Technical Contents

Engineering Guide: 3-D Printing Services

Engineering Insight: Precision in 3D Printing Services for Custom Metal Manufacturing

In the realm of advanced manufacturing, 3D printing services have evolved beyond prototyping to become a cornerstone of high-performance, custom metal component production. At Wuxi Lead Precision Machinery, we recognize that the true value of metal additive manufacturing lies not just in geometric freedom, but in the ability to achieve micron-level precision consistently across mission-critical applications. This precision defines the boundary between functional prototypes and production-grade parts—especially in industries where failure is not an option.

Our engineering team has spent over a decade refining metal 3D printing processes to meet the rigorous demands of aerospace, defense, and high-end industrial sectors. This includes direct involvement in projects supporting Chinese military programs and precision component supply for Olympic-grade equipment, where tolerances under ±0.02 mm are standard and surface finishes must meet stringent functional requirements. These experiences have shaped our approach: precision is not an afterthought—it is engineered into every build.

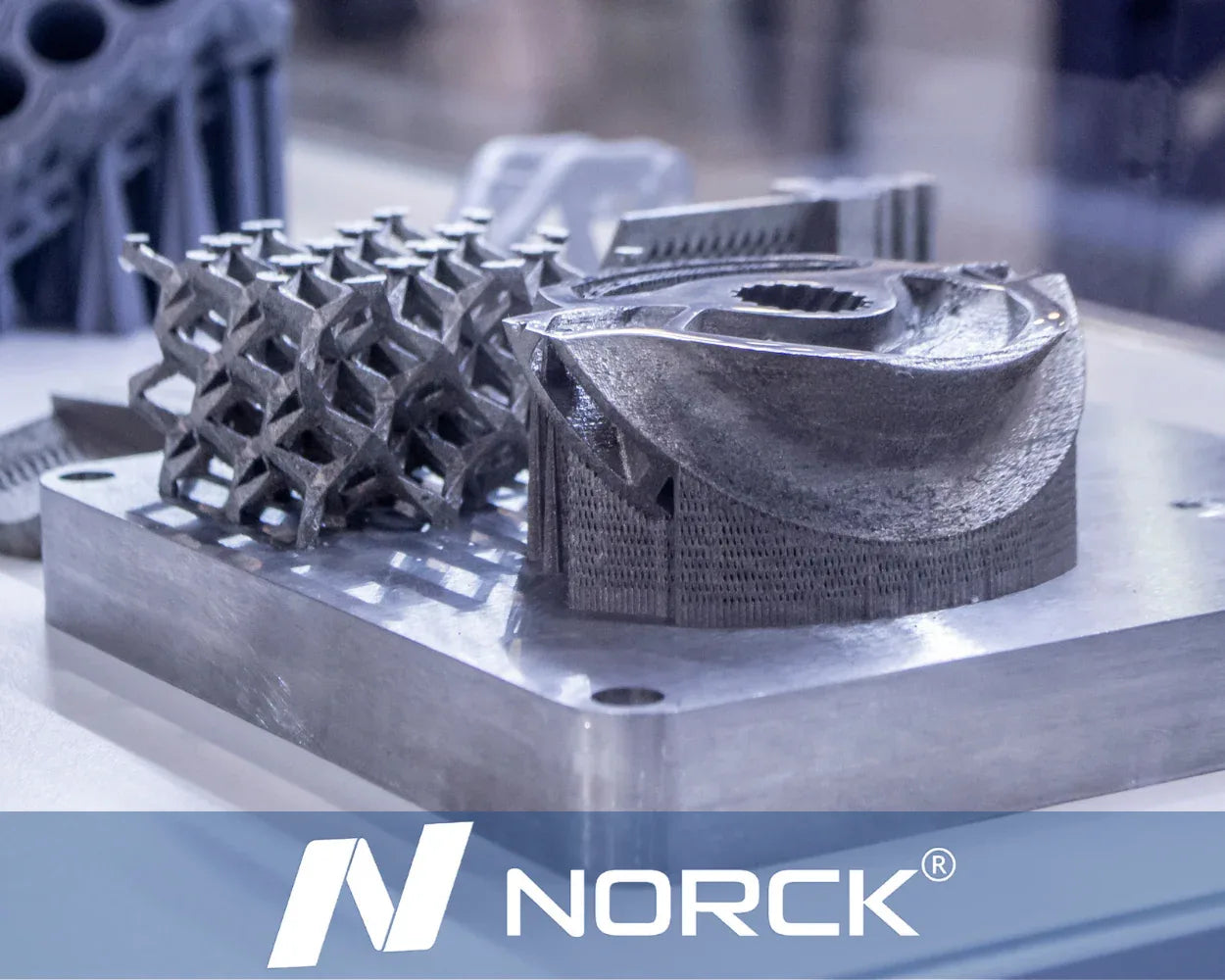

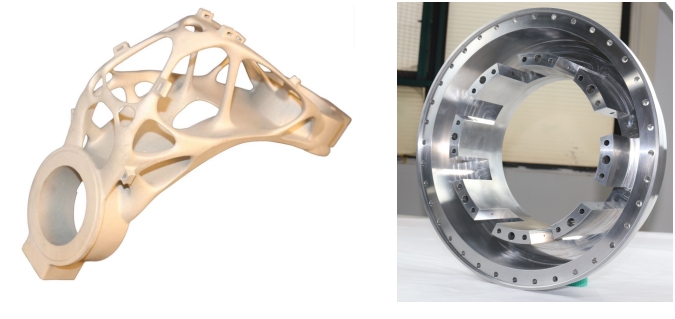

Metal 3D printing, particularly through Laser Powder Bed Fusion (LPBF), enables complex internal geometries and topology-optimized structures unachievable through traditional machining. However, the layer-by-layer nature of additive manufacturing introduces variables such as thermal distortion, residual stress, and anisotropic material behavior. At Lead Precision, we counter these challenges with in-situ monitoring, adaptive scanning strategies, and proprietary post-processing protocols that ensure dimensional accuracy, repeatability, and material integrity.

Each build undergoes rigorous quality validation, including first-article inspection (FAI), CT scanning for internal defect detection, and metallurgical analysis to verify microstructure and mechanical properties. Our ISO 13485 and AS9100-certified production environment ensures compliance with global standards, while our in-house CNC finishing and surface treatment capabilities bridge the gap between as-printed and final-spec components.

The integration of precision 3D printing into end-use manufacturing demands more than advanced machines—it requires deep process understanding, material science expertise, and a culture of engineering excellence. At Wuxi Lead, we combine state-of-the-art equipment with decades of applied experience to deliver metal additive solutions that perform under extreme conditions.

Below are key technical specifications for our metal 3D printing services:

| Parameter | Specification |

|---|---|

| Printing Technology | Laser Powder Bed Fusion (LPBF) |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–60 μm |

| Positional Accuracy | ±0.02 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm (can be reduced to Ra <1.6 μm post-processing) |

| Materials | Stainless Steel (316L, 17-4PH), Inconel 718, Titanium (Ti6Al4V), Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Post-Processing Capabilities | Stress Relieving, Hot Isostatic Pressing (HIP), CNC Machining, Polishing, Coating |

Precision in 3D printing is not merely about hitting tight tolerances—it is about delivering reliability, performance, and confidence in every component we produce.

Precision Specs & Tolerances

Precision Metal Manufacturing Capabilities: Beyond Additive Limitations

While additive manufacturing offers distinct advantages for specific prototyping and low-volume applications, Wuxi Lead Precision Machinery emphasizes that true high-integrity, mission-critical metal components for aerospace, medical, and energy sectors demand the unparalleled precision, material integrity, and surface finish achievable only through advanced subtractive methods. Our core expertise and investment reside in state-of-the-art multi-axis CNC machining, the definitive process for producing end-use metal parts meeting the most stringent performance and regulatory requirements. 3D printing services for metal often face challenges with material density, internal stresses, surface roughness, and achieving tight tolerances consistently across production runs – limitations that our precision machining processes inherently overcome.

Our technical foundation is built upon a modern fleet of 5-axis CNC machining centers. This technology enables simultaneous, complex interpolation of all five axes, allowing us to machine intricate geometries, deep cavities, and compound angles in a single setup. The elimination of multiple fixturing operations is critical; it drastically reduces cumulative error, minimizes part handling damage, and ensures superior dimensional consistency between features. We routinely machine challenging aerospace alloys like Inconel 718 and Ti-6Al-4V, as well as medical-grade stainless steels and cobalt-chromium, achieving the exacting surface finishes and structural integrity required for safety-critical applications. This capability translates directly to reduced scrap rates, faster time-to-assembly, and components that perform reliably under extreme operational stresses.

Quality assurance is non-negotiable and integrated into every stage of production. Every critical component undergoes rigorous inspection using our calibrated Coordinate Measuring Machines (CMM). These systems provide metrology-grade verification of complex 3D geometries, ensuring absolute conformance to the most demanding GD&T specifications. Our CMM inspection protocols are not merely a final check; they are embedded within our process control strategy, enabling real-time adjustments and providing comprehensive, traceable documentation for full regulatory compliance. This systematic approach guarantees that dimensional accuracy is not left to chance but is a measurable, verifiable outcome of our manufacturing process.

The table below details our standard and achievable tolerance capabilities across common high-performance materials, reflecting the precision inherent in our 5-axis CNC and CMM-controlled workflow. These values represent typical production capabilities for features machined under controlled conditions; specific project requirements will be evaluated during engineering review.

| Material Category | Standard Tolerance (mm) | Tight Tolerance Capability (mm) | Critical Notes |

|---|---|---|---|

| Titanium Alloys (e.g., Ti-6Al-4V) | ±0.025 | ±0.005 | Achievable on critical features post-stress relief |

| Nickel-Based Superalloys (e.g., Inconel 718) | ±0.050 | ±0.010 | Dependent on feature geometry and size |

| Stainless Steels (e.g., 316L, 17-4PH) | ±0.020 | ±0.005 | Standard for medical/ aerospace critical surfaces |

| Aluminum Alloys (e.g., 7075-T6) | ±0.025 | ±0.008 | High stability enables tight positional tolerances |

| Cobalt-Chromium (Medical) | ±0.020 | ±0.005 | Surface finish and dimensional accuracy critical for biocompatibility |

Wuxi Lead Precision Machinery delivers not just parts, but guaranteed dimensional and material integrity. Our integrated 5-axis CNC machining and metrology-controlled inspection provide the foundation for manufacturing excellence where performance, reliability, and compliance are paramount. Partner with us for metal components where precision is not an option, but an absolute requirement.

Material & Finish Options

Material selection is a critical decision in custom metal 3D printing, directly influencing the performance, durability, and application suitability of the final component. At Wuxi Lead Precision Machinery, we specialize in high-precision metal additive manufacturing using advanced laser powder bed fusion (LPBF) technology. Our expertise enables us to support clients in selecting optimal materials based on mechanical requirements, environmental exposure, weight constraints, and post-processing needs. The three most widely used metals in industrial 3D printing—aluminum, steel, and titanium—each offer distinct advantages tailored to demanding engineering environments.

Aluminum alloys, particularly AlSi10Mg, are favored for applications requiring lightweight structures with good thermal conductivity and moderate strength. This material is ideal for aerospace components, heat exchangers, and automotive parts where weight reduction is paramount without sacrificing performance. Its excellent castability and fatigue resistance make it a top choice for complex, topology-optimized designs achievable only through additive manufacturing.

Stainless steel, especially grades such as 316L and 17-4 PH, delivers high tensile strength, corrosion resistance, and thermal stability. These properties make steel suitable for harsh environments, including marine, chemical processing, and oil & gas applications. 316L offers superior resistance to chloride corrosion, while 17-4 PH provides exceptional strength through precipitation hardening, making it ideal for high-stress mechanical components.

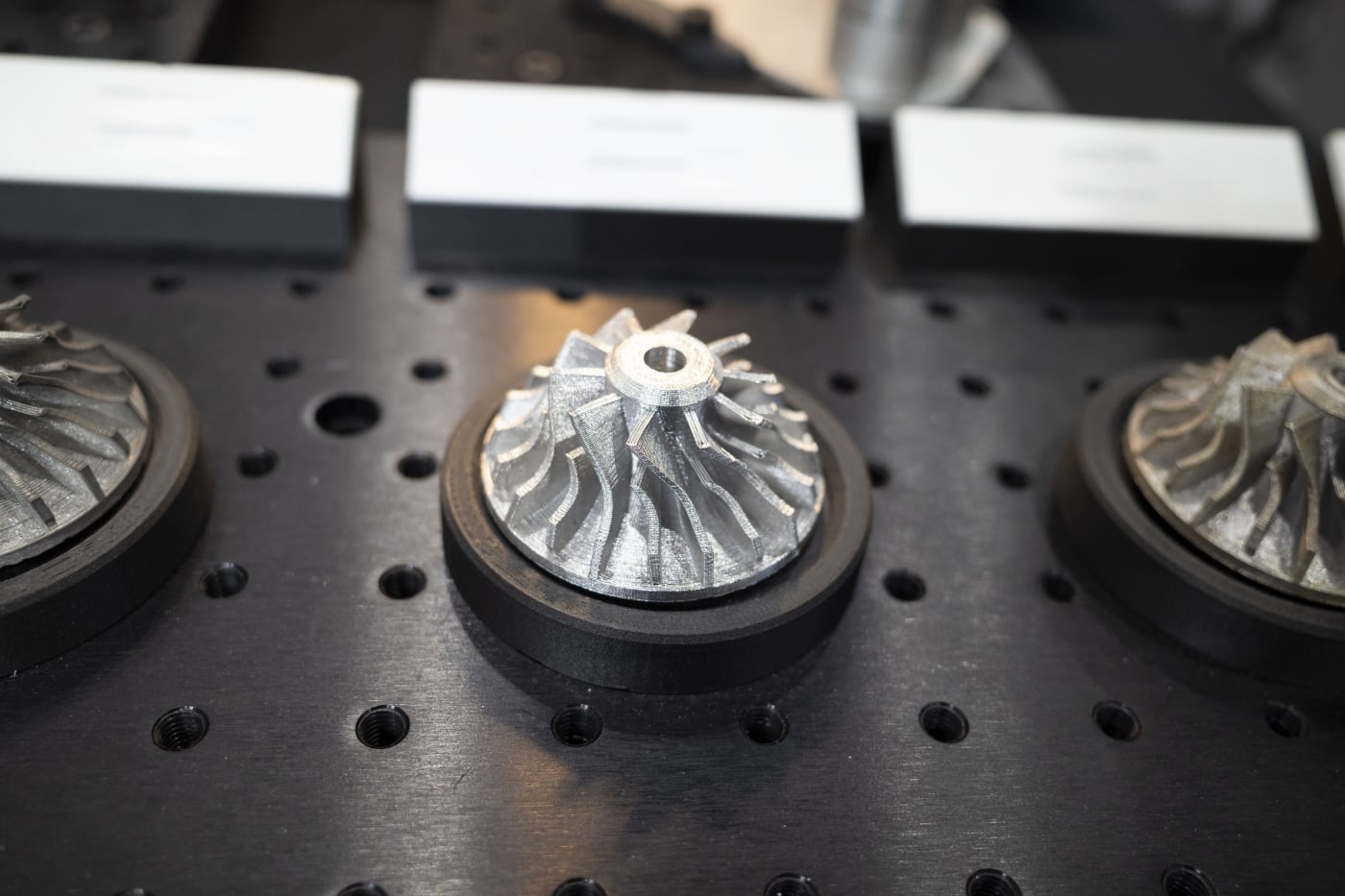

Titanium, primarily Ti6Al4V (Grade 5), stands as the premium choice for high-performance sectors such as aerospace, medical implants, and motorsports. It offers an outstanding strength-to-density ratio, excellent resistance to extreme temperatures, and biocompatibility. Its ability to maintain structural integrity under cyclic loading and corrosive conditions makes it indispensable for safety-critical applications.

Post-processing plays a vital role in enhancing both functionality and aesthetics. Anodizing is a widely used surface treatment, particularly for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and surface hardness. It also allows for color coding through dye integration, aiding in part identification and branding. While anodizing does not typically apply to steel or titanium in the same way, titanium can undergo similar oxide layer enhancement through controlled thermal or electrochemical treatments for medical and aesthetic purposes.

Below is a comparative overview of key material properties relevant to 3D printed metal components.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–500 | 250–300 | 2.67 | 8–12 | Aerospace, Automotive, Heat Exchangers |

| 316L Stainless Steel | 550–650 | 350–450 | 8.0 | 30–45 | Marine, Chemical, Medical Equipment |

| 17-4 PH Steel | 900–1300 | 750–1100 | 7.8 | 10–15 | Aerospace, Tooling, High-Stress Parts |

| Ti6Al4V | 900–1000 | 800–880 | 4.43 | 8–12 | Aerospace, Medical Implants, Racing |

Selecting the right material and finish requires a deep understanding of operational demands. Wuxi Lead Precision Machinery supports clients through every phase—from material consultation to final surface treatment—ensuring components meet exacting industrial standards.

Manufacturing Process & QC

Integrated Production Process for Zero-Defect Metal Additive Manufacturing

At Wuxi Lead Precision Machinery we execute a rigorously controlled production sequence for custom metal 3D printing services ensuring absolute adherence to the Zero Defects philosophy. This integrated workflow spans Design through Prototyping to Mass Production each phase engineered for precision and traceability. Our ISO 9001 and AS9100 certified processes eliminate variability guaranteeing mission-critical components meet exact aerospace defense and medical specifications.

Design Phase

Engineering collaboration begins with comprehensive DfAM analysis. Our specialists optimize part geometry for additive constraints including thermal management support structure strategy and build orientation. Finite element analysis validates structural integrity under operational loads. Material selection leverages our expertise in Inconel 718 Ti-6Al-4V stainless steel 316L and aluminum alloys. Every design file undergoes closed-loop verification against client CAD models and GD&T requirements before release eliminating interpretation errors at the source.

Prototyping Phase

Functional prototypes are produced using identical process parameters and materials as final production. This phase validates design performance and manufacturing feasibility. We conduct metrology-grade validation via coordinate measuring machines and CT scanning to verify internal channels and complex geometries. Material certifications and mechanical test reports accompany each prototype. Client feedback is incorporated through a formal engineering change order system ensuring the final design is perfected before scaling.

Mass Production Phase

High-volume manufacturing utilizes our industrial-grade DMLS and SLM systems operating under strict environmental controls. Real-time melt pool monitoring and inert gas management ensure consistent layer fusion. Every build undergoes in-process inspection with thermal imaging and layer-by-layer verification. Post-processing including precision machining heat treatment and surface finishing occurs within our integrated facility maintaining full chain-of-custody. Final parts receive 100% dimensional inspection and non-destructive testing per ASTM F3301 standards.

The following table details critical specifications across our production phases

| Phase | Key Activities | Quality Control Measures | Output Specification |

|---|---|---|---|

| Design | DfAM optimization FEA validation GD&T review | CAD comparison tolerance stack analysis | Approved build-ready digital file |

| Prototyping | Parameter validation functional testing | CMM CT scan mechanical testing material certification | Certified functional prototype |

| Mass Production | Controlled builds post-processing | Real-time monitoring 100% dimensional NDT | Flight-ready serial production part |

| Zero Defects Integration | Closed-loop data analysis root cause review | Statistical process control traceability documentation | Zero non-conformances per batch |

This seamless transition from virtual model to certified physical component embodies our commitment to perfection. By embedding quality at every interface we deliver metal additive solutions where failure is never an option. Partner with Wuxi Lead to transform complex designs into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal 3D Printing Services

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation define success in high-performance industries such as aerospace, medical devices, energy, and advanced automation. As a leader in custom metal manufacturing, we offer advanced 3D printing services engineered to meet the most demanding technical specifications. Our commitment to quality, combined with cutting-edge technology and decades of engineering experience, positions us as the ideal manufacturing partner for global enterprises seeking precision, scalability, and rapid time-to-market.

Our metal additive manufacturing solutions are built on a foundation of industrial-grade equipment and rigorous quality control. We specialize in producing complex, high-integrity components using selective laser melting (SLM) and direct metal laser sintering (DMLS) technologies. Whether you require low-volume prototypes, functional test parts, or full-scale production runs, our team ensures every component meets exacting standards for mechanical performance, dimensional accuracy, and surface finish.

We work with a wide range of high-performance alloys, including titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel (625, 718), aluminum (AlSi10Mg), and tool steels (H13, Maraging Steel). Each build is supported by comprehensive process documentation, material traceability, and optional third-party inspection reports to meet ISO, AS, and ASTM compliance requirements.

Our engineering team collaborates closely with clients from design for additive manufacturing (DFAM) through post-processing, heat treatment, CNC finishing, and final inspection. This end-to-end integration ensures optimal part performance and manufacturability while reducing lead times and minimizing waste.

Below are the key technical specifications of our metal 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–50 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 12–25 µm |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing, coating |

| Supported Materials | Ti6Al4V, 316L, 17-4 PH, Inconel 625/718, AlSi10Mg, H13, Maraging Steel |

| Quality Standards | ISO 9001:2015, ASTM F75, ASTM F136, AS9100 (in process) |

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem where precision, innovation, and responsiveness drive every project. Our facility in Wuxi, China, is equipped with state-of-the-art monitoring systems and staffed by certified engineers and metallurgists who ensure consistency across every production batch.

For engineering teams and procurement leaders seeking a trusted partner in metal additive manufacturing, the next step is simple. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let us help you turn advanced designs into high-performance realities.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.