance justify higher machining costs for critical implants and turbine parts, though its low thermal conductivity necessitates specialized toolpaths to prevent heat buildup.

Key mechanical properties guide optimal material pairing with your application:

| Material | Key Alloys | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7–2.8 | 310–570 | 95–150 | Excellent (A) |

| Steel | 4140, 17-4PH | 7.8–7.9 | 655–1300 | 200–330 | Good (B) |

| Titanium | Ti-6Al-4V | 4.4 | 900–950 | 330–360 | Fair (C) |

Surface finishing through anodizing significantly enhances aluminum components. Type II (sulfuric acid) anodizing provides moderate corrosion resistance and dye receptivity for consumer-facing parts, with typical thicknesses of 10–25μm. For mission-critical aerospace or defense applications, Type III (hardcoat) anodizing delivers 50–100μm thickness, achieving Rockwell C60+ surface hardness and extreme abrasion resistance. Steel and titanium generally require alternative treatments like passivation or PVD coatings, as anodizing is aluminum-specific.

Selecting the right material-finishing combination requires analyzing load conditions, environmental exposure, and lifecycle costs. Wuxi Lead Precision Machinery engineers validate material-process synergies through rigorous in-house testing, ensuring your hybrid-manufactured components meet ISO 2768-mK tolerances and exceed industry durability benchmarks. Partner with us to translate material science into precision-engineered solutions.

Manufacturing Process & QC

The production process for a 3D printed milling machine at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure absolute precision, structural integrity, and zero-defect performance. This process begins with advanced design engineering and culminates in scalable, high-fidelity mass production, all underpinned by our ISO-certified quality assurance protocols.

Design is the foundational phase, where our engineering team utilizes integrated CAD/CAM/CAE software to develop a fully optimized digital twin of the milling machine. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are applied to validate thermal stability, dynamic load resistance, and vibration damping characteristics. Special attention is given to the integration of 3D printed structural components—typically fabricated from high-strength, heat-resistant metal alloys such as Inconel 718 or AlSi10Mg via laser powder bed fusion (LPBF). These components are topology-optimized to reduce weight without sacrificing rigidity, enabling higher acceleration rates and improved energy efficiency. Design for additive manufacturing (DfAM) principles ensure manufacturability, minimizing support structures and post-processing requirements.

Prototyping follows the design freeze, where a fully functional alpha unit is produced using the same LPBF machines and post-processing workflows intended for mass production. This prototype undergoes a comprehensive battery of tests, including geometric accuracy verification via coordinate measuring machines (CMM), modal analysis for resonance detection, and 100+ hour continuous machining cycles under maximum load. Any deviations are traced through root cause analysis, and design or process adjustments are implemented before progression. This iterative validation ensures that the prototype meets or exceeds all performance benchmarks, forming the golden standard for series production.

Mass production is executed in a controlled environment with strict adherence to statistical process control (SPC) and first-article inspection (FAI) protocols. Each 3D printed component is serialized and tracked through a digital manufacturing execution system (MES), enabling full traceability of material batch, build parameters, heat treatment, and inspection data. CNC machining, surface finishing, and assembly are performed by certified technicians using calibrated tooling. Final units undergo 100% functional testing, including spindle runout checks, linear axis positioning accuracy, and thermal growth monitoring. Our zero-defect objective is enforced through automated optical inspection (AOI) and real-time data analytics that flag anomalies before shipment.

This end-to-end process ensures that every 3D printed milling machine delivered by Wuxi Lead Precision Machinery meets the highest standards of performance, reliability, and precision.

| Specification | Detail |

|---|---|

| Build Technology | Laser Powder Bed Fusion (LPBF) |

| Materials | Inconel 718, AlSi10Mg, Ti6Al4V |

| Dimensional Accuracy (as-built) | ±0.05 mm |

| Surface Roughness (as-built) | Ra 6–8 µm (can be polished to Ra 0.8 µm) |

| Heat Treatment | Stress relief, Hot Isostatic Pressing (HIP) |

| Post-Processing | CNC machining, shot peening, surface coating |

| Quality Standards | ISO 9001, AS9100, GD&T compliance |

Why Choose Wuxi Lead Precision

Elevate Your Hybrid Manufacturing Capabilities with Lead Precision

Wuxi Lead Precision Machinery stands at the forefront of advanced manufacturing integration, uniquely positioned to bridge the gap between additive innovation and precision subtractive finishing. As your strategic partner, we deliver engineered solutions that transform 3D printed milling machine components from prototypes into certified, production-ready assets. Our ISO 9001-certified facility in Wuxi, China, combines German-engineered CNC technology with rigorous quality protocols to ensure every part meets aerospace, medical, and semiconductor industry standards. We understand that hybrid manufacturing demands more than capability—it requires a partner committed to your timeline, tolerances, and total process integrity.

Our technical capabilities are engineered for the exacting demands of post-processing 3D printed structures. Below are core specifications defining our precision machining excellence:

| Specification | Capability Range | Industry Relevance |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Critical for multi-axis printed part alignment |

| Surface Finish (Ra) | 0.2–0.8 µm | Ensures seamless integration with printed substrates |

| Max Work Envelope | 1,200 x 800 x 650 mm | Accommodates large-format printed assemblies |

| Material Compatibility | Titanium, Inconel, Tool Steels, Composites | Matches high-performance AM material requirements |

| Tolerance Control | IT5 to IT7 | Validates dimensional integrity for functional assemblies |

Partnering with Lead Precision means accessing more than machinery—it means embedding our engineering expertise into your development cycle. We provide full technical collaboration from design-for-manufacturability reviews through first-article inspection, ensuring printed components achieve operational reliability. Our dedicated project managers implement real-time communication protocols, secure data handling under strict NDAs, and rapid iteration cycles to compress your time-to-market. With in-house metrology using Zeiss CMM systems and 100% traceable material certifications, we eliminate guesswork in quality validation.

For global manufacturers seeking to industrialize 3D printed milling machine production, precision post-processing is non-negotiable. Lead Precision delivers the technical authority and operational discipline to turn additive potential into field-proven performance. Our facility operates under AS9100 principles, with dedicated cleanrooms for medical-grade finishing and vibration-dampened floors for micron-level stability. We don’t just machine parts—we safeguard your reputation for engineering excellence.

Initiate your partnership with definitive manufacturing authority. Contact our engineering team at [email protected] to submit technical drawings, discuss material-specific finishing protocols, or schedule a virtual facility audit. Specify “3D Printed Milling Machine Collaboration” in your subject line to expedite technical resource allocation. Response time for qualified inquiries: under 4 business hours. Your next-generation manufacturing solution begins with a single, precise action.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.