Technical Contents

Engineering Guide: 3D Print Prototype Service

Engineering Insight: Precision as the Non-Negotiable Foundation of Metal 3D Printing Prototypes

In the high-stakes realm of custom metal manufacturing, the prototype phase is not merely a preliminary step; it is the critical validation point where design intent meets physical reality. For aerospace components, medical implants, or defense systems, dimensional inaccuracy in a prototype propagates catastrophic downstream consequences – failed validations, delayed time-to-market, and compromised safety. At Wuxi Lead Precision Machinery, we treat precision not as a target but as the absolute baseline requirement for every metal 3D print prototype service we deliver. Tolerances measured in microns directly dictate functional performance, assembly integrity, and ultimately, the viability of the final production part. Compromising on this core principle during prototyping introduces unacceptable risk, transforming what should be a cost-saving verification step into a source of expensive rework and reputational damage.

Our engineering approach integrates decades of advanced CNC machining discipline directly into the metal additive process. We recognize that achieving true production-intent accuracy in prototypes demands more than just operating a 3D printer. It requires rigorous process control, material science expertise, and post-processing capabilities honed through demanding applications. This is where Lead Precision’s unique heritage delivers tangible value. Our engineering team possesses proven experience delivering mission-critical components where failure is not an option. We have supported projects for the Beijing Winter Olympics infrastructure, requiring extreme environmental resilience and flawless dimensional consistency under intense scrutiny. Furthermore, our facility and processes are certified to stringent military standards, having manufactured precision parts where tolerances directly impact operational safety and national security. This background instills an uncompromising culture of precision that permeates every prototype we produce.

The table below outlines the core precision capabilities achievable with our industrial metal 3D printing systems for prototype development. These specifications reflect our commitment to delivering prototypes that accurately represent final production quality, enabling reliable design validation and testing.

| Material | Typical Dimensional Tolerance | Max Build Volume (mm) | As-Built Surface Roughness (Ra) | Key Application Sectors |

|---|---|---|---|---|

| Ti6Al4V (Grade 5) | ±0.05 mm | 250 x 250 x 325 | 12-25 µm | Aerospace, Medical Implants |

| Inconel 718 | ±0.06 mm | 250 x 250 x 325 | 15-30 µm | Defense, Oil & Gas, Turbines |

| AlSi10Mg | ±0.07 mm | 250 x 250 x 325 | 10-20 µm | Automotive, High-Performance |

These capabilities are consistently achieved through calibrated machine fleets, in-process monitoring, controlled build environments, and advanced post-processing including precision machining, stress relieving, and surface finishing – all executed within our ISO 9001 and AS9100 certified facility. When your prototype must validate form, fit, and function for the most demanding applications, precision is non-negotiable. Wuxi Lead Precision Machinery leverages its deep engineering heritage in Olympic and military-grade manufacturing to ensure your metal 3D print prototype is not just a model, but a definitive, reliable representation of your final product’s potential. Contact our engineering team to discuss how our precision-focused prototyping service mitigates your development risk.

Precision Specs & Tolerances

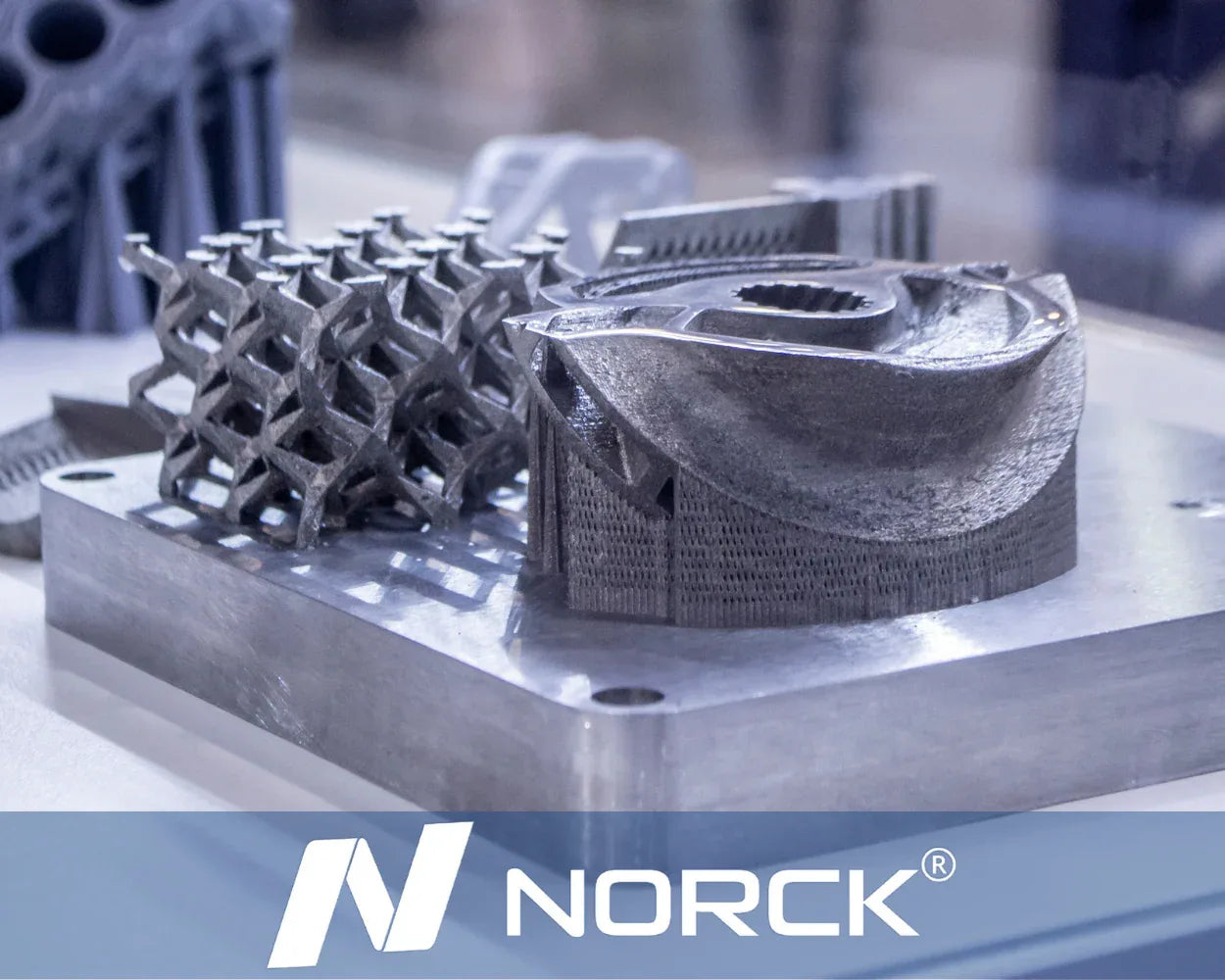

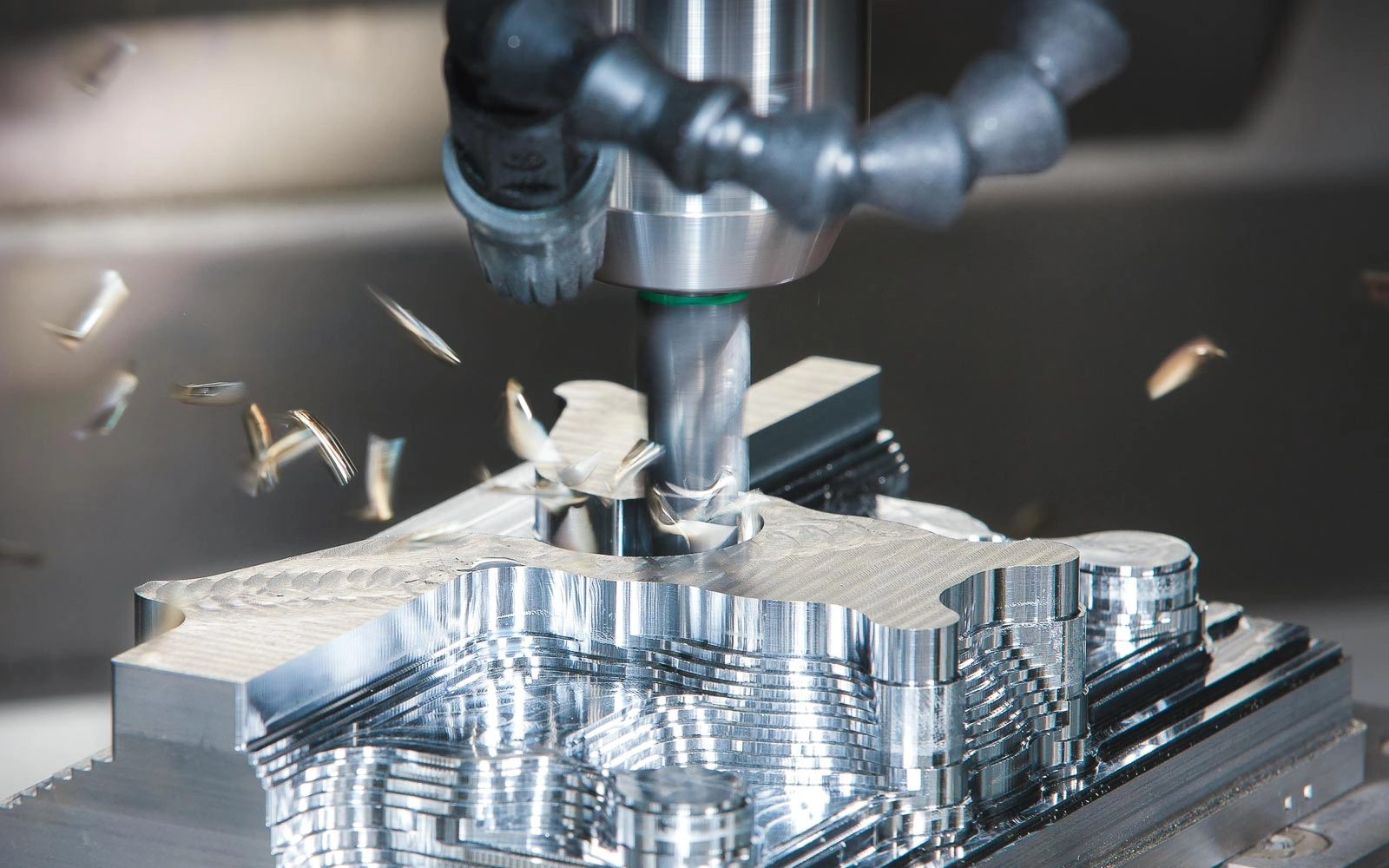

Wuxi Lead Precision Machinery delivers advanced 3D print prototype services integrated with high-precision metal manufacturing capabilities, enabling rapid development of complex, functional prototypes for industrial applications. Our technical infrastructure combines additive manufacturing with subtractive precision, ensuring prototypes meet exact design specifications and performance requirements. Central to our process is the integration of 5-axis CNC machining, which allows for the production of intricate geometries with superior surface finish and dimensional accuracy. This hybrid approach—leveraging both metal 3D printing and multi-axis machining—ensures that prototypes are not only produced quickly but are also fully representative of final production parts in terms of material properties, fit, and function.

Our 5-axis CNC machining centers operate with continuous contouring and simultaneous motion across all axes, enabling the precise fabrication of organic shapes, undercuts, and deep cavities without the need for multiple setups. This reduces cumulative error and enhances repeatability, critical factors in aerospace, medical, and high-performance automotive sectors. The machines are equipped with high-speed spindles, automatic tool changers, and real-time tool monitoring systems to maintain consistency and minimize downtime. All operations are supported by advanced CAM software, ensuring optimized toolpaths and efficient material removal while preserving structural integrity.

Quality assurance is embedded throughout the prototype manufacturing process. Every component undergoes rigorous inspection using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), providing metrology-grade verification of geometric dimensions and tolerances. The CMM system delivers sub-micron measurement accuracy and generates full inspection reports, including GD&T analysis, first-article inspection (FAI) documentation, and dimensional compliance certification. This level of scrutiny ensures that each prototype adheres to international quality standards such as ISO 9001 and AS9100, where applicable.

The following table outlines the standard technical specifications and achievable tolerances for our 3D print prototype service when combined with 5-axis CNC finishing and CMM inspection:

| Parameter | Specification |

|---|---|

| Material Compatibility | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel 718, Aluminum (AlSi10Mg), Tool Steel (H13, Maraging) |

| Layer Resolution (AM) | 20–50 μm |

| Build Envelope (AM) | Up to 250 x 250 x 300 mm |

| 5-Axis CNC Accuracy | ±0.005 mm |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Surface Roughness (CNC finished) | Ra 0.8–1.6 μm |

| Dimensional Tolerance (CNC) | ±0.01 mm for features < 50 mm; ±0.02 mm for features 50–150 mm |

| Positional Tolerance (GD&T) | ±0.015 mm (per ISO 2768-mK) |

| Inspection Equipment | Zeiss CONTURA G2 CMM, 3D Scanning (optional) |

| Reporting | Full FAI Report, CMM Certificate, Material Test Certificate |

By combining metal additive manufacturing with precision CNC finishing and comprehensive metrology validation, Wuxi Lead Precision Machinery ensures that every prototype exceeds functional and dimensional expectations, accelerating product development cycles while minimizing risk in downstream production.

Material & Finish Options

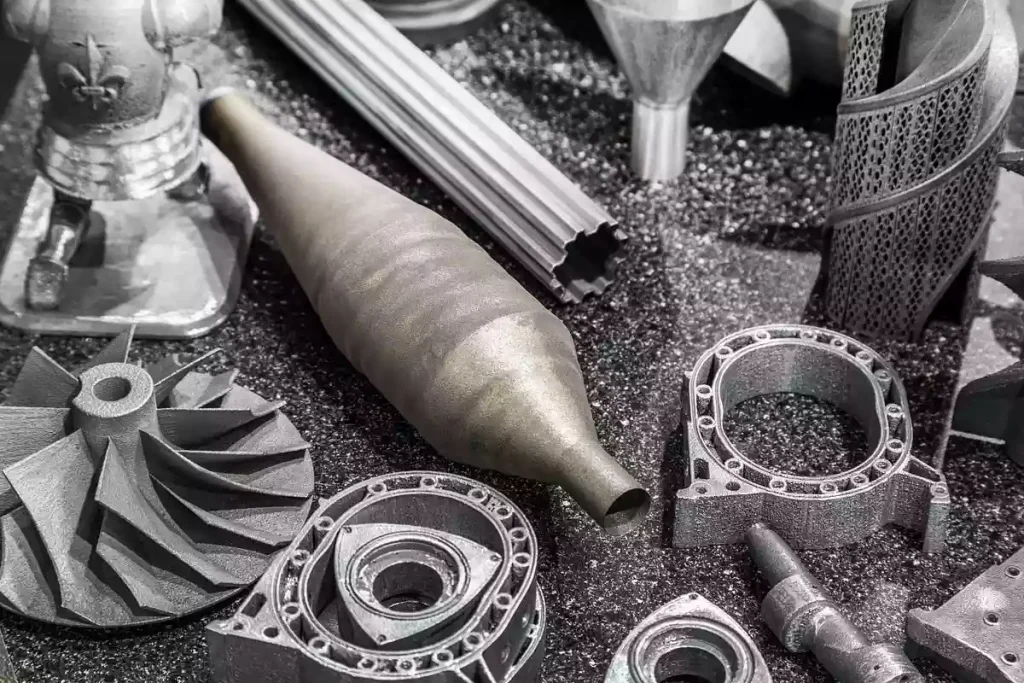

Material Selection for Metal 3D Printed Prototypes: Performance-Driven Choices

Selecting the optimal material for your metal additive manufacturing prototype is critical for validating functional performance, durability, and manufacturability early in the development cycle. At Wuxi Lead Precision Machinery, we prioritize material properties that directly impact your prototype’s ability to simulate end-use conditions. Misalignment here risks misleading test data and costly redesigns. Our engineering team rigorously evaluates each alloy against your specific application demands, focusing on mechanical behavior, thermal response, and environmental resistance. This precision ensures your prototype delivers actionable insights, accelerating time-to-market while mitigating downstream production risks.

Aluminum alloys, particularly AlSi10Mg, dominate lightweight structural applications requiring excellent strength-to-weight ratios and thermal conductivity. Ideal for aerospace brackets, heat exchangers, and automotive components, it offers good machinability post-print and weldability. Its lower density significantly reduces inertia in moving parts. While corrosion resistance is moderate, it excels where weight savings are paramount and environmental exposure is controlled. Surface finish quality is inherently high with our optimized laser parameters.

Stainless steel variants, especially 316L, provide superior corrosion resistance and high strength across diverse environments. This makes them indispensable for medical implants, marine hardware, and chemical processing prototypes demanding biocompatibility and longevity. 316L maintains integrity in saline and acidic conditions where aluminum would degrade. Its higher density is a trade-off for exceptional durability and ease of post-processing. We achieve fine feature resolution critical for fluid dynamics testing.

Titanium Ti-6Al-4V delivers the ultimate strength-to-weight ratio and outstanding biocompatibility, essential for high-stress aerospace components and permanent medical devices. Its exceptional fatigue resistance and performance at elevated temperatures justify the higher material cost for mission-critical applications. While more challenging to process, our parameter libraries ensure dense, defect-free builds with optimal mechanical properties. Note titanium cannot be anodized; alternative surface treatments like plasma spray are required.

Material performance characteristics must guide selection. Key comparative data is provided below:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Application Drivers |

|---|---|---|---|---|

| AlSi10Mg | 400-450 | 250-280 | 2.67 | Lightweight structures, thermal management |

| SS 316L | 550-650 | 300-400 | 8.0 | Corrosion resistance, biocompatibility |

| Ti-6Al-4V | 900-1000 | 800-850 | 4.43 | High strength/weight, fatigue resistance |

Anodizing is a vital post-processing step exclusively for aluminum prototypes. It significantly enhances surface hardness, wear resistance, and corrosion protection while enabling color coding for assembly. Type II (sulfuric acid) anodizing provides standard decorative and protective finishes. For demanding functional prototypes requiring maximum abrasion resistance, Type III (hard coat) anodizing is essential, producing thicker, denser oxide layers. Our process controls ensure precise coating thickness and uniformity, critical for maintaining dimensional tolerances on precision features. Consult our engineering team to specify the optimal anodizing type and thickness for your prototype’s operational stresses.

Manufacturing Process & QC

The production journey at Wuxi Lead Precision Machinery begins with a precise understanding of design intent and culminates in flawless mass production. Our integrated approach ensures complete alignment across design, prototyping, and high-volume manufacturing, with an unwavering commitment to zero defects. This systematic process is engineered to minimize risk, reduce time-to-market, and deliver components that meet the most stringent performance and quality standards in aerospace, medical, automotive, and industrial applications.

Design is the foundation of every successful manufacturing project. Our engineering team collaborates closely with clients to review CAD models, perform Design for Manufacturability (DFM) analysis, and optimize geometries for both 3D printing and CNC post-processing. Material selection, thermal behavior, stress distribution, and surface finish requirements are evaluated at this stage to ensure long-term functionality and reliability. This proactive engineering review prevents costly revisions downstream and ensures that the prototype accurately reflects the final production part.

Prototyping is where concept becomes reality. Using advanced metal additive manufacturing technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), we produce fully dense, high-precision metal prototypes from materials including titanium, stainless steel, aluminum, and Inconel. These prototypes are not only functional but also production-representative, allowing for rigorous performance testing, fit checks, and design validation. All prototypes undergo full metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy and compliance with GD&T specifications.

Once the prototype is approved, we seamlessly transition into mass production. Our ISO 9001-certified facility leverages automated CNC machining, robotic finishing, and in-process quality controls to ensure consistency across every unit. Each stage of production is monitored using Statistical Process Control (SPC) methods, and non-conforming parts are immediately flagged and corrected. Our zero-defect philosophy is enforced through traceability systems that track material lots, machine parameters, and inspection records for every component produced.

The following table outlines key capabilities across our production workflow:

| Process Stage | Technology Used | Materials Supported | Tolerance Range | Lead Time (Typical) |

|---|---|---|---|---|

| Design Review | CAD, DFM Analysis | N/A | N/A | 1–3 business days |

| 3D Print Prototype | SLM / DMLS | Ti6Al-4V, 316L, AlSi10Mg, Inconel | ±0.05 mm | 7–10 days |

| Post-Processing | CNC Machining, Polishing | All prototype materials | ±0.01 mm (CNC) | 3–5 days |

| Mass Production | CNC, Automation, SPC | Carbon steel, alloy steel, metals | ±0.005 mm (CNC) | 10–20 days (batch) |

| Quality Assurance | CMM, 3D Scan, NDT | All produced parts | Full inspection | Integrated in line |

By integrating cutting-edge technology with disciplined process control, Wuxi Lead Precision Machinery ensures that every component—from the first prototype to the last production unit—meets the highest standards of precision, performance, and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Accelerate Your Metal Prototyping from Concept to Production

In high-stakes industrial sectors like aerospace, medical device development, and advanced energy systems, the speed and fidelity of your metal prototypes directly impact time-to-market and regulatory success. Generic 3D printing services often lack the metallurgical expertise and precision engineering required for functional metal parts that must perform under real-world stress, temperature, and fatigue conditions. At Wuxi Lead Precision Machinery, we bridge this critical gap. Our integrated approach combines industrial-grade metal additive manufacturing with decades of CNC machining heritage, ensuring your prototypes are not just visual models but true engineering validation assets. We specialize in producing complex, high-integrity metal components using certified materials and processes validated to stringent industry standards, eliminating the costly rework and delays inherent in substandard prototyping partnerships.

Our dedicated metal additive manufacturing facility operates advanced Laser Powder Bed Fusion (LPBF) systems, purpose-built for demanding prototyping applications. We prioritize material integrity and dimensional accuracy from the first layer, utilizing in-process monitoring and post-build metrology to guarantee parts meet your exact specifications. This is not hobbyist printing; it is precision manufacturing engineered for the factory floor. Partner with us to transform your digital designs into physically validated metal prototypes within days, not weeks, accelerating design iteration cycles while de-risking your path to full-scale production. The table below details our core metal prototyping capabilities for immediate project assessment.

| Parameter | Specification Detail |

|---|---|

| Primary Technology | Laser Powder Bed Fusion (LPBF) |

| Build Envelope | 250 x 250 x 325 mm standard; up to 500 x 500 x 400 mm |

| Material Options | Stainless Steel 316L, 17-4PH; Inconel 718, 625; Titanium Ti6Al4V; Aluminum AlSi10Mg; Tool Steel H13 |

| Typical Accuracy | ±0.05 mm to ±0.1 mm (depending on geometry & material) |

| Surface Roughness (as-built) | Ra 12 – 25 µm; post-processed options available |

| Lead Time (Prototype) | 5-10 business days from approved CAD data |

| Quality Assurance | Full material traceability; First Article Inspection (FAI) reports; ISO 9001 certified processes |

The true value of a prototyping partner lies in their ability to anticipate manufacturing challenges long before tooling begins. Our engineering team collaborates with yours during the design phase, providing Design for Additive Manufacturing (DfAM) feedback to optimize part geometry, reduce support structures, and ensure the prototype accurately reflects production intent. This proactive collaboration prevents costly design flaws from propagating into later stages. Whether you require a single high-complexity turbine component for wind tunnel testing or a batch of surgical instrument prototypes for biocompatibility trials, we deliver the metallurgical confidence and dimensional precision your project demands.

Stop compromising between speed and quality in metal prototyping. Wuxi Lead Precision Machinery provides the technical rigor and responsive partnership essential for advanced manufacturing success. Contact our engineering team today to discuss your specific prototype requirements and receive a precise quotation within 24 hours. Submit your CAD files and project details to [email protected] and experience the Lead Precision difference in speed, accuracy, and engineering partnership. Let us prove why global innovators trust us to turn their most challenging metal concepts into reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.