Technical Contents

Engineering Guide: 316 Stainless Steel Machined Parts

Engineering Insight: 316 Stainless Steel Machined Parts

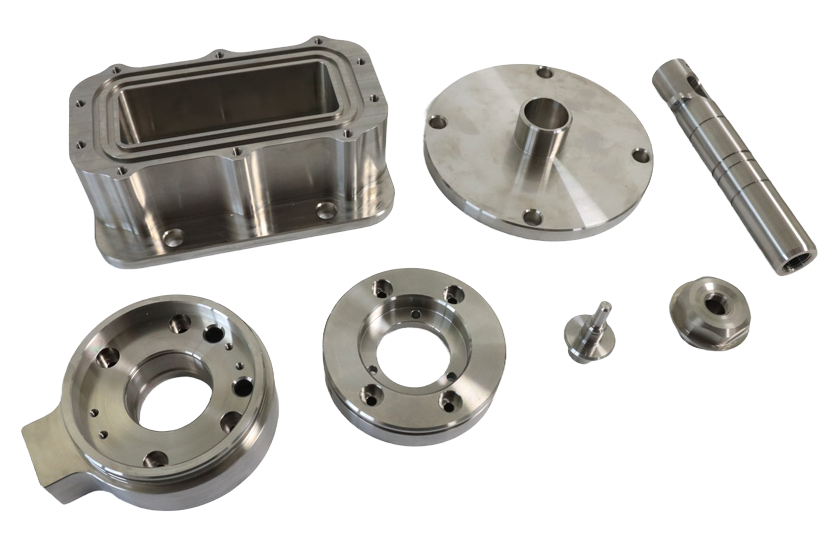

In high-performance industrial applications, the integrity of machined components is not merely a matter of dimensional accuracy—it is a determinant of system reliability, longevity, and safety. 316 stainless steel, renowned for its excellent corrosion resistance, high tensile strength, and performance in extreme environments, is a material of choice across aerospace, marine, medical, and chemical processing industries. However, its advantageous mechanical properties are only fully realized when paired with precision CNC machining processes capable of maintaining tight tolerances and superior surface finishes.

At Wuxi Lead Precision Machinery, we understand that precision in machining 316 stainless steel extends beyond the capabilities of advanced equipment—it demands deep material expertise, process optimization, and rigorous quality control. The austenitic structure of 316 stainless steel, while beneficial for toughness and corrosion resistance, presents unique challenges during machining, including work hardening, built-up edge formation, and thermal conductivity limitations. Without precise toolpath strategies, optimal cutting parameters, and real-time process monitoring, even minor deviations can compromise part functionality, especially in mission-critical applications.

Our engineering team leverages over a decade of specialized experience in machining 316 stainless steel to deliver components with tolerances as tight as ±0.005 mm and surface finishes down to Ra 0.4 μm. This level of precision ensures seamless integration in high-pressure valves, surgical instruments, and marine propulsion systems where failure is not an option. Our facility employs state-of-the-art 5-axis CNC machining centers, high-pressure coolant systems, and in-process probing to maintain consistency across both prototyping and high-volume production runs.

Wuxi Lead Precision Machinery has supplied precision-machined 316 stainless steel components for projects meeting Olympic-standard infrastructure requirements and certified military specifications. These engagements demanded not only dimensional precision but full traceability, material certification, and compliance with ISO 13485 and AS9100 standards. Our ability to meet such stringent requirements underscores our position as a trusted partner in advanced manufacturing.

The following table outlines key machining specifications we routinely achieve with 316 stainless steel:

| Parameter | Typical Capability |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish (Ra) | 0.4 – 1.6 μm |

| Maximum Part Size (L×W×H) | 1200 × 800 × 600 mm |

| Spindle Speed Range | Up to 24,000 rpm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Standard Compliance | ISO 2768, ISO 13485, AS9100 |

Precision in 316 stainless steel machining is not an incremental advantage—it is a foundational requirement for performance in extreme environments. At Wuxi Lead Precision Machinery, we combine technical mastery with proven experience in high-stakes industries to deliver components that perform with unwavering reliability.

Precision Specs & Tolerances

Advanced Technical Capabilities for 316 Stainless Steel Precision Machining

Wuxi Lead Precision Machinery delivers uncompromising precision for critical 316 stainless steel components demanded in aerospace, medical, semiconductor, and high-corrosion marine applications. Our mastery of this challenging austenitic alloy stems from deep material science understanding and state-of-the-art manufacturing infrastructure. 316 stainless steel presents unique machining difficulties due to its tendency for work hardening, low thermal conductivity, and high ductility, requiring specialized tooling strategies, optimized coolant delivery, and rigid machine platforms to maintain dimensional integrity and surface finish. We address these challenges through meticulously programmed 5-axis CNC machining centers, eliminating the need for multiple setups that introduce cumulative error and potential part distortion. This integrated approach ensures geometric complexity is achieved in a single operation, preserving the material’s inherent corrosion resistance by minimizing handling and thermal stress points critical for final part performance.

Our core production fleet comprises DMG MORI, MAZAK, and Hermle 5-axis vertical machining centers, featuring high-torque spindles, sub-micron positional accuracy, and advanced thermal compensation systems. These machines operate under strict environmental controls to mitigate thermal drift, essential for holding tight tolerances on large or thin-walled 316 stainless structures. We utilize premium carbide and ceramic cutting tools with geometries and coatings specifically selected for 316 stainless, coupled with high-pressure through-spindle coolant to manage heat generation and chip evacuation effectively. This combination prevents built-up edge, ensures consistent surface roughness, and extends tool life, directly impacting part quality and production economics.

Quality verification is non-negotiable for mission-critical 316 stainless components. Every production run undergoes rigorous inspection using Zeiss and Hexagon Global S-Class Coordinate Measuring Machines (CMMs), calibrated to ISO 10360-2 standards and traceable to NIST. Our ASQ-certified metrology team performs full First Article Inspection (FAI) reports per AS9102 standards and conducts in-process and final inspections on all critical features. Statistical Process Control (SPC) data is actively monitored, ensuring process stability and immediate corrective action if deviations occur. Material certification, heat lot traceability, and comprehensive inspection documentation are standard deliverables, providing full audit trails for regulated industries.

The following table details our standard achievable tolerances for precision-machined 316 stainless steel parts, reflecting our process capability under controlled conditions:

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) | Up to 300mm; larger sizes scaled per ISO 2768 |

| Geometric (GD&T) | ±0.015 mm (±0.0006″) | ±0.008 mm (±0.0003″) | Includes Position, Profile, Runout |

| Hole Diameter | H7 (±0.009 mm) | H6 (±0.006 mm) | Reamed/bored; drilled holes less tight |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 0.8 µm (32 µin) | As-machined; polished finishes available |

| Flatness | 0.02 mm per 100mm | 0.01 mm per 100mm | Critical sealing surfaces achievable |

Wuxi Lead transforms the complexities of 316 stainless steel machining into a reliable, high-yield process. Our integrated 5-axis capabilities, coupled with metrology-grade inspection protocols, ensure your components meet the most stringent functional and regulatory requirements, mitigating production bottlenecks and safeguarding your end-product performance in the most demanding environments. Partner with us for precision where failure is not an option.

Material & Finish Options

Material Selection for High-Performance 316 Stainless Steel Machined Parts

When engineering precision components for demanding industrial applications, material selection plays a critical role in ensuring long-term reliability, corrosion resistance, and mechanical performance. Among the most widely specified alloys in precision CNC machining, 316 stainless steel stands out for its superior resistance to pitting and chemical corrosion, particularly in chloride-rich environments. This makes it ideal for use in marine, pharmaceutical, chemical processing, and medical device industries. Compared to 304 stainless steel, 316 contains molybdenum—an alloying element that significantly enhances its resistance to acids, alkalis, and localized corrosion.

While aluminum, steel, and titanium are common choices in CNC machining, 316 stainless steel offers a unique balance of strength, durability, and environmental resilience. Aluminum is favored for lightweight applications and excellent thermal conductivity but lacks the corrosion resistance and tensile strength required in harsh conditions. Carbon steel provides high strength and machinability but is prone to oxidation without protective coatings. Titanium delivers an exceptional strength-to-density ratio and corrosion resistance but comes at a higher material and machining cost. For applications requiring both mechanical integrity and resistance to aggressive environments, 316 stainless steel often presents the optimal compromise.

In addition to material choice, surface finish selection is essential to enhance performance and longevity. While anodizing is a common finish for aluminum components—offering improved wear resistance and electrical insulation—it is not applicable to stainless steel due to the material’s passive oxide layer. Instead, stainless steel parts benefit from alternative finishing processes such as passivation, electropolishing, or mechanical polishing. Passivation removes free iron from the surface, enhancing the natural chromium oxide layer and improving corrosion resistance. Electropolishing further refines surface finish, reduces micro-scale roughness, and increases resistance to contamination—critical in sanitary or high-purity applications.

At Wuxi Lead Precision Machinery, we specialize in the precision CNC machining of 316 stainless steel components, ensuring tight tolerances, repeatable accuracy, and compliance with international quality standards. Our engineering team collaborates with clients to select the appropriate material grade and post-machining treatments based on operational requirements.

Below is a comparative overview of key materials used in precision machining:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Machinability | Typical Applications |

|---|---|---|---|---|

| 316 Stainless Steel | 570–680 | Excellent | Moderate | Marine, medical, chemical processing |

| Aluminum 6061 | 310 | Good (with anodizing) | Excellent | Aerospace, electronics, automotive |

| Carbon Steel A36 | 400–550 | Poor (without coating) | Good | Structural components, machinery |

| Titanium Grade 5 | 900 | Excellent | Poor | Aerospace, defense, medical implants |

Understanding the interplay between material properties and finishing options ensures optimal component performance in real-world conditions. For high-end applications where reliability cannot be compromised, 316 stainless steel remains a benchmark material in precision manufacturing.

Manufacturing Process & QC

Precision Production Process for 316 Stainless Steel Machined Parts

Achieving flawless 316 stainless steel components demands a rigorously controlled production sequence, integrating advanced engineering with uncompromising quality oversight. At Wuxi Lead Precision Machinery, we execute a three-phase methodology designed for zero defects in critical applications across medical, aerospace, and semiconductor industries. This process ensures material integrity, dimensional perfection, and absolute compliance with stringent sector requirements.

The journey begins with Engineering Design & Material Validation. Our engineering team collaborates closely with client specifications, conducting thorough Design for Manufacturability (DFM) analysis specific to 316 stainless steel’s properties. We verify material certification against ASTM A276/A479 standards, confirming chemical composition, grain structure, and inherent corrosion resistance. Critical factors like work hardening tendency, thermal conductivity, and optimal cutting parameters are modeled using advanced CAM simulation software. This phase establishes the precise toolpaths, fixture strategies, and coolant protocols essential for maintaining material integrity and achieving micron-level tolerances without inducing stress.

Precision Prototyping & Validation follows, serving as the critical gate before mass production. Utilizing our HAAS and DMG MORI 5-axis machining centers, we produce initial prototypes under full production conditions. Each prototype undergoes exhaustive metrology: CMM inspection verifies geometric dimensioning and tolerancing (GD&T) compliance down to ±0.0002 inches, surface profilometry confirms Ra values, and metallurgical testing checks for microstructural integrity and absence of deformation. We perform functional testing and dimensional stability analysis, including cryogenic stress relief where specified. Client sign-off on these validated prototypes is mandatory, ensuring the process is proven and defect-free before scaling.

Zero-Defect Mass Production leverages the validated process under our certified ISO 9001:2015 and IATF 16949 quality management system. Production occurs on dedicated, monitored CNC cells with real-time tool wear compensation and in-process gauging. Statistical Process Control (SPC) charts track critical dimensions continuously, triggering immediate corrective action if trends approach tolerance limits. Every component undergoes 100% dimensional inspection via automated optical comparators or CMMs, alongside mandatory surface finish and visual inspection under controlled lighting. Full material traceability, from raw bar stock heat number to final part serialization, is maintained. Final packaging adheres to industry-specific cleanliness protocols, ensuring parts arrive ready for mission-critical assembly.

The following table details the achievable specifications for 316 stainless steel machined parts under this controlled process:

| Specification Category | Typical Capability | Tight Tolerance Capability | Measurement Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ±0.001 mm (±0.00004″) | ISO 2768-mK / ASME Y14.5 |

| Geometric Tolerance (GD&T) | ±0.010 mm (±0.0004″) | ±0.002 mm (±0.00008″) | ISO 1101 / ASME Y14.5 |

| Surface Roughness (Ra) | 0.8 μm (32 μin) | 0.2 μm (8 μin) | ISO 4287 / ASME B46.1 |

| Surface Flatness | 0.010 mm per 100 mm | 0.002 mm per 50 mm | ISO 12781-1 |

| Material Certification | ASTM A276/A479 Type 316/316L | Mill Test Reports (MTRs) | Traceable to Heat Number |

This integrated approach—grounded in material science, validated prototyping, and statistically controlled manufacturing—guarantees the production of 316 stainless steel components meeting the highest demands for reliability and performance, with zero defects as the operational standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in 316 Stainless Steel Machined Parts

At Wuxi Lead Precision Machinery, we specialize in the precision CNC machining of high-performance 316 stainless steel components, serving global industries where reliability, corrosion resistance, and dimensional accuracy are non-negotiable. From aerospace and medical devices to semiconductor equipment and marine engineering, our engineered solutions meet the most stringent international standards. When you choose to partner with Lead Precision, you’re not just sourcing parts—you’re gaining a strategic manufacturing ally with deep technical expertise, advanced capabilities, and an unwavering commitment to quality.

Our state-of-the-art CNC machining center is equipped with multi-axis milling and turning systems, enabling us to produce complex 316 stainless steel components with tight tolerances down to ±0.005 mm. We combine advanced process planning with real-time in-process inspection to ensure consistency across both prototyping and high-volume production runs. Our facility operates under ISO 9001:2015 certification, with full traceability of materials, documented inspection reports, and first-article inspection (FAI) protocols available upon request.

What sets us apart is our engineering-first approach. We actively collaborate with design and R&D teams to optimize part geometry, reduce machining time, and improve manufacturability—without compromising performance. Whether you require small, intricate fittings or large-scale structural components, our engineers provide detailed Design for Manufacturability (DFM) feedback to streamline your path from concept to delivery.

We understand that 316 stainless steel is selected for its superior resistance to chlorides, acids, and high-temperature environments. That’s why our machining processes are fine-tuned to preserve the material’s intrinsic properties, including controlled toolpaths to minimize work hardening and post-machining passivation to enhance corrosion resistance. Every component is inspected using calibrated CMMs, optical comparators, and surface finish testers to ensure compliance with your exact specifications.

Below are key technical capabilities for machining 316 stainless steel at Lead Precision:

| Specification | Detail |

|---|---|

| Material | ASTM A276 / AISI 316 / 1.4401 Stainless Steel |

| Tolerance | ±0.005 mm (standard), up to ±0.002 mm (tight-tolerance) |

| Surface Finish | Ra 0.8 µm standard, down to Ra 0.2 µm (polished) |

| Max Work Envelope | 800 x 500 x 400 mm (3-axis), 600 x 400 x 300 mm (5-axis) |

| Machining Processes | CNC Milling (3, 4, 5-axis), CNC Turning, Mill-Turn |

| Secondary Operations | Passivation, Deburring, Laser Marking, Precision Cleaning |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting (CMM, GD&T) |

Partnering with Wuxi Lead Precision Machinery means access to scalable, agile, and technically advanced manufacturing in the heart of China’s industrial corridor. We support global logistics with reliable lead times and responsive project management tailored to your production schedule.

For expert machining of 316 stainless steel components, contact us today at [email protected]. Let our engineering team help you achieve precision, performance, and peace of mind.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.