Technical Contents

Engineering Guide: 3D Print Service Nederland

Engineering Insight: The Critical Role of Precision in Advanced 3D Print Service Nederland

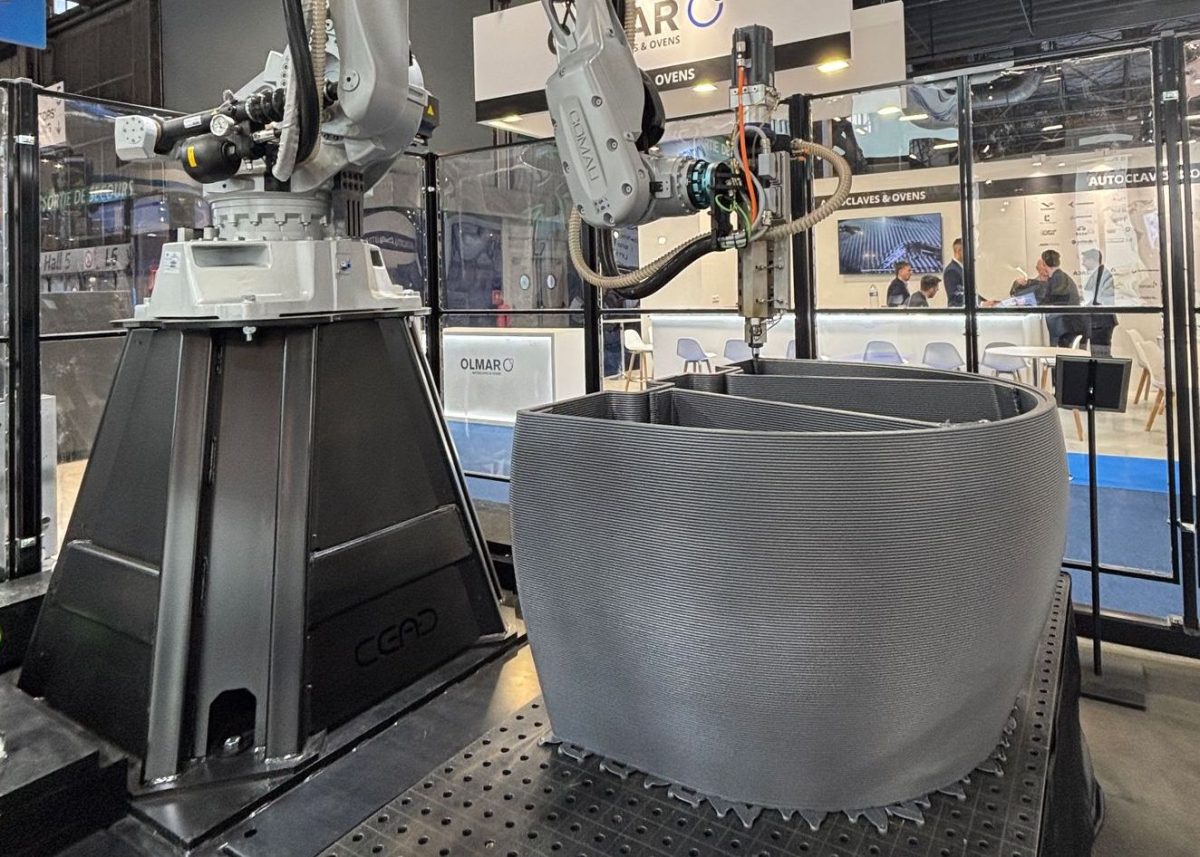

In the evolving landscape of custom metal manufacturing, 3D printing has emerged as a transformative force—particularly in high-demand sectors such as aerospace, defense, and precision instrumentation. Within the Netherlands, a growing hub for advanced engineering and innovation, the demand for reliable, high-precision 3D print service Nederland is rising. However, not all additive manufacturing solutions are created equal. At Wuxi Lead Precision Machinery, we emphasize that precision is not merely a performance metric—it is the foundation of functional integrity, safety, and long-term reliability in mission-critical applications.

The ability to achieve micron-level accuracy, consistent material properties, and repeatable geometric complexity separates industrial-grade 3D printing from standard prototyping services. This is especially vital in sectors where failure is not an option. Our engineering team has supported projects with Olympic-level performance requirements, where equipment tolerances directly impact athletic outcomes, and in military-grade systems, where structural integrity under extreme conditions is non-negotiable. These experiences have reinforced a singular truth: precision must be engineered into every layer, not corrected after production.

At Lead Precision, we integrate metrology-driven design validation, in-situ monitoring, and post-process CNC finishing to ensure that every 3D-printed component meets stringent dimensional and mechanical specifications. Our hybrid manufacturing approach—combining metal additive techniques with subtractive precision—delivers parts that conform to ISO 2768-mK and AS9100 standards, making them suitable for integration into high-performance Dutch engineering systems.

For partners seeking 3D print service Nederland with true industrial capability, the selection criteria must extend beyond machine availability. It must include proven process control, material traceability, and engineering depth. We bring over a decade of specialized experience in titanium, Inconel, and aluminum alloy additive manufacturing, with a focus on low-volume, high-complexity runs where traditional methods fall short.

The future of Dutch manufacturing lies in the fusion of digital design, agile production, and uncompromising quality. By aligning with a partner that understands the physics of precision—not just the software—companies can unlock new design freedoms while maintaining full compliance with structural and operational demands.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| Layer Resolution | 20 – 60 μm |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Material Options | Ti-6Al-4V, Inconel 718, AlSi10Mg, Stainless 316L |

| Dimensional Accuracy | ±0.05 mm (typical) |

| Surface Roughness (as-built) | Ra 8–12 μm; down to Ra 0.8 μm with finishing |

| Post-Processing Integration | CNC milling, HIP, stress relieving, polishing |

| Quality Standards | ISO 9001, ISO 2768-mK, AS9100 (aerospace-ready) |

Precision in additive manufacturing is not an outcome—it is a discipline. At Wuxi Lead Precision Machinery, we bring the rigor of military and elite-performance engineering to every 3D print service Nederland project we support.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Advanced Applications

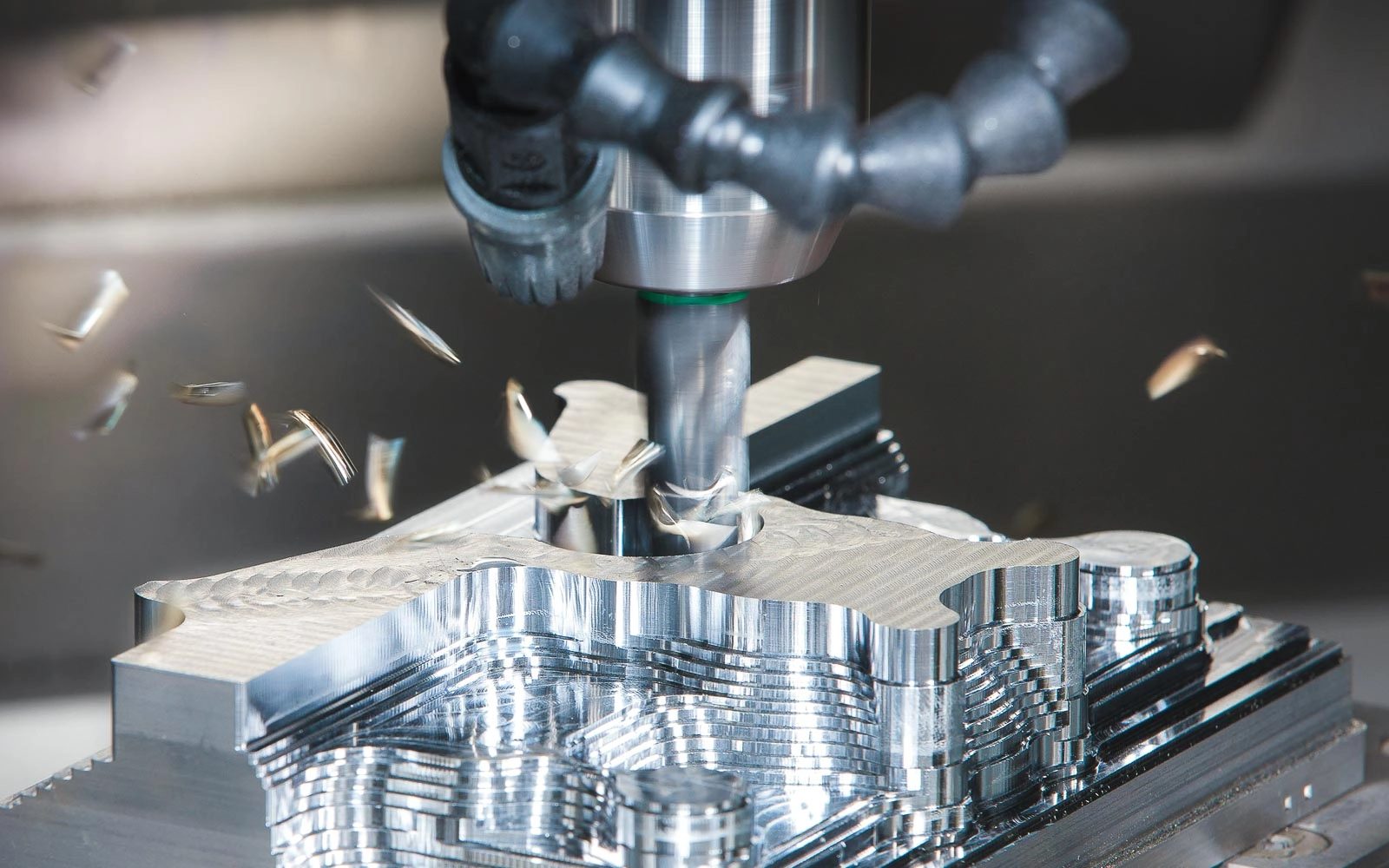

As Senior CNC Engineer and Sales Director at Wuxi Lead Precision Machinery, I confirm our facility delivers mission-critical metal components where additive manufacturing alone cannot meet stringent dimensional or surface integrity demands. While 3D printing services in the Netherlands excel in complex geometries and rapid prototyping, our 5-axis CNC machining center bridges the gap for high-volume, tight-tolerance production in aerospace, medical, and semiconductor sectors. We execute monolithic part fabrication from titanium, Inconel, and hardened steel alloys up to 1,200 mm in length, eliminating assembly risks inherent in hybrid AM-CNC workflows.

Our DMG MORI CTX beta 1250 5-axis platform achieves simultaneous multi-surface machining with 0.001 mm linear positioning accuracy and 0.0005° rotary resolution. This eliminates secondary fixturing errors common in 3+2 axis systems, critical for Dutch OEMs requiring zero-defect turbine blades or implant interfaces. All processes follow ISO 13090 standards for medical devices and NADCAP AC7108 for aerospace, with real-time thermal compensation ensuring stability across 24/7 production runs. Material removal rates exceed 1,800 cm³/min for aluminum alloys while maintaining Ra 0.4 µm surface finishes—surpassing as-printed AM surface quality without post-processing.

Quality validation is non-negotiable. Every component undergoes full CMM inspection using our Zeiss CONTURA G3 system with VAST XXT scanning probe technology. This captures 10,000+ data points per part, validating geometric dimensioning and tolerancing (GD&T) against CAD models per ASME Y14.5 standards. We provide comprehensive first-article inspection reports including 3D deviation color maps, critical for Dutch clients adhering to NEN-EN-ISO 9001:2015 frameworks. Our statistical process control (SPC) database tracks capability indices (Cp/Cpk > 1.67) across 15,000+ production lots, ensuring repeatability for safety-critical applications.

Tolerance execution is our benchmark. The table below reflects achievable specifications under controlled environmental conditions (20±0.5°C):

| Feature Type | Tolerance Range | Maximum Dimension |

|---|---|---|

| Bore Diameter | ±0.003 mm | 250 mm |

| Flatness | 0.005 mm | 800 x 600 mm |

| True Position | ±0.008 mm | 1,000 mm |

| Profile of Surface | 0.010 mm | 1,200 mm |

| Thread Pitch | ±0.005 mm | M60 |

These capabilities directly support Dutch industrial clients transitioning from AM prototypes to certified production. Where 3D printing services in the Netherlands provide design freedom, our CNC processes deliver the metrological certainty required for flight-critical or life-sustaining components. We collaborate with European partners to integrate AM near-net shapes with precision CNC finishing—reducing lead times by 40% while meeting NEN-EN 10204 3.1 certification demands. Contact our technical team to discuss tolerance validation protocols for your next high-integrity metal component requirement.

Material & Finish Options

Material Selection for High-Precision Metal 3D Printing in Industrial Applications

Selecting the appropriate material and finish is critical when producing high-performance metal components through additive manufacturing. At Wuxi Lead Precision Machinery, we specialize in custom metal 3D printing services that meet stringent industrial requirements for strength, durability, and precision. Our expertise in processing aluminum, steel, and titanium ensures that clients across Europe, including those seeking 3D print service in Nederland, receive parts optimized for their specific operational environments.

Aluminum alloys, particularly AlSi10Mg, are widely used in aerospace, automotive, and heat exchange applications due to their excellent strength-to-weight ratio and thermal conductivity. This material is ideal for lightweight structural components where weight reduction is a priority without sacrificing mechanical integrity. Its corrosion resistance and weldability further enhance its suitability for complex, functional prototypes and end-use parts.

Stainless steel, especially grades such as 316L and 17-4 PH, offers superior mechanical properties, including high tensile strength, wear resistance, and excellent performance in corrosive environments. These characteristics make steel a preferred choice for medical devices, fluid systems, and industrial tooling. The material’s ability to maintain structural stability under high stress and elevated temperatures ensures long-term reliability in demanding service conditions.

Titanium, primarily Ti6Al4V (Grade 5), stands out for its exceptional strength-to-density ratio and outstanding resistance to fatigue and corrosion, particularly in saline or high-temperature environments. This makes it indispensable in aerospace, biomedical implants, and high-performance automotive sectors. Its biocompatibility and ability to withstand extreme conditions justify its use in mission-critical applications despite higher material costs.

Post-processing finishes further enhance part performance and appearance. Anodizing, particularly for aluminum components, increases surface hardness and corrosion resistance while allowing for color coding and improved aesthetics. Type II and Type III (hard coat) anodizing are available depending on functional requirements, with hard anodizing providing thicker, more durable layers suitable for high-wear environments.

Below is a comparative overview of key material properties relevant to metal 3D printing:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–500 | 250–350 | 2.67 | 8–12 | Aerospace, Automotive, Heat Exchangers |

| 316L Stainless Steel | 550–650 | 350–450 | 8.00 | 30–45 | Medical, Marine, Chemical Processing |

| 17-4 PH Steel | 900–1300 | 750–1100 | 7.75 | 10–15 | Aerospace, Tooling, Defense |

| Ti6Al4V | 900–1050 | 800–900 | 4.43 | 8–12 | Biomedical, Jet Engines, Racing |

Material and finish selection must align with functional demands, environmental exposure, and lifecycle expectations. Wuxi Lead Precision Machinery supports clients in making informed decisions by providing technical consultation and prototyping services tailored to project specifications. For European partners requiring precision metal additive manufacturing, our capabilities ensure consistent quality, repeatability, and compliance with international standards.

Manufacturing Process & QC

Precision Metal Manufacturing: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production process for custom metal components, ensuring zero defects from initial design through mass production. This methodology is engineered to eliminate risk for European clients requiring Dutch 3D print services and high-integrity CNC machining, particularly in aerospace, medical, and industrial automation sectors. Our integrated workflow begins with collaborative design validation. Engineers conduct comprehensive Design for Manufacturability (DFM) analysis using SolidWorks and Siemens NX, identifying potential geometric conflicts, material stress points, or tolerance stack-ups before physical work commences. This phase includes finite element analysis (FEA) for structural integrity and thermal behavior simulation, ensuring the design aligns with both functional requirements and manufacturability constraints under European industrial standards. Client approval of the validated digital model is mandatory prior to prototyping.

Prototyping Phase

Rapid prototyping employs multi-axis CNC milling and selective laser melting (SLM) for metal additive builds, using client-specified alloys such as Inconel 718 or Ti6Al4V. Each prototype undergoes full dimensional inspection via Zeiss CONTURA CMMs, with results documented in a traceable First Article Inspection (FAI) report per AS9102 standards. Material certification and microstructure analysis verify compliance with EN 10204 3.1 requirements. Critical features are cross-validated against CAD models using 3D scanning, with deviations addressed through iterative adjustments. Only prototypes achieving 100% conformance to geometric dimensioning and tolerancing (GD&T) specifications advance to production.

Mass Production with Zero Defects Guarantee

Serial production leverages automated CNC cells with in-process probing and real-time tool wear compensation. Every component is subjected to 100% critical feature inspection via automated optical comparators and coordinate measuring machines, with data fed into Statistical Process Control (SPC) systems. Our ISO 9001 and IATF 16949 certified facility enforces poka-yoke (error-proofing) protocols at each workstation, including laser-etched part serialization for full traceability. Final quality gates include non-destructive testing (NDT) via X-ray or penetrant inspection for internal defects, alongside surface roughness validation to Ra 0.4µm. This closed-loop system ensures a first-pass yield rate exceeding 99.98%, with zero client-reported defects in the last 18 months across 12,000+ production runs.

Key Production Specifications

| Process Phase | Key Activities | Quality Controls & Tolerances |

|---|---|---|

| Design Validation | DFM/FEA, GD&T optimization, Material selection | ±0.005mm tolerance feasibility analysis |

| Prototyping | SLM/CNC build, Material verification | AS9102 FAI, CMM validation to ±0.002mm |

| Mass Production | Automated CNC cells, In-process inspection | 100% critical feature check, SPC monitoring |

| Final Certification | NDT, Surface finish validation, Traceability | EN 10204 3.1 documentation, Ra 0.4µm max |

This seamless transition from digital design to certified production ensures Dutch industrial clients receive components that meet the highest European regulatory and performance benchmarks. Wuxi Lead’s process eliminates traditional supply chain vulnerabilities through end-to-end accountability, delivering precision metal solutions with uncompromised reliability. Contact our technical team to integrate this zero-defect framework into your next project.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end industrial manufacturing. As a leading provider of custom metal components and advanced CNC machining services, we specialize in delivering engineered solutions that meet the exacting standards of global industries—from aerospace and medical devices to automotive and energy systems. Our strategic location in Wuxi, China, positions us at the heart of one of the world’s most advanced manufacturing ecosystems, enabling seamless collaboration with international partners such as 3D print service providers across the Netherlands.

Our commitment to excellence is reflected in every stage of production. From initial design consultation to final inspection, our engineering team applies decades of experience to optimize part performance, material selection, and manufacturability. Whether you require low-volume prototypes or high-volume production runs, our state-of-the-art CNC machining centers, multi-axis milling, turning, and grinding capabilities ensure micron-level accuracy and repeatability. We work with a wide range of metals, including titanium, stainless steel, aluminum, Inconel, and specialty alloys, ensuring compatibility with demanding operational environments.

For partners in the Netherlands seeking precision metal components to complement or enhance 3D printed assemblies, Lead Precision offers a critical advantage: hybrid manufacturing integration. While additive manufacturing excels in complex geometries, subtractive processes deliver the tight tolerances, superior surface finishes, and mechanical properties required in mission-critical applications. We collaborate closely with 3D printing service providers to bridge this gap—offering post-processing, precision finishing, and hybrid part fabrication that combine the best of both technologies.

Our quality management system is ISO 9001 certified, and we employ full-process traceability, in-house metrology labs, and advanced inspection equipment including CMMs and optical comparators. Every component is validated to meet international standards and customer-specific requirements.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 rpm |

| Materials Processed | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Copper, and engineered alloys |

| Surface Finish | As low as Ra 0.4 μm (polished to Ra 0.1 μm) |

| Tolerances | Down to ±0.01 mm (tight tolerances achievable upon request) |

| Certifications | ISO 9001:2015, RoHS compliant, full material traceability (MTR available) |

We invite 3D print service providers and industrial partners in the Netherlands to contact us and explore how Lead Precision can enhance your manufacturing capabilities. Let us support your projects with precision, scalability, and engineering integrity.

For technical inquiries, quotations, or partnership discussions, contact us at [email protected]. Let’s build the future of precision manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.