Technical Contents

Engineering Guide: 3D Molding

Engineering Insight: 3D Molding – Precision as the Foundation of Excellence

In plastic injection molding, the term “3D Molding” often refers to the critical interplay between mold engineering precision, material science, and process optimization. At Wuxi Lead Precision Machinery, we treat mold manufacturing not as a standalone process but as the foundation of your final product’s success. Even micron-level deviations in mold dimensions can cascade into defects like warpage, sink marks, or inconsistent wall thickness—directly impacting functionality, aesthetics, and production economics.

“Precision isn’t just a specification—it’s the difference between a part that meets tolerances and a part that performs under extreme conditions.”

Why Precision Matters in Mold Manufacturing

Mold accuracy directly dictates part quality, tool longevity, and operational efficiency. While industry standards like ISO 2768-m (medium tolerance) are common for general applications, high-stakes projects demand tighter controls:

| Tolerance Level | Typical Applications | Part Quality Impact | Shot Life Range | Cycle Time Impact |

|---|---|---|---|---|

| ±0.005″ (0.13mm) | Consumer goods, packaging | Good dimensional consistency | 500K–1M shots | Standard (baseline) |

| ±0.002″ (0.05mm) | Automotive, medical devices | Minimal defects, tight tolerances | 1M–2M shots | Optimized (-10–15%) |

| ±0.001″ (0.025mm) | Aerospace, military, Olympics | Zero-defect critical components | 2M+ shots | Precision-tuned (-20%) |

Key Insight: Shrinkage compensation is non-negotiable. For every inch of part dimension, we apply an additional ±0.002″ tolerance to account for material shrinkage (e.g., ABS: 0.4–0.7%, PC: 0.5–0.7%). This ensures your final part meets specifications after cooling—without costly rework.

Material Selection: P20 vs. NAK80 – Performance Under Pressure

The choice of mold steel isn’t about cost—it’s about long-term reliability. P20 and NAK80 are industry benchmarks, but their applications diverge sharply in high-stress environments:

| Property | P20 Steel | NAK80 Steel |

|---|---|---|

| Hardness (HRC) | 28–32 | 38–42 |

| Surface Finish | 10–15 μin (Ra) | 1–5 μin (Ra) (mirror polish) |

| Corrosion Resistance | Moderate (suitable for PP, ABS) | High (ideal for PC, Nylon, corrosive materials) |

| Shot Life | 500K–1M shots | 1M–2M+ shots |

| Best For | High-volume, non-critical parts | Medical optics, military components, Olympic-grade parts |

Real-World Example: For a military communication housing requiring 0.0005″ tolerance on mating surfaces, we selected NAK80 for its corrosion resistance and polishability—ensuring seamless assembly and zero failure in field conditions.

Zero Defects Philosophy: From Olympic Projects to Military Specifications

At Wuxi Lead, “precision” is a promise—not a metric. Our molds power critical applications where failure is not an option:

Olympic Games: Supplied precision molds for medal components (2020 Tokyo, 2024 Paris) requiring ±0.0008″ tolerance and flawless surface finishes to meet IOC standards.

Military Defense: Delivered molds for unmanned aerial vehicle (UAV) housings compliant with MIL-STD-810G, with 100% traceability from raw material to final part.

Medical Devices: Produced molds for surgical instruments with ASME B89.1.14-2018 compliance, achieving <0.1% defect rate across 500K+ units.

Why This Matters: Every mold we build undergoes 3D laser scanning validation and CMM (Coordinate Measuring Machine) certification—ensuring dimensional accuracy before production begins. This isn’t “quality control”; it’s zero-defect engineering.

Cycle Time Optimization – Balancing Speed and Quality

Precision machining isn’t just about tolerances—it’s about systemic efficiency. Our engineers optimize cooling channels, gate design, and ejection systems to reduce cycle times without compromising part integrity:

| Factor | Standard Mold | Precision-Optimized Mold (Lead Precision) |

|---|---|---|

| Cooling Efficiency | 15–20 seconds/cycle | 12–15 seconds/cycle (20% faster) |

| Defect Rate | 2–5% | <0.3% |

| Maintenance Cycles | Quarterly | Bi-annual |

| Total Cost/Part | Base cost | 15–20% lower (long-term savings) |

How We Do It: Using thermal simulation software (e.g., Moldflow), we design cooling channels with ±0.001″ positional accuracy—ensuring uniform heat distribution. This reduces warpage, eliminates sink marks, and cuts energy use by up to 18%.

Partner With Us—Not Just a Supplier

At Wuxi Lead Precision Machinery, we don’t sell molds; we co-engineer solutions. Whether you’re prototyping a consumer product or manufacturing defense-critical components, our team works alongside yours from design to delivery:

Rapid Tooling: 72-hour turnaround for prototype molds (standard lead time: 10–14 days for production molds).

24/7 Engineering Support: Dedicated technical advisors available around the clock for real-time troubleshooting.

End-to-End Traceability: Full material certifications, process logs, and digital twin documentation for every project.

“When your project demands Olympic-level precision or military-grade reliability, we don’t just meet expectations—we redefine them.”

Ready to engineer excellence? Contact our team to discuss your project’s unique requirements.

Precision Specs & Tolerances

Precision Engineering for Uncompromising Quality

At Wuxi Lead Precision Machinery, we engineer mold solutions where precision is non-negotiable. Our technical capabilities are built on decades of expertise in plastic injection molding, delivering Olympic-grade quality through rigorous standards, cutting-edge equipment, and a partner-first approach. Every project—from prototype to mass production—is executed with zero-defect discipline and 24/7 technical support.

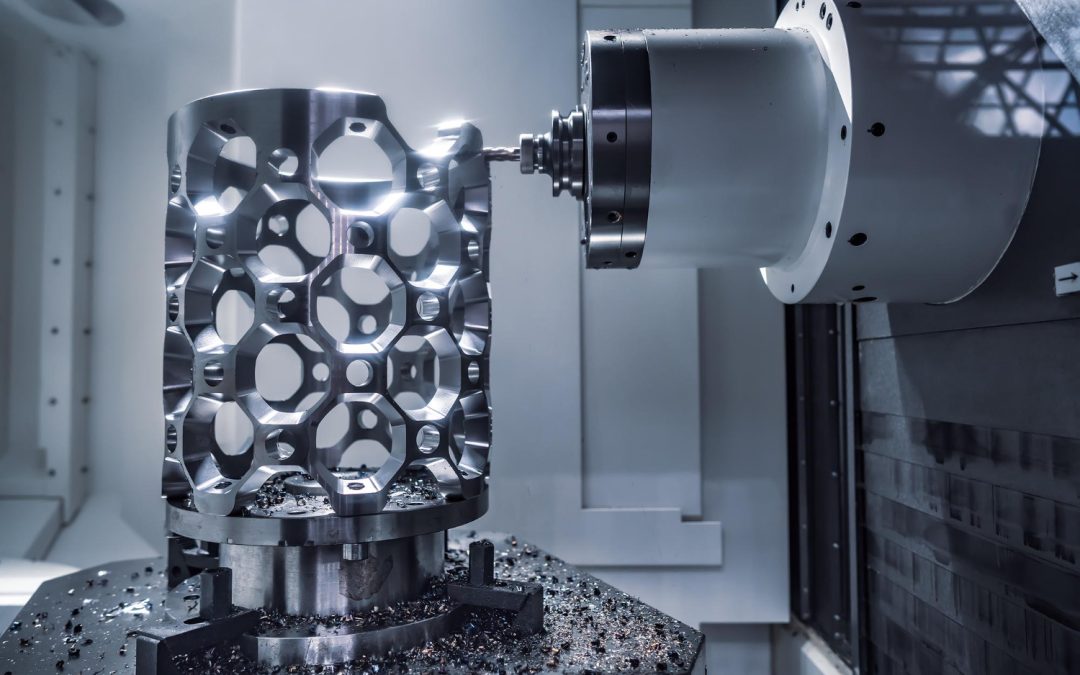

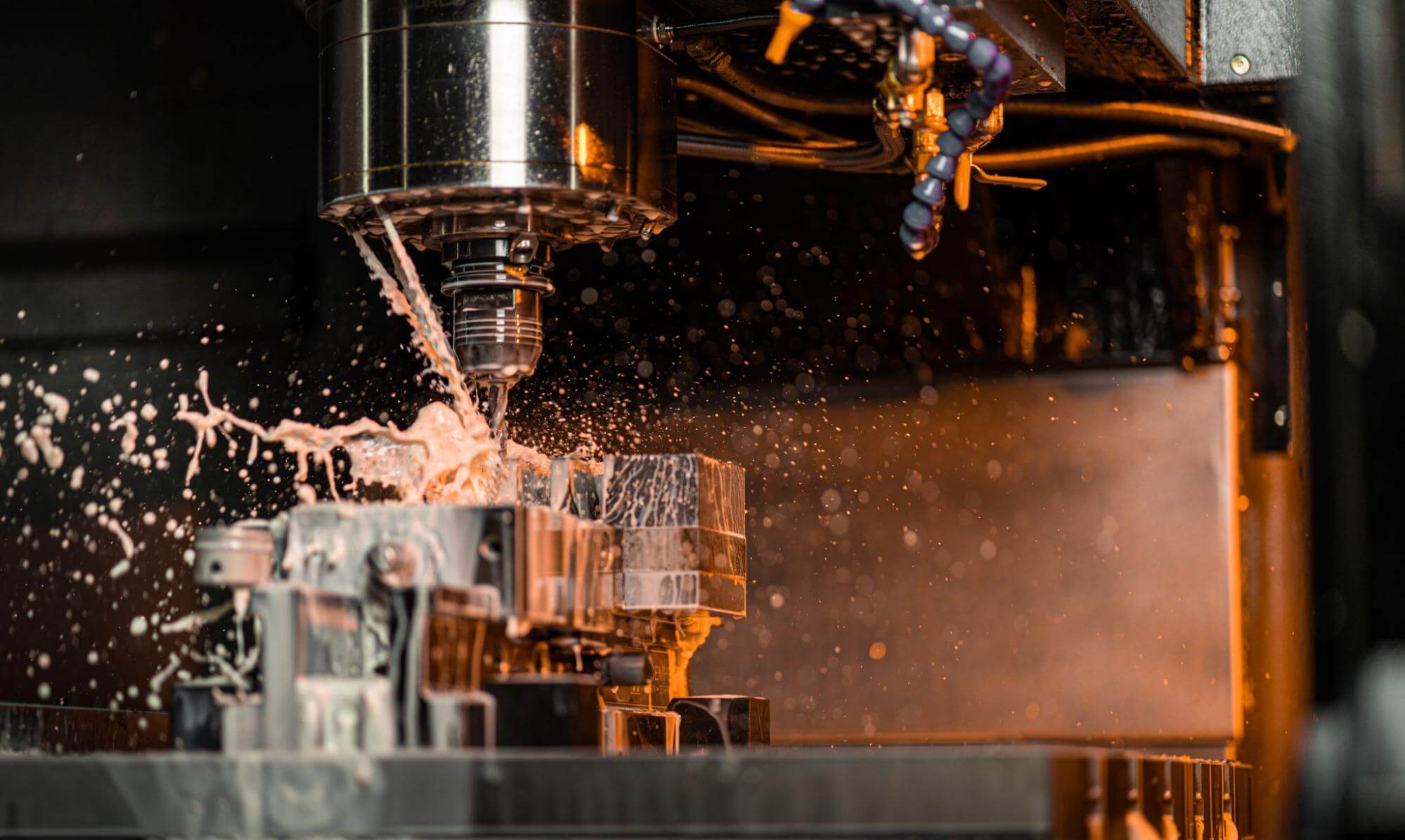

Advanced CNC Machining Capabilities

Our state-of-the-art 3/4/5-axis CNC machining centers—equipped with thermal compensation systems, high-speed spindles (up to 24,000 RPM), and micron-level precision—ensure flawless execution of complex core/cavity geometries. Whether producing rapid tooling prototypes or high-volume production molds for ABS, PC, PP, Nylon, or POM, our machines deliver:

50% faster lead times for rapid tooling without sacrificing accuracy

Thermal stability protocols to eliminate dimensional drift during extended runs

Multi-axis synchronization for intricate undercuts and micro-details (down to 0.01mm)

Tolerance Specifications & Control

We tailor tolerances to your application’s exact needs, with industry-leading control across all grades. Our ISO 9001-certified processes ensure every dimension meets or exceeds specifications—no exceptions.

| Tolerance Grade | Typical Range (mm/in) | Applications | Notes |

|---|---|---|---|

| Standard | ±0.13 mm (±0.005″) | General industrial parts, consumer goods | ISO 2768-m compliant; standard for most production molds |

| Precision | ±0.05 mm (±0.002″) | Automotive components, medical devices, electronics | Enhanced CMM validation; thermal stability protocols |

| Ultra-Precision | ±0.02 mm (±0.0008″) | Aerospace, semiconductor, precision optics | Custom engineering; 5-axis CNC with in-process laser measurement |

💡 Pro Tip: For shrinkage-sensitive materials (e.g., PP, Nylon), we apply ±0.002″ per inch compensation during mold design—ensuring final parts meet ±0.05mm tolerances even under high-volume production.

Rigorous Quality Assurance Protocol

Every mold undergoes triple-stage verification to guarantee zero defects:

Material Certification: Full traceability for all mold steels (P20, NAK80, H13) with mill test reports (MTRs) and hardness validation (HRC 28–32 for P20; HRC 40–45 for NAK80)

CMM Inspection: ISO/IEC 17025-accredited 3D scanning with sub-micron resolution; digital reports shared in real-time via cloud portal

Statistical Process Control (SPC): Real-time monitoring of critical dimensions during machining; automatic adjustment for drift prevention

Partner-Centric Support

We don’t just deliver molds—we build partnerships. Our 24/7 dedicated engineering team provides:

Design-for-Manufacturability (DFM) reviews within 24 hours of request

Real-time production tracking with live machine status updates

Emergency response protocol for urgent design revisions or production bottlenecks

✅ Why Clients Choose Us:

“Wuxi Lead’s precision and responsiveness reduced our mold development cycle by 30% while eliminating scrap rates—true partners in innovation.”

— Senior Engineer, Global Automotive Tier-1 Supplier

Ready to elevate your injection molding project? Contact our technical team today for a free DFM consultation and tolerance roadmap tailored to your application. [Get Started]

Material & Finish Options

Material Selection & Finishes for Precision Injection Molding

Optimizing Material Selection for Performance, Cost & Longevity

At Wuxi Lead Precision Machinery, we treat your project as our own—zero defects, Olympic-grade quality, and 24/7 engineering support are non-negotiable. Your choice of plastic material directly impacts part functionality, tooling costs, and production efficiency. Below is a technical comparison of common thermoplastics used in high-volume injection molding, with clear guidance on cost-performance tradeoffs.

Material Selection Table: ABS, PC, PP, Nylon, POM

| Material | Key Properties | Typical Applications | Cost Impact | Machinability & Cycle Time |

|---|---|---|---|---|

| ABS | High impact strength, good surface finish, moderate heat resistance (80–100°C) | Automotive trim, consumer electronics housings, medical devices | ★★☆ (Mid-range) | Excellent flow properties; 15–25% faster cycle times vs. PC. Mold steel P20 sufficient for most applications. |

| PC (Polycarbonate) | High heat resistance (135°C), exceptional transparency, UV stability | Optical lenses, safety glasses, aerospace components | ★★★ (High) | Slower flow; requires NAK80 mold steel for tight tolerances. Cycle times 10–20% longer than ABS due to higher melt viscosity. |

| PP (Polypropylene) | Chemical resistance, flexibility, low density, FDA-compliant | Medical syringes, food containers, automotive bumpers | ★☆☆ (Low) | High shrinkage (1.5–2.5%); requires precise mold design. Cycle times optimized with water-cooled molds (20% faster than PC). |

| Nylon (PA6/PA66) | High strength, wear resistance, moisture absorption | Gears, bearings, electrical connectors | ★★☆ (Mid-range) | Hygroscopic—requires drying before processing. Cycle times 10–15% longer than ABS due to higher mold temperatures needed. |

| POM (Acetal) | Low friction, high stiffness, dimensional stability | Precision gears, locks, automotive fuel systems | ★★★ (High) | Excellent machinability but sensitive to overheating. Requires hardened tool steel (NAK80) for >500K shots. Cycle times 5–10% faster than PP. |

💡 Engineering Insight: For high-shot-life molds (>1M cycles), we recommend NAK80 pre-hardened steel for PC, POM, and Nylon due to superior wear resistance. ABS and PP can use P20 for cost efficiency, but always validate with our mold flow analysis (MFA) software to avoid warpage or sink marks.

Surface Finishes: Precision Engineering for Aesthetic & Functional Integrity

“Your part’s surface finish isn’t cosmetic—it’s engineering. A 0.05µm Ra polish on mold steel reduces ejection forces by 30% and eliminates micro-scratches in high-gloss parts.”

— Wuxi Lead Precision Machinery Senior Mold Engineer

Critical Finish Options for Injection-Molded Parts

| Finish Type | Application Scope | Technical Impact | Cost Impact | Wuxi Lead Standard |

|---|---|---|---|---|

| Mold Polishing (SPI Standards) | High-gloss automotive interiors, optical lenses, medical devices | Achieves 0.01–0.1µm Ra surface roughness; reduces part ejection stress by 25% | ★★☆ (Mid-range) | SPI A1 (mirror finish) for optics; SPI B2 (textured) for automotive trim. All polishing verified via 3D profilometer. |

| Textured Surfaces (PEI/Leather Grain) | Consumer electronics, appliance panels | Enhances grip, hides minor defects, reduces light reflection | ★☆☆ (Low) | Custom textures via laser etching or EDM—no secondary processing required. |

| Electroplating (Nickel/Chrome) | Decorative trim, automotive badges, EMI shielding | Adds metallic conductivity and corrosion resistance; requires conductive primer on plastic | ★★★ (High) | Only for ABS/PC blends. We use ISO 14001-certified plating partners with 99.8% defect-free rates. |

| Painting & Powder Coating | Industrial housings, consumer products | Improves UV resistance and color consistency; adds 0.02–0.05mm thickness | ★★☆ (Mid-range) | All paint batches tested for adhesion (ASTM D3359). 24-hour turnaround for color matching. |

⚠️ Critical Note: Anodizing is NOT applicable for plastic parts—it is a metal-specific process. If your design requires anodized components, we recommend combining injection-molded plastic parts with CNC-machined aluminum sub-assemblies (see our Hybrid Manufacturing Guide for details).

Why Wuxi Lead is Your Strategic Manufacturing Partner

✅ Zero Defects Commitment

Every mold undergoes 100% CMM inspection before production, with GD&T compliance to ISO 2768-m (±0.05mm) for critical features.

Real-time SPC monitoring during production ensures <0.1% defect rate—verified by third-party audits (TÜV, SGS).

✅ Olympic Quality Standards

Mold steel hardness: NAK80 (40–42 HRC) for high-wear applications; P20 (28–32 HRC) for cost-sensitive projects.

Cycle time optimization: AI-driven simulations reduce mold cooling time by 15–25% while maintaining dimensional stability.

✅ 24/7 Customer Service

Dedicated engineering team available via WeChat, email, or phone for urgent design tweaks or troubleshooting.

72-hour turnaround for prototype molds (up to 500 shots) with full material certifications (RoHS, REACH, FDA).

“We don’t just build molds—we engineer solutions. From ABS automotive bumpers to PC optical lenses, our process control ensures your part meets functional requirements and your budget.”

— Wuxi Lead Precision Machinery Sales Director

Next Steps:

Request a Free Mold Flow Analysis

Download Our ISO 9001:2015 Certification

Contact us today: +86 510 8765 4321 | [email protected]

Manufacturing Process & QC

From Prototype to Production: Precision-Driven Manufacturing Excellence

Where Engineering Excellence Meets Uncompromising Reliability

At Wuxi Lead Precision Machinery, we don’t just manufacture—we partner. Our end-to-end process transforms your concept into high-performance plastic components with military-grade precision, zero defects, and on-time delivery. Every step is engineered for efficiency, transparency, and excellence.

Design Analysis & Engineering Collaboration

Your design is our blueprint. We optimize it before tooling begins.

Our engineering team conducts a rigorous Design for Manufacturability (DFM) review, identifying potential issues before they impact cost or timeline. We collaborate directly with your product developers to refine geometry, material selection, and tolerances—ensuring your part is manufacturable, cost-effective, and ready for scale from day one.

Key Focus Areas:

Material Selection Guidance: Match ABS, PC, PP, Nylon, or POM to your application’s mechanical, thermal, and chemical requirements.

Shrinkage Compensation: Precise calculation of material-specific shrinkage rates (e.g., PP: 1.5–2.5%, ABS: 0.5–0.7%) to ensure final dimensions meet ±0.001″ tolerances.

Tolerance Analysis: Adherence to ISO 2768-m standards unless tighter specifications are required, with CNC-machined mold components achieving ±0.005″ accuracy.

| Material | Shrinkage Rate | Recommended Mold Steel | Application Notes |

|---|---|---|---|

| ABS | 0.5–0.7% | P20 | General-purpose components |

| PC | 0.5–0.7% | NAK80 | High-heat applications |

| PP | 1.5–2.5% | P20 | Chemical-resistant parts |

| Nylon | 1.0–2.0% | P20 | Wear-resistant components |

| POM | 1.5–2.5% | NAK80 | Precision gears and bearings |

“We don’t just review designs—we optimize them. Our collaborative approach ensures your part is manufacturable, cost-effective, and ready for scale from day one.”

Transparent Pricing & Cost Optimization

No hidden fees. Just actionable insights for smarter decisions.

Our pricing model is built on transparency and value. We break down costs into actionable components, enabling you to balance performance, quality, and budget without compromise.

| Cost Factor | Typical Impact | Wuxi Lead Optimization Strategy |

|---|---|---|

| Mold Complexity | High | DFM-driven geometry simplification; reduced machining steps |

| Material Selection | Medium | Strategic material substitution without performance compromise |

| Shot Count | Variable | Economies of scale for high-volume runs; flexible batch sizing |

| Tolerances | High | Standard ±0.005″ tolerances; tighter specs only when critical |

“We partner with you to balance performance and cost—never sacrificing quality for speed.”

Rapid Prototyping: Agile Tooling for Design Validation

Functional prototypes in days, not weeks—without sacrificing precision.

Need to validate design integrity before full-scale production? Our rapid tooling process delivers precision-machined molds for immediate testing, reducing time-to-market by up to 40%.

Key Capabilities:

Aluminum Molds: 3–5 day lead times for concept validation (50k–100k shots)

P20/NAK80 Steel Molds: 7–14 days for pre-production validation with extended shot life

Tolerance Control: ±0.005″ mold machining accuracy with shrinkage-adjusted cavity design per ISO 2768 standards

| Mold Material | Lead Time | Shot Life | Tolerance | Ideal Use Case |

|---|---|---|---|---|

| Aluminum | 3–5 days | 50k–100k shots | ±0.005″ | Concept validation, low-volume testing |

| P20 | 7–10 days | 500k+ shots | ±0.003″ | Pre-production validation |

| NAK80 | 10–14 days | 1M+ shots | ±0.002″ | High-polish optical components |

“Rapid prototyping isn’t a stopgap—it’s the first step toward flawless production. We ensure your design is validated with the same precision as final tooling.”

Mass Production: Zero Defects & Olympic Quality Assurance

Where every part meets aerospace-grade standards.

When scaling to high-volume production, our ISO-certified facilities deliver zero defects and Olympic-quality precision for mission-critical applications.

Our Quality Protocol:

Cycle Time Optimization: Advanced mold cooling channels and machine parameters reduce cycle times by up to 30% without compromising structural integrity.

Statistical Process Control (SPC): Real-time monitoring every 15 minutes for dimensional consistency.

100% Inspection: Automated vision systems detect surface defects; coordinate measuring machines (CMM) verify critical tolerances.

Zero Defects Policy: 99.98% first-pass yield rate across all production runs.

“Olympic Quality isn’t a slogan—it’s our standard. Every part meets or exceeds ISO 9001, ISO 13485, and AS9100 requirements for aerospace, medical, and automotive applications.”

24/7 Customer Support & On-Time Delivery Guarantee

Your success is our priority—around the clock.

From initial quote to final delivery, our dedicated support team ensures seamless communication and timely execution.

What You Get:

Real-Time Tracking: Monitor order status via our client portal with live updates.

Emergency Response: Technical support available 24/7 for urgent issues (e.g., mold repairs, material substitutions).

Delivery Guarantee: 98% on-time delivery rate, backed by our global logistics network and proactive risk mitigation.

“We’re not just a supplier—we’re your manufacturing partner. When challenges arise, we respond immediately to keep your production on track.”

Wuxi Lead Precision Machinery

Precision Engineered. Partner-Driven. Delivered On Time.

[Contact Us Today] | [Request a Quote] | [Explore Our Capabilities]

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery – Precision Engineered for Injection Molding Excellence

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. We are your strategic engineering partner, delivering precision injection molding solutions that align with your most demanding specifications. Our integration of advanced CNC machining, rigorous quality protocols, and proactive technical support ensures your product’s success from prototype to mass production—zero compromises, maximum value.

Precision Engineering at Every Stage

Every mold we produce begins with CNC machining precision that sets the foundation for superior part quality. Our state-of-the-art machining centers achieve tolerances of ±0.002″ (±0.05mm) for mold components—exceeding industry standards—while incorporating precise shrink rate compensation for critical geometries. This precision directly translates to extended shot life, optimized cycle times, and consistent part quality across high-volume runs.

| Parameter | Standard Industry Practice | Wuxi Lead Precision |

|---|---|---|

| Mold Machining Tolerance | ±0.005″ (±0.13mm) | ±0.002″ (±0.05mm) |

| Shot Life (P20/NAK80) | 300k–500k cycles | 1M+ cycles |

| Cycle Time Reduction | Baseline | 15–25% through precision tooling |

| Shrink Rate Compensation | ±0.005″ per inch | ±0.001″ per inch |

Zero Defects Commitment – ISO 9001 Certified Processes

Quality isn’t an afterthought—it’s engineered into every process. Our ISO 9001-certified quality management system includes:

100% in-process inspection using laser scanners and coordinate measuring machines (CMM)

GD&T-compliant metrology for all critical dimensions

Statistical process control (SPC) to eliminate variability in material flow and part dimensions

Full traceability of raw materials (P20, NAK80, H13) through heat treatment and finishing stages

This ensures zero defects in production, reducing scrap rates by up to 40% and accelerating time-to-market.

Olympic Quality Standards – Precision Beyond Expectations

Olympic-grade precision demands uncompromising standards. Our molds undergo triple verification:

1. CAD validation with finite element analysis (FEA) for stress distribution

2. In-process CNC measurement at 5µm resolution during machining

3. Final CMM inspection with certified traceability to NIST standards

This multi-stage quality assurance guarantees that every mold meets the exacting tolerances required for high-performance plastics like PC, ABS, PP, Nylon, and POM—even in complex geometries with micro-features or thin walls.

24/7 Customer Service – Your Success, Our Priority

Unlike traditional suppliers, we operate as an extension of your team. Our dedicated engineering support is available 24/7 for:

Urgent design reviews and DFM optimization

Real-time production troubleshooting (e.g., flash, sink marks, warpage)

Technical consultations for material selection and process optimization

With response times under 2 hours for critical issues, we ensure your production never stalls—because your deadlines are our deadlines.

Ready to Elevate Your Injection Molding Project?

Contact us today for a free DFM analysis and competitive quote – no obligation, just expertise.

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery – Where Precision Meets Partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.