Technical Contents

Engineering Guide: 3D Mini Printing Service

Engineering Insight Precision in Miniature Metal Additive Manufacturing

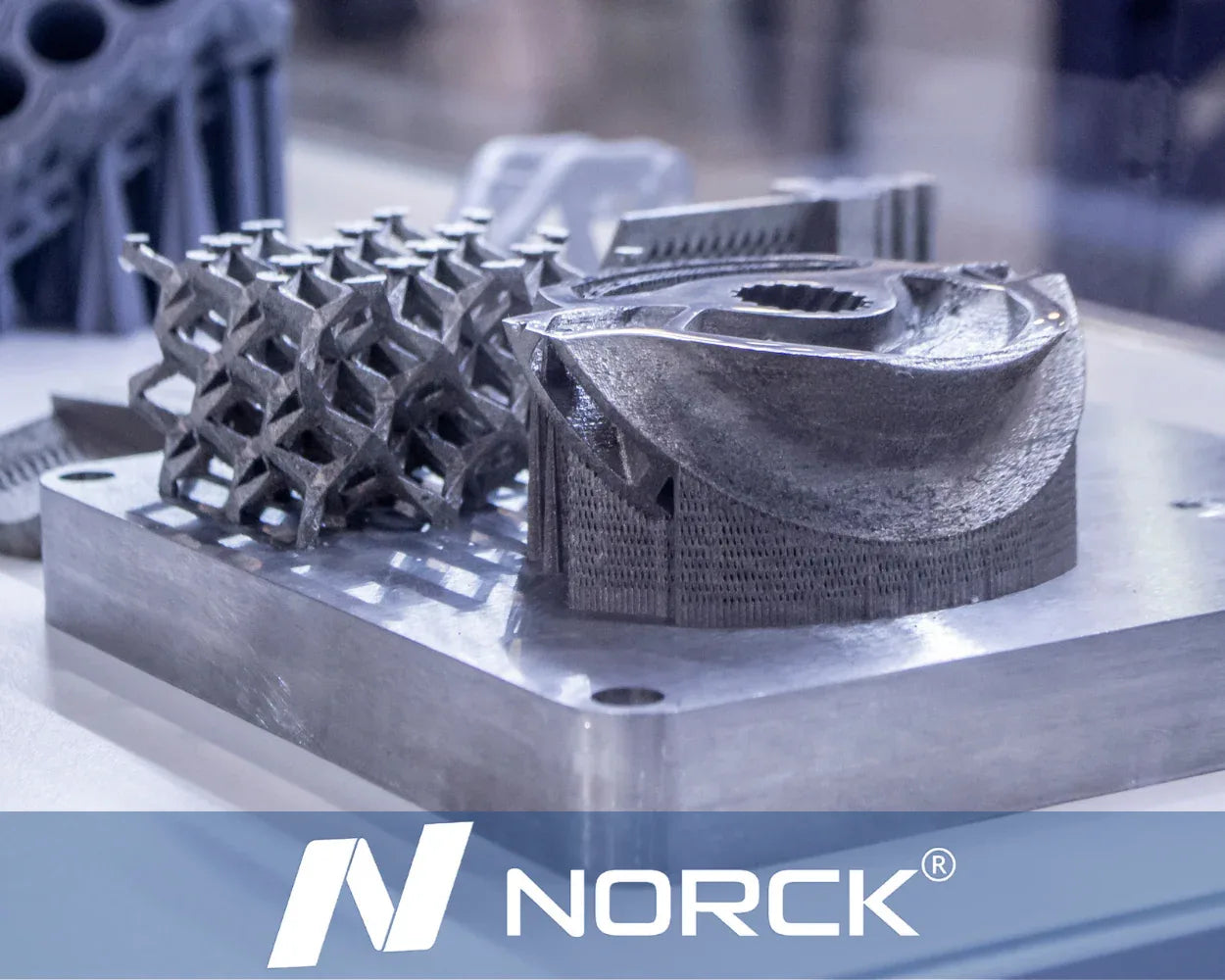

The emergence of 3D mini printing services for metal components represents a paradigm shift in high-value manufacturing, yet its true potential is unlocked only through uncompromising precision. Miniaturized parts—common in aerospace actuators, medical implants, and defense micro-sensors—demand tolerances often tighter than ±5μm. At this scale, thermal distortion during laser melting, powder particle inconsistency, or even microscopic layer adhesion flaws can trigger catastrophic functional failure. Conventional additive processes frequently struggle with dimensional stability below 10mm feature sizes, where surface-area-to-volume ratios amplify residual stress. Achieving repeatability here requires closed-loop monitoring of melt pool dynamics, inert gas purity control to 99.999%, and post-processing calibrated to sub-micron levels. Without this rigor, miniaturization sacrifices reliability for novelty.

Wuxi Lead Precision Machinery has engineered its metal mini printing service specifically for mission-critical applications where failure is not an option. Our systems integrate dual high-resolution 500W fiber lasers with real-time thermal imaging feedback, enabling layer thickness control down to 0.02mm. This capability stems from direct experience delivering components for the Beijing Winter Olympics’ cryogenic sensor arrays and classified military communication modules requiring RF shielding integrity at 0.1mm wall thicknesses. These projects demanded not just dimensional accuracy but material homogeneity meeting ASTM F136 for biocompatibility and AMS 7255 for aerospace fatigue resistance—standards we treat as baseline requirements.

Our process excellence is validated through independent metrology: every build undergoes CT scanning to verify internal lattice structures and 5-axis CMM validation against GD&T callouts. This discipline ensures that a 3mm turbine blade root or a 2mm orthopedic screw anchor performs identically across 1,000 units. The table below outlines core specifications achievable with our industrial-grade mini printing platform:

| Parameter | Specification | Application Impact |

|---|---|---|

| Minimum Feature Size | 0.15 mm | Enables micro-fluidic channels & sensor ports |

| Layer Thickness | 0.02–0.05 mm | Eliminates post-machining for critical surfaces |

| Dimensional Accuracy | ±5 μm per 10 mm | Meets MIL-STD-810G vibration tolerance |

| Surface Roughness (as-built) | Ra 3.2–6.3 μm | Reduces polishing time by 70% vs. competitors |

| Material Density | >99.95% | Achieves forged-equivalent mechanical properties |

Precision in mini metal printing transcends technical specs—it is a commitment to understanding the operational lifecycle of each component. Whether supporting satellite deployment mechanisms or next-generation endoscopic tools, we treat every micron as a functional requirement, not a statistical target. Our Olympic and defense heritage instills a culture where traceability, material certification, and failure mode analysis are non-negotiable. For engineers designing at the edge of possibility, this level of accountability transforms additive potential into deployable reality. Contact our engineering team to discuss how precision mini printing can solve your most constrained design challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the evolving demands of high-precision industries. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-integrity components with exceptional accuracy and surface finish. This advanced machining technology allows for simultaneous multi-directional tool movement, reducing setup times and eliminating the need for multiple fixtures. As a result, we achieve superior geometric precision and consistency across both prototyping and full-scale production runs.

Our 5-axis CNC systems are optimized for a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, and hardened tool steels. These materials are frequently used in aerospace, medical devices, robotics, and precision instrumentation—sectors where component reliability and dimensional stability are non-negotiable. The flexibility of 5-axis machining enables us to produce intricate 3D contours, deep cavities, and undercuts that are unattainable with conventional 3- or 4-axis methods. This capability is particularly advantageous for miniaturized components required in compact, high-performance systems such as those used in micro-mechanical and 3D mini printing applications.

To ensure every component meets the most stringent quality standards, we employ a comprehensive quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D metrology verification, capturing detailed data on form, position, and dimensional conformity. Each part undergoes first-article inspection and batch sampling, with full traceability and inspection reports available upon request. This systematic approach to quality assurance guarantees that tolerances are consistently maintained and that all deliverables align precisely with customer engineering specifications.

Material selection, toolpath optimization, and in-process inspection are all managed through our integrated digital manufacturing environment. This ensures seamless transition from CAD/CAM design to finished part, minimizing variability and maximizing repeatability. Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase to optimize geometry, reduce lead times, and enhance performance without compromising on precision.

The following table outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machining services:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 800 mm × 500 mm × 400 mm |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance (Standard) | ±0.010 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Minimum Feature Size | 0.3 mm |

| Spindle Speed | Up to 24,000 RPM |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Inconel, Tool Steel, Brass |

| Inspection Equipment | Zeiss CMM, Optical Comparators, Micrometers, Calipers |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality control to deliver custom metal components that meet the highest standards of precision and reliability.

Material & Finish Options

Material Selection for Precision 3D Mini Metal Printing

Selecting the optimal material for 3D mini metal printing is critical for achieving the required performance, durability, and cost-efficiency in miniature components. At Wuxi Lead Precision Machinery, we understand that miniaturization intensifies challenges like thermal management, feature integrity, and surface finish. Aluminum alloys, stainless steels, and titanium each offer distinct advantages tailored to specific high-end applications in aerospace, medical devices, and micro-electromechanical systems (MEMS). The chosen material directly impacts printability, post-processing requirements, and final part functionality at microscopic scales.

Aluminum alloys, particularly AlSi10Mg, are preferred for lightweight structural components requiring excellent thermal conductivity and moderate strength. Their lower density reduces inertia in moving micro-parts, while good machinability facilitates secondary operations on delicate features. Aluminum is ideal for heat sinks, drone components, and non-critical housings where weight savings are paramount. However, pure aluminum lacks sufficient strength for high-stress miniaturized applications, necessitating alloy selection.

Stainless steels, especially 316L and 17-4 PH, deliver superior strength, hardness, and corrosion resistance essential for demanding miniature environments. 316L offers exceptional biocompatibility and chemical resistance, making it the standard for medical implants and fluidic micro-channels. 17-4 PH provides high strength through precipitation hardening, suitable for miniature gears, surgical tools, and aerospace actuators requiring wear resistance. Steel’s higher density and melting point increase printing complexity but yield robust, dimensionally stable micro-features.

Titanium (Ti6Al4V) is unmatched for high-strength-to-weight ratio and biocompatibility in critical applications. Its exceptional corrosion resistance and fatigue strength are vital for permanent medical implants and aerospace turbine blades at miniature scales. While titanium printing demands stringent inert atmosphere control and higher energy input, the resulting parts withstand extreme environments where failure is not an option. The material’s osseointegration properties are irreplaceable in dental and orthopedic micro-components.

Surface finishing, particularly anodizing for aluminum, is non-negotiable for mini parts. Hard anodizing creates a dense, wear-resistant oxide layer up to 50µm thick, crucial for protecting fragile micro-threads and sealing porous surfaces inherent in additive processes. This enhances corrosion resistance and provides electrical insulation for micro-electronics housings. Color anodizing also enables precise visual identification of miniature assemblies.

Material properties significantly influence miniaturization success. The following table summarizes key characteristics for informed selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Key Advantages for Mini Parts | Primary Applications |

|---|---|---|---|---|

| AlSi10Mg | 2.67 | 290-360 | Lightweight, excellent thermal conductivity, good machinability | Heat sinks, drone components, housings |

| 316L Stainless | 8.0 | 500-700 | Superior corrosion resistance, biocompatibility | Medical implants, micro-fluidics |

| 17-4 PH Steel | 7.8 | 1000-1300 | High strength, wear resistance, precipitation hardenable | Miniature gears, surgical tools |

| Ti6Al4V | 4.43 | 900-1100 | Highest strength-to-weight, biocompatibility, corrosion resistance | Aerospace blades, permanent medical implants |

Wuxi Lead Precision Machinery leverages advanced laser powder bed fusion and stringent process controls to print these materials with micron-level accuracy. Our engineering team collaborates closely with clients to match material properties and finishing requirements to the exact functional demands of your miniature component, ensuring reliability where precision matters most. Consult our specialists to optimize your material strategy for miniaturized metal additive manufacturing.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the production process for our 3D mini printing service begins with an engineered approach to design. Every custom metal component is first analyzed through advanced CAD/CAM software to ensure dimensional accuracy, structural integrity, and manufacturability. Our engineering team collaborates directly with clients to refine geometries, optimize material usage, and validate thermal and mechanical performance under real-world conditions. This phase integrates Design for Additive Manufacturing (DfAM) principles, enabling complex internal structures and lightweighting without sacrificing strength. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are routinely applied to preempt failure modes and ensure compliance with industry-specific standards such as ISO 13485, AS9100, or IATF 16949 where applicable.

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, we proceed to rapid prototyping using high-precision metal 3D printing technologies, primarily selective laser melting (SLM) and direct metal laser sintering (DMLS). These processes allow us to produce fully dense, functional prototypes in materials such as titanium Ti6Al4V, stainless steel 316L, Inconel 718, and aluminum AlSi10Mg. Each prototype undergoes rigorous metrological verification using coordinate measuring machines (CMM), optical scanning, and micro-CT inspection to confirm conformance to tolerances down to ±0.02 mm. Iterative feedback loops with the client ensure that fit, form, and function are validated before transitioning to mass production. This stage not only reduces time-to-market but also mitigates risks associated with design flaws or material incompatibility.

Mass Production: Scalable Precision with Zero Defects

Our transition to mass production is governed by a zero-defect manufacturing philosophy. Each build is executed on calibrated industrial-grade metal 3D printers with real-time melt pool monitoring and inert gas control to ensure repeatability and material consistency. Post-processing—including stress relieving, hot isostatic pressing (HIP), precision machining, and surface finishing—is performed in-house under controlled environments to meet stringent surface roughness and geometric requirements. Every component undergoes 100% inspection using automated optical systems and non-destructive testing (NDT) methods such as ultrasonic or X-ray inspection. Traceability is maintained through laser marking and digital batch records, enabling full audit trails from raw material to final shipment.

Process Specifications

| Parameter | Capability |

|---|---|

| Minimum Feature Size | 0.2 mm |

| Layer Thickness | 20–50 μm |

| Standard Tolerance | ±0.02 mm per 100 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Max Build Volume | 250 x 250 x 325 mm |

| Materials Available | Ti6Al4V, 316L, Inconel 718, AlSi10Mg, CoCr, Maraging Steel |

| Post-Processing Options | CNC Machining, Polishing, Passivation, HIP, Coating |

Through seamless integration of design intelligence, prototyping agility, and disciplined mass production, Wuxi Lead delivers mission-critical metal components with uncompromising quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Miniature Metal Components

Achieving flawless performance in miniature metal components demands more than standard manufacturing capabilities. For applications in aerospace, medical devices, micro-optics, and advanced electronics, tolerances measured in microns and material integrity at microscopic scales are non-negotiable. Wuxi Lead Precision Machinery specializes in the exacting science of custom metal additive manufacturing for miniaturized parts, transforming complex design challenges into reliable, high-performance realities. Our dedicated 3D mini printing service leverages cutting-edge Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) platforms, engineered specifically for the unique thermal dynamics and precision requirements of small-scale production. We move beyond basic prototyping to deliver end-use parts where dimensional stability, material homogeneity, and surface integrity directly impact system functionality and safety.

Our engineering-driven approach integrates deep metallurgical expertise with rigorous process control. Every build undergoes meticulous parameter optimization tailored to your specific alloy and geometric complexity, ensuring minimal residual stress and optimal microstructure. We excel in processing demanding aerospace and medical-grade materials including Titanium Ti6Al4V, Inconel 718, Stainless Steel 17-4 PH, and Cobalt-Chrome alloys. Critical to miniaturization is our mastery of support structure design and removal – a significant challenge at small scales – combined with proprietary post-processing techniques to achieve surface finishes and dimensional accuracy unattainable through conventional methods alone. Partnering with Lead Precision means accessing a certified manufacturing ecosystem designed for zero-defect delivery in low-to-medium volume production runs.

Technical Capabilities for Miniature Metal Additive Manufacturing

| Specification | Capability Detail |

|---|---|

| Primary Processes | DMLS, SLM |

| Material Range | Ti6Al4V, Inconel 718, 17-4 PH, CoCr, AlSi10Mg |

| Typical Build Volume | 50 x 50 x 50 mm to 100 x 100 x 100 mm |

| Standard Accuracy | ± 0.02 mm for features < 5 mm |

| Surface Finish (As-Built) | Ra 8 – 12 μm; Ra 0.8 – 1.6 μm achievable with finishing |

| Minimum Feature Size | 0.15 mm (wall thickness/hole diameter) |

| Certifications | ISO 9001:2015, ITAR Registered |

The true value of precision miniature manufacturing lies not just in the print, but in the guaranteed performance of the final component within your assembly. Our integrated workflow includes comprehensive metrology using high-resolution CT scanning and CMM verification, stringent material traceability, and full documentation compliant with AS9100 and medical device standards. We collaborate as an extension of your engineering team from initial design feasibility through to serial production, providing actionable data to optimize for manufacturability and performance. When failure is not an option for components measuring millimeters, settle for nothing less than engineered precision.

Initiate your next high-stakes miniature metal project with confidence. Contact our engineering team directly at [email protected] to discuss your specific requirements, material needs, and quality expectations. Provide your design files for a rapid manufacturability assessment and a detailed quotation reflecting our commitment to precision, reliability, and technical partnership. Wuxi Lead Precision Machinery – where microscopic details define macroscopic success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.