Technical Contents

Engineering Guide: 3D Print Auto Parts

Engineering Insight Precision Imperatives in 3D Printed Automotive Components

The integration of additive manufacturing for critical automotive components demands uncompromising precision. Unlike prototyping applications, end-use parts in powertrain, suspension, or safety systems operate under extreme thermal cycles, dynamic loads, and stringent regulatory frameworks. Microscopic deviations in dimensional accuracy or material integrity directly translate to premature fatigue, catastrophic failure, or non-compliance. Automotive OEMs require geometric tolerances consistent with traditional subtractive methods, often within ±0.05mm, alongside validated mechanical properties matching forged or cast equivalents. Achieving this consistently in metal AM requires far more than advanced printers; it necessitates deep metallurgical understanding, rigorous process control, and closed-loop quality systems from raw material to final validation.

At Wuxi Lead Precision Machinery, we address this precision challenge through engineered process mastery. Our facility combines state-of-the-art metal powder bed fusion systems with proprietary thermal management protocols and in-situ monitoring developed over a decade of high-stakes production. This expertise is proven where failure is not an option: we manufactured titanium structural brackets for the Beijing 2022 Winter Olympics bobsled track control systems, requiring absolute dimensional stability under cryogenic conditions and high-G forces. Similarly, our production of hardened steel hydraulic components for military vehicle subsystems demanded certified porosity levels below 0.01% and fatigue resistance exceeding MIL-STD specifications. These projects forged our methodology for automotive applications, ensuring every 3D printed part meets the zero-defect mandate of modern vehicle platforms.

Critical parameters defining production-ready metal AM parts for automotive use are non-negotiable. Our internal quality gates exceed typical industry benchmarks, as demonstrated below:

| Critical Parameter | Industry Baseline | Lead Precision Standard | Verification Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.1 mm | ±0.03 mm | CMM + Optical Scanning |

| Surface Roughness (Ra) | 12.5 μm | ≤ 3.2 μm (as-printed) | Profilometry |

| Material Density | 99.5% | ≥ 99.95% | Micro-CT Scanning |

| Tensile Strength (Ti6Al4V) | 950 MPa min | 1050 ± 30 MPa | ASTM E8 Tensile Testing |

| Fatigue Life (R=0.1) | 1E6 cycles @ 500MPa | 2E6 cycles @ 550MPa | Rotating Beam Testing |

Precision in automotive AM is not merely a technical specification; it is the foundation of safety, performance, and regulatory acceptance. Wuxi Lead Precision Machinery applies the same disciplined engineering rigor honed in Olympic and defense programs to every automotive component we produce. Our integrated approach—spanning material certification, real-time process analytics, and destructive/non-destructive validation—ensures that 3D printed parts perform identically to, or surpass, conventionally manufactured counterparts. For automotive engineers demanding reliability at the edge of innovation, this precision pedigree is non-negotiable. Partner with a manufacturer whose process control delivers certified performance, not just printed geometry.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-engineered metal components tailored for advanced applications in the automotive, aerospace, and industrial sectors. Our technical capabilities are built around state-of-the-art 5-axis CNC machining systems, enabling us to produce complex, high-integrity auto parts with exceptional accuracy and repeatability. These multi-axis platforms allow simultaneous cutting from five different angles, minimizing setup changes and ensuring superior geometric consistency across intricate 3D geometries commonly required in 3D-printed auto component tooling and metal replacements.

Our 5-axis machining centers are equipped with high-speed spindles, dynamic tool compensation, and real-time monitoring systems that maintain cutting precision under variable loads. This capability is essential for manufacturing components with organic shapes, deep cavities, or compound angles—features often found in modern 3D-printed automotive assemblies. By leveraging 5-axis technology, we reduce lead times, improve surface finish, and eliminate the need for multiple fixtures, directly supporting rapid prototyping and low-volume production runs demanded by innovation-driven OEMs.

Every component undergoes a rigorous quality control process anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D metrology verification, ensuring that each part conforms to the original CAD model and meets stringent GD&T requirements. Data from CMM reports is traceable and archived for full production lot accountability, satisfying automotive industry standards for process validation and quality documentation. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate dimensional accuracy and surface integrity across all batches.

We specialize in producing metal parts that either replace or support 3D-printed polymer components in automotive systems, including brackets, sensor housings, coolant manifolds, and structural connectors. These parts are typically manufactured in aluminum alloys, stainless steel, titanium, and high-strength nickel-based alloys, selected for thermal stability, mechanical performance, and compatibility with hybrid manufacturing workflows.

The following table outlines our standard machining tolerances and surface capabilities, reflecting our commitment to precision and consistency.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 100 mm; ±0.01 mm beyond |

| Positional Tolerance | ±0.01 mm | Verified via CMM |

| Angular Accuracy | ±0.05° | Across complex 5-axis features |

| Surface Roughness (Ra) | 0.8 µm (typical) | Down to 0.4 µm with fine finishing |

| Geometric Tolerances (GD&T) | Full compliance | Including flatness, cylindricity, runout |

| Feature Resolution | 0.1 mm | Minimum wall thickness for stable structures |

Our technical infrastructure supports seamless integration with additive manufacturing workflows, providing hybrid solutions where 3D-printed prototypes are transitioned into high-strength metal end-use parts. With advanced machining, comprehensive inspection, and material expertise, Wuxi Lead Precision Machinery ensures every auto component meets the highest standards of performance and reliability.

Material & Finish Options

Material Selection for High-Performance 3D Printed Automotive Components

Selecting the optimal material for 3D printed automotive parts is critical for achieving the required strength, weight savings, thermal stability, and corrosion resistance demanded by modern vehicle systems. At Wuxi Lead Precision Machinery, we prioritize material science expertise to ensure your components meet rigorous OEM specifications and functional requirements. Aluminum alloys, stainless steels, and titanium represent the core high-performance metals for mission-critical applications, each offering distinct advantages.

Aluminum alloys like AlSi10Mg and 6061-T6 dominate lightweight structural applications such as brackets, housings, and suspension components. Their high strength-to-weight ratio reduces vehicle mass, directly improving fuel efficiency and handling. Aluminum also offers excellent thermal conductivity for heat-sensitive areas like brake calipers or sensor mounts. However, its lower melting point compared to steel requires careful thermal management during printing and post-processing.

Stainless steel variants, particularly 17-4 PH and 316L, deliver superior strength, wear resistance, and high-temperature stability. These materials are ideal for drivetrain components, hydraulic fittings, and exhaust system parts exposed to extreme stress or corrosive environments. 17-4 PH achieves exceptional hardness through precipitation hardening, while 316L provides unmatched corrosion resistance in salt-laden or chemical-exposed conditions. Steel’s higher density is a trade-off for applications where absolute strength outweighs weight concerns.

Titanium alloy Ti-6Al-4V is the premium choice for ultra-high-stress, weight-critical applications like connecting rods, valve springs, or aerospace-derived automotive systems. It offers the highest strength-to-weight ratio among these metals, exceptional fatigue resistance, and biocompatibility for specialized medical-adjacent automotive uses. Titanium’s biocompatibility also makes it suitable for high-end interior components requiring hypoallergenic surfaces. Its high cost and complex processing requirements necessitate precise parameter control during printing.

Critical Material Properties for Automotive 3D Printing

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Max Operating Temp (°C) | Key Automotive Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 280-350 | 180-250 | 2.67 | 250 | Brackets, heat sinks, lightweight housings |

| 17-4 PH SS | 1000-1300 | 850-1100 | 7.8 | 350 | Gears, shafts, high-pressure fittings |

| Ti-6Al-4V | 900-1000 | 800-850 | 4.43 | 600 | Connecting rods, suspension arms, exhaust valves |

Surface finishing, particularly anodizing, is essential for aluminum components. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dyeing capability for branding. For critical under-hood or safety components, we recommend Type III (hard coat) anodizing, which creates a thicker, denser oxide layer (typically 25-50 microns) with superior abrasion resistance and thermal stability. This process significantly extends component life in high-vibration or chemically aggressive environments.

Material selection directly impacts part performance, cost, and production lead time. Wuxi Lead leverages extensive metallurgical testing and in-house post-processing capabilities—including precision machining, stress relieving, and certified anodizing—to ensure every 3D printed component meets automotive-grade reliability standards. Partner with us to navigate material complexities and achieve optimal performance for your specific application requirements.

Manufacturing Process & QC

Design: Precision Engineering from the Ground Up

At Wuxi Lead Precision Machinery, the journey to flawless metal 3D printed auto parts begins with a rigorously engineered design phase. We collaborate closely with automotive OEMs and Tier-1 suppliers to translate conceptual requirements into manufacturable, high-performance components. Utilizing advanced CAD software and generative design tools, our engineering team optimizes part geometry for weight reduction, thermal efficiency, and structural integrity—critical factors in modern automotive applications. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are applied to validate performance under real-world conditions, including thermal cycling, vibration, and mechanical load. Every design is reviewed for manufacturability, ensuring compatibility with our metal additive processes and post-processing capabilities. This phase establishes the foundation for zero-defect production by embedding quality into the part’s DNA.

Prototyping: Validating Performance Before Scale

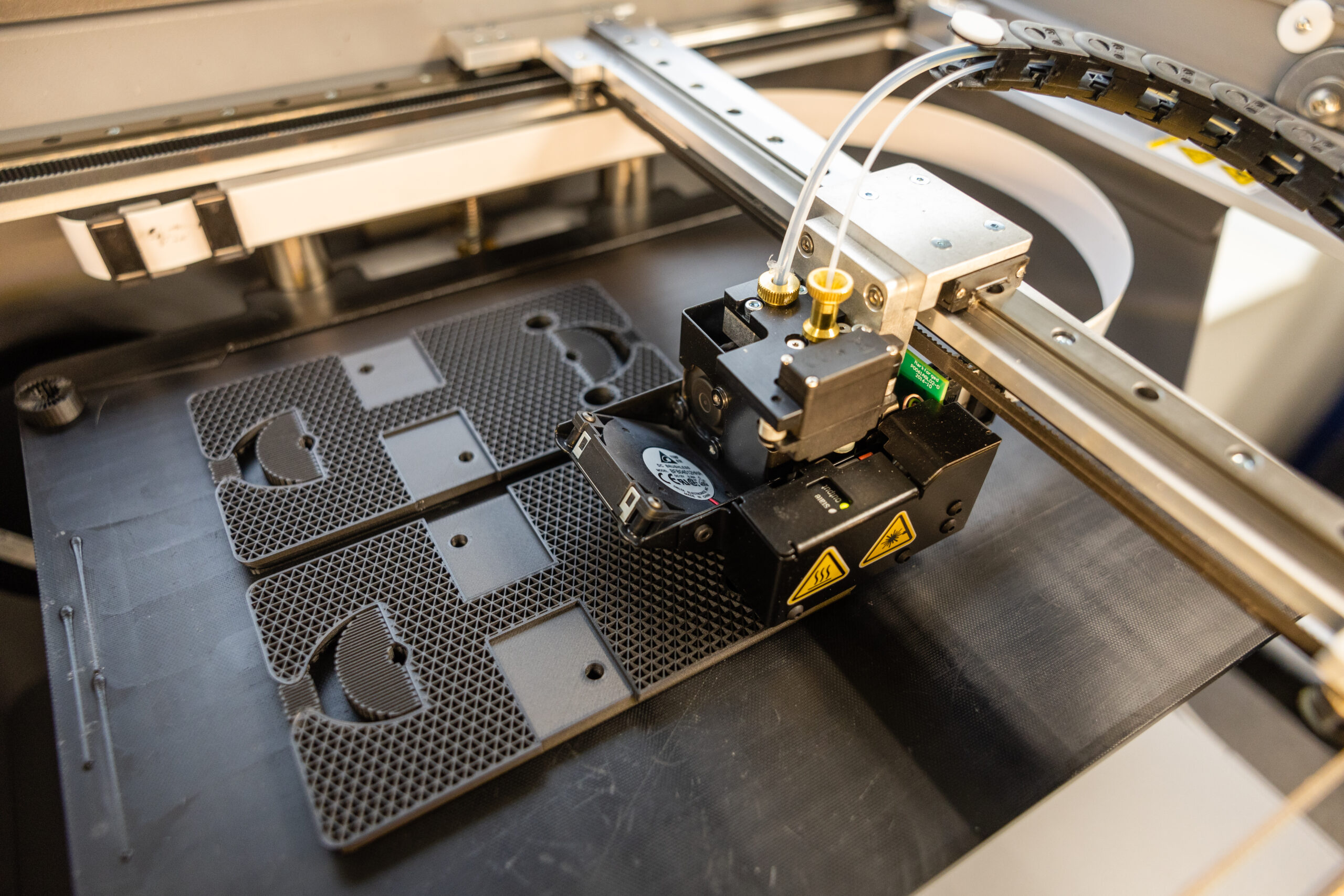

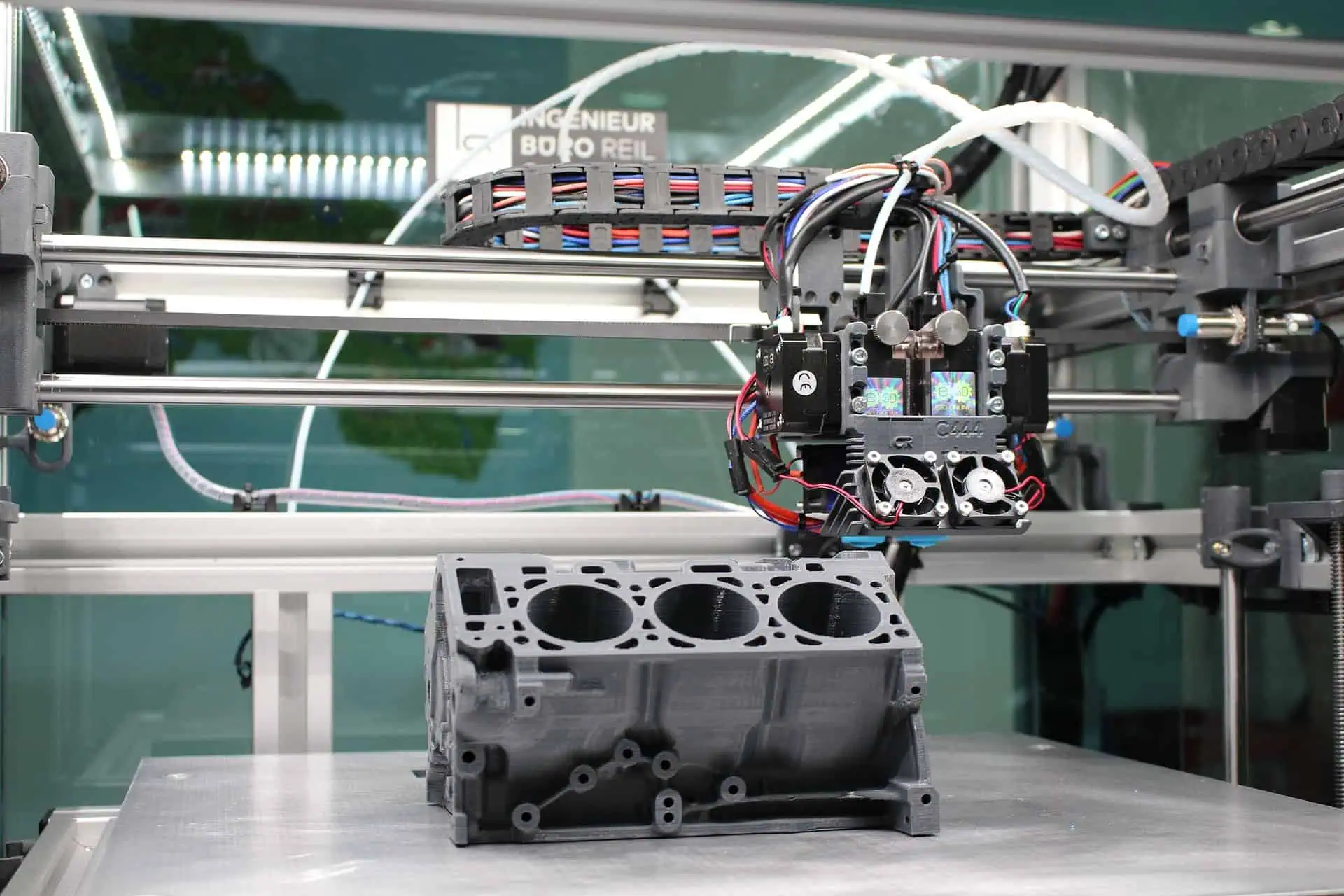

Once the design is finalized, we proceed to rapid prototyping using selective laser melting (SLM) technology with materials such as stainless steel 316L, Inconel 718, and titanium Ti6Al4V. These prototypes are not merely visual models—they are fully functional parts, built layer by layer with micron-level accuracy to validate fit, function, and performance. Each prototype undergoes comprehensive metrology testing using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy against the original CAD model. Non-destructive testing (NDT), including X-ray and ultrasonic inspection, ensures internal integrity and absence of porosity. Feedback from this stage is used to refine the design or process parameters, closing the loop before mass production. This iterative validation is central to our zero-defect philosophy, eliminating risks early in the cycle.

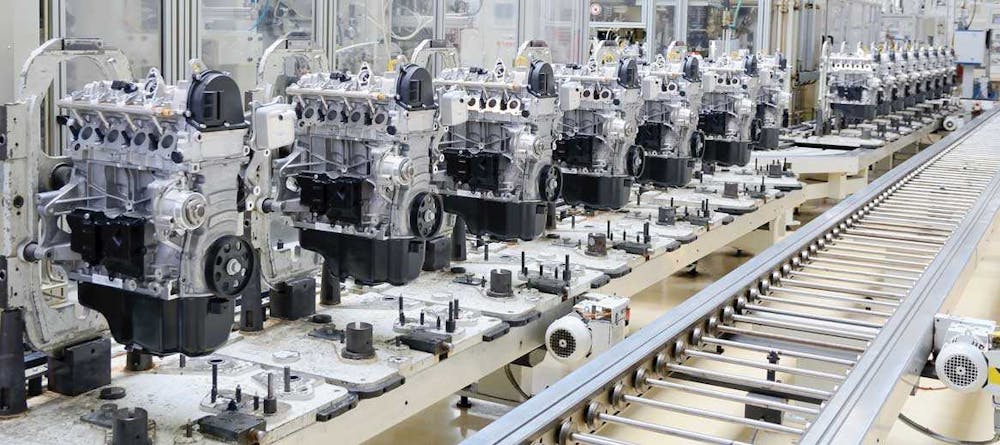

Mass Production: Consistency, Control, and Certification

With prototype approval, we transition to high-volume production using automated SLM systems integrated with real-time monitoring and closed-loop powder management. Each build is tracked through a digital twin system that logs laser power, scan speed, chamber atmosphere, and layer consistency, ensuring full traceability. Post-processing—including heat treatment, stress relieving, CNC machining, and surface finishing—is performed in-house under strict environmental controls. Final parts undergo 100% dimensional inspection and batch sampling for mechanical testing (tensile, hardness, fatigue). All production runs comply with ISO 9001 and IATF 16949 standards, with full documentation provided for audit purposes.

| Parameter | Specification |

|---|---|

| Build Volume | Up to 500 x 500 x 400 mm |

| Layer Thickness | 20–60 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Post-Processing Options | CNC Machining, HIP, Polishing, Passivation |

| Materials | 316L, 17-4PH, Inconel 718, Ti6Al4V, AlSi10Mg |

| Quality Standards | ISO 9001, IATF 16949, ASTM F75, AMS 7000 series |

Through integrated design, validated prototyping, and tightly controlled mass production, Wuxi Lead ensures every 3D printed auto part meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Automotive 3D Printing

The automotive industry demands uncompromising precision and reliability in every component, especially for high-performance or safety-critical applications. Standard additive manufacturing services often fall short when faced with the stringent material properties, geometric complexity, and traceability requirements of modern vehicle systems. Wuxi Lead Precision Machinery bridges this gap. We are not merely a 3D printing service provider; we are your engineering partner, integrating deep metallurgical expertise with advanced metal additive manufacturing and precision post-processing to deliver fully qualified, production-ready auto parts. Our focus is solely on high-integrity metal components where failure is not an option.

We specialize in producing complex geometries impossible with traditional methods – lightweight structural nodes, integrated cooling channels for e-motors, custom brackets for ADAS systems, and rapid prototyping of next-generation powertrain elements. Our DMLS and SLM capabilities, combined with in-house CNC machining, heat treatment, and surface finishing, ensure parts meet exact dimensional tolerances and surface specifications straight from the build plate. Material integrity is paramount. We rigorously qualify all builds against automotive standards, providing full material traceability and comprehensive inspection reports.

The following table outlines our core capabilities for demanding automotive applications:

| Specification Category | Capability Detail |

|---|---|

| Materials | Inconel 718, 625 • Titanium Ti6Al4V • Stainless Steel 17-4PH, 316L • Aluminum AlSi10Mg • Custom Alloys |

| Build Volume | Up to Ø250 x 325 mm (EOS M 290) • Up to 250 x 250 x 300 mm (Concept Laser M2) |

| Accuracy & Tolerance | As-built: ±0.05 mm • Post-processed: ±0.01 mm (CNC Machined Features) |

| Surface Finish | As-built: Ra 12-25 µm • Machined: Ra 0.8-3.2 µm • Polished: Ra <0.4 µm |

| Quality Assurance | ISO 9001:2015 • ISO 13485 • NADCAP Accredited NDT • Full Material Certs • 3D Scanning Reports • Metallurgical Validation |

| Key Automotive Applications | Lightweight Chassis Components • Thermal Management Systems • Sensor Housings • Turbocharger Parts • Custom Brackets • Rapid Prototyping for Validation |

Our integrated workflow eliminates supply chain fragmentation. From initial CAD validation and build parameter optimization through precision machining, non-destructive testing, and final certification, every step occurs under our controlled quality management system. We understand the critical timelines of automotive development cycles and production ramps. Our engineering team collaborates directly with your design and validation groups, providing DfAM guidance and rapid iteration to solve complex challenges without compromising on quality or compliance.

Do not risk vehicle performance or safety with generic additive solutions. Partner with an organization built on the foundation of precision engineering for the world’s most demanding industries. Contact Wuxi Lead Precision Machinery today to initiate a technical consultation. Send your component requirements and validation criteria to Contact [email protected]. Our engineering sales team will respond within one business day with a detailed capability assessment and proposed workflow for your specific application. Elevate your automotive innovation with manufacturing precision you can trust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.