Technical Contents

Engineering Guide: 3D Laser Cutting Services

Engineering Insight: The Non-Negotiable Imperative of Precision in 3D Laser Cutting

In high-stakes sheet metal fabrication, 3D laser cutting transcends basic contouring; it delivers complex geometries essential for aerospace, defense, and advanced industrial systems. Here, precision is not merely desirable—it is the absolute foundation of component functionality, safety, and system integration. Minute deviations in cut angle, edge quality, or dimensional tolerance propagate through assemblies, causing fit failures, structural weaknesses, or catastrophic performance issues in final products. The inherent challenge lies in maintaining micron-level accuracy across intricate three-dimensional paths, where thermal dynamics, material behavior, and machine kinematics interact complexly. Achieving true precision demands far more than advanced hardware; it requires deep process mastery, rigorous environmental control, and an uncompromising engineering culture focused on repeatability under production conditions.

Wuxi Lead Precision Machinery operates at this critical precision frontier. Our engineering approach integrates state-of-the-art multi-axis laser systems with proprietary process calibration protocols developed through decades of solving the most demanding fabrication challenges. We understand that tolerances specified on a drawing are only the starting point; the real test is consistently hitting those targets across batch production, regardless of material grade or geometry complexity. This capability directly reduces secondary operations, minimizes scrap, and eliminates costly assembly errors downstream—delivering tangible value through enhanced yield and accelerated time-to-market. Our commitment to precision engineering is validated by our selection for mission-critical applications, including structural components for Olympic venue infrastructure and specialized subsystems within defense applications where failure is not an option. These projects demanded not only meeting but exceeding stringent international standards under intense scrutiny.

The technical capability to deliver this level of precision is quantifiable. Our dedicated 3D laser cutting platforms are engineered and maintained to achieve exceptional performance metrics consistently. Key specifications underpinning our precision capability include:

| Parameter | Capability | Significance |

|---|---|---|

| Material Thickness | 0.5 mm – 12 mm (Mild Steel) | Handles critical thin-wall to robust sections |

| Positional Accuracy | ± 0.02 mm | Ensures exact feature placement in 3D space |

| Repeatability | ± 0.01 mm | Guarantees batch-to-batch consistency |

| Edge Perpendicularity | < 0.1° deviation | Critical for seamless welding and assembly |

| Kerf Width Control | Optimized per material (0.1-0.2mm) | Maximizes design flexibility, minimizes waste |

This precision capability is the product of continuous investment and hard-won experience. It reflects our operational philosophy: treating every component, whether for a single prototype or high-volume production, with the same rigorous attention to metrological detail that defines our work for the world’s most exacting sectors. For manufacturers where component integrity dictates system success, partnering with an engineering-led precision specialist is not a cost—it is a strategic necessity for assured performance and reliability. At Lead Precision, we engineer precision into every cut.

Precision Specs & Tolerances

Advanced 3D Laser Cutting Capabilities for Precision Sheet Metal Fabrication

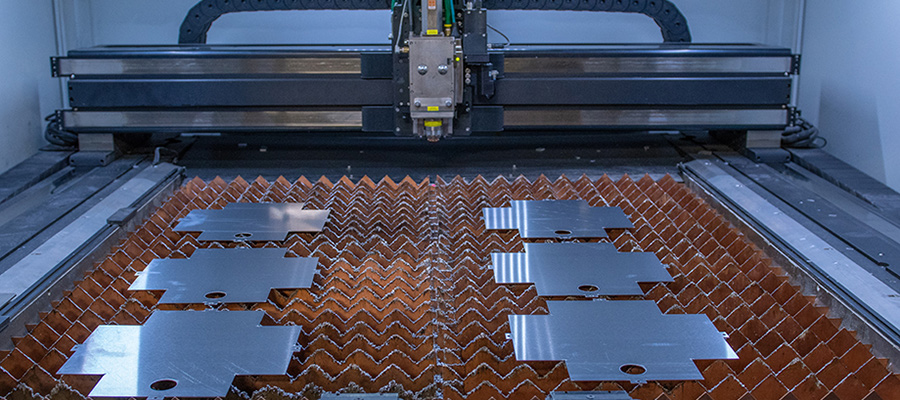

Wuxi Lead Precision Machinery delivers state-of-the-art 3D laser cutting services tailored for high-complexity sheet metal components across aerospace, automotive, medical, and industrial equipment sectors. Our technical capabilities are anchored in a fully integrated 5-axis CNC laser cutting platform, enabling us to process intricate geometries with superior accuracy and repeatability. Unlike conventional 2D systems, our 5-axis architecture allows for dynamic beam positioning, facilitating cuts at compound angles, internal contours, and non-planar surfaces without secondary fixturing or manual repositioning.

Each machine in our laser cutting fleet is equipped with high-power fiber laser sources, optimized for clean, dross-free cuts across a wide range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys. The integration of 5-axis motion control ensures minimal thermal distortion and maximized edge quality, even on thin-gauge materials down to 0.5 mm or structural sections up to 12 mm in thickness. This flexibility supports both prototyping and high-volume production runs with consistent throughput and precision.

Our production workflow is reinforced by a rigorous quality assurance protocol, beginning with CAD/CAM simulation and extending through post-process inspection. All critical dimensions are verified using a Zeiss coordinate measuring machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. The CMM system provides traceable, high-resolution metrology data for first-article inspection reports (FAIR) and batch certification, meeting ISO 9001 and IATF 16949 standards.

In addition to dimensional accuracy, we maintain strict environmental and process controls to minimize variation across production batches. Laser power, assist gas pressure, focal spot size, and cutting speed are monitored in real time, with automated adjustments made via closed-loop feedback systems. This level of process stability ensures repeatable cut quality and edge consistency, reducing downstream finishing requirements and assembly fit-up time.

We support complex nesting and multi-feature cutting, including holes, slots, flanges, and embossments, all executed in a single setup. This reduces lead times and eliminates cumulative errors associated with multiple handling stages. Our engineering team collaborates directly with clients during design-for-manufacturability (DFM) reviews to optimize part geometry for laser process efficiency and cost-effectiveness.

Dimensional Accuracy and Tolerance Specifications

| Parameter | Standard Tolerance | Precision Tolerance (CMM Verified) |

|---|---|---|

| Linear Dimension (up to 100 mm) | ±0.1 mm | ±0.05 mm |

| Linear Dimension (100–500 mm) | ±0.15 mm | ±0.08 mm |

| Angular Cut Accuracy | ±0.5° | ±0.2° |

| Hole Diameter (≥3 mm) | ±0.1 mm | ±0.05 mm |

| Feature Positioning | ±0.12 mm | ±0.06 mm |

| Edge Perpendicularity | 0.15 mm | 0.08 mm |

| Surface Roughness (Ra) | ≤3.2 µm | ≤1.6 µm |

These specifications reflect our commitment to precision engineering and are consistently achieved through synchronized control of machine kinematics, laser parameters, and metrology validation. Wuxi Lead Precision Machinery stands as a trusted partner for mission-critical 3D laser cutting applications where accuracy, repeatability, and quality documentation are non-negotiable.

Material & Finish Options

Material Selection for Precision 3D Laser Cutting

Selecting the optimal material is foundational to achieving performance, cost efficiency, and longevity in sheet metal fabrication. At Wuxi Lead Precision Machinery, our 3D laser cutting expertise demands careful consideration of material properties relative to the application’s mechanical, environmental, and aesthetic requirements. Understanding the nuances of aluminum, steel, and titanium ensures your components meet the highest standards of precision and functionality.

Aluminum alloys, particularly 5000 and 6000 series like 5052 and 6061, are favored for their exceptional strength-to-weight ratio, inherent corrosion resistance, and excellent thermal conductivity. These properties make aluminum ideal for aerospace components, transportation parts, and intricate enclosures where weight reduction is critical. Our fiber laser systems efficiently cut aluminum up to 25mm thick, maintaining tight tolerances and clean edges essential for subsequent welding or assembly. Aluminum readily accepts anodizing, significantly enhancing surface durability and offering customizable aesthetics.

Carbon steel and stainless steel remain the workhorses of industrial fabrication due to their robust strength, wide availability, and cost-effectiveness. Low-carbon steel (e.g., SPCC, DC01) is optimal for structural brackets, chassis, and non-corrosive environments, cut precisely up to 30mm. Stainless steel grades, especially 304 and 316, provide superior corrosion and heat resistance for medical devices, food processing equipment, and marine applications. Our lasers handle stainless steel up to 25mm, producing burr-minimized edges that reduce secondary finishing needs. Stainless steel generally does not require anodizing but benefits from passivation or polishing for critical applications.

Titanium, primarily Grades 2 and 5 (Ti-6Al-4V), delivers unparalleled strength-to-weight ratio, extreme corrosion resistance, and biocompatibility, making it indispensable for aerospace, defense, and medical implants. Cutting titanium demands precise parameter control to prevent heat-affected zone issues and oxidation. Wuxi Lead’s advanced laser systems and inert gas shielding ensure clean, high-integrity cuts up to 15mm thick, preserving the material’s critical properties. Titanium surfaces are typically finished via bead blasting or chemical passivation rather than anodizing.

Anodizing is a vital post-process primarily for aluminum components, creating a hard, wear-resistant oxide layer that enhances corrosion protection and allows for integral color dyeing. Type II (sulfuric acid) anodizing offers standard protection and color options, while Type III (hardcoat) provides superior thickness and abrasion resistance for demanding mechanical parts. Proper masking during anodizing ensures critical mating surfaces retain precise dimensional tolerances achieved through laser cutting.

The following table summarizes key material capabilities for our 3D laser cutting services:

| Material Type | Typical Thickness Range | Max Part Size (LxW) | Key Applications |

|---|---|---|---|

| Aluminum Alloys | 0.5 mm – 25 mm | 3000 mm x 1500 mm | Aerospace frames, heat sinks, enclosures |

| Carbon Steel | 0.8 mm – 30 mm | 3000 mm x 1500 mm | Machinery guards, structural brackets |

| Stainless Steel | 0.8 mm – 25 mm | 3000 mm x 1500 mm | Medical housings, food processing parts |

| Titanium Alloys | 0.8 mm – 15 mm | 2000 mm x 1000 mm | Aircraft components, surgical implants |

Wuxi Lead Precision Machinery combines deep metallurgical knowledge with state-of-the-art 3D laser technology to optimize material selection and processing. We partner with you to ensure the chosen material and finish directly support your product’s performance goals and production efficiency, delivering components that exceed expectations from blueprint to final assembly. Consult our engineering team for tailored material and process recommendations.

Manufacturing Process & QC

The production process for 3D laser cutting services at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure zero defects from concept to final delivery. Rooted in advanced manufacturing principles and precision engineering, our workflow integrates Design, Prototyping, and Mass Production into a seamless, quality-driven pipeline tailored for high-end sheet metal fabrication.

Design begins with comprehensive collaboration between our engineering team and the client. Utilizing the latest CAD/CAM software, we translate conceptual requirements into detailed 3D models. These models are optimized for material efficiency, structural integrity, and manufacturability. Critical parameters such as material type, wall thickness, and geometric complexity are analyzed to ensure compatibility with 3D laser cutting technology. Our design validation includes thermal distortion simulations and stress analysis, minimizing risks before any physical work begins.

Once the digital model is finalized, we proceed to Prototyping. This stage is critical for verifying form, fit, and function. Using the same 3D fiber laser systems intended for mass production, we fabricate initial samples under identical process conditions. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and surface quality assessment. Any deviations are traced back to the source using root cause analysis, and design or process adjustments are implemented immediately. Client feedback is integrated at this stage to ensure alignment with end-use requirements. Only after formal approval do we advance to full-scale production.

Mass Production is executed on our automated 3D laser cutting lines, where precision, repeatability, and consistency are paramount. Our systems utilize high-power fiber lasers with multi-axis manipulators, enabling accurate cutting of complex contours on tubular, curved, and freeform sheet metal components. The entire process is monitored in real time using integrated sensors and machine vision systems that detect anomalies such as focus drift or material variance. Each part is traceable through a digital log, recording laser parameters, inspection data, and operator inputs.

Quality assurance is embedded at every stage. In-process inspections occur at defined intervals, and final products undergo 100% visual and dimensional verification. Non-conforming parts are automatically quarantined, and corrective actions are documented in our quality management system, compliant with ISO 9001 standards.

This end-to-end control ensures zero defects are passed to the next stage, delivering components that meet the most demanding specifications in aerospace, automotive, and industrial equipment sectors.

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser, 1–6 kW |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Material Thickness Range | 0.5 – 25 mm (steel), up to 16 mm (aluminum) |

| Max Workpiece Size | Ø300 – Ø2000 mm (tubular), up to 6000 mm length |

| Cutting Speed | Up to 100 m/min (depending on material) |

| Supported Materials | Carbon steel, stainless steel, aluminum, brass |

| Quality Standard | ISO 9001:2015, ISO 13920 (welding tolerances) |

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Capabilities with Precision Engineering

In high-mix, low-volume sheet metal fabrication, inconsistent tolerances and extended lead times erode profitability and innovation velocity. Wuxi Lead Precision Machinery eliminates these barriers through integrated 3D laser cutting systems engineered for uncompromising accuracy in complex geometries. Our solutions serve aerospace, medical device, and industrial automation leaders who demand repeatable micron-level precision across stainless steel, aluminum, and specialty alloys. Unlike conventional 2D platforms, our 5-axis laser technology processes compound curves, undercuts, and multi-faceted components in a single setup—reducing secondary operations by up to 40% while maintaining ±0.05 mm positional accuracy. This translates to faster time-to-market for mission-critical parts without sacrificing structural integrity or surface finish.

Technical Specifications Driving Your Competitive Edge

| Parameter | Capability | Industry Standard | Advantage |

|---|---|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm | 0.8 mm – 4.0 mm | Wider versatility for thin-gauge precision components |

| Positional Accuracy | ±0.05 mm | ±0.1 mm | Critical for aerospace sealing surfaces |

| Max Work Envelope | 1500 mm × 3000 mm × 500 mm | 1200 mm × 2500 mm | Accommodates larger assemblies |

| Throughput Efficiency | 30% faster cycle times vs. 3-axis | Baseline | Higher ROI on complex part families |

| Surface Roughness (Ra) | ≤ 1.6 µm | ≤ 3.2 µm | Eliminates post-processing for medical-grade finishes |

Our engineering team collaborates at the prototype phase to optimize your designs for laser manufacturability—addressing kerf compensation, heat-affected zone control, and nesting efficiency before cutting begins. Every system operates under ISO 9001-certified protocols with full digital traceability from CAD file to finished part. Real-time process monitoring via integrated sensors ensures dimensional compliance across production runs, while our proprietary gas delivery system minimizes dross formation on reflective materials. This rigorous approach delivers first-article approval rates exceeding 98% for Tier-1 automotive suppliers and defense contractors.

Initiate Your Precision Project Today

Stop compromising between complexity and cost-efficiency in sheet metal fabrication. Wuxi Lead Precision Machinery provides the engineering partnership and technological infrastructure to transform your most challenging designs into production-ready components. Contact our applications engineering team to discuss your specific requirements, request a material test cut, or schedule a virtual factory audit. We respond to all technical inquiries within 24 business hours with actionable data—not generic sales pitches.

Email [email protected] with your project specifications and timeline. Include 3D CAD files for immediate manufacturability analysis. Our engineers will provide a detailed process plan, accuracy validation report, and competitive quotation within 48 hours. Partner with a manufacturer that treats your precision standards as our non-negotiable baseline. Let Lead Precision become your strategic advantage in high-integrity metal fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.