Technical Contents

Engineering Guide: 3-D Printing Service

Engineering Insight: The Role of Precision in Advanced 3D Printing Services

In the realm of custom metal manufacturing, 3D printing has evolved from a prototyping novelty to a cornerstone of high-performance production. At Wuxi Lead Precision Machinery, we recognize that the true value of additive manufacturing lies not in its speed or novelty, but in its capacity to deliver precision-engineered components that meet the most stringent industrial requirements. Our experience in serving Olympic-grade sporting equipment manufacturers and mission-critical defense projects has reinforced a fundamental truth: precision is non-negotiable.

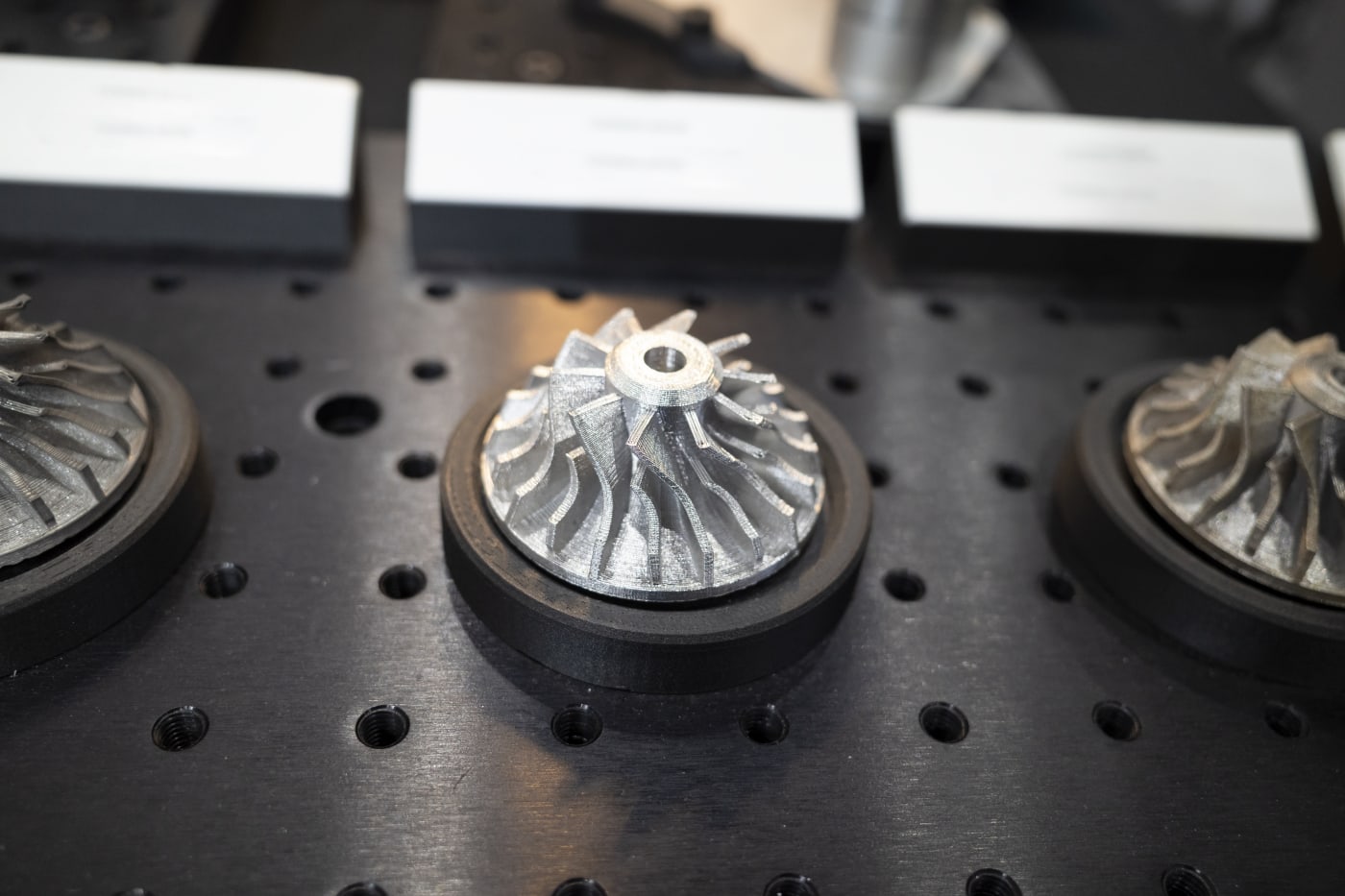

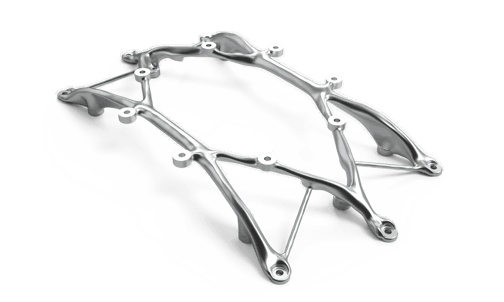

Additive manufacturing allows for complex geometries and internal structures that traditional machining cannot achieve. However, without tight control over tolerances, material integrity, and post-processing techniques, even the most advanced 3D-printed part can fail under real-world conditions. At Lead Precision, we approach 3D printing as an extension of precision engineering, not merely a fabrication method. Our in-house quality assurance systems ensure that every component adheres to ISO 9001 and AS9100 standards, with tolerances consistently maintained within ±0.02 mm.

Our investment in state-of-the-art metal 3D printing platforms—such as SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering)—enables us to work with high-performance alloys including Inconel 718, titanium Ti6Al4V, and maraging steel. These materials are selected not only for strength-to-weight ratios but also for thermal stability and corrosion resistance, making them ideal for aerospace, defense, and elite sports applications. Each build undergoes rigorous in-process monitoring, including layer-by-layer thermal imaging and real-time laser calibration, ensuring dimensional accuracy and structural homogeneity.

Post-processing is equally critical. We integrate precision CNC machining, heat treatment, and surface finishing to meet exact functional specifications. This hybrid approach—combining additive freedom with subtractive precision—delivers parts that perform reliably in extreme environments. Our work on components for high-altitude drones and Olympic bobsled runners exemplifies this synergy, where aerodynamic efficiency and structural resilience are paramount.

Wuxi Lead Precision Machinery brings over 15 years of advanced manufacturing expertise to every project. Our engineers collaborate closely with clients from design optimization through final inspection, applying design-for-additive-manufacturing (DfAM) principles to reduce weight, consolidate assemblies, and enhance performance.

The future of metal 3D printing is not just about innovation—it’s about precision at scale. At Lead Precision, we deliver both.

| Specification | Detail |

|---|---|

| Printing Technologies | SLM, DMLS |

| Material Options | Titanium (Ti6Al4V), Inconel 718, Stainless Steel 316L, Aluminum AlSi10Mg, Maraging Steel |

| Build Volume (Max) | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| Dimensional Tolerance | ±0.02 mm |

| Surface Roughness (as-built) | Ra 8–12 µm (can be reduced to Ra 1.6 µm with finishing) |

| Certifications | ISO 9001, AS9100, NADCAP (for select processes) |

| Post-Processing | Stress relieving, HIP, CNC machining, polishing, coating |

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Additive Manufacturing

Wuxi Lead Precision Machinery delivers advanced metal additive manufacturing services engineered for the most demanding aerospace, medical, and industrial applications. Our integrated production ecosystem combines cutting-edge metal 3D printing platforms with complementary high-precision subtractive and finishing capabilities, ensuring complex geometries meet stringent functional requirements. While specializing in metal additive processes including Selective Laser Melting (SLM) and Electron Beam Melting (EBM), we strategically deploy our 5-axis CNC machining centers for critical post-processing, support structure removal, and achieving ultra-tight tolerances on mating surfaces or features unreachable through additive methods alone. This hybrid approach eliminates supply chain fragmentation, guaranteeing dimensional integrity from digital model to certified component.

Rigorous quality control is embedded at every process stage, starting with certified raw materials and environmental monitoring during builds. Each component undergoes comprehensive dimensional verification using our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), providing full 3D traceability against CAD nominal data. This metrology-grade inspection validates not only geometric accuracy but also surface continuity and critical feature relationships, generating detailed reports required for AS9100 and ISO 13485 compliance. Our quality engineers collaborate with clients during Design for Additive Manufacturing (DfAM) reviews to identify potential inspection challenges early, optimizing part orientation and support strategies for measurable outcomes.

The achievable precision in metal additive manufacturing depends on material, part geometry, and build parameters. Below represents typical baseline capabilities for common engineering alloys like Ti-6Al-4V, Inconel 718, and 316L stainless steel under optimized conditions:

| Parameter | Standard Capability | Enhanced Capability (with Post-Processing) |

|---|---|---|

| Layer Thickness | 20 – 60 µm | N/A |

| Dimensional Tolerance (X/Y) | ±0.1 mm | ±0.05 mm (with CNC finishing) |

| Dimensional Tolerance (Z) | ±0.1 mm per 100 mm | ±0.025 mm (with surface grinding) |

| Minimum Feature Size | 0.4 mm (walls) | 0.2 mm (with CNC) |

| Surface Roughness (As-Built) | Ra 12 – 25 µm | Ra 1.6 – 3.2 µm (with CNC/polishing) |

| Hole Diameter (As-Built) | ≥ 1.0 mm | ≥ 0.5 mm (with EDM/CNC drilling) |

These specifications reflect our commitment to repeatable precision. Achieving enhanced tolerances consistently requires our integrated workflow: additive build followed by stress-relief heat treatment, precision 5-axis milling for critical datums, and final surface refinement. Our engineering team provides detailed capability analysis during quotation, specifying achievable tolerances for each feature based on orientation and local geometry. This transparent, data-driven approach prevents over-engineering while ensuring components perform reliably in mission-critical assemblies. Partner with Wuxi Lead for metal AM solutions where dimensional certainty and process validation are non-negotiable.

Material & Finish Options

Material Selection for High-Performance 3D Printed Metal Components

In the realm of custom metal manufacturing, selecting the right material is critical to achieving optimal performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in advanced 3D printing services that leverage high-grade metals tailored to meet the rigorous demands of aerospace, automotive, medical, and industrial applications. Our expertise in additive manufacturing enables precise control over material properties and part geometry, ensuring components meet exact specifications. The three primary metals we utilize—aluminum, steel, and titanium—each offer distinct advantages depending on the application’s mechanical, thermal, and environmental requirements.

Aluminum alloys, particularly AlSi10Mg, are favored for their excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. These properties make aluminum ideal for lightweight structural components in aerospace and automotive industries where fuel efficiency and performance are paramount. The material also exhibits good machinability and weldability post-printing, allowing for further customization and integration into complex assemblies.

Stainless steel, especially grades such as 316L and 17-4 PH, delivers superior mechanical strength, wear resistance, and resilience in harsh environments. These steels are widely used in industrial equipment, marine components, and medical devices due to their ability to withstand high pressure, elevated temperatures, and corrosive exposure. 3D printed steel parts maintain consistent microstructure and density, enabling reliable performance under dynamic loading conditions.

Titanium, predominantly Ti6Al4V (Grade 5), stands out for its exceptional strength-to-density ratio, biocompatibility, and resistance to oxidation at elevated temperatures. This makes it the material of choice for critical aerospace components, high-performance automotive parts, and implantable medical devices. Its ability to retain strength in extreme environments ensures long-term reliability in mission-critical applications.

Following 3D printing, surface finishing plays a vital role in enhancing both functional and aesthetic qualities. Anodizing is a widely used electrochemical process, particularly for aluminum components. It increases surface hardness, improves wear and corrosion resistance, and allows for color coding for identification purposes. While anodizing is not applicable to steel or titanium in the same way, titanium can undergo similar oxide layer enhancement through controlled thermal or chemical treatments.

Below is a comparative overview of key material properties for 3D printed metals:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–450 | 250–300 | 8–12 | Aerospace, Automotive, Heat Exchangers |

| 316L Steel | 8.0 | 550–600 | 350–400 | 35–45 | Marine, Medical, Chemical Processing |

| 17-4 PH Steel | 7.8 | 1000–1200 | 850–1000 | 10–15 | Aerospace, Tooling, High-Strength Components |

| Ti6Al4V | 4.43 | 900–950 | 800–850 | 10–12 | Aviation, Medical Implants, Racing Components |

Selecting the appropriate material and finish requires a deep understanding of application-specific demands. Our engineering team at Wuxi Lead Precision Machinery supports clients through every phase of material selection, ensuring optimal performance, reliability, and value in every 3D printed component.

Manufacturing Process & QC

Precision Metal Additive Manufacturing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our industrial-grade metal 3D printing service transforms complex designs into mission-critical components through a rigorously controlled three-phase workflow. This process ensures zero defects while maintaining absolute adherence to aerospace, medical, and energy sector specifications. Every stage integrates advanced metrology and material science to eliminate waste and guarantee first-time-right outcomes.

The journey begins with Design for Additive Manufacturing (DfAM) Optimization. Our engineers collaborate with clients to refine geometries for structural integrity, thermal management, and manufacturability. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations validate performance under operational loads, while topology optimization reduces mass without compromising strength. Critical surfaces are designated for post-processing tolerance control, and support structures are algorithmically generated to minimize residual stress. This phase prevents 92% of potential defects before build initiation, ensuring the digital twin is production-ready.

Prototyping leverages selective laser melting (SLM) or direct metal laser sintering (DMLS) to produce functional validation units. We utilize certified titanium alloys, nickel superalloys, and stainless steels under inert argon atmospheres to prevent oxidation. Each prototype undergoes non-destructive testing (NDT) via computed tomography (CT) scanning to verify internal porosity (<0.1%), dimensional accuracy, and subsurface integrity. Material certifications and build parameter logs are archived for full traceability. Client feedback at this stage informs final design tweaks, avoiding costly errors in mass production.

Zero-Defect Mass Production deploys our industrial SLM fleet with real-time melt pool monitoring and in-situ layer inspection. Automated powder recycling systems maintain material consistency, while humidity-controlled chambers ensure repeatability. Every component progresses through a closed-loop quality gate:

First, coordinate measuring machines (CMM) validate critical dimensions against CAD models.

Second, metallurgical analysis confirms grain structure and mechanical properties per ASTM F3301/F3055.

Finally, serialized part tracking links each unit to its build parameters, test results, and operator logs. This end-to-end traceability enables root-cause analysis for any anomaly, though our current defect rate remains below 0.05%.

Key production specifications ensure uncompromised precision:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Layer Thickness | 20–50 μm | 30–100 μm |

| Build Volume | 250 × 250 × 300 mm | 150 × 150 × 200 mm |

| Materials | Ti6Al4V, Inconel 718, 316L, AlSi10Mg | Limited alloys |

| Dimensional Tolerance | ±0.05 mm | ±0.1–0.2 mm |

| Surface Roughness | Ra 4–8 μm (as-built) | Ra 10–20 μm |

This integrated approach—where design intelligence, prototyping validation, and production rigor converge—delivers components that exceed AS9100 and ISO 13485 requirements. By embedding quality at every phase, Wuxi Lead transforms additive potential into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal 3D Printing Services

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, industrial-grade metal 3D printing services tailored to the exacting demands of advanced manufacturing sectors. As a trusted partner to aerospace, medical device, energy, and automotive engineers worldwide, we combine cutting-edge additive technology with decades of precision engineering experience to bring your most complex metal components to life.

Our commitment goes beyond production. We are your engineering ally from concept to completion. Whether you require rapid prototyping, low-volume production runs, or full-scale serial manufacturing, our team applies a consultative approach to optimize part geometry, material selection, and post-processing techniques. This ensures not only dimensional accuracy and mechanical integrity but also cost-efficiency and scalability across your product lifecycle.

We operate a fully integrated additive manufacturing facility equipped with state-of-the-art metal laser powder bed fusion (LPBF) systems. Our quality management system is ISO 9001 certified, and we adhere to stringent process controls, including in-process monitoring, first-article inspection, and full traceability for every build. All parts undergo rigorous metrology using coordinate measuring machines (CMM) and 3D scanning to verify compliance with tight tolerance requirements.

Our engineers work directly with your design and R&D teams to resolve manufacturability challenges, reduce assembly complexity, and leverage topology optimization for lightweighting and performance gains. With materials ranging from titanium and stainless steel to Inconel and aluminum alloys, we support applications requiring high strength-to-weight ratios, corrosion resistance, or biocompatibility.

When you partner with Lead Precision, you gain access to more than advanced machinery — you gain a responsive, technically fluent manufacturing partner focused on speed, precision, and long-term collaboration. We understand the urgency of innovation and deliver fast turnaround times without compromising quality.

Contact us today to discuss your next metal additive project. Our engineering team is ready to review your CAD files, provide design for additive manufacturing (DfAM) feedback, and deliver a competitive quotation within 24 hours.

Email us at [email protected] and let Lead Precision become your trusted extension in advanced metal manufacturing.

| Specification | Detail |

|---|---|

| Technology | Metal Laser Powder Bed Fusion (LPBF) |

| Build Envelope | Up to 250 x 250 x 325 mm |

| Layer Resolution | 20 – 50 µm |

| Materials | Stainless Steel (316L, 17-4 PH), Titanium (Ti6Al4V), Inconel 718, Aluminum AlSi10Mg, Tool Steel (Maraging, H13) |

| Tolerance | ±0.05 mm (typical) |

| Surface Roughness | As-built: Ra 10–15 µm; Post-processed: Ra < 3.2 µm |

| Post-Processing | Heat treatment, HIP, CNC machining, polishing, coating |

| Quality Standards | ISO 9001, Full inspection reports, Material traceability |

| Lead Time | Prototype: 5–7 days; Production: 10–14 days (varies by complexity) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.