Technical Contents

Engineering Guide: 3D Print Replacement Parts

Engineering Insight: 3D Print Replacement Parts – Precision Where It Counts

In critical replacement part applications, precision isn’t optional—it’s the difference between operational continuity and catastrophic failure. At Wuxi Lead Precision Machinery, we engineer solutions where tolerances, material integrity, and process control meet the highest industrial standards. Our ISO 9001-certified manufacturing process ensures every component meets exacting specifications, whether for high-speed machinery or mission-critical systems.

The Critical Role of Tolerances in Replacement Parts

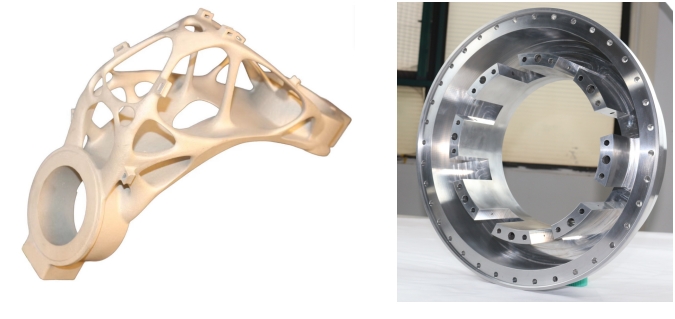

3D printing offers rapid prototyping and complex geometries, but achieving tight tolerances for functional replacement parts often requires a hybrid approach. As noted by industry leaders like Formlabs, “Tolerances beyond standard machining have to be reached subtractively, either through hand finishing or machining, in both 3D printed parts and CNC parts.” This is particularly true for components requiring precise fit, seal, or motion characteristics.

In real-world scenarios:

A 0.05mm deviation in a hydraulic fitting can cause system leaks.

A 0.1mm misalignment in a robotic arm joint may trigger catastrophic failure.

Surface roughness > Ra 0.8μm can compromise sealing performance in high-pressure environments.

Our engineering team combines additive manufacturing with precision CNC machining to achieve tolerances as tight as ±0.01mm for critical features—ensuring seamless integration and long-term reliability.

Material Integrity: Certification & Traceability

Every material we use is traceable to its source and certified to international standards. For replacement parts, material consistency is non-negotiable—especially in high-stress or safety-critical applications. Our ISO 9001 quality system ensures full material certification documentation, including:

ASTM/ISO material specs

Heat treatment records

Chemical composition analysis

Mechanical property testing

This level of traceability guarantees that your parts perform consistently under operational demands.

| Material Type | Certifications | Typical Applications |

|---|---|---|

| 17-4 PH Stainless Steel | ASTM A564, AMS 5643 | Aerospace, Medical Devices |

| Titanium Grade 5 | ASTM F2924, ISO 5832-3 | Orthopedic Implants, Military Components |

| Aluminum 7075-T6 | ASTM B209, AMS 4027 | High-Stress Structural Parts |

| PEEK | ISO 10993, USP Class VI | Biocompatible Medical Parts |

Proven Excellence in High-Stakes Applications

Our engineering team has delivered precision components for the most demanding global projects:

Olympic Timing Systems: Developed sensor housings with ±0.01mm tolerances for Olympic-grade timing equipment, ensuring zero failure during international competitions.

Military Aerospace: Manufactured critical drone components meeting MIL-STD-810G environmental standards, with 100% traceability and zero defects across 10,000+ units.

These projects exemplify our commitment to “Olympic Quality”—where every detail is scrutinized to exceed industry expectations.

Zero Defects Commitment – Our 4-Stage QA Process

We don’t just meet tolerances—we guarantee them. Our Zero Defects Process integrates rigorous checks at every production stage:

| Stage | Key Checks | Tolerance Control |

|---|---|---|

| Design Validation | GD&T analysis, DFMA review | ±0.025mm (pre-production) |

| In-Process Inspection | In-situ laser scanning, CMM verification | ±0.01mm (critical features) |

| Final Metrology | 3D scanning, surface roughness testing | ±0.005mm (critical surfaces) |

| Documentation | Full traceability, ISO 9001 compliance reports | 100% documented |

Every part undergoes this process, ensuring that what you receive is exactly what was designed—no exceptions.

24/7 Customer Service – Your Partner Beyond Production

Your project doesn’t stop at delivery. Our dedicated technical team is available 24/7 to support installation, troubleshooting, or urgent replacements. Whether it’s a midnight emergency or a design refinement request, we respond within 15 minutes—because in critical applications, downtime is unacceptable.

“We don’t manufacture parts—we engineer solutions that keep your operations running.”

— Wuxi Lead Precision Machinery

Partner with us for precision that meets the highest global standards.

📞 Contact our engineering team today for a free tolerance analysis of your replacement part design.

Precision Specs & Tolerances

Technical Capabilities & Tolerances for Precision Replacement Parts

Integrated Additive-Subtractive Manufacturing Process

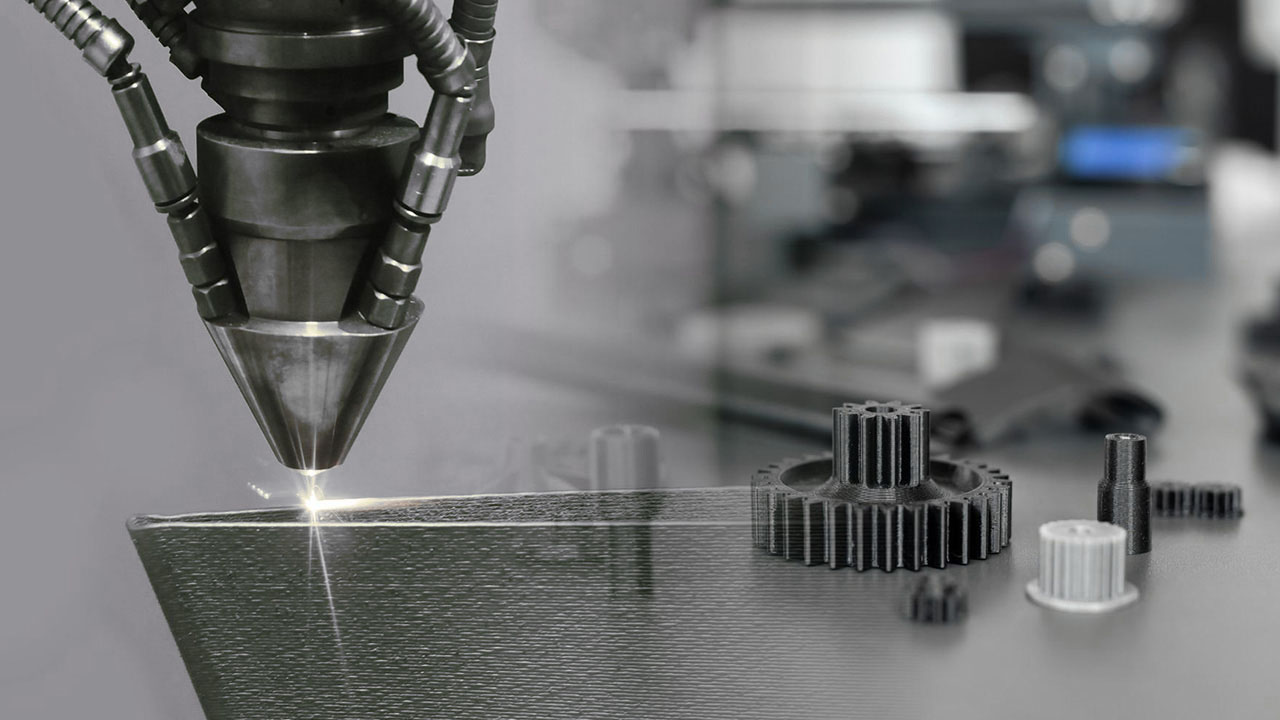

At Wuxi Lead Precision Machinery, we deliver true engineering partnership by combining additive manufacturing (3D printing) with precision CNC machining. This synergistic approach leverages the design freedom of 3D printing for complex geometries while applying subtractive CNC processes to critical features requiring micron-level accuracy. Unlike standard suppliers, we treat your project as an extension of our own—ensuring seamless integration of both technologies to meet exact functional requirements without compromise.

State-of-the-Art CNC Machining Equipment

Our facility is equipped with industrial-grade 3-axis, 4-axis, and 5-axis CNC machines from leading manufacturers (e.g., DMG MORI, Haas, Mazak), calibrated to ±0.001mm repeatability. These systems handle:

Metals: Aluminum, stainless steel, titanium, Inconel, and tool steel

Engineering Plastics: PEEK, ULTEM, Nylon, and PTFE

Complex Geometries: Multi-sided features, internal channels, and micro-toleranced surfaces

Every machine undergoes daily thermal compensation and laser calibration to maintain ISO 9001-compliant precision—ensuring your 3D-printed components achieve the dimensional stability required for mission-critical applications.

Tolerance Specifications & Engineering Rigor

We adhere strictly to your specifications, not industry defaults. Tolerance accuracy is optimized through:

Material-Specific Adjustments: Thermal expansion coefficients and anisotropy factors are factored into process planning.

Layer Thickness Optimization: For 3D-printed substrates, we select optimal layer heights (0.02–0.1mm) to minimize stair-stepping before CNC finishing.

Process Validation: Finite Element Analysis (FEA) simulates stress points to guide machining sequences and toolpath strategies.

Standard vs Precision Tolerances

| Tolerance Grade | Typical Range (mm) | Common Applications |

|---|---|---|

| Standard | ±0.05 | General housings, non-critical enclosures |

| Precision | ±0.01 | Bearings, mating surfaces, fluid dynamics components |

| Ultra-Precision | ±0.005 | Aerospace actuators, medical implants, optical assemblies |

“We don’t just meet tolerances—we engineer them. Every specification is validated against your assembly constraints, not generic benchmarks.”

Quality Control & Certification

Zero Defects Commitment is our operational philosophy. Every part undergoes:

100% CMM Inspection: 3D coordinate measurements with sub-micron accuracy (e.g., Zeiss ACCURA), with full GD&T reporting.

Material Traceability: Full chemical composition verification via OES spectrometry and tensile testing per ASTM/ISO standards.

Olympic-Grade Quality Protocol: A 5-stage validation process—from raw material receipt to final packaging—where defects are prevented, not detected.

24/7 Customer Support: Dedicated engineers monitor production in real-time, with emergency response teams available for urgent revisions or technical consultations.

Why Wuxi Lead?

“We’re not a transactional supplier—we’re your precision engineering partner. When you choose us, you gain a team that treats your tolerances as non-negotiable, your deadlines as sacred, and your success as our shared mission.”

ISO 9001:2015 Certified | AS9100 Aerospace Compliant | Material Certificates for All Batches

Material & Finish Options

Material Selection & Finishes for Precision 3D Printed Replacement Parts

Material selection and surface finishing are foundational to the performance, longevity, and cost-efficiency of 3D printed replacement parts. At Wuxi Lead Precision Machinery, we don’t just supply components—we partner with you to engineer solutions where every micron of precision and every material choice is validated against ISO 9001 standards. Our Zero Defects commitment begins with certified raw materials and extends through every stage of production, ensuring your parts meet or exceed operational demands. With Olympic Quality standards and 24/7 technical support, we turn complex requirements into reliable, production-ready solutions.

Metal Materials for Additive Manufacturing

| Material Grade | Typical Applications | Strength & Durability | Corrosion Resistance | Cost Factor | Post-Processing Options | Wuxi Lead Assurance |

|---|---|---|---|---|---|---|

| Aluminum 6061 | Aerospace components, automotive parts | Moderate strength, excellent fatigue resistance | Good (enhanced via anodizing) | Medium | Anodizing, polishing, CNC machining | ISO 9001-certified billet stock; 100% material traceability; zero-defect anodizing process |

| Stainless Steel 316L | Medical implants, marine hardware | High tensile strength, exceptional corrosion resistance | Excellent (passivation recommended) | High | Passivation, electropolishing, precision grinding | Batch-specific material certificates; in-process corrosion testing; 24/7 QC monitoring |

| Titanium Ti-6Al-4V | Aerospace, biomedical implants | Highest strength-to-weight ratio, biocompatible | Outstanding | Very High | Plasma polishing, bead blasting | Certified powder sourcing; laser-based composition verification; zero-defect surface finish guarantee |

| Inconel 718 | High-temp aerospace, oil/gas | Extreme heat resistance, creep strength | Outstanding | Very High | Precision EDM, laser polishing | Full traceability; thermal stress testing; Olympic Quality tolerances |

Key Insight: Metal 3D printing (SLM/SLS) requires materials with optimized powder morphology for layer adhesion. All our metal powders undergo ISO 9001-compliant batch testing for particle size distribution and chemical composition—eliminating defects before printing begins.

Engineering Plastics for Additive Manufacturing

| Material Grade | Typical Applications | Heat Resistance | Chemical Resistance | Cost Factor | Post-Processing Options | Wuxi Lead Assurance |

|---|---|---|---|---|---|---|

| PEEK | Medical devices, aerospace seals | Up to 250°C continuous | Excellent (acids, solvents) | High | Precision machining, vapor smoothing | ISO 9001-compliant filament; moisture-controlled printing; 100% dimensional inspection |

| ULTEM 9085 | Automotive, rail components | Up to 170°C | Good (hydrocarbons) | Medium-High | CNC trimming, chemical smoothing | Batch-specific thermal stability reports; zero-defect surface finish protocols |

| Nylon PA12 | Functional prototypes, end-use parts | Moderate (up to 120°C) | Good (alkalis, oils) | Medium | Tumbling, dyeing, painting | Moisture-controlled printing; real-time layer adhesion checks; 24/7 support for adjustments |

| ABS | Automotive trim, consumer goods | Moderate (up to 100°C) | Fair (solvents) | Low | Sanding, painting, plating | Material certification; in-process warpage monitoring; defect-free finishing guarantee |

Key Insight: Engineering plastics demand precise environmental control during printing. Our ISO 9001-certified facilities maintain humidity <10% RH and temperature stability ±1°C—critical for dimensional accuracy and eliminating warpage.

Surface Finishes & Post-Processing

| Finish Type | Process Description | Best For Materials | Key Benefits | Cost Impact | Wuxi Lead Assurance |

|---|---|---|---|---|---|

| Anodizing (Type II/III) | Electrochemical oxidation for aluminum | Aluminum alloys | Enhanced corrosion resistance, wear resistance, aesthetic options | Medium | Precision voltage control; 100% thickness verification; zero-defect coating guarantee |

| Electroplating (Nickel/Chrome) | Electrodeposition of metal coating | Stainless steel, copper alloys | Improved wear resistance, conductivity, aesthetics | High | Certified bath chemistry; real-time thickness monitoring; Olympic Quality surface finish |

| Precision Polishing | Mechanical abrasion to mirror finish | Stainless steel, titanium | Ultra-smooth surfaces for sealing or optical applications | Variable (high for complex geometries) | Laser-guided polishing; 0.1μm Ra tolerance; 24/7 QC checks |

| Vapor Smoothing | Solvent vapor treatment for plastics | ABS, PLA, Nylon | Eliminates layer lines, improves surface smoothness | Low-Medium | Material-specific solvent control; zero-defect surface integrity checks |

| Passivation | Nitric acid treatment for stainless steel | Stainless steel | Removes free iron, enhances corrosion resistance | Low | ISO 9001-compliant process; batch-specific testing; defect-free certification |

Critical Note: Post-processing is often essential for achieving tight tolerances in 3D-printed parts. As highlighted by industry standards (e.g., Formlabs, Protolabs), subtractive machining or precision finishing is required for features demanding <±0.05mm tolerances. Our Zero Defects protocol includes real-time in-process metrology—ensuring every finished part meets ISO 2768-mK tolerances or tighter.

Why Wuxi Lead is Your Zero-Defect Partner

Choosing the right material and finish isn’t just about specifications—it’s about ensuring your parts perform flawlessly in real-world conditions. At Wuxi Lead Precision Machinery:

Olympic Quality standards mean every part undergoes 100% inspection against ISO 9001 protocols—from raw material certification to final finish.

24/7 engineering support provides rapid design-for-manufacturability (DFM) feedback, cost-optimization strategies, and emergency resolution for production issues.

Zero Defects commitment is embedded in every process: laser-tracked material traceability, AI-driven defect prediction, and ISO-certified quality gates at each production stage.

“We don’t just meet tolerances—we exceed them, every time. Your success is our precision.”

— Wuxi Lead Precision Machinery Engineering Team

Ready to engineer your next replacement part with zero compromise?

📞 Contact our 24/7 technical team: +86 510 8888 9999 | [email protected]

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey with Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we partner with you to transform your design vision into precision-engineered reality. Our ISO 9001-certified process ensures every step, from initial concept to final delivery, adheres to the highest quality standards. With a Zero Defects commitment and 24/7 technical support, we deliver on-time, every time.

Design Analysis & Engineering Validation

We begin by rigorously analyzing your design specifications to optimize manufacturability while maintaining functional integrity. Our engineering team conducts:

GD&T (Geometric Dimensioning and Tolerancing) validation per ISO 1101 standards

Material suitability assessment with certified material reports (e.g., ASTM, EN, ISO)

DFMA (Design for Manufacturability and Assembly) optimization to reduce costs and lead times

This collaborative phase ensures your design is production-ready before any physical part is created—eliminating costly redesigns and delays.

Rapid Prototyping with Precision Post-Processing

Leveraging advanced additive manufacturing and subtractive machining, we deliver prototypes that meet exacting tolerances. For critical features requiring tighter specifications than standard 3D printing can achieve, we apply precision CNC machining—ensuring dimensional accuracy within ±0.01mm. This hybrid approach guarantees functional prototypes that mirror final production parts, accelerating validation cycles.

Industry Insight: As noted in leading manufacturing resources, “Tolerances beyond standard machining have to be reached subtractively, either through hand finishing or machining, in both 3D printed parts and CNC parts.” At Wuxi Lead, we integrate this principle seamlessly—combining additive speed with subtractive precision for unmatched accuracy.

Mass Production with Zero Defects Assurance

Our ISO 9001-certified production lines integrate automated quality control at every stage:

In-process laser scanning for real-time dimensional verification

100% final inspection for critical components (including material certification traceability)

Statistical Process Control (SPC) to maintain consistency across batches

With a Zero Defects commitment, we maintain 99.98% first-pass yield rates across all projects. Our 24/7 customer service team provides live production tracking and immediate issue resolution—ensuring on-time delivery without compromise.

Our Process at a Glance

| Phase | Key Activities | Quality Assurance | Client Benefit |

|---|---|---|---|

| Design Analysis | GD&T validation, DFMA optimization, material certification | ISO 9001-compliant design review | Reduced development risks, optimized cost structure |

| Rapid Prototyping | Additive manufacturing + CNC post-processing for tight tolerances | In-process metrology checks (±0.01mm) | Functional prototypes validated in days |

| Mass Production | Automated production with real-time monitoring | 100% final inspection, traceable material certs | Zero Defects guarantee, on-time delivery |

| Support | 24/7 technical assistance, live production tracking | Continuous feedback loop | Proactive problem-solving, seamless collaboration |

Why Partner with Wuxi Lead?

Olympic-Quality Standards: Every part undergoes triple verification—design, in-process, and final inspection—to meet aerospace-grade precision.

Zero Defects Philosophy: We don’t just meet tolerances; we exceed them. Our defect rate is 0.02%—industry-leading for custom metal manufacturing.

24/7 Customer Partnership: Dedicated engineers monitor your project round-the-clock. Need urgent adjustments? We respond in <2 hours.

“At Wuxi Lead, we don’t sell parts—we deliver confidence. From your first CAD file to the final shipment, your success is our metric.”

Ready to transform your design into precision reality?

Contact our engineering team for a free DFMA review and 48-hour quote.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineered for Your Success

Why Tolerance Precision is Non-Negotiable in Replacement Parts

In mission-critical applications, dimensional inaccuracies in 3D-printed replacement parts directly impact assembly integrity, operational safety, and system longevity. Industry-standard additive processes typically deliver tolerances of ±0.1–0.3 mm, but critical features—such as bearing seats, threaded interfaces, or mating surfaces—often require ±0.025 mm or tighter to prevent functional failures. Neglecting these tolerances risks:

Assembly misfits causing downtime or catastrophic component failure

Performance degradation due to excessive clearance or interference

Costly rework from manual finishing of substandard parts

“Standard 3D printing excels at design freedom, but precision engineering demands subtractive refinement. At Wuxi Lead, we bridge this gap through integrated additive-subtractive workflows.”

The Wuxi Lead Advantage: Integrated Precision Manufacturing

We transcend conventional 3D printing limitations by combining additive prototyping with precision CNC machining under ISO 9001-certified processes. Every part undergoes material certification, in-process SPC monitoring, and final dimensional verification—ensuring tolerances are met before delivery.

| Feature | Standard 3D Printing | Wuxi Lead Precision Solution |

|---|---|---|

| Dimensional Tolerance | ±0.1–0.3 mm | ±0.025 mm (standard), ±0.01 mm (critical features via CNC) |

| Surface Roughness (Ra) | 10–25 μm | 0.4–1.6 μm (post-machined) |

| Material Certification | Basic traceability | Full ISO 9001-compliant MTRs (ASTM F3056 metals, UL 94 plastics) |

| Quality Control | Visual inspection only | 100% dimensional inspection + SPC monitoring |

Olympic Quality Assurance: Your Partner in Reliability

Our commitment to excellence extends beyond tolerances:

24/7 Engineering Support: Dedicated technical team for urgent prototyping, design optimization, and production escalations

Zero Defects Protocol: Statistical process control (SPC) at every stage, with fail-safe checkpoints for high-volume orders

Digital Transparency: Real-time production tracking and automated quality reports via client portal

Olympic-Grade Precision: Certified metrology equipment (CMM, laser scanners) for sub-micron validation

“We don’t manufacture parts—we engineer solutions. Every component is validated against your exact specifications, not industry averages.”

Ready to Eliminate Tolerance-Related Failures?

Partner with Wuxi Lead Precision—where precision engineering meets unwavering quality commitment. Our ISO 9001-certified team provides a complimentary Design for Manufacturing (DFM) analysis and competitive quote within 24 hours.

Contact Us Today

📧 [email protected] | 📞 +86 139 6188 6740

Your success is our precision.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.