Technical Contents

Engineering Guide: 3D Print Vs Cnc

Engineering Insight: 3D Print vs CNC – The Critical Role of Precision in High-End Manufacturing

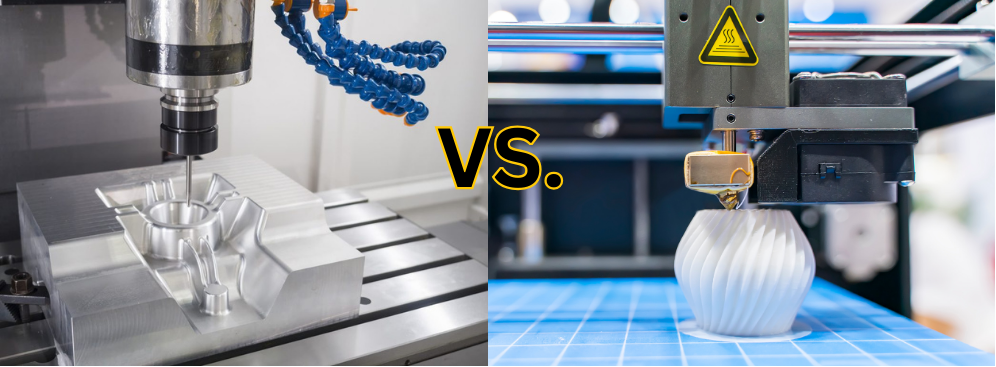

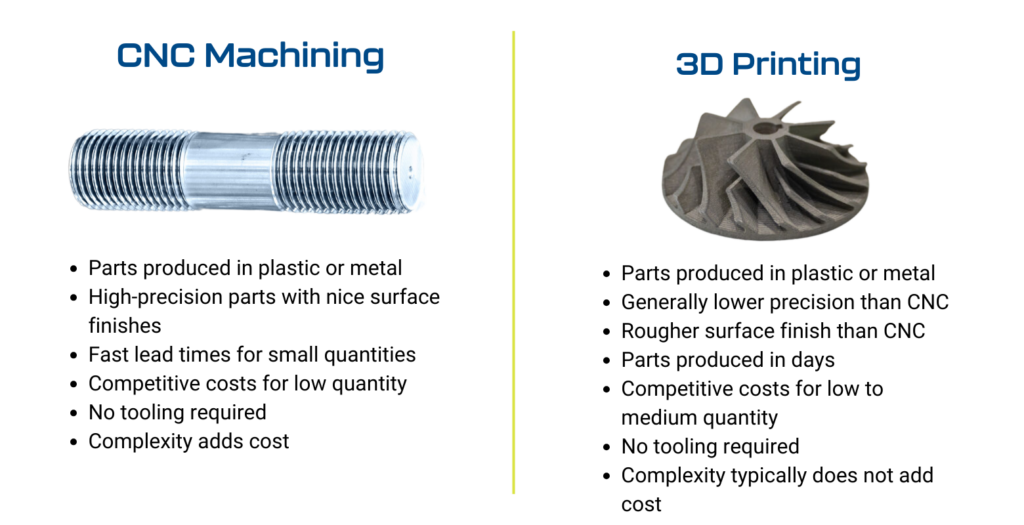

In the evolving landscape of advanced manufacturing, the debate between 3D printing and CNC machining remains central to engineering decision-making. While both technologies offer distinct advantages, the requirement for micron-level precision, material integrity, and repeatability often determines the optimal process. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC machining, delivering components that meet the most stringent performance standards—particularly in sectors where failure is not an option.

Precision is not merely a metric; it is a foundational requirement in aerospace, defense, medical, and high-performance automotive applications. CNC machining excels in this domain, offering tolerances consistently within ±0.005 mm, with surface finishes down to Ra 0.4 µm achievable through secondary operations. These figures are not theoretical—they are routinely achieved across our production floor, supported by state-of-the-art 5-axis machining centers, in-process probing, and full environmental control. In contrast, even the most advanced industrial 3D printing systems typically operate within ±0.1 mm tolerances, with anisotropic mechanical properties and layer-line artifacts that often necessitate post-machining anyway.

Material performance further underscores the advantage of CNC. Machined parts are derived from fully dense, certified stock—aluminum 7075-T6, titanium Ti-6Al-4V, Inconel 718—retaining their full mechanical properties as defined by ASTM and MIL specifications. Additively manufactured parts, while improving, often exhibit microstructural inconsistencies due to rapid solidification and thermal cycling, leading to variable fatigue life and reduced reliability under cyclic loads.

Our experience at Wuxi Lead speaks directly to these demands. We have supplied mission-critical components for Chinese military UAV systems and precision timing elements used in Olympic-grade athletic equipment, where dimensional stability and performance consistency are non-negotiable. These projects demanded not only precision but traceability, full QA documentation, and zero-defect delivery—benchmarks that align naturally with CNC’s strengths.

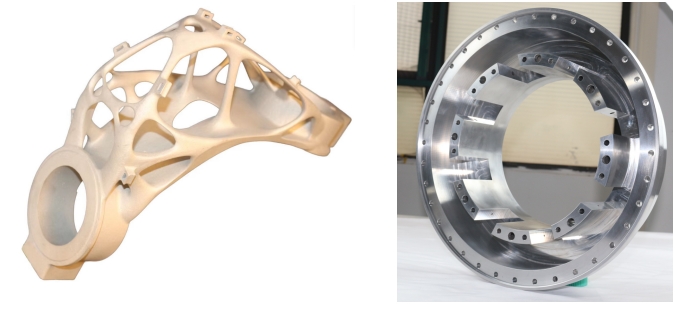

While 3D printing holds value in rapid prototyping, complex internal geometries, and low-volume customization, it cannot yet match CNC machining for high-reliability, high-precision production. For industries where performance, safety, and certification are paramount, CNC remains the gold standard.

| Specification | CNC Machining (Wuxi Lead) | Industrial 3D Printing (Typical) |

|---|---|---|

| Standard Tolerance | ±0.005 mm | ±0.1 mm |

| Surface Finish (as-machined) | Ra 0.8 – 3.2 µm | Ra 6.3 – 25 µm (as-built) |

| Material Density | 100% (wrought stock) | 95–99.9% (varies by process) |

| Common Materials | Aluminum, Titanium, Steel, Inconel, Brass | Nylon, ABS, Resins, Limited Metal Alloys |

| Production Volume Suitability | Low to High | Low to Medium |

| Secondary Finishing Required | Optional (e.g., polishing, anodizing) | Often required (machining, coating) |

At Wuxi Lead Precision Machinery, our commitment to precision engineering ensures that every component we produce meets the highest standards of performance and reliability—proven on the global stage and in the field.

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Machining Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for mission-critical components through advanced multi-axis CNC machining. Our core strength lies in transforming complex engineering designs into high-integrity parts meeting the most stringent aerospace, medical, and industrial automation requirements. Unlike additive processes constrained by layer adhesion and material limitations, our subtractive CNC methodology ensures consistent material properties, superior surface integrity, and geometric accuracy essential for load-bearing, high-wear, or safety-critical applications. This foundation enables predictable performance under extreme operational conditions where dimensional stability is non-negotiable.

Our facility is anchored by a strategic fleet of 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems provide simultaneous multi-directional toolpath control, eliminating the need for multiple setups and fixture-induced errors. This capability is critical for manufacturing complex organic shapes, deep cavities, and intricate contours found in turbine blades, surgical instrument housings, and fluid dynamics components. The integrated high-speed spindles and rigid construction minimize vibration, ensuring micron-level repeatability across production runs. Material versatility spans aerospace-grade aluminum alloys (7075-T6, 2024), medical stainless steels (316L, 17-4PH), titanium (Grade 5), and engineered plastics like PEEK, all processed under tightly controlled environmental conditions.

Quality assurance is intrinsically woven into every manufacturing phase. All critical dimensions undergo rigorous validation using Zeiss and Hexagon Coordinate Measuring Machines (CMMs). Our CMM inspection protocol exceeds ISO 10360-2 standards, utilizing calibrated probes and advanced software for comprehensive geometric dimensioning and tolerancing (GD&T) analysis. This systematic approach verifies not only linear dimensions but also complex form tolerances—flatness, cylindricity, true position—and surface finish parameters critical for sealing interfaces or bearing surfaces. Traceable calibration records and real-time SPC data ensure full compliance with AS9100 and ISO 13485 mandates.

The following table details achievable tolerance ranges for machined features under standard production conditions. Actual capabilities may be refined based on specific part geometry, material, and feature criticality as defined in your engineering documentation.

| Feature Type | Typical Tolerance Range | Material Consideration |

|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | All metals & engineering plastics |

| Hole Diameter (Reamed) | ±0.003 mm (±0.0001″) | Steels, Stainless, Aluminum |

| Hole Position | ±0.010 mm (±0.0004″) | Critical for bolt patterns |

| Surface Flatness | 0.005 mm (0.0002″) per 25mm | Critical sealing surfaces |

| Surface Roughness (Ra) | 0.4 – 0.8 µm (16 – 32 µin) | Machined finishes; polishing available |

Wuxi Lead’s precision machining capability transcends basic part fabrication. It represents a guaranteed pathway to functional reliability, regulatory compliance, and extended service life. When your application demands absolute dimensional fidelity, material integrity, and repeatability across thousands of parts, our CNC process delivers the engineering certainty that additive methods cannot match for high-performance metal components. This precision foundation is where mission success is manufactured.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the correct material is critical in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance machining of engineering-grade metals, with aluminum, steel, and titanium being the most widely used in industrial applications. Each material offers unique mechanical properties and responds differently to post-machining finishes such as anodizing, making informed selection essential for optimal results.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is commonly used in aerospace, automotive, and consumer electronics where lightweight components are crucial. The most popular grade, 6061-T6, balances weldability, strength, and dimensional stability. When paired with anodizing, aluminum gains enhanced surface hardness and improved resistance to wear and corrosion. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard finishes, with Type III providing thicker, more durable oxide layers suitable for demanding environments.

Steel, particularly stainless steel grades such as 303, 304, and 17-4 PH, offers superior strength, hardness, and resistance to high temperatures and corrosion. It is ideal for medical devices, industrial tools, and structural components requiring long-term reliability. While steel is more challenging to machine than aluminum due to higher tool wear and heat generation, modern CNC techniques ensure tight tolerances and fine surface finishes. Passivation is typically used post-machining to enhance corrosion resistance, though anodizing is not applicable to steel.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-density performance and outstanding resistance to extreme environments, including saltwater and high heat. It is the material of choice in aerospace, defense, and high-performance automotive sectors. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and slower cutting speeds during CNC machining. While titanium can undergo anodizing, the process is primarily used for color coding or minor surface enhancement rather than wear protection.

Understanding the interplay between material properties and finishing options ensures optimal component performance. Below is a comparative overview of key specifications.

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Excellent | Anodizing (Type II/III), Powder Coat |

| Steel | 304, 316, 17-4 PH | 505–1300 | 7.9 | Moderate | Passivation, Electroplating |

| Titanium | Ti-6Al-4V (Gr5) | 900–1000 | 4.4 | Poor | Anodizing (decorative), Bead Blast |

At Wuxi Lead, we support clients in selecting the optimal material and finish combination based on functional requirements, environmental exposure, and production volume. Our precision CNC capabilities ensure consistent quality across all material types, enabling performance-driven manufacturing for advanced industrial applications.

Manufacturing Process & QC

Precision Production Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production workflow for CNC machining that ensures zero defects from initial concept to volume delivery. Unlike 3D printing, which often requires iterative adjustments during scaling, our subtractive process maintains unwavering consistency through three integrated phases.

The Design Phase begins with comprehensive DFM analysis. Our engineers collaborate with clients to optimize part geometry for CNC machining, addressing material stress points, tool access, and tolerance stack-ups early. This prevents costly revisions later—unlike 3D printing, where design flaws often surface only during prototyping due to layer adhesion or thermal distortion risks. We validate all models against ISO 2768-mK standards using simulation software that predicts micro-vibrations and thermal expansion, ensuring manufacturability before metal meets tool.

Prototyping leverages high-speed CNC mills for functional validation, not just form checks. While 3D printing offers rapid visual mock-ups, its material properties rarely match end-use requirements, leading to false confidence. Our prototypes use the exact production alloy and undergo full metrology scans against CAD data. This confirms dimensional stability, surface integrity, and assembly fit—critical for aerospace or medical components where failure is non-negotiable. Only after client sign-off on these rigorously tested units do we proceed.

Mass Production deploys our zero-defect ecosystem. Each CNC center runs under closed-loop control: in-process probes measure features mid-machining, auto-compensating for tool wear. Every 50th part undergoes 100% CMM inspection against GD&T callouts, with real-time SPC data fed to operators. Statistical process control maintains CpK ≥1.67, far exceeding typical 3D printing’s batch variability. Our facility’s ISO 9001-certified workflow includes material traceability down to heat lot numbers and environmental controls stabilizing temperature to ±0.5°C—eliminating thermal drift errors common in additive processes.

The table below contrasts critical production capabilities:

| Process Phase | CNC Machining Capability | 3D Printing Limitation |

|---|---|---|

| Design | Full DFM integration; tolerance validation via thermal simulation | Limited DFM tools; anisotropic strength risks overlooked |

| Prototyping | Production-material validation; functional testing | Non-representative material properties; surface porosity |

| Mass Production | Real-time metrology feedback; CpK ≥1.67; full traceability | Layer inconsistency; batch drift; limited in-process QC |

This disciplined approach ensures every component meets stringent zero-defect mandates. For mission-critical applications demanding micron-level repeatability and material integrity, CNC machining remains the only proven solution for scalable precision. Contact Wuxi Lead to validate your production workflow against these uncompromising standards.

Why Choose Wuxi Lead Precision

When navigating the complex decision between 3D printing and CNC machining for your precision manufacturing needs, the right partner can make all the difference. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC machining services tailored to meet the exacting standards of aerospace, medical, automotive, and industrial equipment manufacturers. While 3D printing offers rapid prototyping and design flexibility, CNC machining delivers superior strength, repeatability, and surface finish—critical for end-use components operating under stress or in regulated environments.

Our advanced CNC capabilities include 3-axis, 4-axis, and 5-axis milling, turning, and multi-axis machining centers, allowing us to produce complex geometries with tolerances as tight as ±0.005 mm. With over a decade of experience serving global clients, we combine cutting-edge technology, ISO 9001-certified quality systems, and a deep understanding of material science to deliver precision-machined parts that perform flawlessly in real-world applications.

Partnering with Wuxi Lead Precision Machinery means more than just outsourcing production—it means gaining a strategic manufacturing ally. From initial design consultation to final inspection and global logistics, we work closely with engineering teams to optimize manufacturability, reduce lead times, and lower total production costs. Our facility in Wuxi, China, is equipped with state-of-the-art machinery and supported by a team of skilled machinists and quality assurance professionals who ensure every component meets your specifications.

Below is a comparison of key performance metrics between CNC machining and 3D printing to help guide your technology selection:

| Parameter | CNC Machining (Wuxi Lead) | 3D Printing (Typical) |

|---|---|---|

| Material Options | Aluminum, Steel, Stainless, Titanium, Brass, Plastics | Limited to compatible filaments, resins, or powders |

| Tolerance | ±0.005 mm | ±0.1 mm to ±0.3 mm |

| Surface Finish | Ra 0.8 μm (standard), down to Ra 0.2 μm | Ra 6.3 μm (as-printed), requires post-processing |

| Production Speed | Fast for high volumes | Slower for dense, solid parts |

| Part Strength | Full material density, isotropic | Layered structure, weaker between layers |

| Secondary Operations | Deburring, anodizing, plating, passivation | Sanding, coating, curing required |

| Ideal Use Case | End-use parts, high-volume runs, tight-tolerance components | Prototypes, low-volume, complex internal geometries |

Whether your project demands the structural integrity of aerospace-grade aluminum or the biocompatibility of medical titanium, our CNC machining services provide the precision and consistency you require. We support materials ranging from standard alloys to exotic superalloys, ensuring your components perform under extreme conditions.

Let Wuxi Lead Precision Machinery be your trusted partner in bringing high-performance parts from concept to reality. Contact us today at [email protected] to discuss your project, request a quote, or receive technical support. With our expertise in precision CNC machining, we don’t just meet specifications—we exceed expectations.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.