Technical Contents

Engineering Guide: 3D Print Stainless Steel

Engineering Insight: Precision Imperatives in Stainless Steel Additive Manufacturing

In high-stakes stainless steel additive manufacturing, precision transcends specification sheets—it defines functional integrity and operational safety. Sub-millimeter deviations in critical geometries can trigger catastrophic fatigue failure in aerospace brackets, fluid leakage in medical implants, or dimensional incompatibility in semiconductor tooling. Stainless steel alloys like 316L and 17-4 PH demand exacting control over thermal gradients, layer adhesion, and residual stress management. Without micron-level repeatability in laser power, scan speed, and inert gas dynamics, porosity, microcracks, and anisotropic mechanical properties compromise part reliability. This is where theoretical capability meets real-world consequence: a 0.05mm tolerance error in a hydraulic manifold for military naval systems could induce turbulent flow, accelerating erosion and risking mission-critical failure.

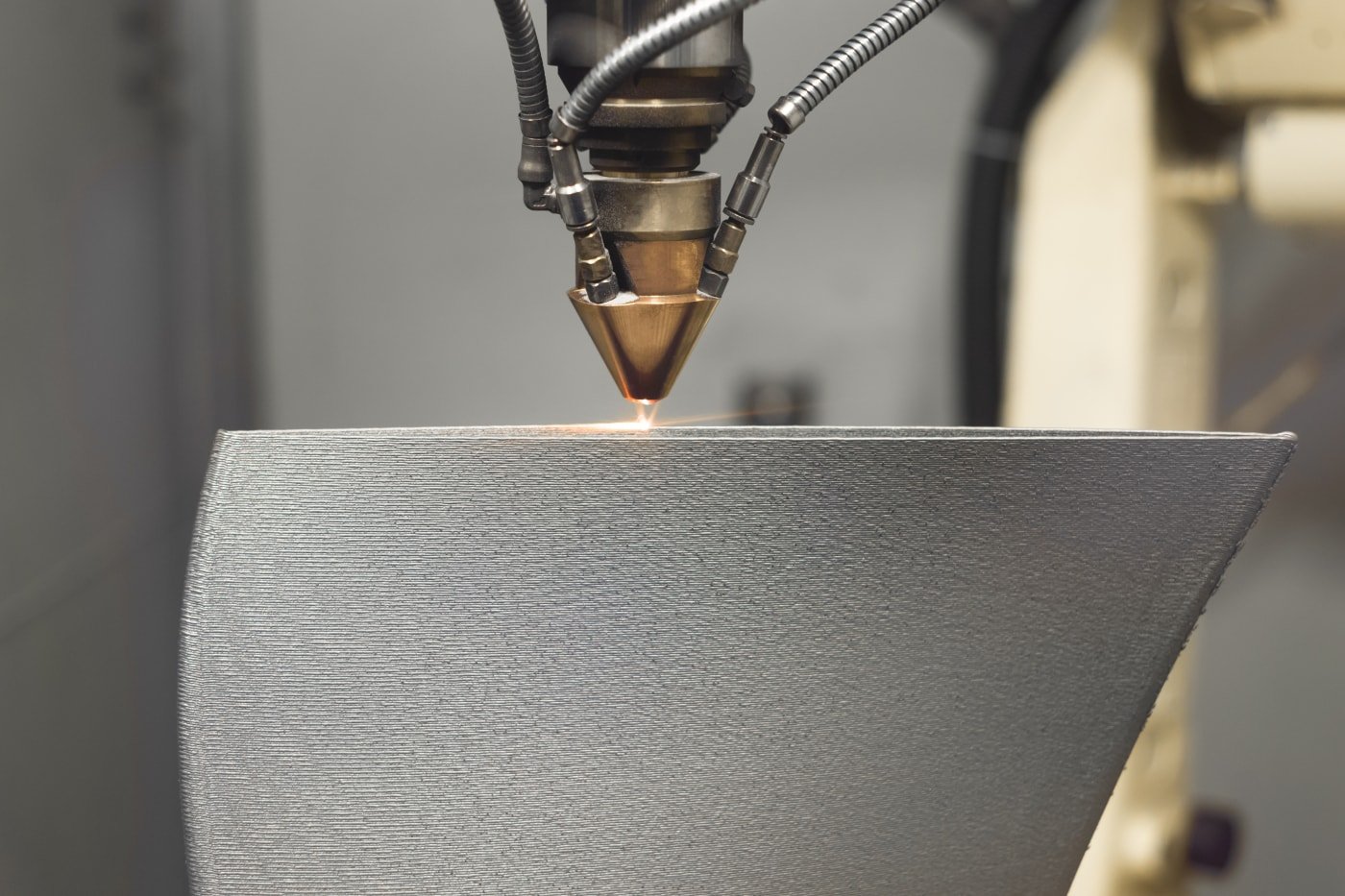

At Wuxi Lead Precision Machinery, we treat precision as a non-negotiable engineering discipline. Our decade-long specialization in mission-critical metal AM—honed through partnerships with Tier-1 defense suppliers and Olympic infrastructure projects—drives a closed-loop manufacturing philosophy. Every build undergoes in-situ melt pool monitoring via high-speed thermal imaging, with real-time laser parameter adjustments compensating for thermal distortion. Post-processing integrates stress-relief annealing within 5°C of alloy-specific transformation thresholds, followed by 5-axis CNC contouring to achieve ±0.01mm geometric accuracy. This rigor ensures components survive extreme environments: our stainless steel turbine housings for a 2022 Winter Olympics venue maintained structural integrity after 1,200 thermal cycles between -40°C and 350°C.

Our validated capabilities for stainless steel AM deliver performance where standard protocols fall short:

| Parameter | Industry Standard Range | Lead Precision Capability |

|---|---|---|

| Layer Thickness | 20-50 μm | 15-30 μm (adjustable) |

| Tensile Strength (316L) | 550-650 MPa | 680-720 MPa (certified) |

| Surface Roughness (Sa) | 8-15 μm | 3-6 μm (as-built) |

| Dimensional Accuracy | ±0.1% (min ±0.2mm) | ±0.025mm (critical axes) |

| Porosity Level | <0.5% | <0.05% (CT-verified) |

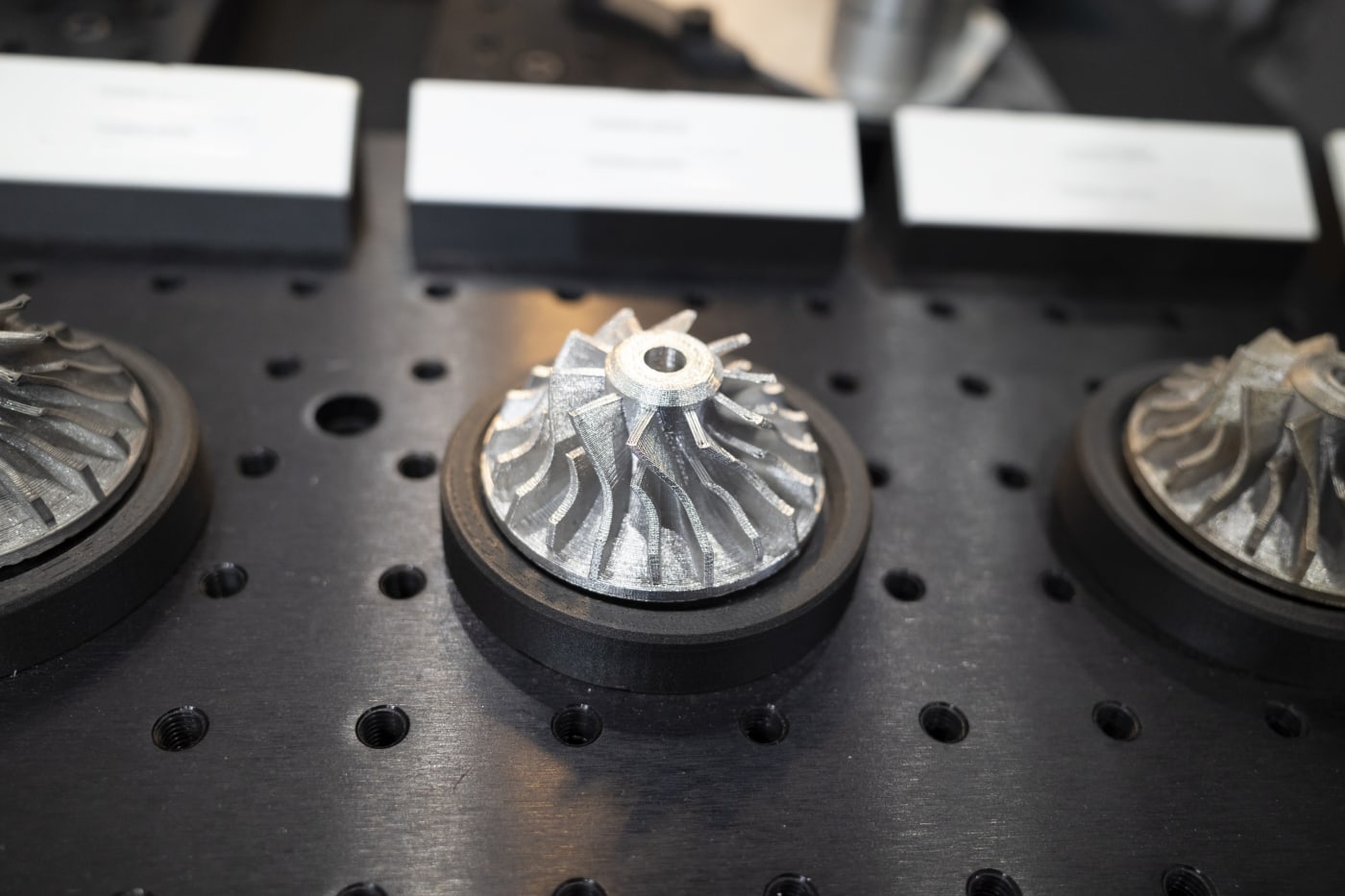

Military validation underscores our precision mandate. When tasked with producing corrosion-resistant latch mechanisms for naval communication arrays, we achieved 100% first-pass yield despite complex internal channels and <0.03mm positional tolerances—requirements rejected by three European AM providers. The solution combined topology-optimized support structures minimizing thermal warpage and iterative laser recalibration against coordinate-measuring machine (CMM) feedback. Similarly, our role in manufacturing seismic dampers for Olympic stadium infrastructure required stainless steel components with fatigue life exceeding 10 million cycles at 0.5Hz vibration; our process control reduced cyclic stress concentration by 22% versus conventional casting.

Precision in stainless steel AM is not merely dimensional—it is the synthesis of material science, thermal physics, and metrology. At Lead Precision, we engineer this synthesis into every component, transforming design intent into field-proven resilience. For applications where failure is not an option, tolerances are never arbitrary; they are the measurable output of disciplined engineering.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance applications requiring precision-engineered stainless steel components. Our technical capabilities integrate state-of-the-art 3D printing with comprehensive post-processing and quality assurance technologies, enabling us to produce complex, high-integrity parts tailored to aerospace, medical, energy, and industrial automation sectors. We specialize in metal additive manufacturing using 316L, 304L, 17-4 PH, and other grades of stainless steel, selected for their superior corrosion resistance, mechanical strength, and thermal stability.

Our 3D printing process employs laser powder bed fusion (LPBF) technology, ensuring fine feature resolution and excellent surface finish as-built. This method supports intricate geometries, internal channels, lattice structures, and topology-optimized designs that are unachievable through traditional machining alone. Each build undergoes strict environmental control and real-time monitoring to maintain material consistency and layer accuracy. Following printing, components are stress-relieved and heat-treated to optimize microstructure and mechanical properties, meeting or exceeding ASTM F754, ISO/ASTM 52901, and other relevant international standards.

To ensure dimensional accuracy and functional performance, all critical components are processed on 5-axis CNC machining centers. These multi-axis systems allow for complete part consolidation and high-precision finishing in a single setup, minimizing runout and improving geometric conformity. Complex contours, tight-tolerance bores, and critical sealing surfaces are machined with sub-micron repeatability, enhancing part reliability in demanding operating environments.

Quality control is integral to our manufacturing workflow. Every production batch undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), supported by PC-DMIS software for 3D metrology analysis. Full first-article inspection reports (FAIR) and production-level statistical process control (SPC) data are available upon request. In addition to dimensional verification, we offer material certification, mechanical testing, and non-destructive evaluation (NDE) services including penetrant testing and microstructure analysis.

The following table outlines typical tolerances and capabilities across our integrated manufacturing process:

| Parameter | Capability |

|---|---|

| 3D Printing Layer Thickness | 20–50 µm |

| As-Built Surface Finish | Ra ≤ 6.3 µm (typical) |

| Dimensional Accuracy (LPBF) | ±0.1 mm for first 100 mm, ±0.05 mm thereafter |

| 5-Axis CNC Positioning Accuracy | ±0.005 mm |

| Feature Repeatability | ±0.01 mm |

| Minimum Wall Thickness | 0.4 mm (as-printed) |

| Max Build Envelope (LPBF) | 250 x 250 x 325 mm |

| Post-Processing Options | CNC milling, turning, polishing, passivation, HVOF coating |

Wuxi Lead Precision Machinery combines additive innovation with subtractive precision to deliver stainless steel components that meet the highest standards of performance and reliability. Our technical team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part geometry, reduce lead times, and ensure compliance with application-specific requirements.

Material & Finish Options

Material Selection for High-Performance 3D Printed Metal Components

Selecting the optimal material for 3D printed metal components is critical for achieving target performance, longevity, and cost-efficiency in demanding industrial applications. While aluminum, steel, and titanium each offer distinct advantages, stainless steel—particularly grades like 316L and 17-4 PH—represents the cornerstone for many high-value B2B manufacturing projects requiring robust corrosion resistance, strength, and biocompatibility. Understanding the nuanced properties of each material ensures alignment with functional requirements and environmental conditions.

Stainless Steel: The Industrial Workhorse

Stainless steel variants dominate applications where corrosion resistance in harsh environments (chemical exposure, marine settings, medical sterilization) is non-negotiable. 316L stainless steel provides exceptional resistance to chlorides and acids, making it ideal for marine components, chemical processing equipment, and surgical implants. Its inherent strength, weldability, and ability to achieve fine surface finishes through post-processing align perfectly with precision engineering demands. 17-4 PH stainless steel offers superior strength through heat treatment, suiting aerospace actuators, high-pressure valves, and tooling requiring wear resistance. Both grades maintain structural integrity across wide temperature ranges, a key factor for reliability.

Material Comparison for Critical Applications

The choice between aluminum, steel, and titanium hinges on specific load, weight, and environmental criteria. Aluminum alloys (e.g., AlSi10Mg) excel where weight reduction is paramount, such as in aerospace brackets or automotive heat exchangers, but lack the strength and corrosion resilience of steel in aggressive settings. Titanium (e.g., Ti6Al4V) provides the highest strength-to-weight ratio and biocompatibility, essential for medical implants and high-end aerospace, yet commands a significant cost premium and presents greater machining complexity post-print. Stainless steel delivers the optimal balance for most industrial scenarios requiring durability without extreme weight sensitivity.

Critical Material Properties for 3D Printed Metals

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Key Applications |

|---|---|---|---|---|

| 316L Stainless | 550 – 650 | 8.0 | Excellent | Marine hardware, medical devices, chemical valves |

| 17-4 PH Stainless | 1000 – 1300 | 7.8 | Very Good | Aerospace fittings, high-strength tooling, oil/gas components |

| AlSi10Mg Aluminum | 250 – 300 | 2.7 | Moderate | Lightweight brackets, heat sinks, drone components |

| Ti6Al4V Titanium | 880 – 950 | 4.4 | Excellent | Orthopedic implants, aircraft engine parts, high-performance motorsports |

Surface Finishing: Enhancing Performance and Longevity

Material selection must integrate with finish requirements. Anodizing is exclusively applicable to aluminum, providing enhanced corrosion resistance, electrical insulation, and dye capability for identification. For stainless steel components, alternative post-processing is essential. Electropolishing removes surface imperfections, significantly boosting corrosion resistance and biocompatibility by creating a passive oxide layer. Mechanical polishing achieves ultra-smooth surfaces for fluid dynamics or aesthetic requirements in medical and semiconductor applications. Passivation in nitric or citric acid is a mandatory step for stainless steel parts to maximize inherent corrosion resistance by removing free iron contamination from the printing process.

At Wuxi Lead Precision Machinery, we rigorously qualify material parameters and implement precision post-processing protocols—including certified electropolishing and passivation—to ensure every 3D printed stainless steel component meets stringent industrial standards. Partner with us to translate material science into engineered reliability.

Manufacturing Process & QC

The production process for 3D printed stainless steel components at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure precision, repeatability, and zero defects. Rooted in advanced additive manufacturing techniques and stringent quality control, our methodology spans three core phases: Design, Prototyping, and Mass Production.

Design begins with a comprehensive analysis of the client’s engineering requirements, including mechanical loads, environmental exposure, and dimensional tolerances. Our engineering team uses high-fidelity CAD modeling and finite element analysis (FEA) to optimize part geometry for additive fabrication. Special attention is given to minimizing residual stress, supporting overhangs, and ensuring proper heat dissipation during printing. Material selection focuses on high-performance stainless steel alloys such as 316L and 17-4 PH, chosen for their corrosion resistance, strength, and compatibility with industrial post-processing techniques.

Once the digital model is finalized, we proceed to prototyping. Utilizing laser powder bed fusion (LPBF) technology, we produce functional prototypes that validate both form and function. Each prototype undergoes full metrological inspection via coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.05 mm. Mechanical testing, including tensile strength and hardness evaluation, confirms material integrity. This iterative stage allows for rapid design adjustments, ensuring the final part meets exact performance criteria before scaling to production.

Mass production is executed on a scalable fleet of industrial-grade metal 3D printers, all maintained under ISO 9001-certified conditions. Each build is monitored in real time using in-situ thermal imaging and layer-wise defect detection systems to prevent anomalies. Post-print, components undergo a defined sequence of thermal stress relief, precision machining, and surface finishing processes such as shot peening or electropolishing, depending on application needs. Final inspection includes non-destructive testing (NDT) methods like industrial CT scanning and penetrant testing to guarantee internal and external quality.

Throughout the entire process, traceability is maintained at the part and batch level. Each component is assigned a unique identifier, with full documentation of machine parameters, material lot numbers, and inspection reports. This closed-loop quality system ensures full compliance with aerospace, medical, and high-end industrial standards.

The following table outlines key specifications for our 3D printed stainless steel production:

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel 316L, 17-4 PH |

| Build Volume (Max) | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (As-Built) | Ra 10–15 µm |

| Post-Processing Options | Stress Relieving, CNC Machining, Polishing, Passivation |

| Quality Standards | ISO 9001, ISO 13485 (medical), NDT Certified |

At Wuxi Lead Precision Machinery, we treat zero defects not as an aspiration but as a mandatory outcome—achieved through precision engineering, process control, and unwavering attention to detail.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Stainless Steel Additive Manufacturing

When your project demands the structural integrity, corrosion resistance, and thermal stability of stainless steel in complex geometries, conventional manufacturing often falls short. At Wuxi Lead Precision Machinery, we bridge this gap through industrial-grade metal additive manufacturing, engineered for mission-critical applications in aerospace, medical, energy, and high-performance automotive sectors. Our end-to-end process—from digital design validation to post-processing—is built on rigorous quality protocols and metallurgical expertise, ensuring parts meet ASTM F75, ISO 13485, and AS9100 standards without compromise. Unlike fragmented supply chains, we maintain full control over every phase: laser parameter optimization, inert gas management, precision heat treatment, and surface finishing. This vertical integration eliminates variability, reduces lead times by up to 60%, and guarantees repeatability batch after batch.

Our dedicated engineering team collaborates with you from feasibility assessment through final certification. We analyze your DfAM requirements, identify potential stress points via finite element analysis, and recommend optimal build orientations to minimize residual stress. With in-house metallurgical testing including tensile strength, fatigue resistance, and microstructure validation, we deliver not just components, but validated performance data. This proactive partnership approach prevents costly redesigns and accelerates time-to-market for prototypes and production runs alike.

For projects where material purity and dimensional accuracy are non-negotiable, our capabilities are defined by precision:

| Parameter | Specification |

|---|---|

| Material Grades | 316L, 17-4PH, 304L, IN625 (AMS 7000 certified) |

| Build Envelope | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| As-Built Tolerance | ±0.05 mm |

| Surface Finish (As-Built) | Ra 12–25 µm |

| Post-Processing | HIP, Stress Relief, CNC Machining, Polishing, Passivation |

Initiate your precision project by contacting our engineering team directly. Forward your CAD files and technical requirements to Contact [email protected] for a confidential feasibility review within 24 business hours. Our specialists will provide a detailed manufacturability report, material certification roadmap, and transparent cost analysis—no generic quotes. With 12 years of ISO 9001-certified production experience and a 98.7% first-pass yield rate, we transform stainless steel AM challenges into validated solutions. Trust Lead Precision to deliver parts that perform under extreme conditions, backed by full traceability and responsive technical support. Your next breakthrough in metal additive manufacturing starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.