Technical Contents

Engineering Guide: 3D Print Parts Online

Engineering Precision in Online Metal Additive Manufacturing

The proliferation of online 3D printing services has democratized access to complex metal parts, yet precision remains the non-negotiable cornerstone for mission-critical applications. In aerospace, defense, and high-performance industrial systems, dimensional accuracy directly impacts safety, longevity, and functional reliability. Tolerances exceeding ±0.1 mm can cascade into catastrophic failures—warped turbine blades, misaligned hydraulic components, or compromised structural joints. While entry-level platforms emphasize speed and cost, leading manufacturers recognize that raw geometry alone is insufficient; material integrity, residual stress management, and surface consistency define true engineering viability.

Metal additive manufacturing (AM) introduces unique precision challenges absent in traditional CNC machining. Layer-by-layer fusion generates thermal gradients that induce micro-distortion, while powder characteristics and laser calibration directly influence part density and fatigue resistance. Without rigorous in-process monitoring and post-build validation, online AM orders risk dimensional drift exceeding 0.5%—unacceptable for flight-certified or military-spec components. At Wuxi Lead Precision Machinery, we address this through closed-loop thermal management protocols and proprietary stress-relief annealing cycles, ensuring geometric stability down to ±0.05 mm. Our ISO 13485 and NADCAP-accredited workflows treat every build as a certified production run, not a prototype.

Critical specifications define the boundary between functional parts and costly failures. The table below outlines parameters where precision dictates real-world performance:

| Parameter | Wuxi Lead Capability | Industry Standard Threshold |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.1–0.2 mm |

| Surface Roughness (Ra) | 0.8–3.2 μm | 6–12 μm |

| Material Density | >99.95% | 98–99.5% |

| Residual Stress | <50 MPa | 100–300 MPa |

| Quality Assurance | NADCAP, 100% CT Scan | Visual Inspection Only |

These metrics reflect our commitment to engineering rigor, not marketing claims. For instance, our work on Olympic timing systems demanded sub-10-micron repeatability to synchronize high-speed sensors—a standard later adapted for military drone propulsion housings requiring MIL-STD-810G vibration resistance. Similarly, satellite antenna waveguides produced for China’s space program leveraged our titanium alloy expertise to achieve RF performance specifications unattainable through casting.

Online 3D printing portals often obscure these technical realities behind simplified interfaces. True precision engineering requires transparency: material traceability, build parameter logs, and post-processing documentation. At Wuxi Lead, every component undergoes multi-axis CMM validation and metallurgical analysis before shipment, with data packets accessible via client portals. This discipline—forged through Olympic and defense projects—ensures that when you order “3D print parts online,” you receive not just a shape, but a certified engineering solution. In critical manufacturing, precision isn’t optional; it’s the price of entry.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries including aerospace, medical, automotive, and industrial automation. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining technology, enabling us to produce complex, high-precision components with exceptional surface finish and dimensional accuracy. Our 5-axis machining centers provide simultaneous multi-directional cutting, allowing for intricate geometries that would be unachievable with conventional 3-axis systems. This capability significantly reduces setup times, improves part consistency, and supports the production of fully finished components in a single operation.

All machining processes are supported by integrated CAD/CAM software, ensuring seamless translation from digital design to physical part. Our engineering team works closely with clients to optimize part design for manufacturability, minimizing material waste and cycle time while maximizing structural integrity and performance. We work with a wide range of metals including aluminum alloys, stainless steel, titanium, tool steel, and high-temperature superalloys such as Inconel, making us a versatile partner for demanding applications.

Quality control is embedded at every stage of production. Each component undergoes rigorous inspection using a Zeiss DuraMax and CONTURA G2 Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our metrology lab is calibrated to international standards, providing traceable, repeatable measurement data for every production batch. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and hardness testing equipment to validate material and surface properties.

Our commitment to precision is reflected in the tight tolerances we consistently achieve across all production runs. The table below outlines our standard and advanced tolerance capabilities for critical dimensions.

| Feature | Standard Capability | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Tolerances | ±0.025 mm | ±0.005 mm | Achieved with thermal compensation |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | Verified via CMM |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | Depending on material and geometry |

| Angular Tolerance | ±0.05° | ±0.01° | 5-axis simultaneous control |

| Thread Accuracy | Class 6G | Class 4H | ISO metric standards |

| Feature-to-Feature Alignment | ±0.015 mm | ±0.005 mm | Full 5-axis fixturing control |

Wuxi Lead Precision Machinery maintains full process traceability, with inspection reports and material certifications provided as standard. Our facility operates under ISO 9001:2015 quality management protocols, ensuring consistent performance and continuous improvement. Whether prototyping or high-volume production, our technical capabilities are designed to meet the most stringent engineering requirements, delivering precision metal parts that perform reliably in mission-critical environments.

Material & Finish Options

Material Selection for Precision Metal 3D Printed Components

Selecting the optimal material for metal 3D printed parts is critical to achieving performance, durability, and cost efficiency in high-stakes industrial applications. At Wuxi Lead Precision Machinery, we guide clients through this decision by aligning material properties with functional requirements, environmental exposure, and post-processing needs. Below we detail key considerations for aluminum, steel, and titanium alloys, alongside anodizing as a critical surface enhancement.

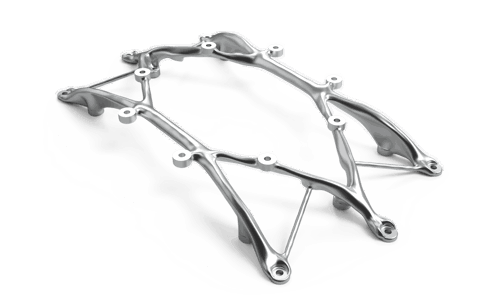

Aluminum alloys, particularly AlSi10Mg and AlSi7Mg, dominate aerospace and automotive sectors due to their exceptional strength-to-weight ratio and thermal conductivity. These materials excel in complex, lightweight structures where weight reduction is paramount. However, raw aluminum 3D printed parts require post-processing to achieve mechanical integrity; our precision CNC machining ensures dimensional accuracy while heat treatment optimizes fatigue resistance. Aluminum’s natural corrosion resistance suits many environments, but anodizing is essential for enhanced wear protection and electrical insulation in demanding assemblies.

Stainless steel variants like 316L and 17-4 PH offer superior strength, corrosion resistance, and biocompatibility, making them ideal for medical implants, marine components, and high-pressure systems. 316L provides excellent chemical resistance for fluid-handling applications, while 17-4 PH achieves high hardness through precipitation hardening. Steel’s density increases weight versus aluminum but delivers unmatched toughness in impact-prone scenarios. Post-build machining is non-negotiable for critical tolerances, and passivation is recommended alongside anodizing alternatives like electropolishing for medical-grade finishes.

Titanium Ti6Al4V remains the premium choice for extreme environments, including aerospace turbine parts and biomedical implants, owing to its unparalleled strength-to-weight ratio, biocompatibility, and resistance to oxidation at high temperatures. Its biocompatibility and corrosion resistance justify the higher material cost in life-critical applications. However, titanium’s reactivity necessitates inert atmosphere processing during printing and stringent CNC machining protocols to prevent contamination. Anodizing titanium creates decorative or functional oxide layers but requires specialized electrolytes distinct from aluminum processes.

Anodizing transforms aluminum surfaces by growing a controlled oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for secondary coatings. Type II (sulfuric acid) anodizing is standard for industrial parts, while Type III (hardcoat) delivers extreme durability for hydraulic or pneumatic components. Color customization is achievable but must be specified early, as dye absorption affects dimensional tolerances. Note that anodizing is not applicable to steel or titanium without process modifications; these materials require alternative finishes like PVD coating or laser texturing.

Material performance metrics guide rational selection. Typical properties for common alloys are summarized below.

| Material | Key Properties | Common Grades | Best For |

|---|---|---|---|

| Aluminum | Low density, high thermal conductivity | AlSi10Mg, AlSi7Mg | Lightweight structures, heat exchangers |

| Stainless Steel | High strength, corrosion resistance | 316L, 17-4 PH | Medical, marine, high-pressure systems |

| Titanium | Extreme strength-to-weight, biocompatible | Ti6Al4V | Aerospace, biomedical implants |

Material choice directly impacts manufacturability, lead time, and lifecycle cost. Wuxi Lead Precision Machinery combines deep metallurgical expertise with advanced CNC capabilities to ensure your selected material achieves target specifications after printing, machining, and finishing. Consult our engineering team early in design to optimize material selection for your application’s unique demands.

Manufacturing Process & QC

From Concept to Consistency: The Wuxi Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we understand that precision in custom metal manufacturing begins long before metal meets machine. Our end-to-end production process is engineered for performance, repeatability, and zero-defect output—delivering high-integrity 3D printed metal parts on demand. From initial design to full-scale production, every phase is optimized for accuracy, efficiency, and quality assurance.

The journey begins with Design for Additive Manufacturing (DfAM). Our engineering team collaborates directly with clients to analyze part geometry, material requirements, and functional application. Using advanced simulation software, we optimize internal structures, support layouts, and thermal behavior to ensure print stability and dimensional accuracy. This stage eliminates potential failure points before a single laser pulse is fired, reducing risk and accelerating time to market.

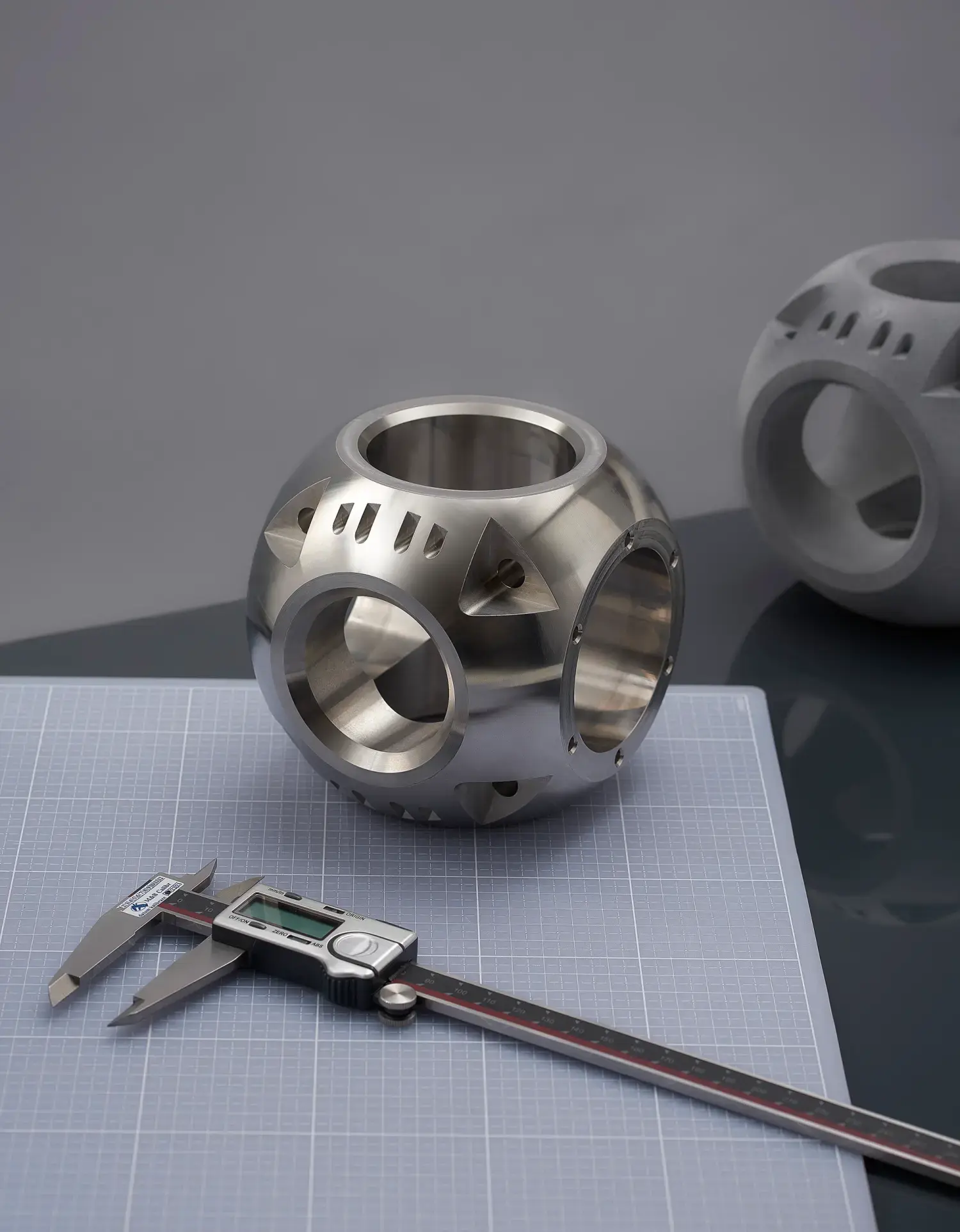

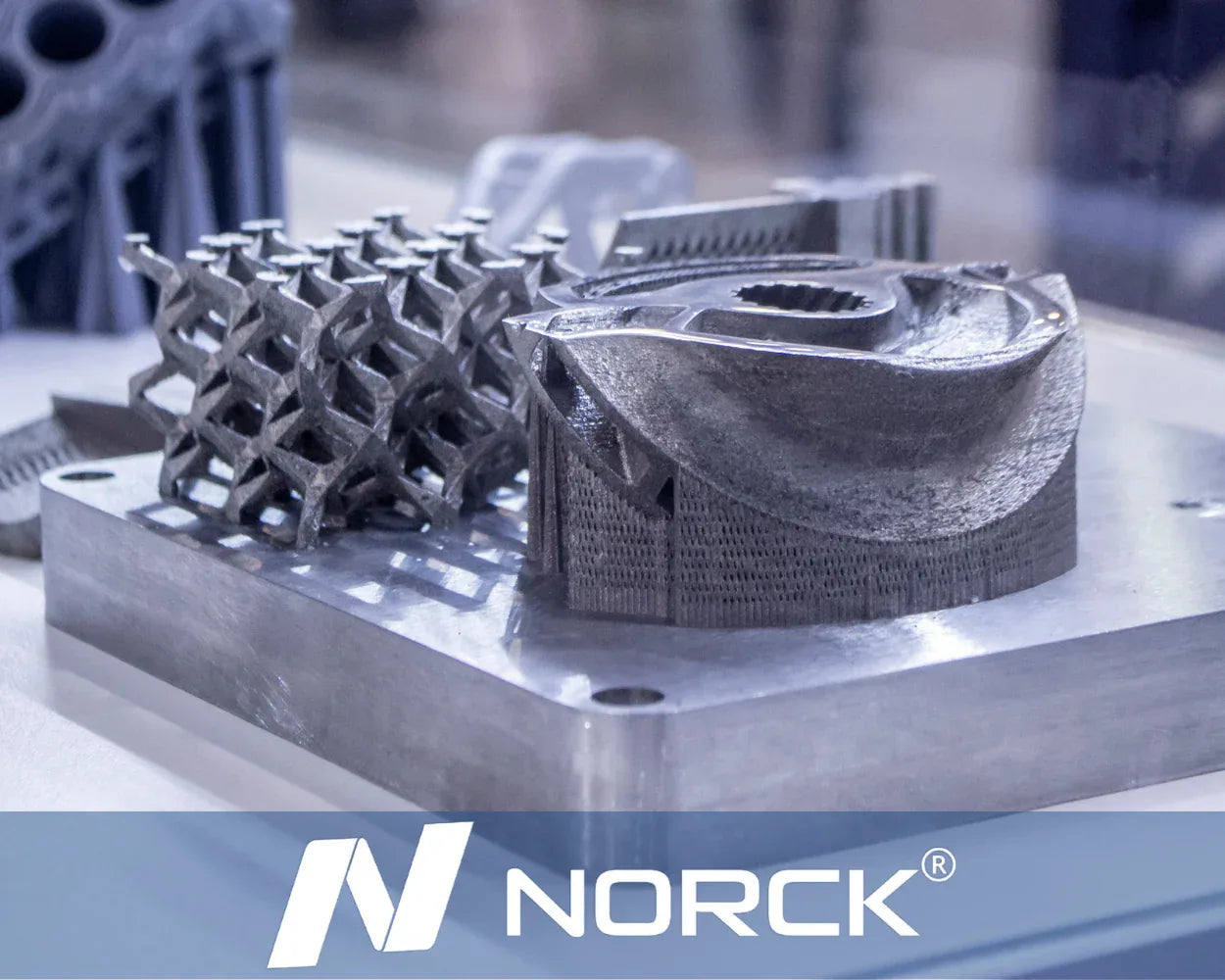

Next comes Prototyping and Validation. Utilizing state-of-the-art metal 3D printing systems—including selective laser melting (SLM) and electron beam melting (EBM)—we produce functional prototypes in the final production material. Each prototype undergoes rigorous metrology testing, including coordinate measuring machine (CMM) inspection and, when required, computed tomography (CT) scanning to verify internal integrity. Material certifications and mechanical testing reports are provided to confirm compliance with industry standards such as ISO 13485, AS9100, and ASTM F75.

Once design validation is complete, we transition seamlessly into High-Volume, Zero-Defect Production. Our factory integrates automated build preparation, real-time process monitoring, and closed-loop quality control systems to maintain consistency across thousands of parts. Each build is tracked through a digital twin system, recording laser power, scan speed, layer consistency, and chamber conditions. Post-processing—including heat treatment, stress relieving, CNC finishing, and surface treatment—is performed in-house under controlled environments to preserve dimensional stability and material properties.

Final inspection is non-negotiable. Every batch undergoes 100% visual inspection, dimensional verification, and batch traceability documentation. Our zero-defect protocol means no part ships without full conformance to customer specifications.

| Parameter | Capability |

|---|---|

| Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel 718, Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Build Volume | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–60 μm |

| Dimensional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm (can be reduced to Ra 1–2 μm with polishing) |

| Post-Processing | Heat treatment, HIP, CNC machining, shot peening, anodizing, passivation |

| Quality Standards | ISO 9001, ISO 13485, AS9100, ASTM, NADCAP (upon request) |

At Wuxi Lead, we don’t just manufacture metal 3D printed parts—we engineer trust into every micron.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Additive Excellence

In high-stakes industries like aerospace, medical device manufacturing, and energy, the integrity of your 3D printed metal components is non-negotiable. Wuxi Lead Precision Machinery transcends the role of a standard supplier; we function as your strategic engineering partner, delivering precision metal parts that meet the most exacting global standards. Our integrated facility in Wuxi, China, combines advanced metal additive manufacturing with decades of CNC mastery, ensuring every component we produce is engineered for performance, reliability, and seamless integration into your critical assemblies. We understand that tolerances measured in microns and material properties validated to ASTM/AMS specifications are not optional—they are the foundation of your product’s success. Partnering with Lead Precision means leveraging our full-spectrum capabilities from prototype to high-volume production, all under one roof with rigorous in-house quality control.

Our metal additive systems are calibrated and operated by senior engineers with deep metallurgical expertise, not just machine operators. We specialize in producing complex geometries in demanding alloys where conventional manufacturing fails, backed by comprehensive material traceability and NDT validation. The technical capabilities below reflect our commitment to exceeding industry benchmarks for precision and repeatability.

| Specification | Capability | Industry Standard Compliance |

|---|---|---|

| Materials | Ti6Al4V, Inconel 718, 316L, AlSi10Mg, CoCr | AMS, ASTM, ISO 22068 |

| Accuracy | ±0.05 mm per 100 mm | ISO 2768-m |

| Surface Finish (as-built) | Ra 8–12 μm (standard), Ra 3–5 μm (polished) | Customizable per requirement |

| Max Build Volume | 250 x 250 x 300 mm | Scalable for larger projects |

| Post-Processing | Precision CNC machining, HIP, stress relief | Full in-house capability |

| Quality Assurance | 100% CMM inspection, PMI, microstructure analysis | AS9100D, ISO 13485 ready |

The Lead Precision advantage lies in our engineered workflow. Submit your CAD files and requirements through our secure portal, and our applications engineering team engages within 24 hours—not with automated replies, but with actionable technical feedback. We analyze part geometry, material suitability, and manufacturability to optimize for performance and cost, providing DFM insights that prevent downstream delays. Our production pipeline integrates additive build, precision CNC finishing, and metrology in a controlled environment, eliminating third-party dependencies that compromise quality or timelines. Every shipment includes full documentation: material certs, inspection reports, and process validation data tailored to your industry’s regulatory demands.

For mission-critical applications, settling for generic 3D printing services introduces unacceptable risk. Wuxi Lead Precision Machinery delivers certified metal components where failure is not an option. Initiate your project with engineers who speak your technical language and prioritize your success as rigorously as you do. Contact our additive manufacturing specialists directly at [email protected] to discuss material selection, lead times, or request a confidential quotation. Include your part specifications and target application for a detailed capability assessment within one business day. Your next breakthrough component starts with precision engineering—not just printing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.