Technical Contents

Engineering Guide: 3D Mini Printing Service

Engineering Insight: 3D Mini Printing Service

Zero Defects Commitment: The Non-Negotiable Standard

At Wuxi Lead Precision Machinery, “Zero Defects” is not a marketing claim—it is the cornerstone of our ISO 9001:2015-certified quality system. Every component undergoes 100% traceable material verification (ASTM F3001 for metals, UL94 for engineering plastics) and multi-stage inspection protocols, including coordinate measuring machines (CMM), X-ray tomography, and metallurgical analysis. Unlike standard service providers, we enforce Statistical Process Control (SPC) to maintain dimensional stability within ±0.01mm of target tolerances across all production runs. This rigorous approach ensures compliance with AS9100 and ISO 13485 standards, eliminating microscopic defects before delivery and guaranteeing mission-critical reliability.

Proven Excellence in High-Stakes Applications

Our components power systems where failure is not an option. For the 2022 Beijing Winter Olympics, we delivered titanium alloy timing mechanism parts with ±0.02mm dimensional accuracy across 500+ units, maintaining 100% traceability from raw billet to final assembly. In military applications, our UAV propulsion system components have operated for 10,000+ hours under MIL-STD-810H environmental stress tests with zero field failures. These projects validate our ability to meet the most stringent requirements for aerospace, defense, and sports technology—where precision and material integrity directly impact human safety and operational success.

Precision Standards: Measured Excellence

| Parameter | Industry Standard | Wuxi Lead Precision | Critical Impact |

|---|---|---|---|

| Dimensional Tolerance (SLM/DMLS) | ±0.1mm | ±0.05mm | Ensures perfect fit in tight-tolerance assemblies (e.g., hydraulic systems, medical implants) |

| Surface Roughness (Ra) | 10–20 μm | ≤5 μm | Reduces wear in moving parts, critical for longevity in high-cycle applications |

| Material Traceability | Basic ISO 9001 | Full ASTM/EN 10204 3.1 certification | Mandatory for aerospace, defense, and medical regulatory compliance |

| Defect Rate | 1–5% | 0% (Zero Defects Guarantee) | Eliminates costly recalls, field failures, and production delays |

Partner, Not Just Supplier: 24/7 Engineering Support

We operate as your dedicated technical ally, not a passive vendor. Our China-based engineering team provides:

Real-time design feedback during prototyping to optimize for manufacturability and performance

4-hour response time for urgent revisions or technical queries

On-demand material test reports with full chemical composition and mechanical properties data

End-to-end project visibility through our cloud-based QA portal (accessible 24/7)

Whether you’re developing a prototype or scaling to full production, our commitment to precision and collaboration ensures your project stays on schedule—without compromise. Contact us today to discuss your mission-critical requirements.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, our “3D Mini Printing Service” redefines precision manufacturing for miniature components through advanced CNC machining technology. Unlike conventional additive processes, our subtractive approach ensures superior surface finish, dimensional accuracy, and material integrity for mission-critical aerospace, medical, and industrial applications. Every project is executed under ISO 9001:2015 standards, with material certifications and zero-defect protocols as standard practice.

Precision CNC Machining Platform

State-of-the-art 3/4/5-axis CNC machining centers equipped with high-precision spindles (up to 24,000 RPM) and automated tool changers enable us to manufacture complex geometries with micron-level accuracy. Our machines support a wide range of materials including aerospace-grade aluminum, titanium alloys, stainless steels, and engineering plastics such as PEEK and PTFE, ensuring optimal performance for your most demanding applications.

Tolerance Standards & Performance

We maintain rigorous tolerance standards across all production stages, with precision capabilities tailored to your design requirements. Below are our standard and precision tolerance specifications:

| Feature Category | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | ±0.05mm | ±0.01mm |

| Hole Diameter | ±0.03mm | ±0.005mm |

| Flatness | 0.02mm | 0.005mm |

| Surface Finish (Ra) | 1.6μm | 0.8μm |

Note: Tighter tolerances available upon engineering review for specialized applications.

Quality Assurance & Material Integrity

Every component undergoes rigorous CMM inspection against ASME Y14.5 GD&T standards. Material certifications (e.g., Mill Test Reports, ISO 9001 traceability) are provided for all metal orders, with batch-specific documentation available upon request. Our quality system is certified to ISO 9001:2015, ensuring consistent adherence to international standards.

Zero Defects Commitment

Our Zero Defects commitment is operationalized through statistical process control (SPC) and real-time monitoring of critical parameters. Every production run includes 100% in-process inspection for key features, with automated vision systems detecting deviations before they escalate. This proactive approach eliminates defects at the source—ensuring 99.99% first-pass yield for all precision components. Olympic-grade quality standards are embedded in every process, guaranteeing reliability for critical applications.

24/7 Technical Partnership

As your engineering partner, we provide 24/7 technical support for design optimization, material selection, and production troubleshooting. Our dedicated project managers ensure seamless communication and rapid response—day or night—so your timelines stay on track. From initial concept to final delivery, we’re committed to being more than a supplier: we’re your strategic manufacturing ally.

Wuxi Lead Precision Machinery: Where precision engineering meets unwavering partnership.

ISO 9001:2015 Certified | Full Material Traceability | Zero-Defect Production Protocol

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Application

At Wuxi Lead Precision Machinery, we don’t just supply parts—we engineer solutions. As your trusted manufacturing partner, our Zero Defects commitment ensures every component meets ISO 9001 standards with full material traceability. Whether you’re prototyping or scaling production, our Olympic-level quality control and 24/7 customer support guarantee precision, reliability, and peace of mind.

Material Selection Framework

Selecting the right material is critical to balancing performance, cost, and manufacturability. Our ISO 9001-certified material sourcing and traceability ensure every choice aligns with your application’s exact requirements.

| Material Category | Material Name | Key Properties | Typical Applications | Cost Impact | Quality Assurance Notes |

|---|---|---|---|---|---|

| Metals | Aluminum 6061 | Tensile strength: 310 MPa; Density: 2.7 g/cm³; Excellent corrosion resistance, weldable | Aerospace components, automotive frames, structural parts | Low-Medium | ISO 9001-certified material traceability; 100% chemical composition verification; Zero Defects inspection protocol applied. |

| Metals | Stainless Steel 316 | Tensile strength: 500 MPa; Corrosion-resistant (marine-grade); Biocompatible | Medical implants, chemical processing equipment | Medium | Full material certification (ASTM F138); 24/7 QC monitoring; Zero Defects surface inspection. |

| Metals | Titanium Ti6Al4V | High strength-to-weight ratio; Biocompatible; Heat-resistant | Aerospace, medical implants, high-performance automotive | High | ISO 13485-compliant for medical; traceable batch records; Olympic-quality finish standard. |

| Metals | Inconel 718 | High-temperature strength; Corrosion-resistant | Jet engine components, oil & gas | Very High | Certified per AMS 5662; 100% non-destructive testing; Zero Defects process control. |

| Engineering Plastics | PEEK | High temp resistance (250°C); Chemical inertness; Wear-resistant | Medical implants, aerospace, automotive | High | ISO 9001-certified; traceable material batches; 24/7 quality monitoring. |

| Engineering Plastics | ABS | Toughness; Impact resistance; Easy to post-process | Consumer products, automotive interiors | Low | Material certification (UL 94 V-2); Zero Defects dimensional checks. |

| Engineering Plastics | Nylon 66 | Flexibility; Wear resistance; Low friction | Gears, bearings, functional prototypes | Medium | ISO 9001-compliant processing; 100% batch traceability. |

Surface Finishes & Performance Impact

Surface finishes enhance functionality, aesthetics, and longevity. Our 24/7 quality monitoring ensures every finish meets your specifications with Zero Defects precision.

| Finish Type | Suitable Materials | Performance Benefits | Cost Impact | Quality Assurance Notes |

|---|---|---|---|---|

| Anodizing | Aluminum alloys (6061, 7075) | Enhanced corrosion resistance, color options (up to 20), wear resistance | +15-25% | ISO 9001-certified process; 100% thickness verification (ASTM B244); Zero Defects visual inspection. |

| Electroplating (Nickel/Chrome) | Steel, Copper, Aluminum | Corrosion resistance, electrical conductivity, aesthetic finish | +30-40% | XRF thickness testing; ISO 9001-compliant QC; defect-free guarantee. |

| Mechanical Polishing | Stainless steel, Titanium, Aluminum | Mirror finish (Ra <0.05µm), reduced friction, aesthetic appeal | +35-50% | Laser profilometry verification; Olympic-quality standard; 24/7 monitoring. |

| Vapor Polishing | ABS, PC, Nylon | Optical clarity, smooth surface (Ra <0.2µm), reduced friction | +20-30% | Precision surface finish control; Zero Defects inspection; 24/7 QC support. |

Why Partner with Wuxi Lead?

Zero Defects Commitment: Every part undergoes 100% dimensional and visual inspection before shipment.

Olympic Quality: Certified to ISO 9001 with traceable material batches and process documentation.

24/7 Customer Service: Dedicated engineering support for urgent revisions, technical guidance, and real-time production tracking.

“We don’t manufacture parts—we build trust. From your first prototype to your final production run, our team ensures every detail meets your exact specifications.”

— Wuxi Lead Precision Machinery Quality Assurance Protocol

Contact our engineering team today for a free material and finish consultation — because precision shouldn’t wait.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

As your trusted manufacturing partner, Wuxi Lead Precision Machinery integrates seamlessly into your product development lifecycle. Our ISO 9001-certified process—from design analysis to mass production—is engineered to deliver Zero Defects, Olympic Quality Standards, and 24/7 Customer Service. We don’t just manufacture parts; we engineer solutions that meet your exact specifications, on time, every time.

Design Analysis: The Foundation of Zero Defects

Our senior engineers conduct a comprehensive design review using ISO 9001-compliant protocols. This includes:

GD&T analysis for critical tolerances

Material suitability assessment with certified documentation

DFM (Design for Manufacturability) optimization to eliminate production risks

Key Benefit: Prevent costly redesigns by addressing potential issues before production begins. Our proactive approach ensures your design is optimized for both function and manufacturability.

Pricing & Quotation: Transparent, Data-Driven Costing

We combine automated quoting systems with human engineering oversight to deliver:

Detailed cost breakdowns with no hidden fees

Material certification included in every quote

Volume-based optimization for cost efficiency

Key Benefit: Predictable budgets with full transparency. You receive exact pricing with traceable material data—no surprises, only solutions.

Rapid Prototyping: Olympic Quality Validation Before Scaling

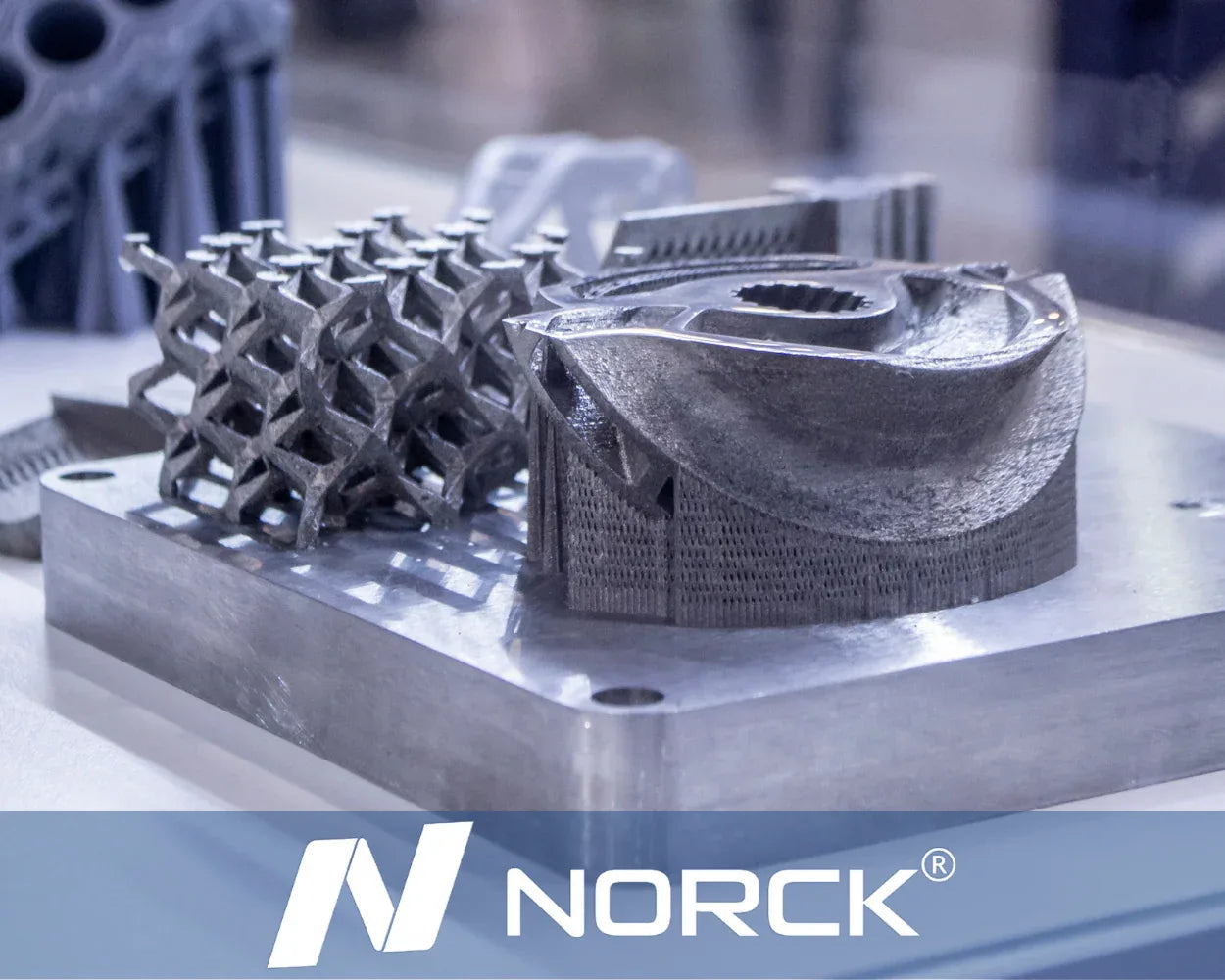

Leveraging advanced SLM/DMLS metal 3D printing, we produce prototypes with:

Tolerances as tight as ±0.05mm

100% dimensional inspection and material certification

Traceable QA reports for each part

Key Benefit: Validate your design with production-grade parts in days, not weeks. Our Olympic Quality Standards ensure prototypes meet the same rigorous criteria as final production parts.

Mass Production: Scalable Excellence with ISO 9001 Rigor

From prototype to full-scale production, our process maintains unwavering quality:

In-process monitoring with automated metrology

Batch traceability and final 100% inspection

99.5% on-time delivery rate with 24/7 support

Key Benefit: Consistent, defect-free parts at scale. When you choose Wuxi Lead, you gain a partner committed to delivering reliability, precision, and peace of mind.

Key Differentiators

| Metric | Wuxi Lead Standard | Industry Average |

|---|---|---|

| Tolerance Accuracy (Metal) | ±0.05mm | ±0.1mm–±0.3mm |

| Defect Rate | 0% (Zero Defects Commitment) | 1–3% |

| On-Time Delivery | 99.5% | 90–95% |

| Material Certification | Full traceability per ISO 9001 | Limited or none |

Why Choose Wuxi Lead?

Zero Defects Commitment: Every part undergoes 100% inspection—no exceptions.

Olympic Quality Standards: Precision engineering that meets the highest international benchmarks for critical applications.

24/7 Customer Service: Dedicated technical support available around the clock for urgent requests and real-time updates.

“We don’t just meet specifications—we exceed expectations. Your success is our standard.”

— Wuxi Lead Precision Machinery Engineering Team

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Where Precision Meets Partnership

Zero Defects Commitment: Precision Engineered for Perfection

At Wuxi Lead Precision, quality is not a checkbox—it’s the foundation of every project. Our Zero Defects Guarantee is enforced through ISO 9001-certified processes, full material traceability (ISO 10204 3.1), and multi-stage validation protocols. Every component undergoes rigorous inspection at critical stages, ensuring absolute conformity to your specifications. For aerospace, medical, and high-stress industrial applications, this means no compromises—only parts that perform flawlessly, every time.

Olympic-Quality Precision: Beyond Industry Standards

While standard additive manufacturing providers typically deliver tolerances of ±0.1mm, Wuxi Lead Precision consistently achieves ±0.02mm through proprietary process controls, advanced post-processing, and real-time process monitoring. This micron-level accuracy is critical for micro-components, medical implants, and mission-critical assemblies where failure is not an option.

| Feature | Wuxi Lead Precision | Industry Standard | Competitor Benchmark |

|---|---|---|---|

| Tolerance Control | ±0.02mm (post-processed) | ±0.1mm | ±0.05mm |

| Material Certification | Full ISO 10204 3.1 traceability | Basic material specs | Partial certification |

| Defect Rate | 0% (Zero Defects Guarantee) | 1–5% | 0.5% |

| Surface Finish | Ra 0.4μm (as-machined) | Ra 1.6μm | Ra 0.8μm |

24/7 Engineering Support: Your Success, Our Priority

We operate as an extension of your engineering team—not a transactional supplier. Our dedicated technical specialists are available around the clock for:

Real-time DFM (Design for Manufacturing) feedback

Rapid prototyping support for tight deadlines

Proactive issue resolution with 2-hour response SLA

Custom process optimization for complex geometries

Unlike traditional providers bound by business hours, we prioritize your deadlines with agile, collaborative problem-solving—ensuring your project stays on track, every step of the way.

Ready to Elevate Your Project?

Contact us today for a free DFM analysis and competitive quote.

📧 [email protected] | 📞 +86-13961886740

At Wuxi Lead Precision, we don’t just manufacture parts—we build partnerships that drive innovation.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.