Technical Contents

Engineering Guide: 3D Printed Aerospace Parts

Engineering Insight Precision Imperatives in Additive Aerospace Manufacturing

The aerospace industry operates under zero-tolerance conditions where component failure is not an option. In 3D printed aerospace parts, dimensional precision transcends mere specification; it is the foundational requirement for flight safety, structural integrity, and operational longevity. Microscopic deviations in critical features like turbine blade cooling channels, fuel system manifolds, or structural brackets can trigger catastrophic thermal stress, aerodynamic inefficiency, or fatigue failure under extreme operational loads. Additive manufacturing (AM) introduces unique challenges – thermal distortion, residual stress, and layer adhesion variability – demanding rigorous process control far beyond standard industrial tolerances. Precision here is measured in microns, not millimeters, requiring closed-loop monitoring, sophisticated post-processing, and metrology traceable to national standards. Engineers understand that achieving consistent part-to-part repeatability in demanding alloys like Inconel 718 or Ti-6Al-4V is where theoretical AM capability meets real-world aerospace viability.

Wuxi Lead Precision Machinery addresses this critical precision gap through integrated hybrid manufacturing expertise. We combine advanced metal AM systems with decades of high-precision CNC machining, heat treatment, and non-destructive testing (NDT) under one roof. This vertical integration ensures geometric accuracy is maintained from the initial powder bed through final surface finishing. Our proprietary stress-relief protocols and in-situ monitoring during printing minimize distortion, while coordinate measuring machines (CMM) with sub-micron resolution validate compliance at every stage. This holistic approach transforms AM from a prototyping tool into a certified production solution for mission-critical components. Our facility operates under AS9100D aerospace quality management standards, with processes validated in environments where failure is inconceivable.

This capability is proven in the most demanding applications. Lead Precision supported precision components for Beijing 2022 Winter Olympic infrastructure requiring extreme cold-weather reliability. More significantly, our engineered AM parts undergo continuous deployment in classified military aerospace systems, subjected to supersonic stress, vibration, and thermal cycling where precision directly correlates to mission success and personnel safety. We translate this frontline experience into reliable production for commercial aerospace clients.

The following table outlines critical precision parameters achievable for aerospace AM components at Lead Precision:

| Parameter | Lead Precision Capability | Typical Industry Standard | Significance for Aerospace |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm | ±0.05 mm to ±0.1 mm | Ensures fit/function in tight assemblies; critical for rotating machinery |

| Surface Roughness (As-Built) | Ra 8-12 µm | Ra 15-25 µm | Reduces need for extensive post-processing; improves fatigue life |

| Feature Resolution | 0.1 mm min. wall thickness | 0.3-0.5 mm | Enables complex internal geometries (e.g., conformal cooling) |

| Material Density | >99.95% | >99.5% | Eliminates porosity-induced failure points under cyclic loading |

| Build Volume (Single) | Ø400 x 500 mm | Ø250 x 300 mm (common) | Supports larger monolithic structures reducing weld joints |

Precision in aerospace AM is non-negotiable. At Wuxi Lead Precision Machinery, we engineer reliability into every layer, leveraging proven military-grade process discipline to deliver 3D printed components that meet the uncompromising demands of flight. Partner with us to transform additive potential into certified aerospace reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored for high-performance industries, with a strong focus on aerospace applications where precision, reliability, and material integrity are non-negotiable. Our technical capabilities are engineered to meet the rigorous demands of producing 3D printed aerospace components, combining state-of-the-art metal additive manufacturing with high-accuracy post-processing technologies. Central to our production workflow is the integration of 5-axis CNC machining, which enables us to achieve complex geometries, tight tolerances, and superior surface finishes that are essential for flight-critical parts.

Our 5-axis CNC machining centers provide full simultaneous motion across all five axes, allowing for multi-faceted cutting in a single setup. This reduces cumulative errors, improves dimensional accuracy, and significantly enhances part consistency. For 3D printed aerospace components—often characterized by organic shapes, internal channels, and thin-walled structures—this capability ensures precise feature alignment, optimal material removal, and efficient finishing. We support a wide range of aerospace-grade alloys, including Inconel 718, Ti-6Al-4V, aluminum 7075, and stainless steel 17-4 PH, ensuring compatibility with both additive builds and post-processing requirements.

To guarantee compliance with aerospace quality standards, every component undergoes comprehensive quality control, anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems deliver micron-level measurement accuracy, enabling full geometric dimensioning and tolerancing (GD&T) verification. This metrology-backed validation ensures that all critical features—such as hole locations, profile deviations, and surface alignments—conform strictly to engineering specifications. All inspection data is documented and traceable, supporting full compliance with AS9100 and ISO 9001 quality management systems.

In addition to CMM inspection, our quality assurance process includes surface roughness testing, material certification, and first-article inspection reports (FAIR), providing customers with complete confidence in part performance and repeatability. Our in-house technical team works closely with engineering partners to optimize designs for manufacturability, ensuring that additive builds are supported by precision post-processing that meets aerospace certification requirements.

The following table outlines the key technical specifications and tolerances achievable through our integrated 5-axis CNC and inspection processes:

| Parameter | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Geometric Tolerance (GD&T) | ±0.01 mm (per ASME Y14.5) |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish) |

| Feature Size Tolerance | ±0.01 mm for critical dimensions |

| Maximum Work Envelope (CNC) | 1200 x 800 x 600 mm |

| Measurement Accuracy (CMM) | ±1.5 + L/300 µm (L in mm) |

| Material Compatibility | Ti-6Al-4V, Inconel 718, Al 7075, 17-4 PH, 316L |

By combining 5-axis CNC precision with rigorous CMM-based quality assurance, Wuxi Lead Precision Machinery ensures that every 3D printed aerospace component meets the highest standards of performance, safety, and reliability.

Material & Finish Options

Material Selection for 3D Printed Aerospace Components

Material choice directly impacts flight safety, component longevity, and operational efficiency in aerospace additive manufacturing. At Wuxi Lead Precision Machinery, we prioritize materials meeting stringent AMS, ASTM, and NADCAP standards. Aluminum alloys dominate lightweight structural applications like brackets and housings due to their optimal strength-to-weight ratio and thermal conductivity. AlSi10Mg is our recommended grade for laser powder bed fusion, offering excellent castability and fatigue resistance while reducing mass critical for fuel economy. For high-stress landing gear components or engine mounts, maraging steel (e.g., 18Ni300) delivers exceptional toughness and wear resistance up to 500°C, with post-build heat treatment enabling precise hardness control. Titanium alloys, particularly Ti6Al4V, are indispensable for extreme environments—combining near-steel strength at 40% less weight while resisting corrosion in 600°C+ exhaust zones or seawater exposure.

Critical properties must align with mission profiles. The following table compares key aerospace materials for metal additive processes:

| Material | Key Properties | Aerospace Applications | Typical Finishes |

|---|---|---|---|

| Aluminum (AlSi10Mg) | Density: 2.68 g/cm³; UTS: 400 MPa | Ducting, satellite brackets | Anodizing (Type II/III), Alodine |

| Steel (18Ni300) | Density: 8.0 g/cm³; UTS: 1300 MPa | Landing gear, hydraulic fittings | Passivation, HVOF coating |

| Titanium (Ti6Al4V) | Density: 4.43 g/cm³; UTS: 950 MPa | Engine blades, airframe connectors | Laser polishing, plasma spray |

Surface finishing is non-negotiable for aerospace functionality. Anodizing is our primary recommendation for aluminum components, creating a hard, corrosion-resistant oxide layer that enhances paint adhesion for radar-absorbing coatings. Type III (hardcoat) anodizing achieves 50-70 μm thickness for wear-prone areas like actuator housings, while Type II suits non-critical surfaces. Crucially, all anodizing processes at Wuxi Lead undergo salt spray validation per AMS-C-81706 to guarantee 1,000+ hours of corrosion resistance. For titanium and steel, we implement precision vibratory finishing or isotropic micro-machining to eliminate surface defects that could initiate fatigue cracks under cyclic loads.

Wuxi Lead’s material qualification protocol includes full traceability from certified powder lots through in-process monitoring and final NDT. We collaborate with clients during design phase to match material behavior to thermal cycles, vibration spectra, and regulatory requirements—ensuring your 3D printed components exceed FAA and EASA airworthiness benchmarks. Partner with us to transform material science into flight-certified performance.

Manufacturing Process & QC

The production of 3D printed aerospace parts at Wuxi Lead Precision Machinery follows a rigorously controlled, end-to-end process designed to ensure structural integrity, dimensional accuracy, and full compliance with aerospace industry standards. Every stage—from initial design to final mass production—is engineered to achieve zero defects through precision engineering, advanced simulation, and real-time quality assurance.

The process begins with collaborative design engineering, where our technical team works directly with aerospace OEMs to optimize part geometry for additive manufacturing. Using high-fidelity CAD modeling and topology optimization software, we ensure the design meets performance requirements while minimizing weight and material waste. Thermal and stress simulations are conducted to predict material behavior during printing, enabling preemptive correction of potential weaknesses. Design for Additive Manufacturing (DfAM) principles are applied to enhance manufacturability, including support structure optimization and orientation planning.

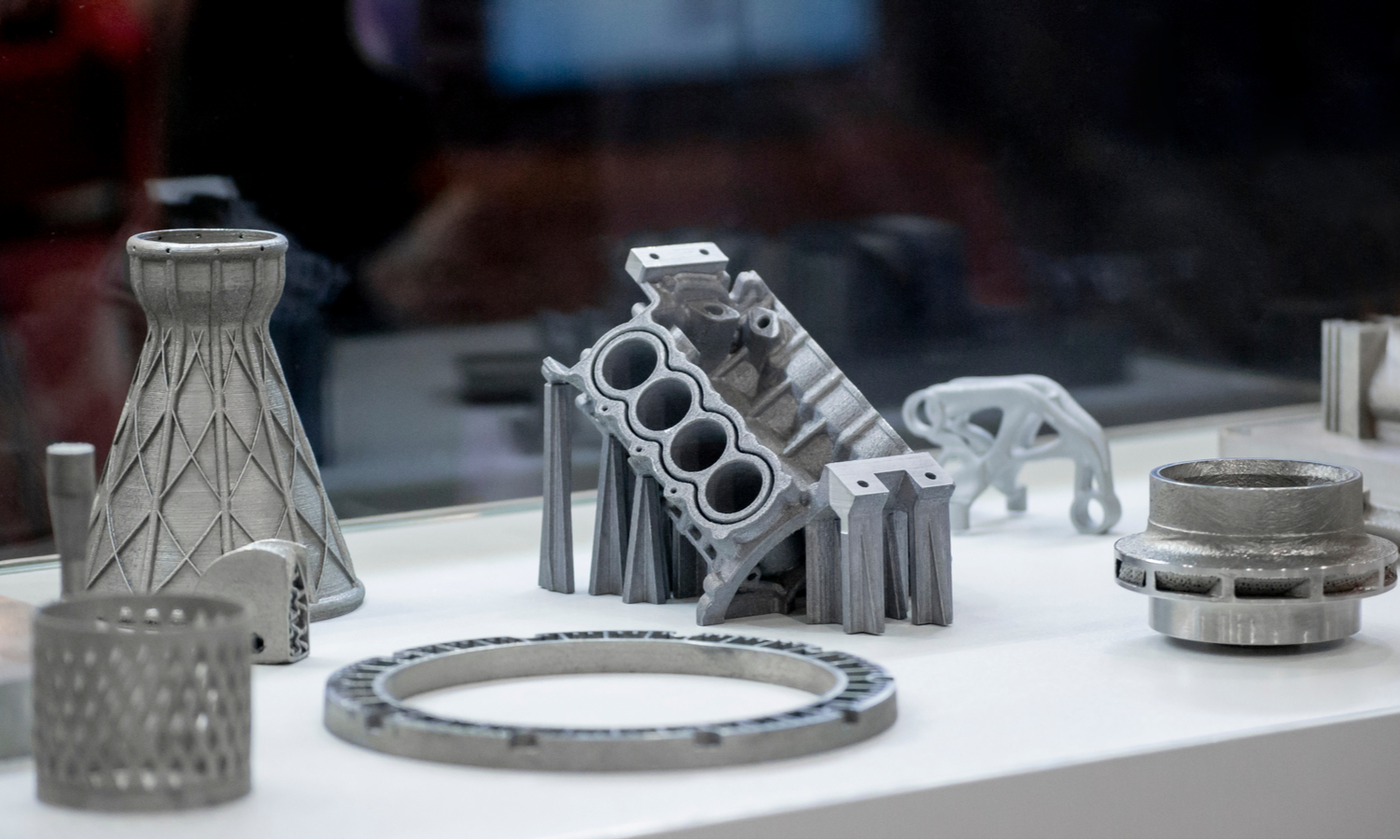

Once the digital model is finalized, we proceed to prototyping using selective laser melting (SLM) technology with aerospace-grade materials such as Inconel 718, Ti-6Al-4V, and AlSi10Mg. Prototypes are produced on certified metal 3D printers with inert gas environments to prevent oxidation and ensure material purity. Each prototype undergoes full metrological validation using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.05 mm. Non-destructive testing (NDT), including micro-CT scanning and ultrasonic inspection, is performed to detect internal porosity or defects at the micron level.

Upon prototype approval, the process transitions to scalable, zero-defect mass production. Our production cells operate under strict environmental controls, with real-time monitoring of laser power, layer thickness, and chamber conditions. Each build is tracked via a digital twin system that logs every parameter for full traceability. In-process monitoring systems detect anomalies during printing, enabling immediate corrective action and preventing defective outputs.

Post-processing is executed in-house using automated stress-relief heat treatment, precision machining, and surface finishing techniques such as micro-shot peening to enhance fatigue resistance. Every component is subjected to final inspection, including chemical composition verification, mechanical testing, and full documentation per AS9100 and NADCAP standards.

This seamless integration of design intelligence, advanced manufacturing, and uncompromising quality control ensures that every 3D printed aerospace part meets the highest performance and safety benchmarks.

| Specification | Detail |

|---|---|

| Materials | Inconel 718, Ti-6Al-4V, AlSi10Mg, Stainless Steel 316L |

| Layer Thickness | 20–60 μm |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (as-printed) | Ra 10–15 μm |

| Post-Processing | Heat Treatment, CNC Machining, Shot Peening, Polishing |

| Quality Standards | AS9100, ISO 9001, NADCAP, Full Material Traceability |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Aerospace Additive Manufacturing

In the high-stakes aerospace sector, component failure is not an option. Wuxi Lead Precision Machinery delivers certified, flight-ready 3D printed metal parts engineered to withstand extreme thermal cycles, vibration, and structural loads. With over 15 years of AS9100-certified precision manufacturing and deep expertise in metal additive technologies, we transform complex aerospace designs into reliable hardware. Our integrated approach spans material science, in-process metrology, and post-build validation—ensuring every part meets stringent FAA, EASA, and NADCAP requirements. Stop compromising between speed and compliance. Partner with a manufacturer that treats your mission as our own.

We eliminate the guesswork in aerospace additive production through closed-loop process control. Our facility combines EOS M 400-4 and SLM Solutions S500 systems with real-time melt pool monitoring, ensuring consistent microstructure integrity across builds. Each component undergoes rigorous non-destructive testing (NDT), including CT scanning and ultrasonic inspection, with full material traceability from powder lot to finished part. This disciplined methodology reduces certification risk and accelerates your path to flight approval—without sacrificing geometric accuracy or surface quality.

Technical Capabilities for Aerospace Applications

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Materials | Inconel 718, Ti-6Al-4V, AlSi10Mg, CoCr, Maraging Steel | AMS, ASTM, MMPDS |

| Build Volume | Up to 500 x 400 x 400 mm | Custom configurations available |

| Dimensional Accuracy | ±0.05 mm for features < 50 mm | ISO 2768-mK |

| Surface Finish | As-built: Ra 12–25 μm; Post-processed: Ra 0.8–1.6 μm | Customer-specified |

| Certifications | AS9100:2016, NADCAP (NDT), ISO 9001:2015 | Full PPAP documentation |

| Secondary Operations | CNC machining, HIP, stress relieving, shot peening | Nadcap-accredited |

Your aerospace program demands more than a supplier—it requires a technical collaborator. At Lead Precision, our engineering team engages at the design phase to optimize topology, support structures, and build orientation, minimizing post-processing and maximizing part performance. We provide comprehensive material test reports, build logs, and metallurgical validation data to streamline your airworthiness substantiation. Whether you need low-volume prototypes for wind tunnel testing or serial production of turbine components, we deliver repeatable quality with 25% faster lead times than conventional aerospace foundries.

Do not risk program delays with unproven vendors. Contact our aerospace engineering team today to discuss your specific requirements. Email [email protected] with your part geometry, material specifications, and certification needs. We will respond within 4 business hours with a detailed technical package—including feasibility assessment, timeline, and cost analysis—tailored to your mission’s critical path. Let Lead Precision become your trusted partner in advancing aerospace innovation, one certified component at a time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.