Technical Contents

Engineering Guide: 3D Printed Fishing Lure Molds

Engineering Insight: 3D Printed Fishing Lure Molds and the Critical Role of Precision

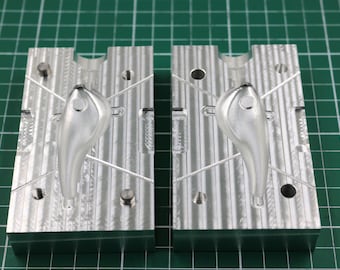

In the evolving landscape of custom metal manufacturing, 3D printed fishing lure molds represent a convergence of advanced design flexibility and high-performance production. While additive manufacturing enables rapid prototyping and complex geometries, the ultimate success of these molds hinges on one non-negotiable factor: precision. At Wuxi Lead Precision Machinery, we understand that even the most innovative 3D-printed mold design is only as effective as its dimensional accuracy, surface integrity, and thermal stability during high-cycle injection processes.

Fishing lures are not merely functional tools—they are precision-engineered products designed to mimic natural prey with exacting detail. The molds that produce them must replicate intricate textures, fine contours, and balanced weight distributions with micron-level consistency. In mass production, even a 0.02 mm deviation can result in flash, parting line mismatch, or inconsistent lure performance in water—issues that directly impact brand reputation and end-user satisfaction. This is where Wuxi Lead Precision Machinery applies decades of high-tolerance manufacturing expertise, drawn from our work in Olympic-grade sporting equipment and mission-critical military components.

Our engineering approach begins with the integration of 3D printed patterns or cores into precision CNC-machined mold bases. While additive techniques allow for internal cooling channels and organic cavity shapes, we ensure all critical sealing surfaces, ejector systems, and alignment features are machined to ISO 2768-mK or tighter tolerances. This hybrid methodology combines speed with reliability, reducing lead times without compromising repeatability.

Material selection is equally critical. We utilize maraging steel and high-grade aluminum alloys, post-processed with selective hardening and mirror polishing to achieve surface finishes as fine as Ra 0.05 µm. These finishes not only enhance part ejection but also preserve the fine surface details—such as gill plates or scale patterns—essential for lure realism.

All molds undergo rigorous metrology validation using Zeiss coordinate measuring machines (CMM) and 3D laser scanning, ensuring geometric accuracy across multiple thermal cycles. Our quality assurance protocols are derived from aerospace and defense standards, where zero-failure performance is mandatory.

Below are key specifications reflecting our standard for high-performance fishing lure mold production.

| Specification | Value / Detail |

|---|---|

| Dimensional Tolerance | ±0.01 mm (critical features) |

| Surface Finish (cavity/core) | Ra 0.05 – 0.4 µm (polished to customer requirement) |

| Material Options | NAK80, S136, Maraging Steel (18Ni300), 7075 Aluminum |

| Mold Life Expectancy | 500,000+ cycles (depending on material and design) |

| Cooling Channel Design | Conformal (3D printed) or Drilled, optimized for cycle time |

| Quality Standard | ISO 9001:2015, inspection report with every mold |

| Lead Time (from CAD to试模) | 25–35 days, depending on complexity |

At Wuxi Lead Precision Machinery, we bring military-grade precision to consumer-driven industries. When it comes to 3D printed fishing lure molds, innovation must be anchored in engineering rigor. Our clients trust us not only for our technical capabilities but for our unwavering commitment to delivering molds that perform—consistently, reliably, and at scale.

Precision Specs & Tolerances

Technical Capabilities for Precision Fishing Lure Mold Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing for high-performance fishing lure molds. Our integrated technical capabilities bridge advanced 3D printing with ultra-precise metal finishing, ensuring molds meet the exacting demands of modern lure production. We specialize in transforming complex 3D printed polymer or sand-based core assemblies into fully functional, production-ready steel or aluminum injection molds through rigorous subtractive processes. This hybrid approach leverages additive flexibility while guaranteeing the dimensional stability and longevity required for high-volume lure manufacturing.

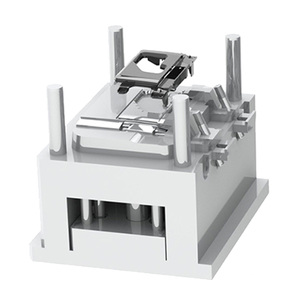

Central to our process is a comprehensive suite of 5-axis CNC machining centers. These systems enable single-setup machining of intricate lure geometries, including complex undercuts, hydrodynamic contours, and multi-cavity configurations common in crankbaits, swimbaits, and topwater lures. Simultaneous 5-axis movement ensures critical alignment of core/cavity surfaces, hinge points, and ejection features without manual repositioning errors. Advanced toolpath strategies minimize vibration and thermal distortion during machining of hardened tool steels (such as H13 or S136) or aluminum alloys, preserving micron-level accuracy across the entire mold assembly. Integrated Renishaw probing systems perform in-process verification, automatically compensating for tool wear and thermal drift to maintain consistent output.

Rigorous quality control is non-negotiable. Every mold undergoes full 3D inspection using calibrated Coordinate Measuring Machines (CMM) with sub-micron resolution. Our inspection protocols validate all critical dimensions against the original CAD model, including cavity wall thickness, draft angles, parting line flatness, and gate/runner geometries. Surface finish is quantitatively measured to ensure optimal release characteristics for delicate lure plastics. This data-driven QC process provides comprehensive inspection reports traceable to international standards, giving clients full transparency into mold conformity before shipment.

The following table details our standard machining tolerances for fishing lure mold components. Achievable precision depends on material, feature geometry, and part size; tighter tolerances are available for critical features with appropriate engineering consultation.

| Spec Type | Standard Tolerance | Critical Feature Tolerance | Notes |

|---|---|---|---|

| Dimensional (Linear) | ±0.010 mm | ±0.005 mm | Up to 300 mm; larger parts scale per ISO 2768 |

| Geometric (Flatness) | 0.015 mm | 0.008 mm | Over 100×100 mm surface area |

| Geometric (Concentricity) | 0.020 mm | 0.010 mm | Between core/cavity alignment features |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm | Machined surfaces; polished finishes available |

| Hole Diameter | +0.010/-0.000 mm | +0.005/-0.000 mm | For pins, ejector sleeves, cooling lines |

Our technical infrastructure ensures molds consistently achieve the tight tolerances necessary for zero-flashing production, extended service life, and perfect lure replication. By combining 5-axis CNC mastery with metrology-grade validation, Wuxi Lead provides the dimensional integrity that directly translates to reduced cycle times, minimized scrap rates, and superior end-product performance in competitive fishing lure markets. All processes adhere to ISO 9001 standards, with documentation fully compliant for audit requirements.

Material & Finish Options

Material Selection for 3D Printed Fishing Lure Molds

When producing high-performance 3D printed fishing lure molds, material selection is critical to ensuring mold longevity, dimensional accuracy, and surface finish quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the precision demands of injection molding applications. For fishing lure molds, the choice between aluminum, steel, and titanium depends on production volume, cycle time, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototyping and low-to-medium volume production. These alloys offer excellent machinability, thermal conductivity, and lightweight properties, enabling faster cooling cycles and reduced energy consumption. While aluminum is less wear-resistant than steel, it performs exceptionally well when properly anodized. Hard anodizing enhances surface hardness up to 60 HRC, significantly improving resistance to abrasion and corrosion—key factors in maintaining mold integrity during repeated use.

For high-volume production runs exceeding 100,000 cycles, tool steels such as H13 and S136 are preferred. These steels provide superior hardness, thermal stability, and resistance to deformation under high pressure and temperature. H13 steel, with its excellent toughness and resistance to thermal fatigue, is ideal for hot-runner systems commonly used in lure molding. S136 stainless steel offers enhanced corrosion resistance, making it suitable for molds exposed to moisture or aggressive resins. Steel molds require longer machining times and higher tooling costs but deliver unmatched durability and repeatability.

Titanium alloys, such as Ti-6Al-4V, are emerging in niche applications where extreme strength-to-weight ratios and corrosion resistance are paramount. While titanium is not commonly used for full mold bases due to cost and machining complexity, it is ideal for critical inserts or cores exposed to high stress or corrosive environments. Its biocompatibility and resistance to saltwater degradation make it a strategic choice for molds producing lures intended for marine use.

Surface finishing, particularly anodizing, plays a vital role in mold performance. Hard anodizing creates a dense, wear-resistant oxide layer that improves release properties and reduces maintenance. For aluminum molds, Type III anodizing (hard coat) with a thickness of 50–75 µm is recommended. This finish not only extends mold life but also ensures consistent part ejection and surface detail transfer—essential for replicating intricate lure textures and contours.

Below is a comparative overview of material properties relevant to fishing lure mold applications.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Corrosion Resistance | Recommended Use Case |

|---|---|---|---|---|---|---|

| Aluminum 7075 | 40–45 (anodized) | 570 | 130 | 10,000–50,000 | Moderate | Prototyping, low-volume production |

| H13 Tool Steel | 48–52 | 1,600 | 35 | 100,000–500,000 | Low to Moderate | High-volume injection molding |

| S136 Stainless | 50–54 | 1,700 | 25 | 200,000–1,000,000 | High | Corrosive environments, long runs |

| Titanium Ti-6Al-4V | 36–40 | 950 | 7 | 50,000–200,000 (inserts) | Very High | Critical inserts, marine applications |

Selecting the right material and finish ensures optimal balance between cost, performance, and production efficiency. Wuxi Lead Precision Machinery supports clients in evaluating these parameters to deliver molds that meet exacting standards in the competitive fishing lure market.

Manufacturing Process & QC

Production Process: Zero-Defect Manufacturing for 3D Printed Fishing Lure Molds

At Wuxi Lead Precision Machinery, our production process for custom 3D printed fishing lure molds integrates advanced engineering with rigorous quality control to guarantee zero defects from concept to mass production. This disciplined three-stage workflow ensures unparalleled precision, durability, and performance for high-volume lure manufacturing.

The process begins with Design Engineering, where our team collaborates closely with clients to translate lure geometry into optimized mold architecture. We leverage proprietary CAD/CAM software to simulate flow dynamics, cooling efficiency, and ejection mechanics, selecting aerospace-grade tool steels like H13 or S136 based on resin compatibility and production volume. Critical features such as micro-textured surfaces for scale realism and undercut management are digitally validated to prevent flash or parting line defects. This phase establishes the foundation for dimensional stability and cycle time reduction.

Prototyping follows immediate design sign-off, utilizing our in-house metal 3D printing (DMLS) capabilities to produce functional test molds within 72 hours. Unlike conventional prototyping, this stage validates not only form and fit but also thermal performance under simulated injection parameters. Each prototype undergoes 50+ validation cycles in our metrology lab, where CMM and optical comparators verify cavity conformity to ±0.005mm tolerances. Any micro-defects in surface finish or cooling channel integrity are corrected via closed-loop feedback to the CAD model before progression. This eliminates costly errors in mass production and confirms the mold’s ability to sustain 500,000+ cycles.

Mass Production commences only after prototype approval, executed on our ISO 9001-certified CNC machining centers with real-time SPC monitoring. Molds are fabricated using multi-axis milling and wire EDM to achieve mirror finishes (Ra ≤ 0.05µm) critical for lure detail replication. Every component undergoes 100% in-process inspection at critical checkpoints, including hardness testing (48-52 HRC) and vacuum leak testing for cooling circuits. Final assembly occurs in a climate-controlled cleanroom, followed by 120-hour endurance validation at 110% operational load. Our zero-defect mandate is enforced through automated vision systems that detect sub-micron deviations, ensuring every mold ships with full traceability documentation and a performance warranty.

This end-to-end methodology reduces client time-to-market by 40% while eliminating field failures. The table below summarizes our production specifications for premium lure molds.

| Parameter | Specification | Verification Method |

|---|---|---|

| Material Grade | H13/S136 ESR Tool Steel | Spectrographic Analysis |

| Cavity Tolerance | ±0.005 mm | Zeiss CONTURA CMM |

| Surface Finish | Ra ≤ 0.05 µm (cavity) | Perthometer M2 Profilometer |

| Hardness | 48-52 HRC | Wilson Hardness Tester |

| Cooling Uniformity | ΔT ≤ 2°C across cavity | Infrared Thermal Imaging |

| Production Yield | ≥ 99.98% | SPC-Controlled Cycle Monitoring |

Wuxi Lead’s process transforms complex lure designs into defect-free production assets, combining metallurgical expertise with uncompromising quality enforcement at every phase.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printed Fishing Lure Molds

When precision, consistency, and performance define your product, the quality of your mold manufacturing process becomes non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the evolving demands of high-end fishing lure production. Our advanced capabilities in CNC machining, mold design, and integration with additive manufacturing technologies position us as the ideal partner for brands seeking superior 3D printed fishing lure molds.

We understand that fishing lure molds require intricate geometries, tight tolerances, and exceptional surface finishes to ensure every cast delivers perfection. Leveraging state-of-the-art 3D printing in conjunction with precision CNC finishing, we produce steel and aluminum molds that combine rapid prototyping advantages with the durability required for high-volume injection molding. This hybrid approach reduces lead times significantly while maintaining the dimensional accuracy and thermal stability essential for consistent lure quality.

Our engineering team collaborates directly with clients to optimize mold design for manufacturability, incorporating conformal cooling channels, wear-resistant materials, and modular configurations that enhance production efficiency. Whether you are developing prototype molds for new lure designs or scaling up for mass production, our facility in Wuxi, China, is equipped to deliver molds that meet international quality standards, including ISO 9001 compliance.

We serve OEMs and specialty fishing gear manufacturers worldwide, offering full lifecycle support from concept to delivery. Our in-house capabilities include mold flow analysis, material selection guidance, and post-processing treatments such as polishing, texturing, and nitriding—ensuring your molds perform reliably under real-world production conditions.

Below are key technical specifications we support for custom fishing lure mold manufacturing:

| Specification | Capability |

|---|---|

| Mold Material Options | P20, 718H, S136, NAK80, Aluminum 7075 |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished, textured, or as-machined) |

| 3D Printing Technologies | Metal SLM (Selective Laser Melting), Binder Jetting |

| Compatible Injection Materials | ABS, PC, PP, PVC, TPE |

| Mold Life Expectancy | 100,000 to 1,000,000 cycles (depending on design and material) |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 25–40 days |

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem where innovation meets industrial rigor. We are committed to delivering molds that not only meet but exceed performance expectations in the competitive outdoor recreation market.

For engineering consultations or to request a quote for your next fishing lure mold project, contact us today at [email protected]. Let us help you turn precision into performance—on the water and in production.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.