Technical Contents

Engineering Guide: 3D Print Ceramic Mold

Engineering Insight: 3D Printed Ceramic Molds in High-Precision Metal Manufacturing

In the evolving landscape of advanced metal manufacturing, 3D printed ceramic molds represent a transformative leap in design flexibility, production speed, and dimensional accuracy. At Wuxi Lead Precision Machinery, we integrate this technology into our custom metal manufacturing workflows to deliver components that meet the exacting standards of aerospace, defense, and high-performance industrial applications. The foundation of this capability lies in precision—both in the 3D printing process and in the subsequent casting and finishing stages.

Ceramic molds produced via additive manufacturing eliminate many of the constraints associated with traditional mold-making techniques. Complex internal geometries, undercuts, and conformal cooling channels—once impossible or prohibitively expensive to produce—are now achievable with micron-level repeatability. This level of control is critical when producing turbine blades, structural aerospace components, or specialized military hardware, where even minute deviations can compromise performance or safety.

The precision of 3D printed ceramic molds begins with high-resolution stereolithography (SLA) or digital light processing (DLP) systems capable of layer resolutions down to 25 microns. These systems build molds from silica-based or zirconia ceramic slurries, which are then debound and sintered to achieve full density and thermal stability. The resulting molds withstand molten metal temperatures exceeding 1,600°C, making them ideal for investment casting of nickel superalloys, titanium, and other high-strength materials.

Wuxi Lead Precision Machinery brings over 15 years of experience in high-tolerance manufacturing, including certified production for Olympic-standard equipment and mission-critical military components. Our engineering team leverages proprietary post-processing protocols to ensure mold surface finishes reach Ra < 0.8 µm, minimizing post-cast machining and ensuring consistent wall thicknesses across intricate geometries. This expertise translates into faster time-to-market, reduced material waste, and superior part integrity.

Our integration of 3D printed ceramic molds is not just a technological upgrade—it is a strategic enhancement of our precision manufacturing ecosystem. From initial CAD modeling to final inspection using 5-axis CMM systems, every step is calibrated to meet international standards, including ISO 9001 and AS9100.

The table below outlines key technical specifications of our 3D printed ceramic mold process:

| Parameter | Specification |

|---|---|

| Minimum Feature Resolution | 0.2 mm |

| Layer Thickness Range | 25 – 100 µm |

| Surface Roughness (as-printed) | Ra 1.6 – 3.2 µm |

| Surface Roughness (finished) | Ra < 0.8 µm |

| Sintered Density | > 99.5% theoretical |

| Thermal Resistance | Up to 1,700°C |

| Compatible Alloys | Inconel, Ti-6Al-4V, Stainless Steels, etc. |

| Dimensional Accuracy | ±0.1% (with a minimum tolerance of ±0.05 mm) |

At Wuxi Lead Precision Machinery, we combine cutting-edge 3D ceramic printing with deep metallurgical expertise to deliver metal components where precision is non-negotiable. This is not just manufacturing—it is engineered excellence.

Precision Specs & Tolerances

Advanced Technical Capabilities for Ceramic Mold Post-Processing

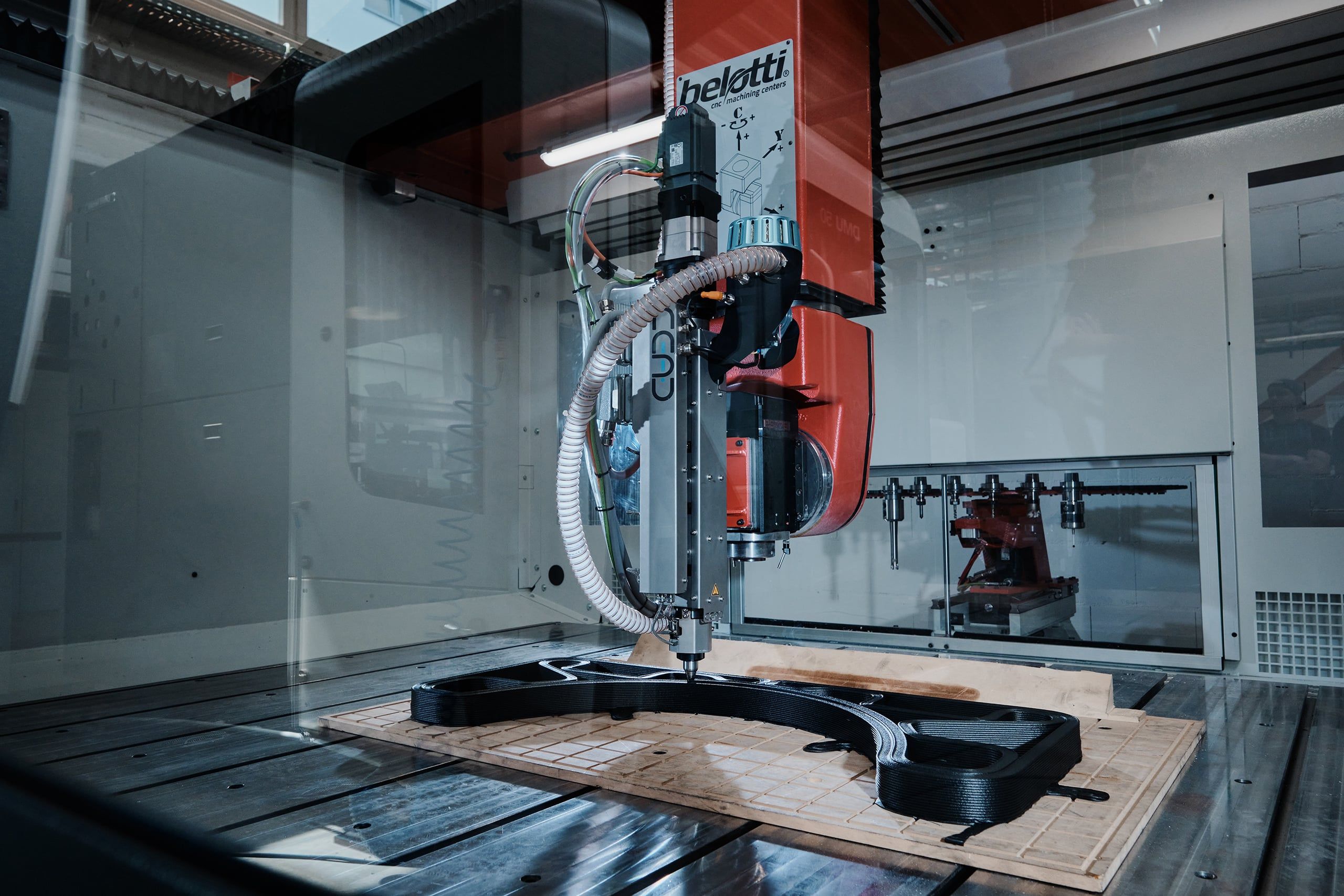

Wuxi Lead Precision Machinery delivers mission-critical precision for 3D printed ceramic molds used in investment casting and metal additive manufacturing. Our integrated workflow bridges additive fabrication with ultra-precise CNC post-processing, ensuring ceramic molds meet the stringent geometric and surface integrity requirements of aerospace, medical implant, and energy sector applications. Unlike standard machine shops, we specialize in the unique challenges of machining fragile, near-net-shape ceramic components after sintering, where dimensional stability and edge integrity directly impact final metal part quality.

Our core capability centers on state-of-the-art 5-axis CNC machining systems from DMG MORI and Makino, equipped with high-frequency spindles (42,000 RPM) and sub-micron linear encoders. These platforms enable simultaneous multi-axis contouring of complex mold cavities, undercuts, and cooling channels that cannot be achieved through conventional 3-axis methods. Advanced toolpath strategies minimize vibration and thermal load, preventing micro-cracking in alumina or zirconia-based ceramics. Each machine operates within a temperature-stabilized environment (±0.5°C) and utilizes non-contact laser tool measurement for continuous process validation, ensuring repeatability down to 2µm.

Complementing our machining infrastructure is a full-spectrum metrology suite anchored by Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMMs). Every ceramic mold undergoes comprehensive first-article inspection and batch sampling per AS9102 or PPAP standards. Our CMM protocols include GD&T analysis of critical mold features—such as gate geometries, parting lines, and datum references—with traceability to NIST-certified standards. Surface texture analysis via Alicona IFM verifies Ra values across critical flow paths, while X-ray computed tomography (optional) validates internal channel integrity without destructive testing. All inspection data is delivered in ISO 10303-21 (STEP-NC) format for seamless integration into customer PLM systems.

The table below defines our certified tolerance capabilities for post-processed ceramic molds, validated across 10,000+ production runs:

| Feature Size Range | Geometric Tolerance | Linear Tolerance | Surface Roughness (Ra) | Material Compatibility |

|---|---|---|---|---|

| < 10 mm | ±0.005 mm | ±0.003 mm | 0.4 µm | Al₂O₃, ZrO₂, SiC |

| 10–50 mm | ±0.010 mm | ±0.008 mm | 0.8 µm | Al₂O₃, ZrO₂, Si₃N₄ |

| 50–200 mm | ±0.025 mm | ±0.020 mm | 1.6 µm | Al₂O₃, ZrO₂ |

| > 200 mm | ±0.050 mm | ±0.040 mm | 3.2 µm | Al₂O₃ |

All tolerances conform to ISO 2768-mK and are achievable on sintered densities ≥99.5%. Minimum wall thickness: 0.8 mm.

This technical foundation—combining 5-axis micro-machining expertise, metrology-grade verification, and material-specific process knowledge—enables Wuxi Lead to transform 3D printed ceramic molds into production-ready tooling. We eliminate the “valley of death” between additive fabrication and metal casting by guaranteeing mold dimensional fidelity, directly reducing scrap rates in titanium, Inconel, and cobalt-chrome production. Partner with us to convert complex ceramic mold designs into certified, high-yield manufacturing assets.

Material & Finish Options

Material Selection for 3D Printed Ceramic Molds in High-Precision Metal Manufacturing

In the advanced landscape of custom metal manufacturing, the integration of 3D printed ceramic molds has revolutionized production efficiency, geometric complexity, and dimensional accuracy. At Wuxi Lead Precision Machinery, we specialize in leveraging this technology to deliver high-performance tooling solutions tailored to the specific demands of aluminum, steel, and titanium casting processes. The selection of base material for the final metal component directly influences the design, thermal properties, and longevity of the ceramic mold, necessitating a strategic approach to material compatibility and post-processing finishes.

Aluminum is often the preferred choice for lightweight, high-conductivity applications such as aerospace components and automotive heat exchangers. Its low melting point (660°C) allows for reduced thermal stress on 3D printed ceramic molds, extending mold life and enabling rapid cycling. Aluminum’s fluidity during casting supports intricate geometries achievable through additive ceramic molding, making it ideal for complex, thin-walled parts. When enhanced surface durability is required, aluminum parts are commonly finished with anodizing—a controlled electrochemical process that increases surface hardness, corrosion resistance, and wear performance. Hard anodizing, in particular, can achieve coatings up to 100 µm thick with excellent dimensional stability, critical for precision-fit components.

Steel, particularly tool and stainless grades, demands higher processing temperatures (1370–1520°C), placing greater thermal strain on ceramic molds. However, the superior strength, hardness, and temperature resistance of steel make it indispensable for high-wear industrial components. To compensate for increased thermal load, ceramic molds for steel casting are formulated with enhanced refractory content and optimized wall thickness, ensuring structural integrity during pour and cooldown. While anodizing is not applicable to steel, alternative surface treatments such as passivation or PVD coatings are recommended to improve corrosion resistance without compromising dimensional accuracy.

Titanium, with its exceptional strength-to-density ratio and biocompatibility, is widely used in aerospace and medical implant manufacturing. Its reactivity at elevated temperatures (melting point ~1668°C) requires ceramic molds with ultra-low contamination risk and high chemical stability. We utilize yttria-stabilized zirconia-based ceramic formulations for titanium applications to prevent mold-metal reactions that could compromise part integrity. Due to titanium’s natural oxide layer, additional anodizing is primarily decorative or for enhancing osseointegration in medical devices, rather than for wear protection.

Below is a comparative overview of material and mold performance characteristics:

| Material | Melting Point (°C) | Mold Thermal Load | Surface Finish Option | Key Application Sector |

|---|---|---|---|---|

| Aluminum | 660 | Low | Hard Anodizing | Aerospace, Automotive |

| Steel | 1370–1520 | High | Passivation, PVD | Industrial Machinery |

| Titanium | ~1668 | Very High | Decorative Anodizing | Medical, Defense, Aerospace |

Selecting the appropriate material and corresponding ceramic mold design is foundational to achieving repeatable, high-yield production. At Wuxi Lead Precision Machinery, we combine advanced 3D ceramic printing with deep metallurgical expertise to optimize your manufacturing workflow.

Manufacturing Process & QC

Ceramic Mold Production Process: Zero Defects from Design to Mass Production

At Wuxi Lead Precision Machinery, our ceramic mold manufacturing for investment casting adheres to a rigorously controlled three-phase workflow. This process eliminates defects at origin, ensuring aerospace and medical clients receive flawless metal components. We begin with Design Engineering, where our team conducts deep-dive Design for Manufacturing (DFM) analysis using Siemens NX. Every mold geometry is stress-tested via finite element analysis (FEA) to predict thermal deformation during metal pouring. Critical factors like ceramic slurry viscosity, sintering shrinkage rates, and thermal expansion coefficients are modeled to prevent cracking or dimensional drift. Client CAD data undergoes cross-validation against ISO 286 tolerance standards, with design iterations completed within 72 hours to lock in zero-compromise parameters.

Prototyping leverages our industrial-grade ceramic 3D printers (ExOne S-Max Flex) to produce functional molds for casting validation. Unlike competitors, we subject prototypes to full thermal cycling at 1650°C—matching production conditions—to verify structural integrity. Each prototype undergoes computed tomography (CT) scanning to detect micro-porosity or layer adhesion flaws invisible to surface inspection. Dimensional verification uses Zeiss CONTURA CMMs with 0.5μm accuracy, comparing as-built molds against nominal CAD within 0.01mm tolerance. Only molds passing 100% of thermal and metrology checkpoints advance to mass production.

Mass Production integrates closed-loop quality control at every station. Ceramic molds are printed in climate-controlled cells (22±1°C, 45% humidity) to stabilize material properties. In-process monitoring tracks slurry density, layer thickness, and sintering profiles in real time via IoT sensors. Post-sintering, each mold undergoes automated optical inspection (AOI) against GD&T callouts, with deviations triggering immediate process recalibration. Final validation includes pressure decay testing to confirm leak-tightness and surface profilometry to ensure Ra ≤ 0.8μm—critical for turbine blade surface finish. This end-to-end traceability yields 99.98% casting yield, with full material certifications (EN 10204 3.1) provided per batch.

Key process specifications guaranteeing zero defects:

| Parameter | Specification | Testing Standard |

|---|---|---|

| Thermal Resistance | 1650°C continuous | ASTM C371 |

| Dimensional Tolerance | ±0.05mm per 100mm | ISO 2768-mK |

| Surface Roughness (Ra) | ≤ 0.8μm | ISO 4287 |

| Sintered Density | ≥ 2.65 g/cm³ | ASTM B962 |

| Thermal Shock Cycles | 50 cycles (RT to 1650°C) | Internal Protocol LP-TC-09 |

Wuxi Lead’s process transforms ceramic mold production from a variable casting step into a precision engineering discipline. By embedding metrology and material science into each phase, we deliver molds that consistently produce zero-defect metal castings—reducing client scrap rates by up to 92% versus conventional suppliers. Your critical components deserve this level of foundational reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printed Ceramic Mold Solutions in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing solutions that integrate cutting-edge technologies to meet the evolving demands of modern industry. As a leader in advanced production engineering, we have pioneered the application of 3D printed ceramic molds in investment casting and precision forming processes. This innovation enables faster prototyping, complex geometries, and superior surface finishes—critical advantages in aerospace, medical, automotive, and energy sectors.

Our partnership model is built on collaboration, technical excellence, and responsiveness. When you choose to work with Lead Precision, you are not just sourcing components—you are gaining a strategic manufacturing partner with deep expertise in material science, mold design, and process optimization. We utilize state-of-the-art binder jetting and stereolithography (SLA) techniques to produce fully dense, high-temperature resistant ceramic molds tailored to your exact specifications. These molds are ideal for casting superalloys, titanium, and other high-performance metals where dimensional accuracy and thermal stability are non-negotiable.

What sets us apart is our end-to-end control over the manufacturing workflow. From initial CAD design and simulation to mold printing, post-processing, and final metal casting validation, every step is monitored under ISO 9001-certified quality standards. Our engineering team works closely with clients to optimize part design for manufacturability, reduce lead times, and ensure consistency across production batches.

We understand that in high-end manufacturing, performance specifications are paramount. Below are key technical capabilities of our 3D printed ceramic mold process:

| Specification | Performance |

|---|---|

| Minimum Wall Thickness | 0.3 mm |

| Dimensional Accuracy | ±0.1 mm / 100 mm |

| Surface Roughness (Ra) | 1.6 – 3.2 µm |

| Maximum Build Size | 250 × 250 × 300 mm |

| Firing Temperature | Up to 1600°C |

| Compatible Alloys | Inconel, Titanium, Stainless Steel, Cobalt-Chrome |

| Lead Time (Prototype) | 7–10 days |

| Production Scalability | Low to medium volume, batch customizable |

By leveraging additive manufacturing in ceramic tooling, we eliminate traditional constraints associated with mold fabrication—enabling internal cavities, conformal cooling channels, and organic shapes that were previously impossible or cost-prohibitive to produce.

If you are developing next-generation metal components and require a reliable, innovative partner with proven capabilities in 3D printed ceramic molds, contact us today. Our engineering team is ready to support your project from concept to completion.

Email us at [email protected] to initiate a technical consultation and discover how Lead Precision can accelerate your manufacturing innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.