Technical Contents

Engineering Guide: 3D Print Online Shop

Engineering Insight Precision in On-Demand Metal Additive Manufacturing

The rise of online 3D printing platforms has democratized access to metal additive manufacturing (AM), yet a critical nuance often overlooked is the profound difference between availability and assured precision. While standard online services offer geometric complexity, high-stakes industrial applications demand micron-level dimensional stability, repeatable material properties, and certified process control. True precision in metal AM extends far beyond layer resolution; it encompasses thermal management, residual stress mitigation, powder quality control, and post-processing validation. Without rigorous engineering oversight, seemingly identical digital files can yield parts with unacceptable variations in fatigue life, surface integrity, or fit-for-assembly – risks unacceptable in aerospace, medical, or defense systems where failure is not an option.

At Wuxi Lead Precision Machinery, we confront this precision gap daily. Our engineering protocols were forged under extreme requirements: producing titanium timing sensors for Olympic winter sports where 0.01mm deviation alters medal outcomes, and fabricating Inconel fluid manifolds for military avionics operating under supersonic stress. These projects demanded not just printing capability, but a closed-loop system integrating real-time melt pool monitoring, inert atmosphere validation, and multi-axis coordinate measuring machine (CMM) verification against AS9100 and MIL-STD-883 standards. Online platforms rarely provide this depth of metallurgical and dimensional accountability, leaving critical applications vulnerable to hidden process drift.

Material performance remains non-negotiable. Generic online services often prioritize speed over material science, risking porosity or anisotropic strength. Our certified processes enforce strict powder reuse limits, in-situ thermal imaging, and mandatory destructive testing per ASTM F3301 for critical components. Consider the specifications achievable through engineered AM versus standard online offerings:

| Parameter | Standard Online Service | Wuxi Lead Precision Certified Process |

|---|---|---|

| Layer Thickness | 30-50 μm | 20-30 μm (validated) |

| Dimensional Tolerance | ±0.1% (no certification) | ±0.025 mm (CMM certified per print) |

| Surface Roughness (as-built) | Ra 12-25 μm | Ra 4.5-8 μm (with controlled parameters) |

| Material Density | >99.5% (typical claim) | >99.95% (verified via micro-CT) |

| Process Certification | None | Full traceability to AMS7000, NADCAP |

Precision engineering for AM requires designing with the process, not just for geometry. Our team collaborates early with clients to optimize support structures, build orientation, and thermal profiles – transforming online print requests into mission-ready components. When your application demands parts that perform identically across batches under extreme conditions, the distinction between printing and precision manufacturing becomes your most critical specification. Partner with engineers who validate every micron, because in high-stakes manufacturing, tolerance isn’t just a number – it’s a promise.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for high-performance industries including aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a modern fleet of 5-axis CNC machining centers, enabling us to produce highly complex geometries with superior accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in machining intricate contours, deep cavities, and organic shapes that are unattainable with conventional 3-axis equipment. Our programming team utilizes industry-leading CAM software to optimize toolpaths, minimize setups, and ensure consistent part quality across both prototyping and high-volume production runs.

All machining operations are supported by in-house material sourcing, fixturing design, and process validation, ensuring full control over lead times and quality. We work with a wide range of engineering-grade metals, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 2, Grade 5), brass, and high-temperature alloys such as Inconel 718 and Hastelloy. Our machines are maintained to OEM specifications and monitored through preventive maintenance schedules to ensure operational reliability and precision longevity.

Quality assurance is integral to our manufacturing workflow. Every critical dimension is verified using a Zeiss CONTURA G2 coordinate measuring machine (CMM), providing traceable, high-resolution metrology data for first-article inspections and batch validation. Our inspection protocols comply with ISO 9001 standards, and full inspection reports are available upon request. In addition to CMM-based checks, we employ surface roughness testers, micrometer-grade calipers, and optical comparators to validate dimensional and surface integrity across all deliverables.

The following table outlines our standard machining tolerances, which are achievable under normal production conditions. Tighter tolerances can be achieved upon engineering review and are subject to part geometry, material, and finishing requirements.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions (machined) | ±0.005 mm | Up to 100 mm; ±0.01 mm beyond |

| Hole Diameter (drilled/reamed) | +0.01 / 0 mm | Reaming to H7 achievable |

| Positional Tolerance | ±0.01 mm | Relative to datum |

| Profile Tolerance | ±0.02 mm | Complex surfaces |

| Surface Roughness (Ra) | 0.8 μm (typical) | As-machined; 0.4 μm achievable with polishing |

| Angular Tolerance | ±0.1° | Between features |

| Flatness | 0.01 mm per 50 mm | Verified via CMM and granite surface plate |

Our technical team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce cost, and accelerate time-to-market. With full 5-axis CNC capability, stringent quality control, and engineering-driven production planning, Wuxi Lead Precision Machinery ensures every component meets the highest standards of precision and reliability.

Material & Finish Options

Material Selection for Precision Metal Components

Selecting optimal materials is critical for achieving performance, longevity, and cost efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, thermal, and environmental demands. Below, we detail key considerations for aluminum, steel, and titanium alloys, alongside essential finishing processes like anodizing.

Aluminum alloys offer an exceptional strength-to-weight ratio and corrosion resistance, making them ideal for aerospace, automotive, and consumer electronics. Grade 6061-T6 provides balanced machinability and weldability for structural components, while 7075-T6 delivers superior strength for high-stress applications like aircraft fittings. Aluminum’s thermal conductivity also suits heat sinks and enclosures. For enhanced surface durability and aesthetics, anodizing is highly recommended.

Steel remains indispensable for high-wear, high-load scenarios. Carbon steels like 1045 offer cost-effective strength for shafts and gears, whereas stainless steels (304, 316) excel in corrosive or hygienic environments such as medical devices and marine hardware. Tool steels (e.g., A2, D2) are reserved for dies and cutting tools requiring extreme hardness. Note that steel components often require passivation or plating for corrosion resistance, though anodizing is not applicable.

Titanium, particularly Grade 5 (Ti-6Al-4V), dominates aerospace and biomedical sectors due to its unmatched strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosion. It is the material of choice for critical components like aircraft landing gear and surgical implants. However, its abrasive nature increases machining complexity and cost, necessitating specialized tooling and expertise.

Material Property Comparison

| Material | Common Grades | Tensile Strength (MPa) | Key Applications | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 572 | Aerospace frames, heat sinks | High (with anodizing) |

| Steel | 1045, 304, 17-4 PH | 630, 585, 1000 | Shafts, medical devices, tooling | Moderate to High |

| Titanium | Grade 2, Grade 5 | 345, 900 | Aircraft components, implants | Excellent |

Anodizing: Precision Surface Enhancement

Anodizing electrochemically thickens aluminum’s natural oxide layer, significantly improving wear resistance, corrosion protection, and aesthetic options. Type II (sulfuric acid) anodizing offers versatility in color and moderate durability for consumer goods. For mission-critical parts, Type III (hardcoat) anodizing delivers a harder, thicker layer (50–100 µm) essential in aerospace and defense applications. Critical note: Anodizing adds dimensional growth; tolerances below ±0.005 mm require post-process machining. Always specify critical features during design to ensure functional integrity.

Material selection directly impacts part functionality, lifecycle cost, and manufacturability. Wuxi Lead Precision Machinery combines deep metallurgical expertise with advanced CNC capabilities to match your project’s exact requirements. Consult our engineering team early in the design phase to optimize material choice, finishing, and tolerances for peak performance in demanding service environments.

Manufacturing Process & QC

From Concept to Completion: The Wuxi Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we engineer excellence into every stage of custom metal manufacturing. Our end-to-end production process is designed to deliver zero-defect components, ensuring precision, consistency, and reliability for high-performance industrial applications. From initial design to full-scale mass production, our integrated workflow guarantees optimal outcomes at every phase.

The journey begins with Design Engineering, where our team collaborates closely with clients to translate concepts into manufacturable solutions. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we validate geometries, material selections, and tolerances before any physical work begins. This digital-first approach minimizes risk and accelerates development timelines. Our engineers specialize in optimizing designs for both functionality and manufacturability, ensuring that every component meets stringent performance criteria while remaining cost-effective to produce.

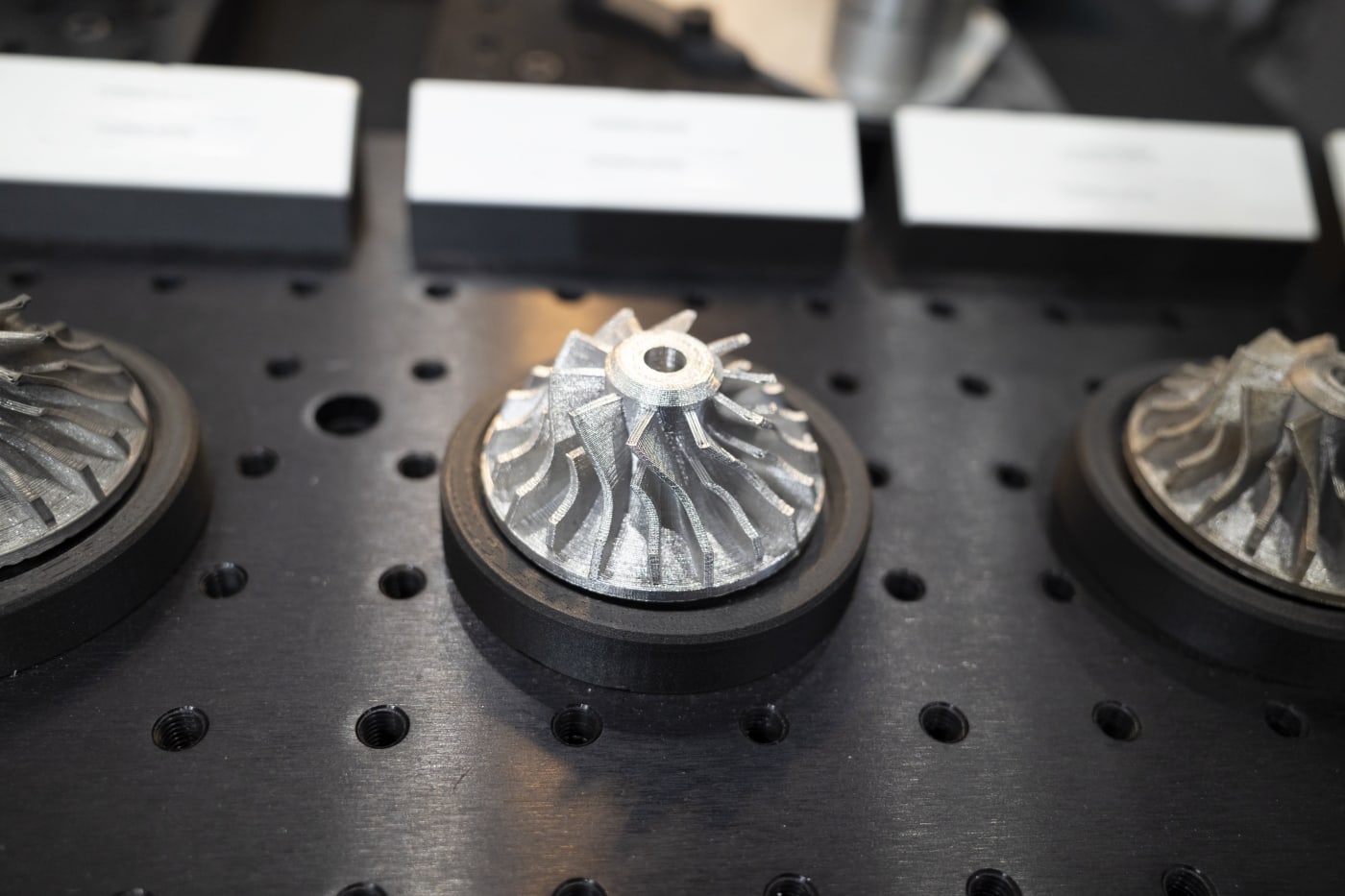

Next, we move into Prototyping, a critical validation step that bridges design and production. Using state-of-the-art 5-axis CNC machining, wire EDM, and selective laser melting (SLM) for complex metal 3D printed parts, we produce high-fidelity prototypes in the actual production-grade materials. These prototypes undergo rigorous dimensional inspection, material testing, and functional evaluation. Our metrology lab, equipped with coordinate measuring machines (CMM) and optical scanners, ensures tolerances are verified to ±0.002 mm. Feedback from this stage is incorporated iteratively, allowing for design refinement and process optimization—long before tooling is committed.

Once prototype approval is secured, we transition seamlessly into Mass Production. Our ISO 9001-certified facility leverages automated production cells, in-process gauging, and real-time SPC (Statistical Process Control) monitoring to maintain consistency across batches. Each operation is governed by standardized work instructions and operator certifications, with full traceability from raw material to finished part. We employ a zero-defect philosophy through preventive quality gates, including first-article inspection (FAI), ongoing sampling plans, and final 100% visual and dimensional checks where required.

Our commitment to precision is reflected in the capabilities of our manufacturing systems. Below are key technical specifications that define our production envelope.

| Parameter | Capability |

|---|---|

| Materials | Aluminum Alloys, Stainless Steel (304, 316, 17-4 PH), Titanium (Grade 5), Inconel 718, Tool Steels |

| Tolerances | ±0.002 mm (standard), ±0.001 mm (tight) |

| Surface Finish | Ra 0.4 µm (machined), Ra 1.6–3.2 µm (as-printed SLM) |

| Max Part Size (CNC) | 1200 x 800 x 600 mm |

| Max Part Size (SLM) | 250 x 250 x 300 mm |

| Production Capacity | Up to 10,000 units/month (automated lines) |

| Quality Standards | ISO 9001, PPAP, FAI, CMM Reports, Material Certs |

Through disciplined execution and technological precision, Wuxi Lead ensures that every component—whether a single prototype or a high-volume run—meets the highest standards of quality and performance.

Why Choose Wuxi Lead Precision

Elevate Your 3D Printing Output with Precision Metal Manufacturing

While 3D printing unlocks unprecedented design freedom for complex prototypes and low-volume parts, achieving true end-use functionality and dimensional integrity for critical metal components demands more. Standalone additive processes often fall short on tight tolerances, surface finish requirements, material density, and structural reliability essential for aerospace, medical, and high-performance industrial applications. Wuxi Lead Precision Machinery bridges this gap, transforming your printed concepts into mission-ready metal components through integrated precision manufacturing. We are not merely a service provider; we are your strategic partner in overcoming the inherent limitations of additive manufacturing alone.

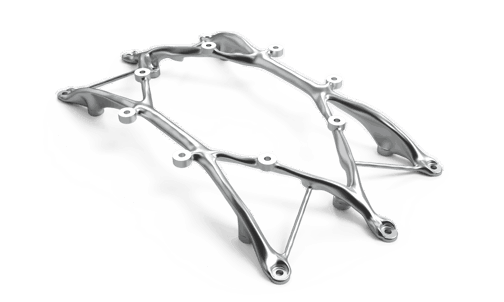

Our core strength lies in merging advanced CNC machining, grinding, and finishing capabilities with deep metallurgical expertise. We specialize in post-processing 3D printed metal parts—removing support structures, achieving micron-level tolerances unattainable through printing alone, and applying critical surface treatments. Furthermore, for applications where hybrid manufacturing or pure subtractive methods deliver superior performance, cost-efficiency, or material properties, we offer seamless transition and execution. Partnering with Lead Precision ensures your designs meet the rigorous demands of real-world deployment, reducing assembly failures, extending component life, and accelerating time-to-market.

Our technical capabilities are engineered for the highest standards of precision and repeatability. The following specifications demonstrate our capacity to handle your most demanding metal fabrication challenges:

| Capability | Specification Range | Application Impact |

|---|---|---|

| Material Expertise | Titanium, Inconel, Stainless Steels, Aluminum Alloys, Tool Steels | Ensures biocompatibility, extreme temperature resistance, and structural integrity |

| Dimensional Tolerance | ±0.002 mm (Sub-micron repeatability on critical features) | Guarantees perfect fit, function, and interchangeability in assemblies |

| Surface Finish | Ra 0.1 µm to Ra 1.6 µm (Customizable) | Meets stringent aerospace, medical, and sealing requirements |

| Max Work Envelope | 1200 x 800 x 650 mm | Accommodates complex, larger-scale printed or machined components |

| Quality Assurance | ISO 9001:2015 Certified, CMM, Optical Comparator, Metallurgical Lab | Provides full traceability and validation of critical parameters |

Collaborating with Lead Precision means accessing a dedicated engineering team committed to your success from initial design consultation through final inspection. We proactively identify manufacturability improvements for both additive and subtractive processes, optimizing cost without compromising performance. Our agile production cells and rigorous process controls ensure on-time delivery of components that consistently exceed industry benchmarks for quality. We understand the critical nature of your projects and operate with the urgency and precision your business requires.

Do not let the limitations of additive manufacturing constrain your innovation or compromise your product’s performance. The transition from printed prototype to certified, high-integrity metal component is where Wuxi Lead Precision Machinery delivers unmatched value. Initiate your precision manufacturing partnership today. Email your project specifications, CAD files, and requirements to [email protected]. Our engineering team will respond within 24 hours to discuss feasibility, provide actionable feedback, and outline a tailored production pathway. Transform your 3D printing vision into precision-engineered reality with Lead Precision. Your next breakthrough component starts with this email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.