Technical Contents

Engineering Guide: 3D Mold

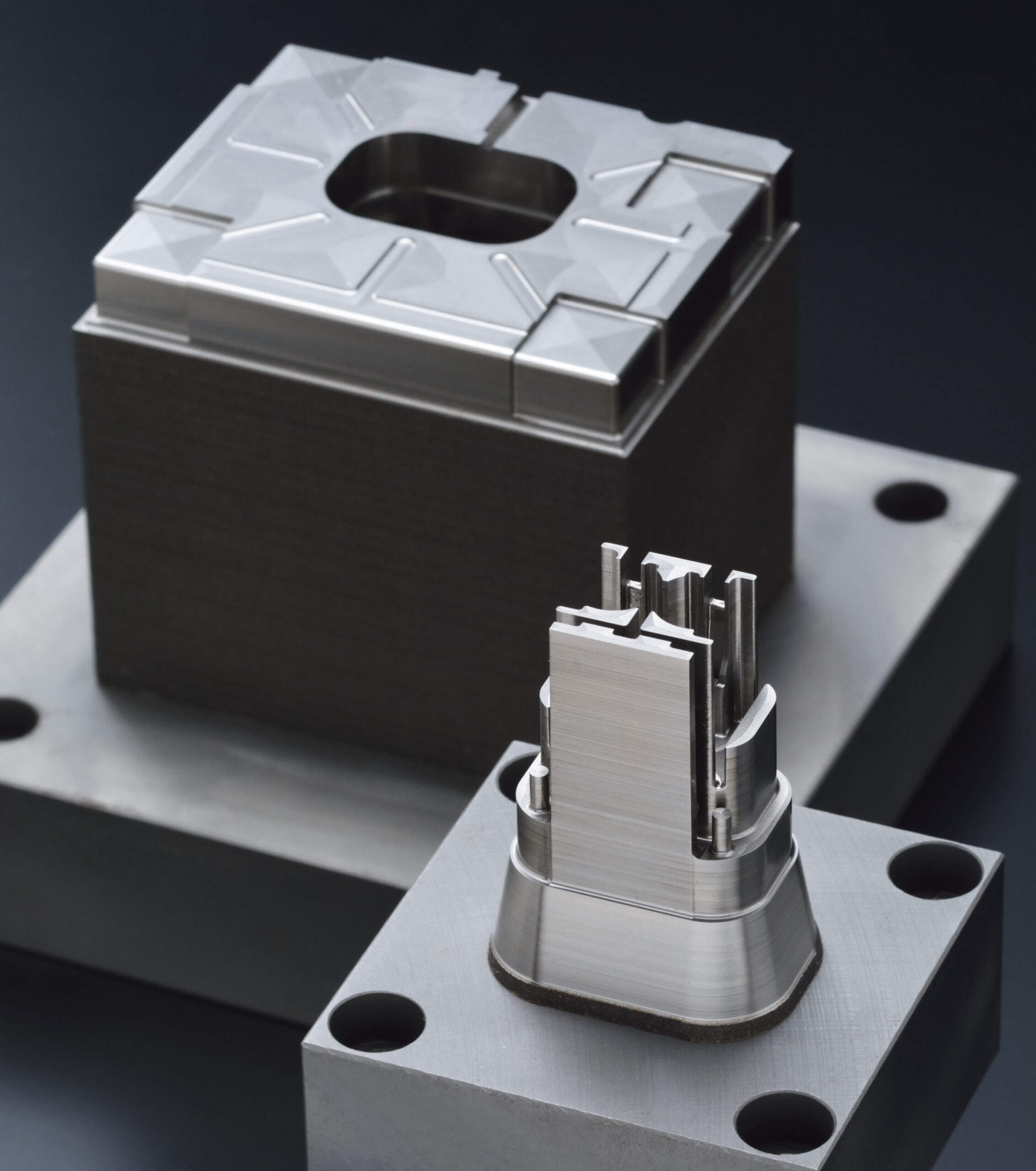

Engineering Insight Precision as the Non-Negotiable Foundation of 3D Mold Manufacturing

In the realm of custom metal manufacturing, particularly for complex 3D molds, precision transcends mere specification—it is the absolute determinant of functional success, longevity, and economic viability. The intricate geometries, tight undercuts, and demanding surface finishes inherent in high-performance 3D molds leave zero margin for error. Microscopic deviations in cavity dimensions or core alignment propagate exponentially during the molding process, leading to part warpage, flash, premature wear, and catastrophic mold failure. The cost implications extend far beyond scrap rates; they encompass production downtime, rework expenses, and reputational damage when mission-critical components fail in end-use applications. Achieving true precision demands more than advanced machinery; it requires an integrated engineering philosophy governing material selection, thermal management, toolpath optimization, and rigorous in-process metrology at every machining stage.

At Wuxi Lead Precision Machinery, we treat dimensional accuracy and surface integrity as inseparable from the mold’s core function. Our approach begins with finite element analysis to predict and mitigate thermal distortion during high-cycle operation, ensuring cavity stability under extreme pressure and temperature fluctuations. We employ multi-axis simultaneous machining with sub-micron resolution controls, coupled with real-time probing systems that validate geometry during cutting, not merely post-process. This proactive verification is essential for maintaining tolerances where traditional methods introduce cumulative error. Material science expertise guides our selection of pre-hardened alloys and specialized coatings, balancing wear resistance with machinability to achieve flawless surface finishes critical for optical or medical-grade parts.

Our commitment to uncompromising precision is validated through projects where failure is not an option. We have engineered and manufactured molds for structural components in Olympic venue construction, demanding absolute dimensional conformity across massive scale assemblies. Similarly, our work for defense sector partners involves molds for aerospace actuators and communication housings, adhering to stringent MIL-STD and AS9100 requirements where tolerances directly impact system safety and reliability. This experience instills a culture where ±0.002mm is the baseline expectation, not the exception.

The following table outlines the precision capabilities standard across our 3D mold production for critical applications:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Linear Dimensional Tolerance | ±0.001 mm to ±0.005 mm | CMM (Calibrated to ISO 17025) |

| Geometric Tolerance (GD&T) | Positional: ±0.002 mm; Flatness: 0.001 mm/m² | Laser Tracker Verification |

| Surface Roughness (Ra) | 0.05 µm to 0.4 µm (Mirror Finishes) | Profilometer (ISO 4287) |

| Material Hardness Range | Up to 60 HRC (Pre-hardened Steels) | Rockwell C Scale |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Machine Bed Capacity |

Precision in 3D mold manufacturing is not an incremental advantage—it is the foundational requirement for enabling innovation in end products. When your application demands flawless replication under high pressure, extreme cycles, or stringent regulatory oversight, the engineering rigor embedded in every micron of our molds delivers the reliability your project requires. Contact Wuxi Lead Precision Machinery to discuss how our certified precision process mitigates risk for your most demanding mold challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for complex 3D mold applications. Our facility is equipped with state-of-the-art 5-axis CNC machining centers, enabling us to produce intricate geometries with superior surface finishes and tight dimensional accuracy. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring and undercut machining—critical for molds with deep cavities, compound angles, and organic shapes.

Our 5-axis machining process eliminates the need for multiple setups, reducing cumulative error and improving part consistency. This capability significantly enhances production efficiency while maintaining micron-level precision across complex features. Whether producing injection molds, die-cast tooling, or prototype molds for aerospace and medical applications, our machining centers support a wide range of materials including hardened steels, aluminum alloys, titanium, and high-temperature superalloys.

Quality assurance is integrated at every stage of production. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with stringent international standards. The CMM system provides full 3D metrology data, verifying form, position, and dimensional conformity with traceable results. This level of inspection supports first-article validation, process stability monitoring, and final product certification.

We maintain strict environmental controls in our inspection lab to minimize thermal drift, ensuring measurement repeatability down to ±0.001 mm. In addition to CMM, our quality protocol includes surface roughness testing, hardness verification, and optical comparison for fine details. These procedures are aligned with ISO 9001 standards and customer-specific requirements, providing full transparency and documentation upon delivery.

The following table outlines our standard technical specifications and achievable tolerances:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.2 µm (polished finish achievable) |

| Dimensional Tolerance | ±0.01 mm (standard), ±0.005 mm (tight) |

| Angular Tolerance | ±0.05° |

| Material Compatibility | Tool steel, stainless steel, aluminum, titanium, brass, copper alloys |

| Inspection Method | CMM (ZEISS CONTURA G2), surface profilometer, optical comparator |

| Quality Standards | ISO 9001:2015, GD&T (ASME Y14.5) |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous quality control to deliver reliable, repeatable results for high-end 3D mold manufacturing. Our technical expertise ensures that every component meets the demanding performance requirements of modern industrial applications.

Material & Finish Options

Material Selection for High-Performance 3D Molds: Precision Engineering Fundamentals

Selecting the optimal material for complex 3D molds is a critical engineering decision directly impacting tool longevity, part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, our CNC expertise ensures material properties align precisely with your application’s thermal, mechanical, and surface finish demands. This guide outlines key considerations for aluminum, steel, and titanium alloys, alongside essential anodizing processes for enhanced performance.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping and low-to-medium volume production. Their high thermal conductivity accelerates cycle times, while lower density reduces machine load and energy consumption. Aluminum machines rapidly, lowering initial tooling costs. However, inherent lower hardness and wear resistance compared to steel limit use in high-volume or abrasive material molding. Surface treatments like hard anodizing are often essential to extend service life in these scenarios.

Tool steels, such as P20, H13, and S136, are the industry standard for high-volume, high-precision 3D molds requiring exceptional durability and dimensional stability. These alloys provide superior hardness, wear resistance, and resistance to thermal fatigue under repeated heating and cooling cycles. H13 excels in applications involving significant thermal cycling, while corrosion-resistant grades like S136 are vital for molding PVC or other corrosive polymers. The higher initial machining cost is typically offset by vastly extended tool life in demanding production environments.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), serve highly specialized applications demanding extreme strength-to-weight ratio, exceptional corrosion resistance, or biocompatibility, such as in aerospace or medical device molding. While offering outstanding performance in niche areas, titanium presents significant machining challenges due to low thermal conductivity and high reactivity, requiring specialized CNC processes and significantly higher costs. Its use is generally justified only when material properties are non-negotiable.

Anodizing, specifically Type III (Hardcoat) anodizing, is a vital surface enhancement for aluminum molds. This electrochemical process creates a dense, wear-resistant aluminum oxide layer integral to the substrate. Hard anodizing dramatically improves surface hardness (up to 600 HV), abrasion resistance, and corrosion protection, effectively bridging the performance gap between aluminum and steel for many applications. It also provides excellent electrical insulation and reduces galling. Proper sealing is crucial for maximizing corrosion resistance in demanding environments.

Material performance characteristics must be evaluated rigorously. The following table summarizes key properties relevant to 3D mold construction:

| Material | Typical Hardness (HRC/HB) | Thermal Conductivity (W/m·K) | Key Advantages | Primary Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 150 HB | 130 | Fast machining, high thermal conductivity, lightweight | Prototyping, low-volume production |

| Tool Steel H13 | 48-52 HRC | 35 | High hot hardness, thermal fatigue resistance, toughness | High-volume injection molding |

| Tool Steel S136 | 50-52 HRC | 28 | Superior corrosion resistance, polishability | Corrosive polymer molding |

| Titanium Ti-6Al-4V | 36 HRC | 7 | Extreme strength-to-weight, biocompatibility, corrosion resistance | Aerospace, medical implants |

Material selection is not merely a cost exercise; it is an engineering investment in process stability and part quality. Wuxi Lead Precision Machinery leverages decades of CNC machining experience and material science knowledge to recommend and fabricate molds using the optimal material and surface treatment for your specific 3D geometry and production requirements. Contact our engineering team to discuss how precise material selection can enhance your mold performance and ROI.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the journey of a 3D mold begins with a meticulously engineered design phase, where accuracy and functionality converge. Our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models using advanced software such as Siemens NX, SolidWorks, and Autodesk PowerShape. Finite Element Analysis (FEA) is integrated early to simulate thermal distribution, stress points, and material flow, ensuring optimal mold performance under real-world production conditions. Every geometric feature, cooling channel, and ejection mechanism is optimized for longevity, dimensional stability, and cycle efficiency. This phase culminates in a comprehensive digital twin of the mold, validated through internal design reviews and client approval, setting the benchmark for zero-defect manufacturing.

Prototyping: Validating Performance Before Scale

Following design finalization, we proceed to prototype development—a critical checkpoint in our zero-defect strategy. Utilizing high-speed CNC machining centers with sub-micron accuracy, we fabricate prototype molds from pre-hardened tool steels or aluminum alloys, depending on the application. These prototypes undergo rigorous functional testing, including trial runs on client-specified molding machines to verify part geometry, surface finish, and cycle time. Any deviations are captured through automated inspection using coordinate measuring machines (CMM) and 3D laser scanning, enabling rapid design corrections. This iterative validation ensures that mold behavior in early production mirrors final performance, eliminating costly errors during mass manufacturing.

Mass Production: Consistency Through Advanced Manufacturing

With prototype approval, we transition to full-scale production using a fully controlled, ISO 9001-certified manufacturing process. Our facility in Wuxi integrates multi-axis CNC machining, wire EDM, and surface grinding technologies, all monitored in real time via IoT-enabled systems to maintain tolerances as tight as ±0.002 mm. Each mold component is traceable through a digital production log, recording machine parameters, inspection data, and operator inputs. Quality assurance is enforced through a tiered inspection protocol: in-process checks, first-article inspection, and final validation against the original CAD model. Surface treatments such as PVD coating or nitriding are applied as required to enhance wear resistance and release properties.

Throughout the entire workflow, our zero-defect philosophy is upheld by statistical process control (SPC), preventive maintenance schedules, and continuous operator training. This systematic approach ensures every 3D mold delivered meets the highest standards of precision, durability, and repeatability.

Typical Mold Specifications at Wuxi Lead Precision Machinery

| Parameter | Specification Range |

|---|---|

| Material Options | P20, 718H, H13, S136, NAK80, 420SS |

| Tolerance | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (mirror to matte) |

| Maximum Mold Size | 2000 mm × 1500 mm × 1200 mm |

| Production Lead Time | 25–45 days (depending on complexity) |

| Quality Standards | ISO 9001:2015, VDA 6.3, PPAP Level 3 |

| Machining Equipment | 5-axis CNC, Wire EDM, CMM, Laser Scanner |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising 3D Mold Excellence

In the demanding realm of high-precision 3D mold manufacturing, tolerances measured in microns dictate success. Generic solutions introduce unacceptable risk to your production integrity and time-to-market. Wuxi Lead Precision Machinery transcends standard contract manufacturing by integrating deep metallurgical expertise with advanced multi-axis CNC capabilities. We engineer molds that deliver consistent, zero-defect production runs—critical for aerospace components, medical devices, and complex consumer electronics. Our facility operates under stringent AS9100 and ISO 9001 frameworks, ensuring every electrode, cavity, and core meets the exact thermal, wear, and dimensional requirements of your application. Partnering with us means eliminating costly rework cycles and securing a single-source advantage from initial design validation through volume production.

Our technical capacity is built on purpose-configured equipment and process rigor validated across 12,000+ mold projects. Below are core specifications defining our 3D mold execution capability:

| Parameter | Capability | Relevance to Your Project |

|---|---|---|

| Positional Tolerance | ±0.001 mm | Ensures perfect part alignment in multi-cavity molds |

| Surface Finish | Ra 0.05 µm (mirror grade) | Critical for optical clarity and ejection performance |

| Material Range | P20, H13, S136, Maraging Steel, CuW | Tailored thermal conductivity and wear resistance |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates large, complex automotive and industrial molds |

| Lead Time Reduction | 22% vs. industry average | Accelerates your prototyping to production timeline |

This precision is sustained through our closed-loop manufacturing ecosystem. Every mold undergoes in-process CMM verification against 3D CAD models, with real-time thermal compensation algorithms correcting for material behavior during machining. Our engineering team collaborates directly with your designers during DFM analysis—identifying potential sink marks, weld lines, or cooling inefficiencies before metal is cut. This proactive partnership prevents $200k+ in downstream tooling modifications typical with reactive suppliers. For projects requiring rapid iteration, our 72-hour prototype program delivers functional test molds with production-intent materials, compressing development cycles by 40%.

The true differentiator lies in our commitment to your operational continuity. We maintain dedicated production cells for long-term programs, with full material traceability and bi-annual preventive maintenance on all critical assets. When your high-volume line depends on mold performance, our 99.2% uptime guarantee becomes your competitive safeguard. This level of accountability is why global Tier 1 suppliers trust Lead Precision for molds operating 24/7 in harsh production environments.

Initiate your next 3D mold project with engineering certainty. Contact our technical sales team at [email protected] to schedule a confidential consultation. Include your CAD file or project specifications for a detailed capability assessment within 24 business hours. We will outline precise machining strategies, material optimization pathways, and a validated timeline—no generic quotations. For urgent requirements, reference priority code LP-MOLD-2024 when emailing. Your path to defect-free molding starts with a single, precise action.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.