Technical Contents

Engineering Guide: 3D Printed Crown Molding

Engineering Insight Precision in 3D Printed Metal Crown Molding

Achieving architectural excellence in custom metal crown molding demands uncompromising precision. Traditional fabrication methods often struggle with the intricate profiles, tight radii, and seamless continuity required for high-end installations. Even minor deviations—measured in microns—become visually unacceptable in large-format architectural elements where light interacts dynamically with surfaces. At Wuxi Lead Precision Machinery, we recognize that precision isn’t merely a specification; it is the foundation of structural integrity, aesthetic perfection, and client trust in luxury environments. Our engineering approach begins with metrology-grade design validation, ensuring digital models account for thermal dynamics, material behavior, and post-processing requirements before a single layer is printed. This eliminates costly rework and guarantees that complex geometries—such as layered acanthus motifs or compound curvature transitions—meet architectural intent without compromise.

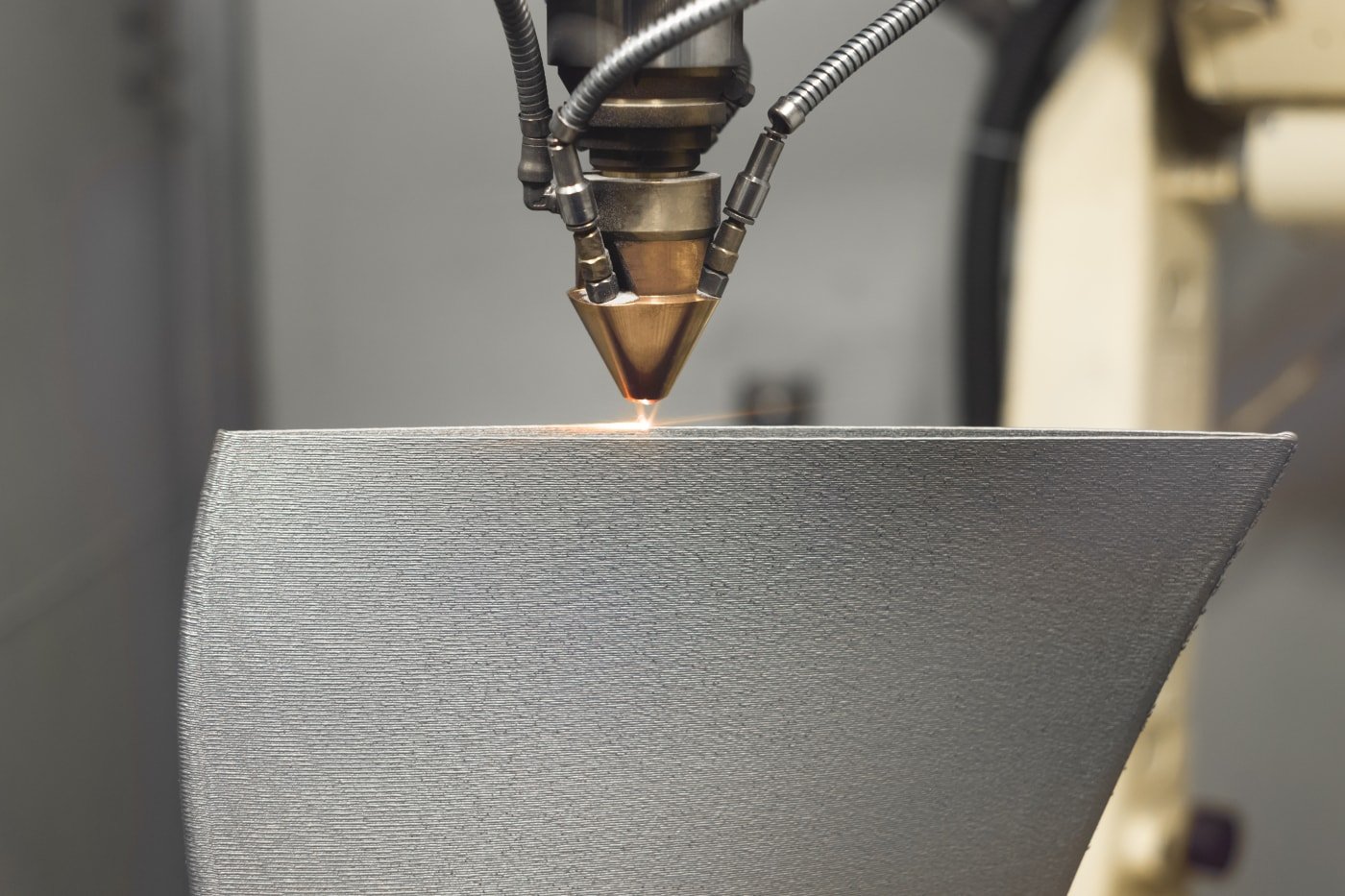

Metal additive manufacturing uniquely addresses these challenges by building components layer by layer, bypassing tooling limitations inherent in milling or casting. However, raw print capability is insufficient. True precision requires integrated expertise in parameter optimization, in-situ monitoring, and stress management. We deploy industrial-grade laser powder bed fusion systems with real-time melt pool analysis to maintain consistent density and microstructure across expansive profiles. This is critical for crown molding, where internal porosity or inconsistent grain structure could lead to warpage during finishing or failure under environmental stress. Our proprietary thermal management protocols ensure dimensional stability from the first layer to the final meter of extrusion, even in alloys prone to distortion like aluminum 7075 or stainless steel 316L.

The following specifications reflect our standard for architectural metal 3D printing, validated across demanding sectors:

| Parameter | Specification | Relevance to Crown Molding |

|---|---|---|

| Layer Thickness | 20–60 μm | Enables smooth curvature without stair-stepping artifacts |

| Dimensional Tolerance | ±0.05 mm per 100 mm | Ensures seamless joint alignment in long runs |

| Surface Roughness (As-Printed) | Ra 8–12 μm | Provides optimal substrate for hand-polishing to mirror finishes |

| Max Build Envelope | 500 x 500 x 1000 mm | Accommodates full-scale architectural segments |

| Material Density | >99.95% | Prevents micro-cracking during thermal cycling |

This rigor is not theoretical. Our engineering team has delivered mission-critical components for Olympic venue infrastructure and defense applications where tolerances below 0.02 mm were non-negotiable. These projects demanded zero-failure performance under extreme conditions—lessons directly applied to architectural metalwork. For crown molding in five-star resorts or cultural landmarks, the same discipline ensures profiles remain flawless across decades of humidity fluctuations and structural movement. Precision here transcends measurement; it embodies the unspoken expectation that luxury is defined by invisible perfection. At Lead Precision, we engineer that certainty into every contour.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the evolving demands of high-end architectural and decorative applications, including the production of 3D printed crown molding components. Our technical capabilities are anchored in precision engineering, advanced machining systems, and rigorous quality assurance protocols, ensuring that every component meets the exacting standards required by luxury construction and design sectors.

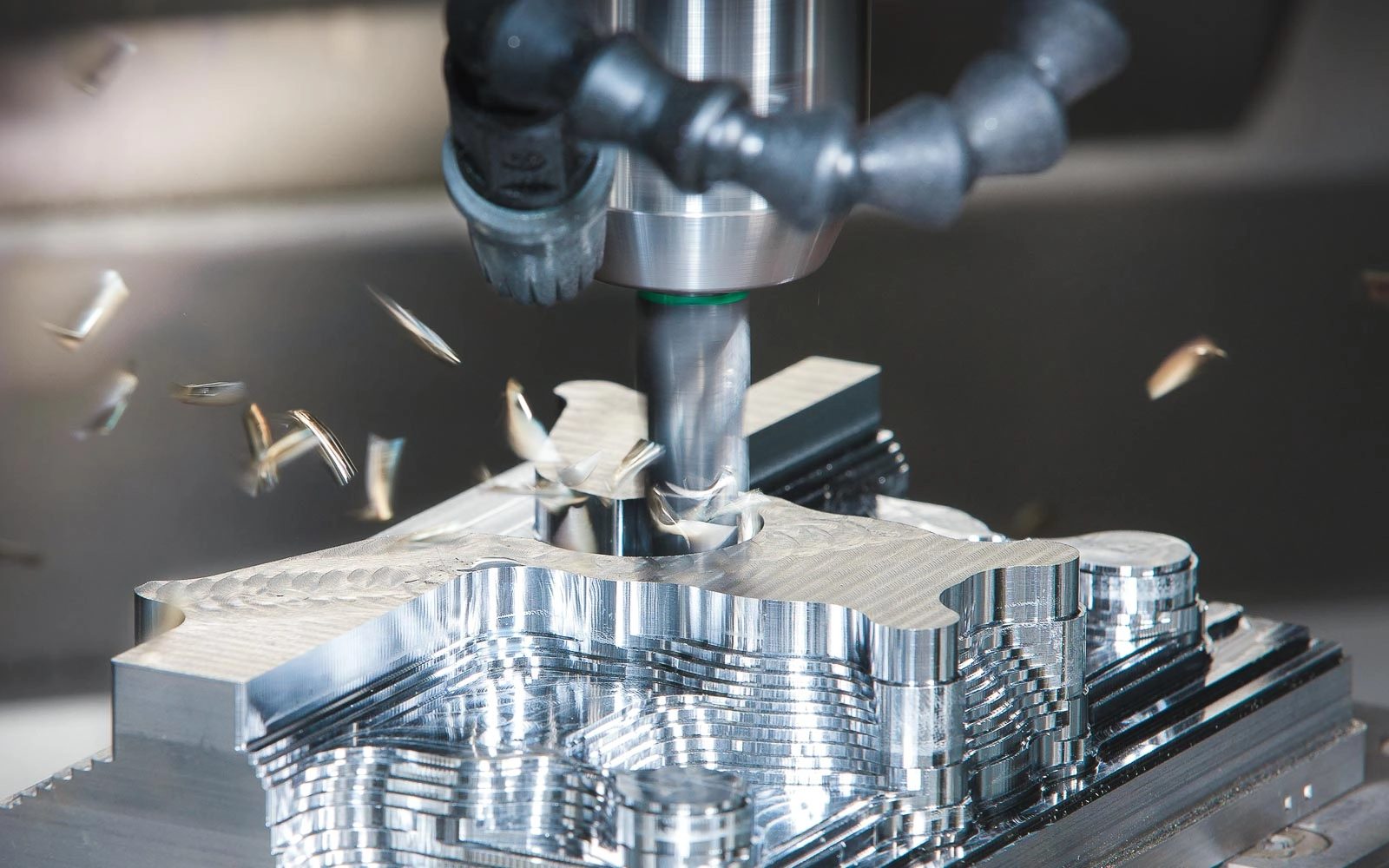

At the core of our manufacturing process is our 5-axis CNC machining technology. This state-of-the-art system enables us to produce complex geometries with exceptional accuracy and surface finish, essential for replicating the intricate profiles and ornate detailing characteristic of crown molding. Unlike conventional 3-axis machines, our 5-axis CNC centers allow simultaneous movement across five planes, facilitating multi-angle machining in a single setup. This reduces cycle time, eliminates cumulative errors from repositioning, and ensures superior dimensional consistency across both prototyping and full-scale production runs.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems, enabling continuous operation with minimal human intervention. This level of automation supports efficient production of small-batch custom runs as well as scalable manufacturing for larger projects. Materials commonly processed include aluminum alloys, brass, stainless steel, and other architectural-grade metals, all machined to retain fine surface textures suitable for plating, polishing, or powder coating.

Quality control is integral to our workflow. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with design specifications down to the micron level. Our CMM system performs non-contact and touch-probe measurements, generating detailed reports that verify geometric dimensioning, surface profiles, and critical tolerances. This data is archived for full traceability, meeting international quality standards and client-specific requirements.

The following table outlines the standard technical specifications and tolerances achievable through our 5-axis CNC manufacturing and inspection process:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensional Tolerance | ±0.05 mm | ±0.01 mm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished finish) |

| Geometric Tolerance (GD&T) | ±0.03 mm | ±0.01 mm |

| Feature Positioning Accuracy | ±0.04 mm | ±0.015 mm |

| Minimum Wall Thickness (Al) | 0.8 mm | 0.5 mm |

| Max Work Envelope (mm) | 1200 × 800 × 600 | N/A |

All processes are supported by in-house engineering teams who collaborate directly with clients to optimize part design for manufacturability, ensuring aesthetic fidelity without compromising structural integrity. From digital model to finished component, Wuxi Lead Precision Machinery provides a seamless, precision-driven manufacturing pathway for the most demanding 3D printed crown molding applications.

Material & Finish Options

Material Selection for Precision Metal 3D Printed Crown Molding

Selecting the optimal material is paramount for achieving the demanding aesthetic and functional requirements of 3D printed metal crown molding in high-end architectural applications. Unlike traditional plaster or polymer counterparts, metal offers unparalleled durability, fire resistance, and a distinctive luxury finish. However, the inherent properties of the chosen alloy directly impact print fidelity, surface quality, weight, installation complexity, and long-term performance in varied environments. Wuxi Lead Precision Machinery leverages advanced metal additive manufacturing to transform intricate digital crown molding designs into reality, but material choice dictates the achievable outcome. We focus on three core alloys suited for this application, each with distinct advantages and considerations.

Aluminum alloys, particularly AlSi10Mg, are the preferred choice for most premium metal crown molding projects. Its low density significantly reduces the final weight compared to steel or titanium, easing installation on walls and ceilings while maintaining structural integrity for complex profiles. Aluminum offers excellent thermal conductivity and inherent corrosion resistance in typical interior environments. Crucially, it achieves superior surface finish quality straight from the printer, minimizing post-processing needs for the fine details characteristic of crown molding. Subsequent anodizing provides a durable, decorative, and protective oxide layer available in a vast color palette, enhancing the architectural statement. Anodizing also significantly boosts wear and corrosion resistance for areas near moisture.

Stainless steel, specifically 316L, is selected when ultimate strength, exceptional corrosion resistance, or specific regulatory requirements (like fire ratings) are critical. Its higher density increases weight, necessitating robust mounting solutions, but delivers unmatched rigidity for very long spans or high-traffic areas. 316L excels in environments with higher humidity or potential chemical exposure, such as near kitchens, bathrooms, or in coastal properties. While achieving a fine surface finish is possible, post-processing like precision polishing is often more intensive than with aluminum to reach the required aesthetic standard for visible crown molding. Finishes typically involve mechanical polishing, brushing, or specialized passivation rather than anodizing.

Titanium (Ti6Al4V) represents the pinnacle for extreme durability and lightweight performance in highly corrosive or specialized environments. Its exceptional strength-to-weight ratio surpasses both aluminum and steel, and its corrosion resistance is virtually unmatched, ideal for marine settings or critical historical restoration. However, titanium’s significantly higher material cost, more complex printing parameters, and challenging post-processing make it a niche selection, justified only when its unique properties are essential. Surface finishing requires specialized techniques, and anodizing offers limited color options compared to aluminum.

The following table summarizes key comparative specifications for these primary materials in the context of 3D printed crown molding:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Printability | Best For |

|---|---|---|---|---|---|

| AlSi10Mg | 2.68 | 270-350 | Good (Interior) | Excellent | Most applications, weight-sensitive, color via anodizing |

| 316L Stainless Steel | 8.00 | 550-700 | Excellent | Good | High strength, humidity, marine proximity |

| Ti6Al4V | 4.43 | 880-950 | Exceptional | Moderate | Extreme environments, critical restoration |

Material selection fundamentally shapes the project’s feasibility, cost, and final aesthetic. Wuxi Lead Precision Machinery’s engineering team collaborates closely with architects and contractors during the design phase to recommend the optimal alloy and finishing process, ensuring your 3D printed metal crown molding meets both visionary design intent and rigorous performance standards. Consult our specialists to determine the precise material solution for your unique architectural challenge.

Manufacturing Process & QC

The production process for 3D printed crown molding at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure precision, repeatability, and zero defects. As a leader in custom metal manufacturing, we integrate advanced digital workflows with precision engineering to deliver architectural components that meet the highest standards of form and function.

The process begins with Design, where our engineering team collaborates closely with clients to translate artistic concepts into manufacturable digital models. Utilizing high-fidelity CAD software and parametric modeling tools, we develop 3D designs that capture intricate mold details while ensuring structural integrity and print feasibility. Design for Additive Manufacturing (DfAM) principles are applied throughout this phase to optimize wall thickness, support structures, and material distribution, minimizing post-processing and distortion risks. Every model undergoes automated and manual design rule checks to verify printability and tolerance compliance before progression.

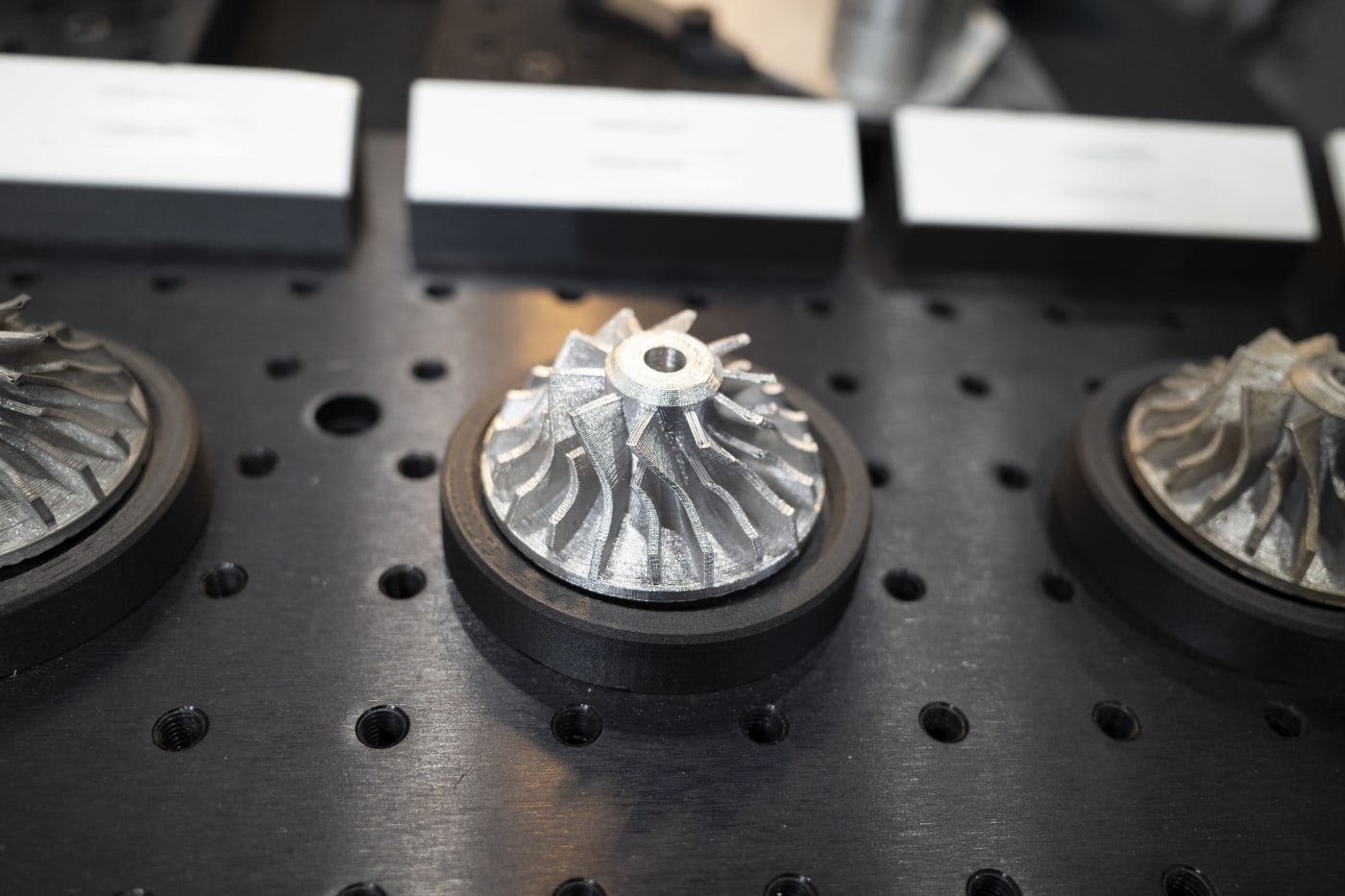

Prototyping follows as a critical validation step. Using selective laser melting (SLM) or direct metal laser sintering (DMLS), we produce functional prototypes in the final production-grade metal—typically aluminum alloy (AlSi10Mg), stainless steel (316L), or titanium (Ti6Al4V). These prototypes are subjected to full dimensional inspection via coordinate measuring machines (CMM) and 3D scanning to verify geometric accuracy within ±0.05 mm. Surface finish, fit, and assembly compatibility are also evaluated under real-world conditions. Client feedback is incorporated at this stage, allowing for iterative refinement without impacting the production timeline. This phase not only confirms design intent but also validates the entire downstream manufacturing chain.

Mass Production leverages our automated additive manufacturing cells, where multiple units are built in parallel using optimized nesting and build orientation strategies. Each print job is monitored in real time through integrated sensors and AI-driven anomaly detection systems that identify deviations in melt pool stability, layer adhesion, or thermal distortion. Post-print, components undergo stress relief heat treatment, support removal, and precision machining for critical interfaces. Surface finishing is performed via robotic blasting or electrochemical polishing to achieve a consistent, high-quality aesthetic. Every unit is 100% inspected using non-destructive testing (NDT) methods such as industrial CT scanning and dye penetrant inspection to guarantee internal and external defect-free output.

Our zero-defect philosophy is enforced through full traceability: each component is serialized, and process data—including laser power, scan speed, and environmental conditions—is logged and archived for audit. This closed-loop quality system ensures consistency across batches and compliance with ISO 9001 and IATF 16949 standards.

Below are key production specifications for our 3D printed crown molding process:

| Parameter | Specification |

|---|---|

| Material Options | AlSi10Mg, 316L Stainless Steel, Ti6Al4V |

| Layer Thickness | 20–50 μm |

| Build Volume | Up to 250 x 250 x 300 mm |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processing | Stress relieving, support removal, CNC trimming, polishing |

| Quality Standards | ISO 9001, IATF 16949, 100% NDT inspection |

This end-to-end process ensures that every 3D printed crown molding component meets exacting architectural and engineering requirements, combining artistic detail with industrial reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Metal Additive Manufacturing Excellence

Wuxi Lead Precision Machinery stands at the forefront of industrial metal additive manufacturing, delivering precision-engineered solutions for complex architectural and high-end decorative metal components. While traditional crown molding remains a woodworking domain, the demand for intricate, custom metal elements in luxury interiors, restoration projects, and bespoke architectural millwork has surged. Our advanced metal 3D printing capabilities transform conceptual designs into structurally sound, dimensionally accurate metal parts that redefine what is possible in architectural metal fabrication. We specialize in producing complex geometries—such as ornate brackets, custom medallions, and integrated lighting housings—that would be prohibitively expensive or impossible with conventional subtractive methods. Partnering with Lead Precision means accessing a vertically integrated manufacturing ecosystem where engineering rigor meets artistic ambition, ensuring your metal components achieve both aesthetic perfection and mechanical integrity.

Our proprietary metal additive processes eliminate tooling constraints and material waste while accelerating time-to-market. Unlike standard foundry or CNC-machined alternatives, we achieve net-shape complexity with minimal post-processing, maintaining micron-level precision across challenging overhangs, lattices, and organic contours. This capability is critical for high-value architectural applications where design fidelity and material consistency directly impact project success. Every component undergoes stringent in-process monitoring and post-build metrology, certified to ISO 9001 standards, guaranteeing repeatability batch after batch. We collaborate closely with architects, fabricators, and OEMs from initial concept validation through to serial production, providing DFM expertise that optimizes cost without compromising on the visionary intent of your designs.

Below outlines our core technical specifications for metal additive manufacturing, tailored for architectural and decorative metal applications:

| Parameter | Capability | Relevance to Architectural Metalwork |

|---|---|---|

| Material Range | Stainless Steel 316L, Titanium Ti6Al4V, Inconel 718, Aluminum AlSi10Mg | Corrosion resistance for interior/exterior use; lightweight strength for large installations |

| Build Volume | 250 x 250 x 300 mm | Accommodates large-scale mold inserts or modular decorative panels |

| Precision Tolerance | ±0.05 mm per 100 mm | Ensures seamless integration with secondary structures |

| Surface Finish (As-Built) | Ra 12–25 µm | Minimizes hand-finishing for high-gloss applications |

| Lead Time (Prototype) | 7–10 business days | Accelerates design iteration for time-sensitive projects |

The convergence of digital design and metal additive manufacturing demands a partner with deep process mastery and unwavering quality commitment. At Lead Precision, we do not merely produce parts—we engineer solutions that solve your most demanding fabrication challenges. Our technical team provides comprehensive support, from material selection and topology optimization to post-processing guidance, ensuring your metal components meet both functional requirements and aesthetic visions. Whether revitalizing heritage structures with historically accurate reproductions or pioneering avant-garde installations, our facility in Wuxi operates with the agility and precision expected by global leaders in architecture and luxury manufacturing.

Initiate your project with confidence. Contact our engineering team directly at [email protected] to discuss your specific requirements. Include your design files or sketches for a rapid feasibility assessment and tailored production plan. We respond to all technical inquiries within 24 business hours, providing clear timelines, material recommendations, and cost analysis. For urgent projects, request our expedited consultation service—available to qualified partners. Trust Wuxi Lead Precision Machinery to translate intricate metal designs into reality, where innovation meets industrial excellence. Your vision, perfected in metal, begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.