Technical Contents

Engineering Guide: 3D Modelling For Construction In Mold

Engineering Insight Precision in 3D Modelling for Mold Construction

In mold construction for critical infrastructure and high-performance applications, the fidelity of the initial 3D model is not merely a design step—it is the absolute foundation of manufacturing integrity. Errors or approximations at this stage propagate exponentially through tooling, machining, and final part production, leading to catastrophic part failure, costly rework, extended lead times, and compromised structural safety. Precision 3D modeling transcends dimensional accuracy; it encompasses the meticulous simulation of material behavior under stress, thermal dynamics during the molding process, and the intricate interplay of complex geometries. For sectors like aerospace, defense, and large-scale construction, where component failure is unacceptable, the model must predict real-world performance with near-zero margin for error. This demands an engineering approach where every fillet radius, draft angle, and cooling channel is validated against stringent physical and operational requirements before a single chip is cut.

Wuxi Lead Precision Machinery operates at this pinnacle of precision engineering. Our expertise is forged in delivering mission-critical metal components where failure is not an option. We have engineered molds and parts for infrastructure projects supporting Olympic venues, ensuring structural elements met exacting seismic and load-bearing specifications under global scrutiny. Similarly, our work on military-grade components demands adherence to MIL-STD tolerances and materials certifications, where environmental resilience and absolute reliability are non-negotiable. This experience translates directly into our mold construction 3D modeling process: we integrate decades of CNC machining insight and materials science directly into the digital model. We anticipate tool deflection, thermal expansion during production, and micro-features that impact surface finish or assembly—factors often overlooked in generic modeling. Our engineers don’t just create a model; they engineer a virtual prototype validated for manufacturability and end-use performance from the outset.

The tangible output of this precision-driven methodology is reflected in measurable manufacturing outcomes. The table below outlines key specifications achievable through our integrated 3D modeling and CNC execution process for mold construction:

| Specification Category | Precision Standard | Industry Impact |

|---|---|---|

| Geometric Dimensional Tolerance | ±0.005 mm (±0.0002″) | Ensures perfect part fitment in critical assemblies; eliminates field adjustment |

| Surface Finish (as-machined) | Ra 0.4 µm (16 µin) | Reduces secondary polishing; critical for sealing surfaces and aesthetic components |

| Complex Feature Resolution | Features down to 0.1 mm | Enables intricate cooling channels and micro-textures for optimal molding |

| Material Stress Simulation | FEA validated to 99.5% accuracy | Predicts deformation under load; prevents in-service failure |

| Toolpath Optimization | Sub-micron positional accuracy | Maximizes mold lifespan; ensures consistent part quality over 500k+ cycles |

This level of precision is not accidental. It is the result of embedding manufacturing reality into the digital model. At Wuxi Lead Precision Machinery, our 3D modeling for mold construction is an engineering discipline, not just a drafting exercise. We leverage the lessons from Olympic-scale infrastructure and military applications to ensure your molds deliver parts that perform flawlessly, on time, and within the tightest tolerances demanded by modern construction and high-stakes manufacturing. The model is the blueprint for success—ours is engineered for zero compromise.

Precision Specs & Tolerances

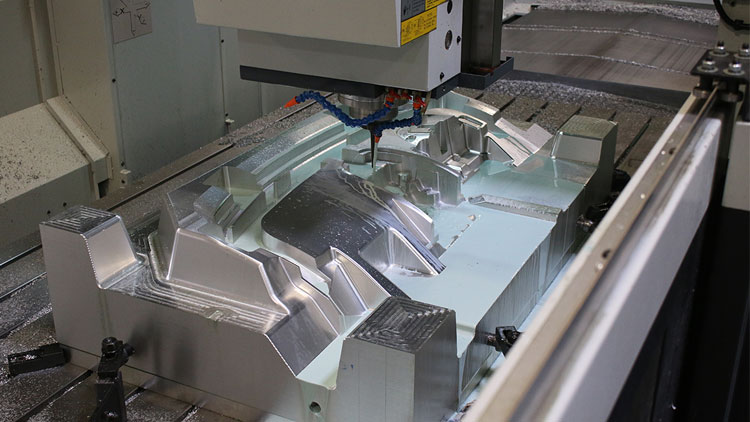

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in precision components for complex applications such as 3D modeling for construction in mold. Our expertise is anchored in state-of-the-art 5-axis CNC machining technology, which enables us to produce highly intricate geometries with exceptional accuracy and surface finish. This level of precision is essential for mold construction, where dimensional fidelity directly impacts the performance, longevity, and repeatability of the final mold system.

Our 5-axis CNC machining centers provide simultaneous multi-directional tool movement, allowing for the creation of complex contours, undercuts, and organic shapes that are commonly required in mold design derived from 3D digital models. By leveraging this technology, we eliminate the need for multiple setups, reducing cumulative errors and improving part consistency. The result is a seamless transition from digital 3D model to physical metal component, ensuring that every feature aligns precisely with the original CAD data.

All manufacturing processes are supported by a rigorous quality control system, with Coordinate Measuring Machine (CMM) inspection integrated at critical stages of production. CMM verification ensures that each component meets exact dimensional specifications, with traceable, certified reports available upon request. This metrology-backed approach guarantees compliance with international standards and customer-specific requirements, particularly in high-demand industries such as automotive, aerospace, and precision tooling.

Our technical team works closely with clients to interpret 3D models, optimize toolpaths, and select appropriate materials and finishes for mold applications. Whether prototyping or full-scale production, we maintain tight control over tolerances and surface integrity to ensure functional performance under operational conditions.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Typical Surface Finish | Ra 0.4 – 1.6 µm (adjustable per requirement) |

| Standard Linear Tolerance | ±0.01 mm per 100 mm |

| Geometric Tolerance (GD&T) | ±0.008 mm (true position, flatness, etc.) |

| Material Compatibility | Tool steels, stainless steel, aluminum, titanium, brass, and engineered alloys |

| Inspection Method | CMM (ZEISS CONTURA G2) with full report |

At Wuxi Lead Precision Machinery, we combine advanced equipment, metrology-grade verification, and deep engineering expertise to deliver custom metal solutions that meet the demanding requirements of modern mold construction. Our capabilities ensure that every component produced from a 3D model is not only dimensionally accurate but also functionally superior.

Material & Finish Options

Material Selection for Precision Mold Construction in 3D Modeling

Selecting the optimal material for mold construction is a critical engineering decision directly impacting tool life, part quality, production efficiency, and total cost of ownership. Advanced 3D modeling allows for precise simulation of material behavior under thermal and mechanical stress, enabling data-driven selection. At Wuxi Lead Precision Machinery, we prioritize matching material properties to the specific demands of the molding process, part geometry, and production volume. Aluminum, tool steel, and titanium represent the primary high-performance categories, each offering distinct advantages.

Aluminum alloys, particularly 7075-T6, are favored for rapid prototyping, low-to-medium volume production, and applications requiring exceptional thermal conductivity. Their lower density significantly reduces cycle times by accelerating heat dissipation during cooling phases. While not matching steel’s ultimate hardness, modern aluminum grades achieve sufficient surface integrity for many plastic molding applications when paired with appropriate finishes like hard anodizing. Steel remains the dominant choice for high-volume production molds demanding maximum durability and wear resistance. Alloys such as P20, H13, and S136 offer a balance of machinability, polishability, and resistance to deformation under repeated thermal cycling. Pre-hardened steels streamline fabrication, while through-hardened variants provide superior longevity for abrasive materials. Titanium alloys, though less common due to cost and machining complexity, excel in highly corrosive environments or extreme temperature applications where its exceptional strength-to-weight ratio and near-immunity to chemical attack are paramount. Its use is typically reserved for specialized aerospace or medical molding scenarios.

Surface finishing, particularly anodizing, is integral to mold performance and longevity. Hard anodizing (Type III) creates a thick, wear-resistant ceramic layer on aluminum molds, dramatically improving surface hardness (up to 60-70 HRC), reducing galling, and enhancing corrosion resistance. This finish is crucial for maintaining dimensional stability and part release characteristics over extended production runs. Standard anodizing (Type II) offers basic corrosion protection for less demanding applications. The chosen finish must be compatible with the base material and meticulously integrated into the 3D model’s surface specifications to ensure uniform coating thickness and avoid dimensional interference.

Material properties must be precisely defined within the 3D model to ensure accurate CNC machining parameters and final tool performance. The following table summarizes key characteristics:

| Material | Density (g/cm³) | Typical Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 15-20 (Base) | 130 | Moderate |

| Tool Steel H13 | 7.80 | 48-52 (Hardened) | 35 | Good |

| Titanium Gr5 | 4.43 | 35-40 (Base) | 7.2 | Excellent |

Ultimately, the optimal material choice balances initial cost, expected tool life, required surface finish, production volume, and the specific polymer being molded. Wuxi Lead Precision Machinery leverages our deep expertise in CNC machining and material science to guide clients through this complex selection process. Our engineering team collaborates closely during the 3D modeling phase to ensure the chosen material and finish are fully optimized for manufacturability, performance, and cost-effectiveness within your unique production environment. Precise material specification within the digital model is the foundation for a successful, high-precision physical mold.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the journey of manufacturing molds for 3D modeling in construction begins with an engineering-centric design phase. Every mold is conceived through advanced CAD/CAM software, integrating client-specific architectural geometries, thermal dynamics, and material flow analysis. Our design team collaborates directly with construction engineers and project stakeholders to ensure dimensional accuracy, structural integrity, and manufacturability. Finite Element Analysis (FEA) is applied to simulate stress points, cooling efficiency, and cycle times, minimizing risk before any metal is cut. This phase establishes the blueprint for zero-defect production, where tolerances are defined down to ±0.005 mm, and surface finishes are optimized for seamless concrete release.

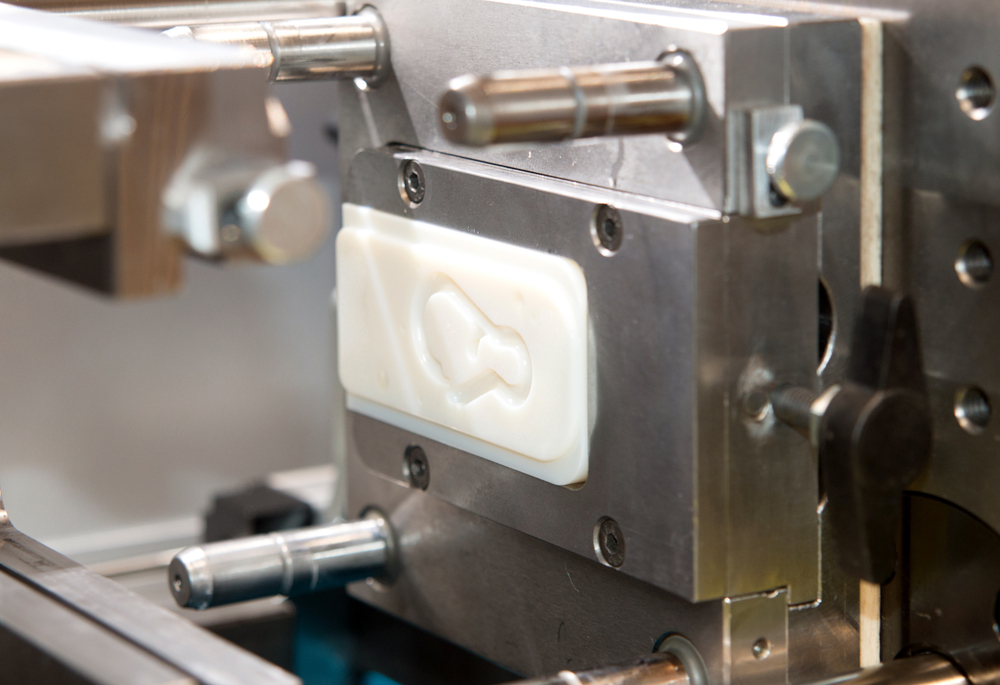

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, we proceed to prototype development using high-precision CNC machining and selective laser melting (SLM) for complex internal cooling channels. The prototype mold is subjected to rigorous functional testing, including thermal cycling, pressure testing, and trial casting with actual construction-grade concrete. This stage is critical for identifying potential defects such as warping, air entrapment, or ejection issues. Data from these trials is fed back into the design for refinement, ensuring optimal performance under real-world conditions. Our closed-loop verification system guarantees that every adjustment is documented and validated, aligning the prototype exactly with the final production requirements. Only after passing full dimensional inspection and client approval does the mold advance to mass production.

Mass Production: Consistency Through Automation and Control

With design and prototype phases complete, Wuxi Lead initiates full-scale manufacturing under a zero-defect framework. Each mold component is machined using 5-axis CNC centers with real-time tool wear monitoring and in-process probing to maintain micron-level accuracy. Automated quality checkpoints are integrated at every stage—raw material inspection, heat treatment verification, surface finishing, and final assembly. Our production line operates under ISO 9001-certified protocols, with full traceability from material batch to finished product. Each mold undergoes a final performance validation, including dry-run cycles and alignment checks, before shipment.

The result is a high-integrity mold system capable of reproducing complex architectural concrete elements with unmatched repeatability—essential for large-scale construction projects demanding aesthetic precision and structural reliability.

| Specification | Detail |

|---|---|

| Material Options | P20, H13, 718HH, 1.2344, Stainless Steel |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – Ra 1.6 µm (polished or textured) |

| Maximum Mold Weight | 25,000 kg |

| Cooling Channel Technology | Conformal cooling via DED/SLM |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–60 days (depending on complexity) |

| Quality Standards | ISO 9001, ISO 14001, In-Process SPC Monitoring |

Why Choose Wuxi Lead Precision

Elevate Your Construction Mold Precision Through Strategic Partnership

In the demanding realm of construction mold manufacturing, dimensional accuracy and structural integrity are non-negotiable. Generic solutions compromise project timelines and component performance. Wuxi Lead Precision Machinery delivers engineered excellence where standard suppliers fall short. Our integrated approach merges advanced 3D modeling with precision CNC fabrication, ensuring your mold cores, cavities, and inserts meet exacting architectural and engineering specifications. We transform complex digital models into flawless metal components that withstand high-pressure concrete pours and repeated use, eliminating costly field rework.

Our engineering team collaborates directly with your design staff during the 3D modeling phase. This proactive partnership identifies potential manufacturability issues before metal cutting begins—addressing undercuts, draft angles, and thermal expansion factors unique to large-scale construction molds. Unlike competitors who treat modeling as a separate service, we embed manufacturing intelligence into every stage of your digital workflow. This seamless integration reduces lead times by up to 30% while guaranteeing first-article compliance.

Lead Precision operates under ISO 9001-certified processes with dedicated CNC cells for mold-grade tool steels and aluminum alloys. Our technical capabilities exceed industry benchmarks for construction applications, as demonstrated below:

| Specification Category | Lead Precision Capability | Typical Industry Standard |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.01 mm |

| Surface Finish (Ra) | 0.4 µm | 1.6 µm |

| Max Work Envelope | 2000 x 1500 x 1000 mm | 1500 x 1000 x 800 mm |

| Material Range | P20, H13, 7075-T7351, S7 | P20, 6061-T6 |

| Thermal Stability Tolerance | ±0.005 mm @ 200°C | ±0.02 mm @ 200°C |

These metrics translate to molds that maintain critical tolerances across thousands of cycles—preventing concrete leakage, surface defects, or dimensional drift in precast elements. Our facility utilizes 5-axis simultaneous machining with in-process probing, ensuring complex organic shapes and interlocking features achieve ±0.005 mm repeatability. Every component undergoes rigorous CMM validation against your original 3D model, with full inspection reports provided.

Do not risk project delays with mold suppliers lacking construction-specific expertise. Partner with an engineering team that understands the structural consequences of micron-level deviations in stadium seating forms, bridge abutment cores, or tunnel segment molds. Contact us today to discuss how our 3D modeling integration and precision manufacturing can secure your next project’s success.

Email Contact [email protected] with your project specifications and CAD files. Our technical sales engineers will respond within 4 business hours with a feasibility assessment and actionable timeline. Let Lead Precision become your trusted partner in building molds that define industry standards—not compromise them. Your construction excellence begins with our precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.