Technical Contents

Engineering Guide: 3D Cad Model For Sheet Metal Product

Engineering Insight: The Critical Role of 3D CAD Models in Sheet Metal Fabrication

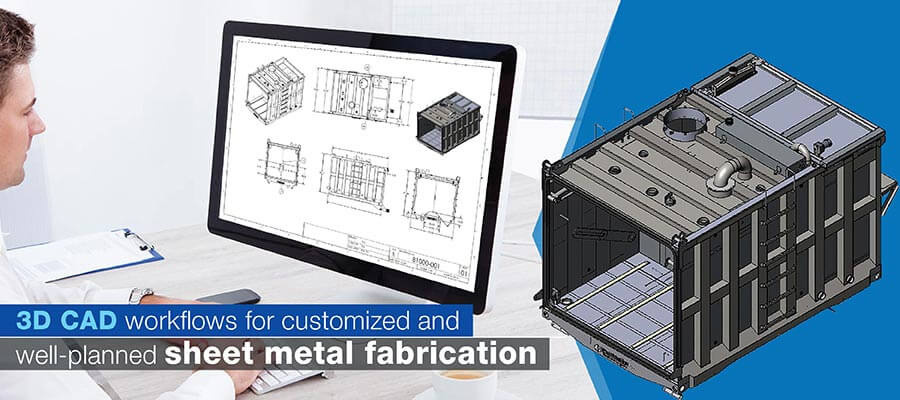

In high-precision sheet metal fabrication, the foundation of every successful component begins not on the shop floor, but within the digital workspace—where 3D CAD models serve as the blueprint for accuracy, repeatability, and performance. At Wuxi Lead Precision Machinery, we understand that a meticulously designed 3D CAD model is not merely a visualization tool; it is a comprehensive engineering specification that governs material behavior, geometric tolerance, and manufacturability. For industries where failure is not an option—such as aerospace, defense, and high-end industrial automation—precision in the digital model directly translates to reliability in the physical product.

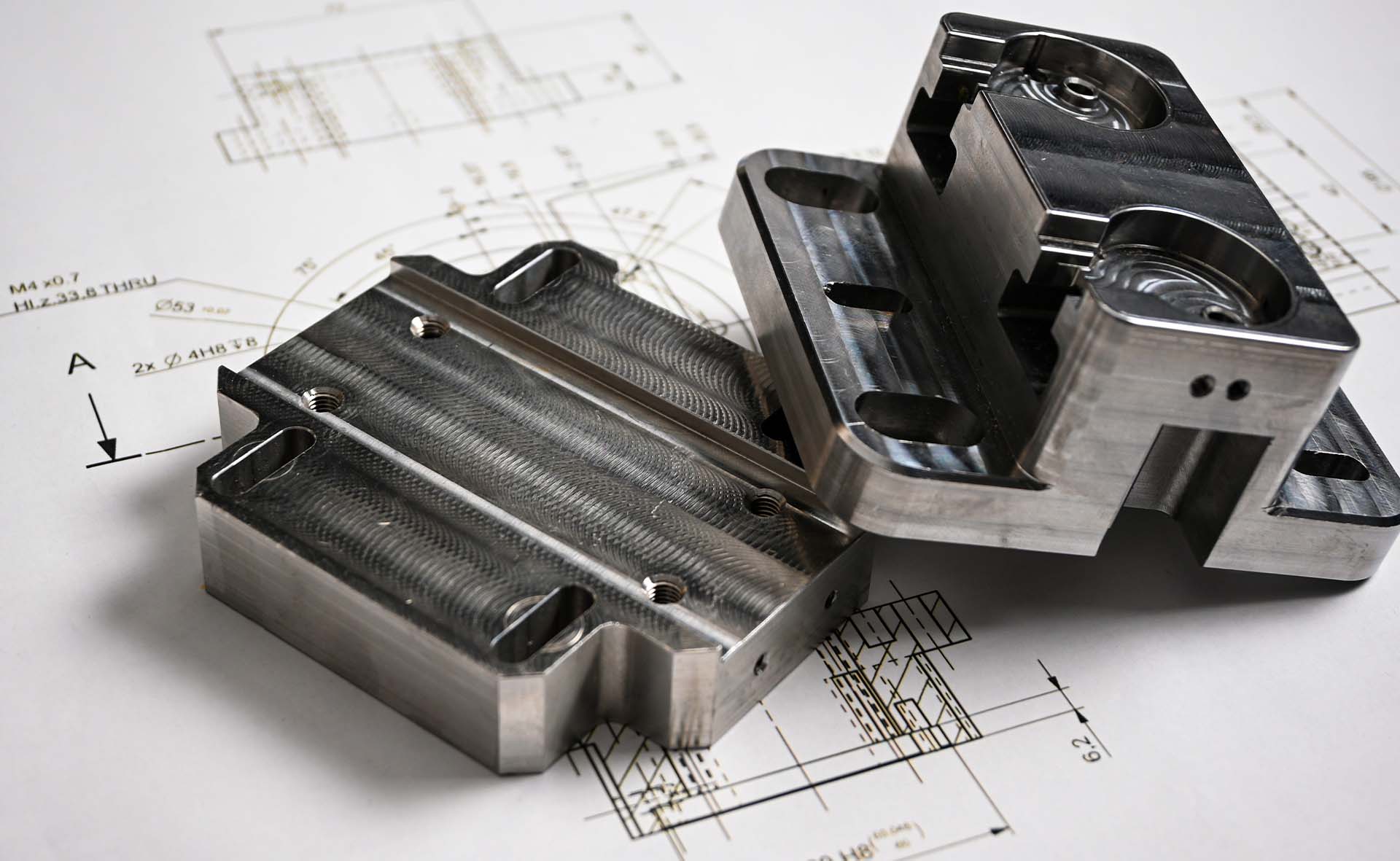

Our experience fabricating components for Olympic-standard equipment and military-grade systems has reinforced a fundamental principle: even the most advanced machinery cannot compensate for an inaccurate or poorly structured CAD model. Sheet metal behaves uniquely under stress, bending, and forming, and these characteristics must be anticipated during the design phase. A properly constructed 3D CAD model accounts for factors such as bend allowances, k-factors, springback, and tooling constraints. At Lead Precision, our engineering team collaborates closely with clients to validate and optimize CAD designs, ensuring that every flange, cutout, and perforation aligns with both functional intent and production feasibility.

We utilize industry-leading CAD software including SolidWorks, Siemens NX, and Autodesk Inventor to create parametric, feature-based models that support seamless integration with CNC punching, laser cutting, and press brake programming. This digital continuity—from CAD to CAM to production—enables us to maintain tolerances as tight as ±0.05 mm and ensures batch-to-batch consistency across high-volume runs.

Our engineering protocols also include Design for Manufacturability (DFM) reviews, where potential issues such as interference, excessive bends, or non-standard tooling requirements are identified and resolved before any metal is cut. This proactive approach reduces lead times, minimizes material waste, and enhances overall product quality.

Below are key specifications and capabilities supported by our 3D CAD-integrated manufacturing process:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm (steel, stainless, aluminum) |

| Tolerance (Standard) | ±0.1 mm |

| High-Precision Tolerance | ±0.05 mm |

| Supported CAD Formats | STEP, IGES, Parasolid, SolidWorks Part/Assembly |

| Bend Allowance Calculation | Dynamic, based on material and tooling |

| Integration with CNC Systems | Full digital workflow (CAD/CAM/PDM) |

| DFM Analysis Turnaround | Within 24 hours of model submission |

At Wuxi Lead Precision Machinery, our commitment to engineering excellence is reflected in every 3D model we process and every component we produce. By combining advanced digital modeling with decades of hands-on fabrication expertise, we deliver sheet metal solutions that meet the highest standards of precision and performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication from 3D CAD Model to Finished Component

Wuxi Lead Precision Machinery delivers exceptional sheet metal fabrication directly from your 3D CAD model, leveraging integrated digital workflows to ensure manufacturability and dimensional accuracy from concept to shipment. Our engineering team conducts rigorous Design for Manufacturability (DFM) analysis on every submitted CAD file, identifying potential issues like minimum bend radii, hole-to-edge distances, or complex feature interactions before cutting begins. This proactive review minimizes costly revisions and delays, translating your digital design into a physically flawless component. We accept all major native and neutral CAD formats including STEP, IGES, and Parasolid, ensuring seamless integration with your existing design ecosystem. Our systems enforce strict version control and material specification validation against your model, guaranteeing the correct alloy, thickness, and finish are applied throughout production.

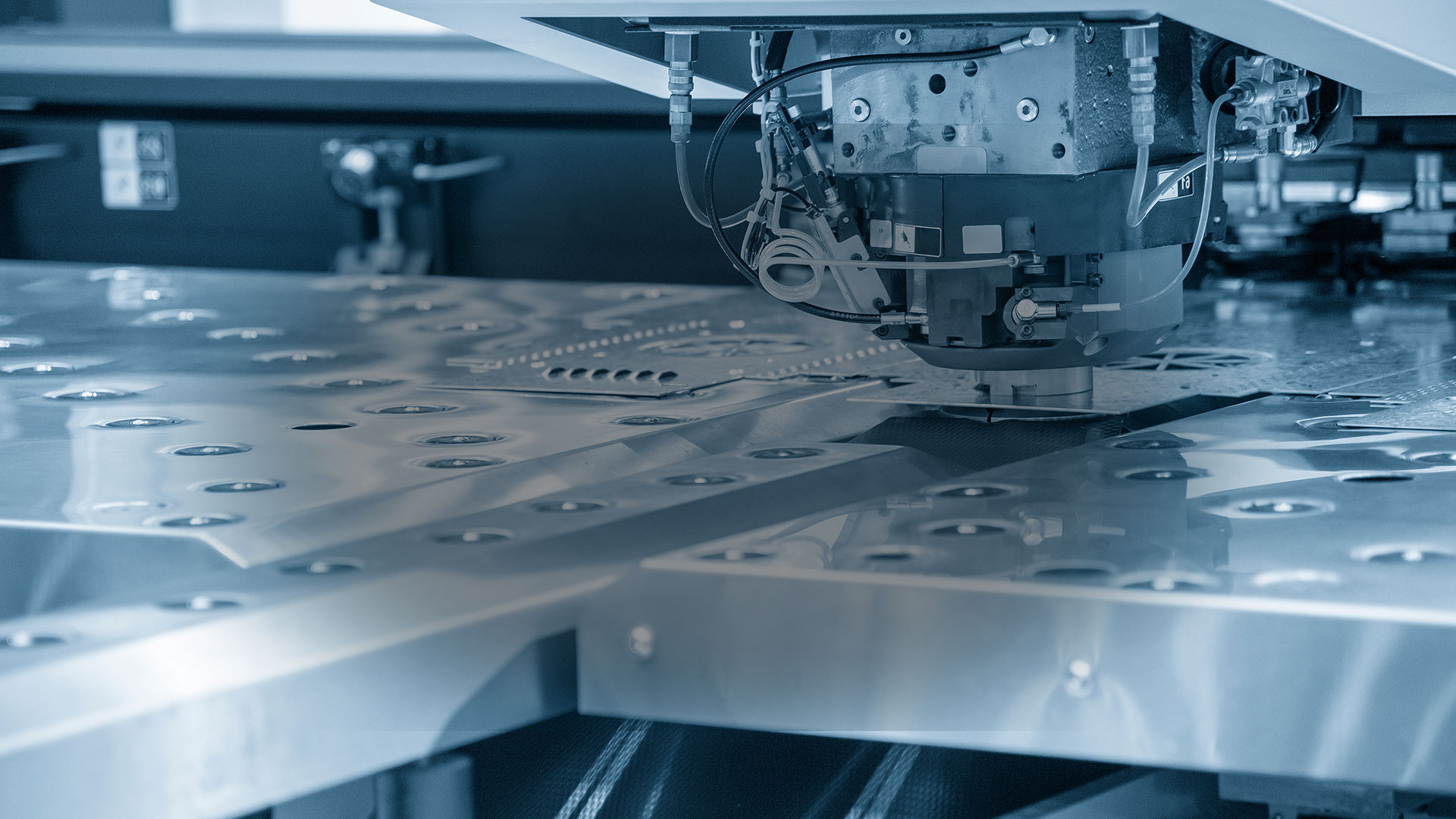

Our core manufacturing capability centers on advanced 5-axis CNC laser cutting and fiber laser systems. These machines provide unparalleled flexibility for complex sheet metal geometries, executing precise cuts, notches, and intricate contours in a single setup. The 5-axis capability allows for bevel cutting and compound angle features without secondary operations, significantly reducing handling and potential alignment errors. High-power fiber lasers efficiently process materials ranging from thin foils up to 6.0mm stainless steel and 8.0mm mild steel, maintaining exceptional edge quality and minimal heat-affected zones critical for subsequent welding or finishing. Integrated nesting software maximizes material yield while optimizing cutting paths for speed and precision, directly impacting cost efficiency and lead time for your project.

Quality control is non-negotiable and embedded at every stage. All critical dimensions and geometric features defined in your 3D CAD model are verified using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs perform comprehensive first-article inspections and in-process checks against the original digital model, measuring complex profiles, hole patterns, and form tolerances with micron-level accuracy. This direct model-to-part comparison eliminates interpretation errors inherent in 2D drawings. Statistical Process Control (SPC) data from CMM inspections is analyzed to monitor process stability and drive continuous improvement. Final inspection reports, including full CMM data output aligned to your CAD model, are provided with every shipment, offering complete traceability and confidence in part conformity.

The following table details our standard achievable tolerances for sheet metal fabrication, reflecting the precision enabled by our CAD-driven processes, 5-axis CNC equipment, and stringent CMM validation:

| Parameter | Capability | Standard Reference |

|---|---|---|

| Material Thickness | 0.5mm – 6.0mm SS / 8.0mm MS | ISO 9445 |

| Linear Dimension (≤100mm) | ±0.10mm | ISO 2768-m |

| Linear Dimension (>100mm) | ±0.15mm + 0.1mm/m | ISO 2768-m |

| Hole Diameter | ±0.05mm (reamed) / ±0.10mm (pierced) | ISO 286-2 (h11) |

| Hole Position (≤100mm) | ±0.10mm | ISO 2768-f |

| Bend Angle | ±0.5° | ISO 2768-f |

| Bend Radius | ±0.2mm | ISO 2768-m |

| Flatness (≤300x300mm) | 0.15mm | ISO 2768-f |

These tolerances represent our standard production capability under controlled conditions. Tighter tolerances are achievable for critical features through specific process controls and are readily discussed during the DFM phase. Wuxi Lead Precision Machinery’s commitment to precision engineering, validated by direct 3D CAD model comparison and CMM inspection, ensures your sheet metal components meet the most demanding application requirements for fit, function, and reliability. We deliver consistent, zero-defect production for aerospace, medical, and advanced industrial applications.

Material & Finish Options

Material Selection for Sheet Metal Fabrication: Aluminum, Steel, and Titanium

Selecting the appropriate material for sheet metal components is a critical decision in precision manufacturing. At Wuxi Lead Precision Machinery, we emphasize material performance in relation to application requirements, environmental exposure, mechanical load, and finishing compatibility. The most widely used materials in high-end sheet metal fabrication are aluminum, steel, and titanium, each offering distinct advantages depending on the project’s technical demands.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications in aerospace, electronics enclosures, and transportation where weight reduction is essential. Grade 6061-T6 is commonly used for structural components due to its weldability and moderate strength, while 5052-H32 is selected for parts requiring superior formability and resistance to marine environments. Aluminum naturally forms a protective oxide layer, but when enhanced surface durability and aesthetic control are needed, anodizing is recommended.

Steel remains the backbone of industrial sheet metal fabrication due to its high strength, availability, and cost efficiency. Cold-rolled steel (CRS) offers tight tolerances and a smooth surface finish, making it suitable for precision enclosures and machinery frames. For corrosive environments, stainless steel grades such as 304 and 316 are preferred. 304 provides general corrosion resistance and excellent formability, while 316 includes molybdenum for enhanced resistance to chlorides and acids, making it ideal for marine and chemical processing applications.

Titanium, though more expensive and challenging to process, delivers unmatched strength-to-density performance and exceptional resistance to extreme temperatures and corrosion. Grade 2 titanium is commonly used in sheet form for aerospace, medical implants, and high-performance automotive systems. Its biocompatibility and non-magnetic properties further expand its utility in specialized sectors.

Surface finishing plays a vital role in both functionality and appearance. Anodizing, primarily applied to aluminum, electrochemically thickens the natural oxide layer, improving wear resistance, corrosion protection, and allowing for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for architectural and industrial parts, while Type III (hardcoat anodizing) is used for components subject to high abrasion.

Below is a comparative overview of key material properties:

| Material | Common Grades | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 2.7 | 290–320 | High | Aerospace, electronics, transport |

| Carbon Steel | CR1018, CR1022 | 7.85 | 370–500 | Low (uncoated) | Industrial frames, enclosures |

| Stainless Steel | 304, 316 | 8.0 | 515–620 | Very High | Food processing, marine, medical |

| Titanium | Grade 2, Grade 5 | 4.5 | 345–860 | Exceptional | Aerospace, medical, defense |

At Wuxi Lead Precision Machinery, we support material selection with in-house testing, prototyping, and finishing capabilities to ensure optimal performance and compliance with international standards.

Manufacturing Process & QC

Precision Sheet Metal Production: From CAD Model to Zero Defects Fulfillment

Precision begins with an intelligent 3D CAD model, the absolute foundation of flawless sheet metal fabrication. At Wuxi Lead Precision Machinery, our engineering team initiates every project with rigorous Design for Manufacturability (DFM) analysis integrated directly within the CAD environment. We meticulously define material specifications, grain direction, bend radii, and critical geometric dimensioning and tolerancing (GD&T) callouts. This phase is not merely drafting; it involves simulating the entire forming process, including laser cutting paths, punch sequences, and critical bending operations, to anticipate and eliminate potential springback, distortion, or tooling interference. Our proprietary DFM protocols ensure the digital model inherently supports manufacturability, minimizing downstream rework and establishing the baseline for zero defects by validating feasibility before any metal is cut.

Prototyping: Validating the Digital Blueprint

Rapid physical prototyping is the critical bridge between virtual design and scalable production. Leveraging the validated 3D CAD model, we generate precise machine code for our state-of-the-art fiber laser cutters and multi-axis CNC press brakes. Initial prototypes undergo comprehensive dimensional verification against the CAD model using high-accuracy coordinate measuring machines (CMM). We rigorously test functional fit, assembly interfaces, and structural integrity. Crucially, this stage incorporates real-world material behavior data—such as exact springback characteristics—to refine bending compensation algorithms within the model. Client feedback on these tangible samples is integrated swiftly, ensuring the final production program embodies absolute conformance. This iterative validation loop, grounded in empirical data from the prototype, is non-negotiable for achieving zero defects in volume.

Mass Production: Sustaining Perfection at Scale

Transitioning to high-volume manufacturing demands seamless integration of the perfected CAD model with automated, closed-loop production systems. Our connected factory environment utilizes the final CAD data to drive laser cutting, automated bending cells, and robotic welding with micron-level precision. Real-time in-process monitoring—measuring critical dimensions after each key operation—feeds data directly into Statistical Process Control (SPC) systems. Any deviation beyond our stringent tolerance bands triggers immediate corrective action, preventing defect propagation. Every component undergoes final CMM inspection against the master CAD model, with full traceability from raw material lot to finished part. This closed-loop methodology, where the original 3D model remains the immutable quality reference throughout, guarantees consistent output meeting the most demanding aerospace, medical, and industrial specifications.

Wuxi Lead’s unwavering commitment to zero defects is engineered into every phase, from the initial CAD model integrity through prototype validation and into the rigor of mass production. Our process transforms digital precision into physical reality, ensuring your sheet metal components perform flawlessly in their final application.

| Critical Production Specification | Wuxi Lead Precision Standard |

|---|---|

| Material Thickness Tolerance | ±0.05 mm |

| Bend Angle Tolerance | ±0.5° |

| Hole Positional Accuracy | ±0.01 mm |

| Flatness Tolerance (per 100mm) | 0.05 mm |

| Edge Burr Height (Laser Cut) | ≤ 0.05 mm |

| First Article Inspection (FAI) | AS9102 Compliant |

| In-Process SPC Monitoring | 100% Critical Features |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Expertise

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end manufacturing. When your project demands a seamless transition from 3D CAD model to finished sheet metal product, partnering with a trusted, experienced fabricator is essential. We specialize in transforming complex digital designs into high-tolerance, production-ready components — consistently, efficiently, and to the exacting standards your industry demands.

Our engineering team collaborates directly with your design and manufacturing departments to ensure every 3D CAD model is optimized for manufacturability. From initial geometry validation to material selection, bend allowances, and tooling compatibility, we apply decades of precision sheet metal experience to eliminate errors before production begins. Whether your components require laser cutting, CNC punching, precision bending, or robotic welding, our advanced machinery and quality control systems guarantee repeatability and accuracy down to ±0.05 mm.

We support all major CAD formats, including STEP, IGES, SolidWorks, and DXF, enabling fast, error-free data exchange. Our integrated digital workflow ensures your 3D model is translated into a real-world product without compromise. With in-house prototyping and full-scale production capabilities, we serve industries where performance is paramount — including automation, medical equipment, power systems, and advanced electronics.

Our facility in Wuxi, China, is equipped with state-of-the-art fiber laser cutters, Amada CNC press brakes, and automated assembly lines, backed by ISO 9001-certified quality management. We combine cutting-edge technology with skilled craftsmanship to deliver parts that meet not only your dimensional requirements but also your timeline and budget constraints.

Below are key technical capabilities that define our sheet metal fabrication services:

| Specification | Detail |

|---|---|

| Material Types | Stainless Steel, Aluminum, Galvanized Steel, Copper, Brass |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance | ±0.05 mm (standard), tighter upon request |

| Max Part Size | 3000 mm × 1500 mm |

| CAD Compatibility | STEP, IGES, SolidWorks, DXF, DWG, Parasolid |

| Finishing Options | Powder Coating, Anodizing, Passivation, Brushing, Plating |

| Production Capacity | Prototyping to High-Volume Runs (up to 100,000 units/month) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier — you gain a precision engineering ally. We are committed to delivering solutions that enhance your product performance, reduce lead times, and lower total manufacturing costs.

Contact us today to discuss your next sheet metal project. Send your 3D CAD model to [email protected] and receive a detailed manufacturability analysis and competitive quote within 24 hours. Let us help you turn design intent into precision reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.