Technical Contents

Engineering Guide: 3D Print Copper

Engineering Insight Precision Imperatives in Copper Additive Manufacturing

Copper’s exceptional thermal and electrical conductivity make it indispensable for high-performance applications like heat exchangers, RF components, and electric motor parts. However, its high reflectivity and thermal conductivity present significant challenges in laser-based additive manufacturing, directly impacting part integrity and performance. Achieving the required precision is not merely desirable; it is fundamental to functional success. Inadequate density control leads to porosity, compromising thermal pathways and structural strength. Suboptimal surface finish increases flow resistance in fluid channels and creates initiation points for fatigue failure. Dimensional inaccuracies, even at the micron level, disrupt electromagnetic field behavior in waveguides or prevent critical sealing surfaces from functioning. The margin for error in mission-critical components is effectively zero.

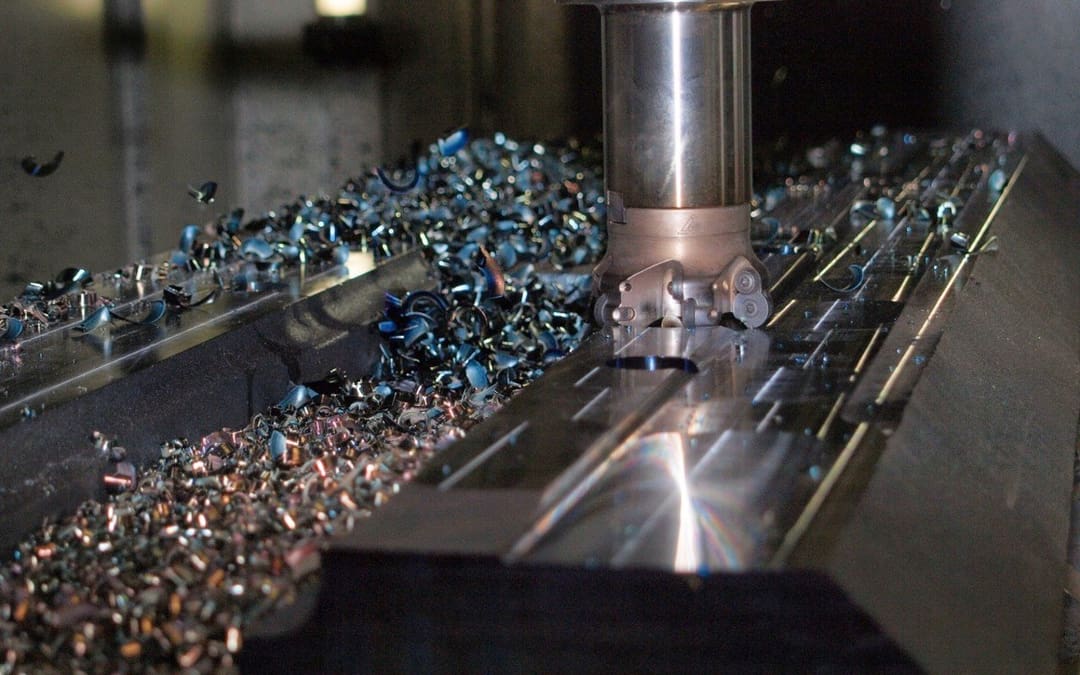

At Wuxi Lead Precision Machinery, we address these complexities through deep metallurgical understanding and rigorous process control. Our engineering protocols specifically target copper’s unique behavior during melting and solidification. We utilize optimized laser parameters, specialized atmospheric control, and proprietary powder handling to achieve near-theoretical density and minimal internal defects. This focus on precision extends beyond the build chamber; our integrated post-processing capabilities, including precision CNC machining and surface treatments, ensure final components meet exacting geometric and functional tolerances. The consequences of imprecision in copper AM are too severe for high-stakes applications – thermal runaway in power electronics or signal loss in radar systems are unacceptable outcomes.

Our commitment to precision is validated through demanding real-world deployments. Lead Precision engineered and manufactured complex copper cooling channels for Beijing 2022 Winter Olympic venue systems, where thermal efficiency directly impacted athlete performance and spectator comfort under extreme conditions. Furthermore, we produce critical radar waveguide components for advanced military communication systems, where dimensional accuracy and surface integrity are paramount for signal fidelity and operational reliability. These projects demanded and achieved levels of precision exceeding standard industry benchmarks, proving our capability where failure is not an option.

The table below outlines key performance metrics achievable with our copper AM process, demonstrating the precision standard required for advanced applications:

| Parameter | Lead Precision Specification | Typical Industry Standard |

|---|---|---|

| Relative Density | ≥ 99.95% | 99.0% – 99.5% |

| As-Built Surface Roughness (Ra) | ≤ 12 μm | 15 μm – 25 μm |

| Machined Surface Finish (Ra) | ≤ 5 μm | 8 μm – 12 μm |

| Minimum Feature Size | 0.15 mm | 0.25 mm – 0.4 mm |

| Oxygen Content (OFHC) | ≤ 10 ppm | ≤ 30 ppm |

Mastering copper additive manufacturing requires moving beyond basic part creation to guaranteeing predictable, repeatable material properties and geometric fidelity. Wuxi Lead Precision Machinery leverages extensive experience in high-demand sectors to deliver copper components where precision is non-negotiable. Contact our engineering team to discuss how our validated copper AM process can solve your most challenging thermal or electrical conduction requirements.

Precision Specs & Tolerances

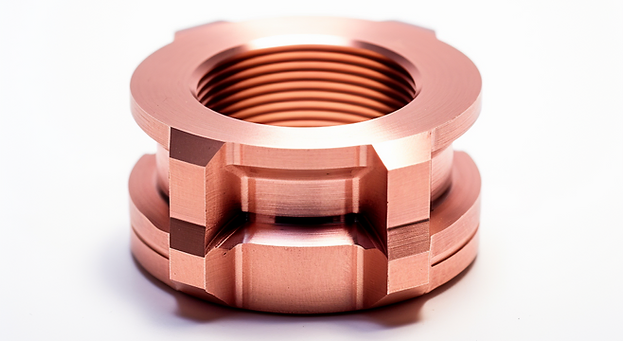

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions, integrating precision engineering with cutting-edge technology to meet the demanding requirements of high-performance industries. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional accuracy and surface integrity. These multi-axis platforms allow simultaneous movement across five planes, ensuring optimal tool positioning and minimizing setup changes. This results in tighter tolerances, improved part consistency, and reduced lead times—critical advantages for clients in aerospace, energy, medical, and high-frequency electronics sectors where copper components are essential.

Copper, known for its excellent thermal and electrical conductivity, presents unique machining challenges due to its ductility and tendency to work-harden. Our engineering team applies material-specific strategies, including optimized cutting parameters, specialized tooling, and advanced coolant techniques, to maintain dimensional stability and surface quality. Whether producing intricate heat sinks, RF waveguides, or custom electrodes, our 5-axis CNC platforms ensure precise feature control and repeatability across both prototypes and high-volume production runs.

Quality assurance is integral to our manufacturing process. Every copper component undergoes rigorous inspection using a coordinate measuring machine (CMM) to verify conformance to design specifications. Our CMM systems provide metrology-grade verification of geometric dimensions, positional tolerances, and surface profiles, ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. All inspection data is documented and traceable, supporting full quality traceability for regulated applications.

We maintain strict environmental and process controls within our facility to minimize thermal drift and vibration, further enhancing machining precision. Our skilled technicians and engineers collaborate closely with clients during design for manufacturability (DFM) reviews, offering expert feedback to optimize part geometry, reduce costs, and accelerate time-to-market without compromising performance.

The following table outlines the standard technical specifications and tolerances achievable with our 5-axis CNC machining process for copper materials:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm |

| Positional Tolerance | ±0.020 mm | ±0.008 mm |

| Flatness | 0.03 mm per 100 mm | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished finish) |

| Angular Tolerance | ±0.1° | ±0.05° |

| Feature Repeatability | ±0.015 mm | ±0.005 mm |

Our commitment to precision, backed by advanced equipment and rigorous quality control, positions Wuxi Lead Precision Machinery as a trusted partner for high-end copper component manufacturing. We combine technical expertise with scalable production capacity to deliver mission-critical parts that perform under the most demanding conditions.

Material & Finish Options

Material Selection for High-Performance Copper Additive Manufacturing

Selecting the optimal material for additive manufacturing (AM) is critical for achieving functional performance in demanding industrial applications. While aluminum, steel, and titanium alloys dominate many AM sectors, pure copper and copper alloys represent a specialized, high-value category essential for thermal management, electrical conductivity, and RF components. Unlike these other metals, copper presents unique challenges and opportunities in powder bed fusion processes due to its exceptional thermal and electrical properties. Its high reflectivity and thermal conductivity demand precise laser parameter control to ensure consistent melt pool stability and part density, making machine capability and process expertise paramount. For applications requiring superior heat dissipation—such as heat exchangers, electrical busbars, or microwave waveguides—copper is often the only viable solution, where alternatives like aluminum fall short despite their own AM advantages.

It is crucial to clarify that anodizing, a common surface finish for aluminum AM parts, is not applicable to copper. Copper develops a natural oxide layer and is typically finished through mechanical polishing, electroplating (e.g., nickel or silver), or specialized chemical treatments to enhance corrosion resistance, solderability, or aesthetic appearance. Selecting copper necessitates understanding its distinct post-processing requirements compared to other AM metals. The decision hinges on the core functional need: prioritize copper when thermal conductivity exceeding 390 W/m·K or electrical conductivity above 100% IACS is non-negotiable for the application’s success.

Wuxi Lead Precision Machinery specializes in overcoming the inherent difficulties of copper AM. Our industrial-grade metal printers feature optimized laser systems and controlled atmospheres specifically calibrated for high-reflectivity, high-conductivity materials. We implement rigorous powder handling protocols and proprietary parameter sets to achieve near-full density (>99.95%) and consistent mechanical properties in complex geometries impossible with traditional manufacturing. Partnering with a supplier experienced in copper’s nuances ensures your thermal or electrical performance targets are met reliably.

Key copper material specifications for AM are summarized below:

| Material Grade | Thermal Conductivity (W/m·K) | Electrical Conductivity (% IACS) | Relative Density (Typical AM) | Primary Applications |

|---|---|---|---|---|

| Oxygen-Free Copper (C10100) | 390 – 400 | 101 – 102 | >99.95% | High-power electronics, RF components |

| Copper Chromium (C18150) | 250 – 300 | 80 – 85 | >99.9% | Welding electrodes, resistance welding |

| Copper Zirconium (C15000) | 250 – 280 | 75 – 80 | >99.9% | High-strength conductors, springs |

Choosing copper for AM is a strategic decision driven by extreme functional requirements. At Wuxi Lead, we provide the advanced technology, material science expertise, and stringent quality control necessary to transform complex copper designs into high-performance, mission-critical components. Contact our engineering team to evaluate if copper AM is the optimal solution for your thermal or electrical challenge.

Manufacturing Process & QC

Design Excellence Begins with Precision Engineering

At Wuxi Lead Precision Machinery, the production process for 3D printed copper components begins with a rigorous design phase rooted in advanced simulation and material science. Our engineering team collaborates closely with clients to translate functional requirements into optimized geometries suited for additive manufacturing. Utilizing finite element analysis (FEA) and computational fluid dynamics (CFD), we ensure thermal conductivity, structural integrity, and electromagnetic performance meet exacting industrial standards. Design for Additive Manufacturing (DfAM) principles are applied to minimize support structures, reduce post-processing effort, and enhance part reliability. Every design undergoes internal review and client validation before progression, ensuring alignment with application-specific performance goals.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move to rapid prototyping using state-of-the-art laser powder bed fusion (LPBF) systems. Copper’s high reflectivity and thermal conductivity present unique challenges in 3D printing, which we overcome with proprietary parameter optimization and high-power fiber lasers tuned specifically for pure copper and copper alloys. Prototypes are built layer by layer using oxygen-controlled environments to ensure density and minimize oxidation. Each prototype undergoes full metrological verification via coordinate measuring machines (CMM) and CT scanning to confirm dimensional accuracy and internal integrity. Functional testing—including thermal cycling, pressure validation, and conductivity measurement—is performed to verify real-world performance. This iterative validation ensures that design assumptions are empirically confirmed, reducing risk in mass production.

Zero-Defect Mass Production with Full Traceability

With prototype approval, we transition to scalable, zero-defect mass production. Our production cells operate under ISO 9001-certified protocols with real-time in-process monitoring using melt pool sensors and layer-wise imaging. Each build is tracked through a digital twin system, enabling full traceability of machine parameters, material batch numbers, and environmental conditions. Post-processing follows strict protocols including stress relief annealing, support removal via 5-axis machining, and surface finishing tailored to application needs—be it as-built, polished, or coated. Every component undergoes 100% inspection using automated optical scanning and ultrasonic testing where applicable.

Our commitment to zero defects is enforced through statistical process control (SPC) and continual feedback loops that refine production parameters across batches. This closed-loop quality system ensures consistency, repeatability, and compliance with aerospace, power electronics, and high-energy physics industry standards.

| Specification | Detail |

|---|---|

| Material Options | Pure Copper (Cu-ETP), Oxygen-Free Copper (C10100), Copper-Chromium Alloys |

| Build Volume | Up to 250 x 250 x 300 mm |

| Layer Thickness | 20–50 μm |

| Density | ≥ 99.95% (as-built), ≥ 99.99% (HIP-treated) |

| Surface Roughness (as-built) | Ra 10–20 μm |

| Post-Processing | Stress Relieving, HIP, CNC Machining, Polishing, Coating |

| Quality Standards | ISO 9001, AS9100 (aerospace-ready), Full NDT & CMM Reporting |

From concept to volume output, Wuxi Lead delivers precision-engineered 3D printed copper solutions with uncompromised quality and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Copper Additive Manufacturing

Copper’s exceptional thermal and electrical conductivity make it indispensable for advanced thermal management, RF components, and high-power electrical systems. However, conventional 3D printing processes consistently fail to deliver the density, purity, and geometric precision required for mission-critical industrial applications. Oxidation during processing, poor layer adhesion, and residual porosity plague standard systems, resulting in parts that cannot meet performance or reliability standards. Wuxi Lead Precision Machinery overcomes these fundamental limitations through purpose-built technology and deep materials science expertise. We do not offer generic printing services; we engineer copper solutions that perform under extreme operational demands.

Our dedicated copper additive manufacturing platform integrates inert gas processing chambers, optimized laser parameters for high-reflectivity materials, and proprietary post-processing protocols. This ensures near-theoretical density, minimal oxygen content, and surface finishes suitable for direct integration into aerospace, medical, and semiconductor tooling systems. Every build leverages our ISO 9001-certified processes and decades of metallurgical experience specific to copper alloys. The result is complex, high-conductivity components impossible to achieve through casting, machining, or standard AM methods—delivered with the repeatability your supply chain requires.

The technical foundation of our copper printing capability is validated through rigorous in-house testing. Key performance metrics consistently achieved include:

| Parameter | Specification | Advantage |

|---|---|---|

| Build Volume | 500 x 500 x 500 mm | Production-scale complex geometries |

| Layer Resolution | 20 – 50 μm | Fine features & smooth as-printed surfaces |

| Relative Density | ≥ 99.95% | Thermal/electrical performance near wrought |

| Oxygen Content | < 150 ppm | Prevents embrittlement & conductivity loss |

| Surface Roughness | Ra 8 – 15 μm (as-built) | Reduced post-processing requirements |

| Material Options | OFE C10100, C18150 | Tailored conductivity/strength balance |

Partnering with Lead Precision means accessing more than equipment—we provide engineering collaboration from concept through qualification. Our technical team works directly with your design and manufacturing engineers to optimize part geometry for additive production, select the optimal copper alloy, and validate performance against your specific thermal or electrical benchmarks. We understand that copper components often serve as the thermal backbone of your systems; failure is not an option. Our traceable material batches, full build documentation, and NDT capabilities ensure compliance with AS9100, ISO 13485, and other stringent industry requirements.

For applications demanding the highest thermal efficiency and structural integrity in copper, generic printing services introduce unacceptable risk. Wuxi Lead Precision Machinery delivers certified, high-performance copper components on schedule, backed by the technical accountability expected from a strategic manufacturing partner. Contact us to discuss your specific thermal management challenge or high-conductivity component requirement.

Contact [email protected] to initiate a technical consultation. Provide your application details and performance targets for a tailored capability assessment within 24 business hours.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.