Technical Contents

Engineering Guide: 3D Cnc Machining

Engineering Insight: 3D CNC Machining – The Benchmark of Precision in Advanced Manufacturing

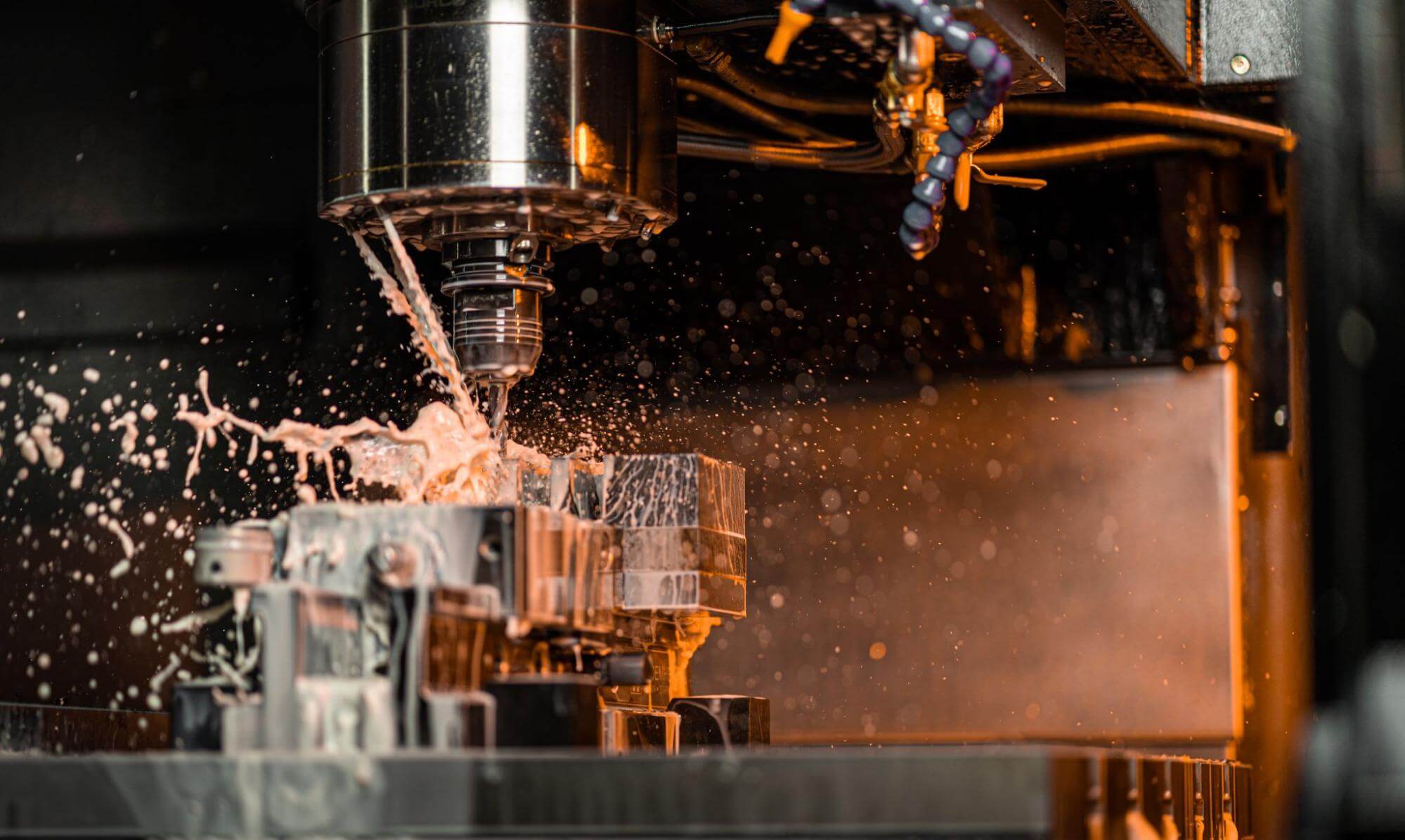

In the realm of modern manufacturing, 3D CNC machining represents the convergence of computational intelligence and mechanical precision. Unlike conventional machining processes limited to two or 2.5 axes, 3D CNC machining leverages multi-axis coordination—typically 3, 4, or 5 axes—to sculpt complex geometries with micron-level accuracy. This capability is not merely an enhancement in flexibility; it is a fundamental requirement for industries where form, fit, and function are non-negotiable. At Wuxi Lead Precision Machinery, we recognize that precision is not an outcome—it is engineered into every process, material selection, and calibration cycle.

The significance of precision in 3D CNC machining extends beyond dimensional accuracy. It encompasses surface integrity, repeatability, and thermal stability during prolonged operations. A deviation of even 5 microns can compromise the performance of aerospace actuators, medical implants, or high-frequency defense electronics. This is why Lead Precision adheres to ISO 2768-mK and ISO 1302 standards across its machining centers, ensuring geometric tolerances remain within ±0.005 mm and surface finishes achieve Ra ≤ 0.8 µm when required. Our CNC systems are equipped with real-time probing, tool wear compensation, and environmental monitoring to maintain consistency across production runs.

With over 15 years of specialized experience, Wuxi Lead Precision Machinery has delivered mission-critical components for projects demanding the highest reliability. Our portfolio includes precision-machined structural elements used in Olympic-standard timing systems, where synchronization accuracy depends on flawless mechanical alignment. Additionally, we have supported defense contractors with ruggedized housings and guidance components compliant with MIL-STD-810G, demonstrating our capability to meet stringent environmental and performance benchmarks.

Our machining infrastructure integrates 5-axis simultaneous milling, high-speed spindle technology (up to 24,000 RPM), and advanced CAM software such as Siemens NX and Mastercam. This enables us to produce organic contours, undercuts, and internal channels in a single setup—minimizing human intervention and eliminating cumulative error. Materials range from aerospace-grade aluminum (7075-T6) and titanium (Ti-6Al-4V) to high-performance polymers like PEEK and PPSU, all processed under controlled cleanroom conditions when necessary.

The table below outlines the core technical specifications maintained across our 3D CNC machining operations:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 × 800 × 600 mm (5-axis) |

| Spindle Speed Range | 8,000 – 24,000 RPM (HSK-A63 interface) |

| Tool Changer Capacity | 30T – 60T (automatic) |

| Standard Tolerances | ±0.005 mm (tighter upon request) |

| Surface Finish (Typical) | Ra 1.6 – 0.8 µm (polishing available) |

| Supported Materials | Aluminum, Steel, Stainless, Titanium, PEEK, PPSU, Brass |

| Quality Standards | ISO 9001, ISO 2768, MIL-STD-810G (select lines) |

Precision in 3D CNC machining is not an isolated attribute—it is the result of integrated engineering discipline, continuous calibration, and domain-specific experience. At Wuxi Lead Precision Machinery, we apply this philosophy to every component, ensuring our clients receive not just parts, but performance-certified solutions.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding 3D CNC machining applications. Our core strength lies in mastering complex geometries and stringent tolerances required by aerospace, medical device, and advanced industrial sectors. We achieve this through a foundation of advanced multi-axis technology, rigorous process control, and metrology-grade verification. Our engineering team possesses deep expertise in optimizing toolpaths and fixturing specifically for intricate 3D surfaces and internal features, ensuring dimensional integrity and surface finish consistency across every production run. This capability directly translates to reduced assembly steps, enhanced part performance, and accelerated time-to-market for our clients.

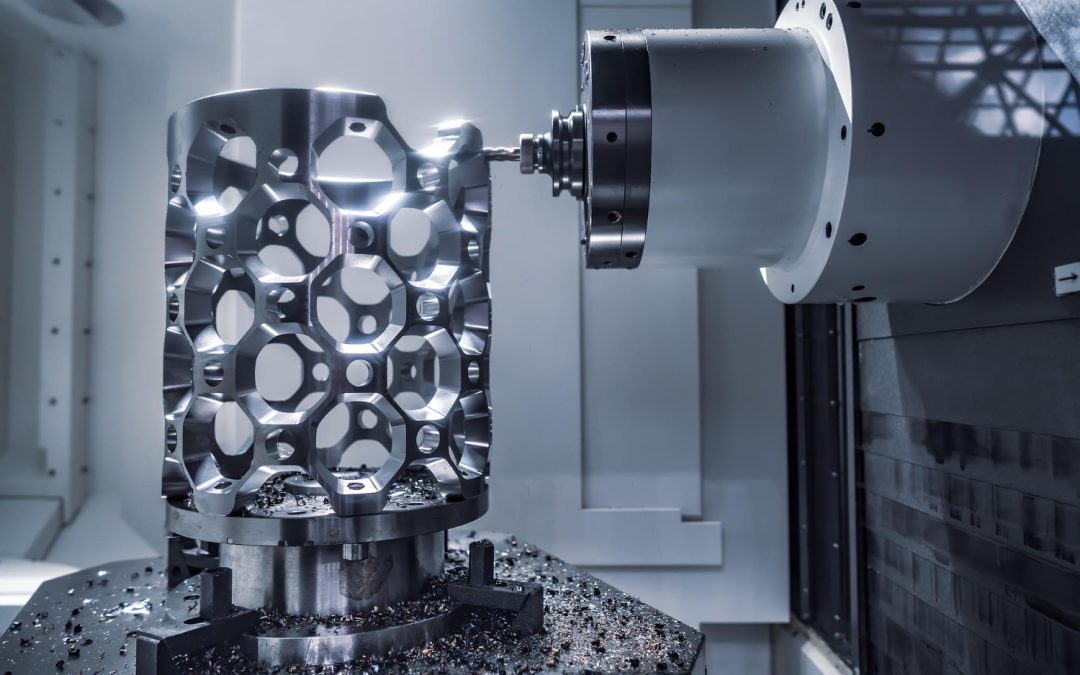

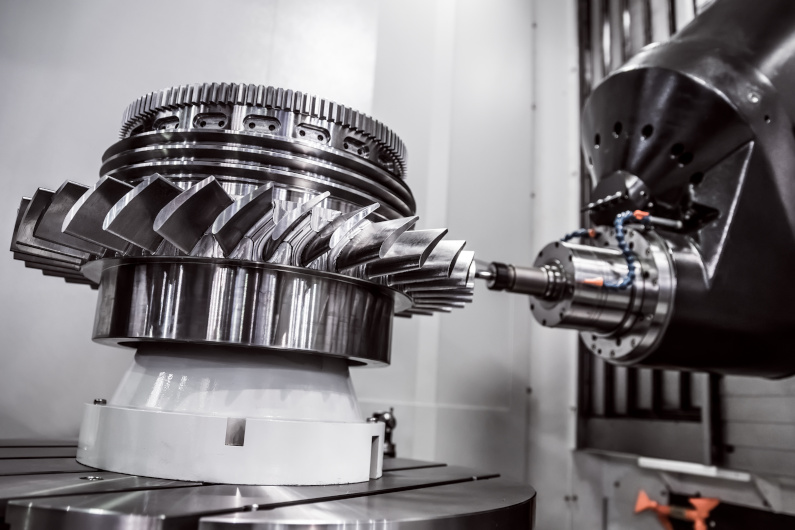

Central to our 3D machining capability is our fleet of state-of-the-art 5-axis CNC machining centers. These machines, featuring high-precision rotary tables and spindles with minimal runout, enable true simultaneous 5-axis motion. This eliminates the need for multiple setups, drastically reducing cumulative error and handling damage risks inherent in complex part production. We utilize machines equipped with Fanuc or Siemens controls, integrated probing systems like Renishaw, and high-speed spindles capable of maintaining accuracy during aggressive material removal rates. This technology allows us to machine organic shapes, deep cavities, undercuts, and compound angles in a single operation – essential for turbine blades, surgical implants, and fluid dynamics components. Material versatility is inherent, with proven processes for titanium alloys, Inconel, hardened steels, aluminum aerospace grades, and high-performance plastics.

Quality assurance is not a final step but an integrated process at Wuxi Lead. Every critical dimension and feature undergoes verification using calibrated Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMMs, operating in temperature-controlled environments, provide traceable, NIST-certified measurements. Full first-article inspection reports (FAIR) and comprehensive CMM inspection documentation are standard deliverables, ensuring complete transparency and adherence to client specifications. Statistical Process Control (SPC) methodologies are applied to monitor critical characteristics in real-time during production, enabling proactive correction and guaranteeing consistent batch quality. This metrology backbone provides the data-driven confidence our clients require for mission-critical components.

Our precision is quantifiable across diverse materials and feature types. The following table details our standard achievable tolerance ranges under controlled production conditions:

| Feature Type | Material Group | Standard Tolerance Range | Critical Feature Tolerance Range |

|---|---|---|---|

| Linear Dimensions | Aluminum, Plastics | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) |

| Linear Dimensions | Steels, Stainless | ±0.012 mm (±0.0005″) | ±0.008 mm (±0.0003″) |

| Linear Dimensions | Titanium, Inconel | ±0.015 mm (±0.0006″) | ±0.010 mm (±0.0004″) |

| Geometric (Flatness) | All Materials | 0.010 mm (0.0004″) / 100mm | 0.005 mm (0.0002″) / 100mm |

| Geometric (True Pos) | Critical Holes/Pins | ±0.015 mm (±0.0006″) | ±0.008 mm (±0.0003″) |

| Surface Finish (Ra) | Machined | 0.8 – 1.6 µm (32-63 µin) | 0.4 µm (16 µin) achievable |

This technical capability framework – advanced 5-axis machining, integrated CMM verification, and documented tolerance performance – forms the bedrock of Wuxi Lead’s value proposition. We transform complex 3D designs into reality with the precision, reliability, and documentation rigor demanded by global high-tech manufacturing leaders. Partner with us to eliminate your most challenging machining bottlenecks.

Material & Finish Options

Material Selection in 3D CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical step in precision 3D CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance components from aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific industrial applications. Understanding the characteristics of these materials ensures optimal design outcomes in aerospace, automotive, medical, and industrial equipment sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly common in structural and prototyping applications due to its weldability and moderate strength. It is ideal for lightweight components requiring tight tolerances and smooth surface finishes. For enhanced surface durability and aesthetic control, aluminum parts are often finished with anodizing—a process that increases surface hardness and provides electrical insulation while allowing for color customization.

Steel, particularly stainless steel grades such as 304 and 17-4 PH, delivers superior strength, wear resistance, and high-temperature performance. These properties make steel the material of choice for load-bearing components, medical instruments, and environments requiring sterilization or exposure to harsh chemicals. While more challenging to machine than aluminum, modern CNC techniques ensure precise results with excellent surface integrity. Post-machining treatments such as passivation enhance corrosion resistance, especially in marine and pharmaceutical applications.

Titanium, specifically Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and outstanding resistance to extreme environments, including high heat and corrosive media. Its biocompatibility makes it indispensable in aerospace and medical implant manufacturing. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and controlled machining parameters to prevent work hardening and tool wear. Despite higher material and processing costs, titanium remains unmatched for mission-critical components where reliability is non-negotiable.

Surface finishing further enhances performance and appearance. Anodizing, primarily applied to aluminum, creates a durable oxide layer that improves wear and corrosion resistance. Type II (sulfuric acid) anodizing supports color dyeing for identification or branding, while Type III (hardcoat) anodizing delivers extreme surface hardness for industrial wear parts.

The table below summarizes key mechanical properties and machinability characteristics of these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Hardness (HB) | Machinability Rating | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | 95 | Excellent | Anodizing, Bead Blast |

| Stainless Steel 304 | 505 | 8.0 | 200 | Moderate | Passivation, Polishing |

| Steel 17-4 PH | 1000 | 7.8 | 330 | Moderate to Difficult | HVOF, Passivation |

| Titanium Ti-6Al-4V | 900 | 4.4 | 360 | Difficult | Anodizing, DLC Coating |

Material selection in 3D CNC machining must balance performance requirements with manufacturability and cost. At Wuxi Lead Precision Machinery, we support clients in choosing the optimal material and finish to ensure precision, reliability, and long-term value in every component produced.

Manufacturing Process & QC

Precision 3D CNC Machining: The Zero Defects Production Process at Wuxi Lead

Achieving true zero defects in high-precision 3D CNC machining demands a rigorously controlled, end-to-end production process. At Wuxi Lead Precision Machinery, we integrate advanced engineering with systematic quality protocols across three critical phases: Design, Prototyping, and Mass Production. This seamless workflow eliminates downstream errors, ensuring every component meets exacting aerospace, medical, and industrial specifications without compromise.

The foundation is our collaborative Design for Manufacturability (DFM) phase. Our engineering team works directly with your CAD models, conducting comprehensive manufacturability analysis before any metal is cut. We identify potential geometric conflicts, material stress points, and tool access limitations using advanced simulation software. This proactive review optimizes part geometry for CNC efficiency, minimizes post-processing needs, and inherently prevents design-induced defects. Critical tolerances, surface finishes, and material certifications are locked in during this stage, establishing the unambiguous quality baseline for all subsequent steps.

Prototyping transitions validated designs into physical reality under full production conditions. We utilize the same 5-axis CNC machines, tooling, and metrology systems designated for mass production, eliminating process variation. Each prototype undergoes metrology-grade validation against the approved CAD model using CMM and optical scanning. Dimensional accuracy, surface integrity, and functional performance are verified against the strictest tolerances. This phase is not merely about creating a sample; it is a critical process qualification step where we refine cutting parameters, fixture setups, and inspection routines to achieve statistical process capability before scaling up.

Mass Production executes the perfected process with unwavering consistency. Our facility employs real-time statistical process control (SPC) on every machining center, continuously monitoring critical dimensions and tool wear. Automated in-process gauging triggers immediate corrective actions if deviations approach tolerance limits. Full traceability links each component to specific machine parameters, tooling batches, and operator logs. Every part undergoes 100% critical feature inspection via automated vision systems or CMM, with final first-article and periodic batch validation. This closed-loop system ensures sustained process stability and absolute adherence to the zero defects mandate.

Wuxi Lead Production Process Specifications

| Process Phase | Key Activities | Quality Control Metrics |

|---|---|---|

| Design (DFM) | CAD analysis, Tolerance stack-up study, Material suitability verification, Process simulation | 100% DFM sign-off, Tolerance feasibility report, Material certification alignment |

| Prototyping | Machining on production equipment, Metrology validation (CMM/optical), Functional testing | Cpk ≥ 1.67 on critical features, Full GD&T report, Prototype approval documentation |

| Mass Production | SPC monitoring, Automated in-process gauging, 100% critical feature inspection, Full traceability | Ppk ≥ 1.33 sustained, 0 PPM defect rate target, Real-time SPC charts, Complete batch traceability records |

This integrated approach transforms zero defects from an aspiration into a measurable outcome. By embedding quality at every stage—from initial design validation through statistically proven mass production—we deliver components that consistently exceed global precision standards, minimizing your risk and total cost of ownership. Wuxi Lead’s process is engineered for perfection, not just production.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched 3D CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver precision components—we deliver confidence. As a global leader in high-end 3D CNC machining, we specialize in transforming complex engineering concepts into flawless, high-performance parts. Our advanced manufacturing capabilities, combined with decades of technical expertise, make us the preferred partner for industries where precision, reliability, and repeatability are non-negotiable. From aerospace and medical devices to automotive innovation and industrial automation, our clients trust us to meet the most demanding specifications with unwavering consistency.

Our state-of-the-art facility in Wuxi, China, is equipped with multi-axis CNC machines, high-speed spindles, and real-time in-process monitoring systems. These technologies enable us to achieve micron-level tolerances and superior surface finishes on a wide range of materials, including aluminum alloys, titanium, stainless steel, engineering plastics, and exotic composites. Every component undergoes rigorous quality control, including CMM inspection, optical measurement, and material certification, ensuring full compliance with ISO 9001:2015 and other international standards.

What sets Lead Precision apart is our engineering-first approach. We don’t just machine parts—we collaborate. From design for manufacturability (DFM) analysis to rapid prototyping and full-scale production, our team works closely with your engineers to optimize performance, reduce lead times, and control costs. Whether you require one-off prototypes or high-volume serial production, our agile manufacturing model adapts to your project’s unique demands without compromising on quality.

We understand that in today’s competitive landscape, speed and precision go hand in hand. That’s why we leverage intelligent automation, digital twin simulation, and integrated ERP systems to streamline workflows and ensure end-to-end traceability. Our clients benefit from faster time-to-market, reduced risk, and a transparent, responsive partnership built on technical excellence and accountability.

When you choose Wuxi Lead Precision Machinery, you’re not just outsourcing a machining process—you’re gaining a strategic manufacturing ally. We are committed to exceeding expectations, delivering not only precision-machined components but also long-term value through innovation, reliability, and service.

For engineering teams seeking a trusted partner in 3D CNC machining, the next step is simple. Contact us today to discuss your project requirements, request a quote, or schedule a technical consultation. Let us help you turn precision into performance.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC machining centers |

| Maximum Work Envelope | 1200 × 800 × 650 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish | As low as Ra 0.4 μm (polished to Ra 0.1 μm) |

| Materials Supported | Aluminum, Titanium, Stainless Steel, PEEK, PTFE, Inconel, Brass, Carbon Steel |

| Lead Times (Prototype) | From 7 days |

| Quality Standards | ISO 9001:2015, Full inspection reporting |

Contact us at [email protected] to begin your next precision machining project with confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.