Technical Contents

Engineering Guide: 3 D Printer Parts

Engineering Insight: Precision in 3D Printer Parts Manufacturing

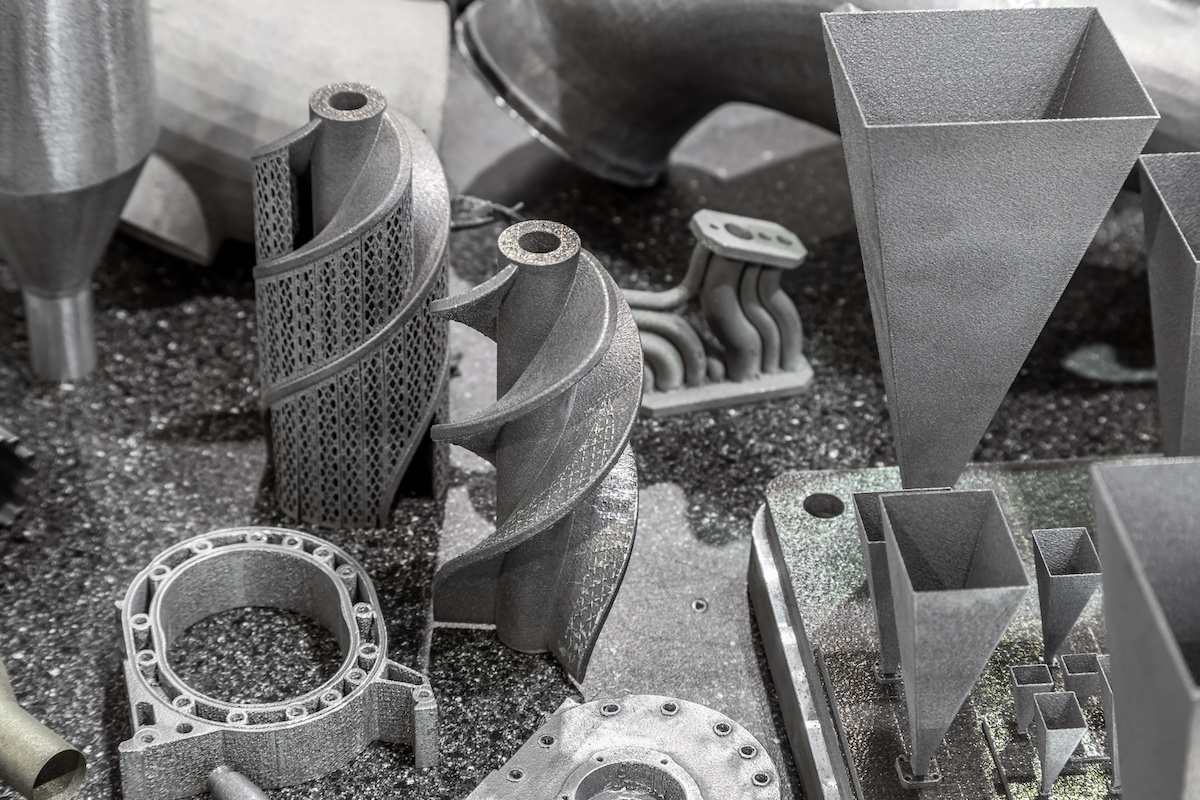

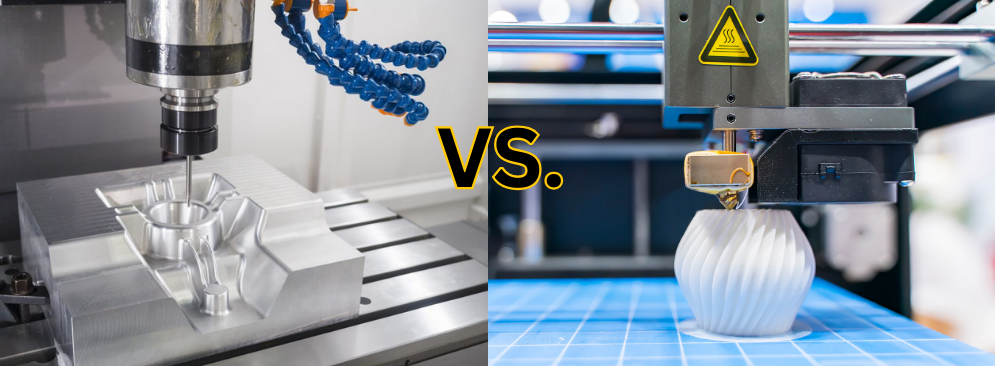

In the realm of advanced manufacturing, 3D printing has emerged as a transformative force, enabling rapid prototyping, complex geometries, and customized production across aerospace, medical, and industrial sectors. However, the performance and reliability of 3D printers themselves depend critically on the precision of their internal metal components. At Wuxi Lead Precision Machinery, we understand that the success of additive manufacturing systems is intrinsically tied to the quality of their subtractively manufactured core parts.

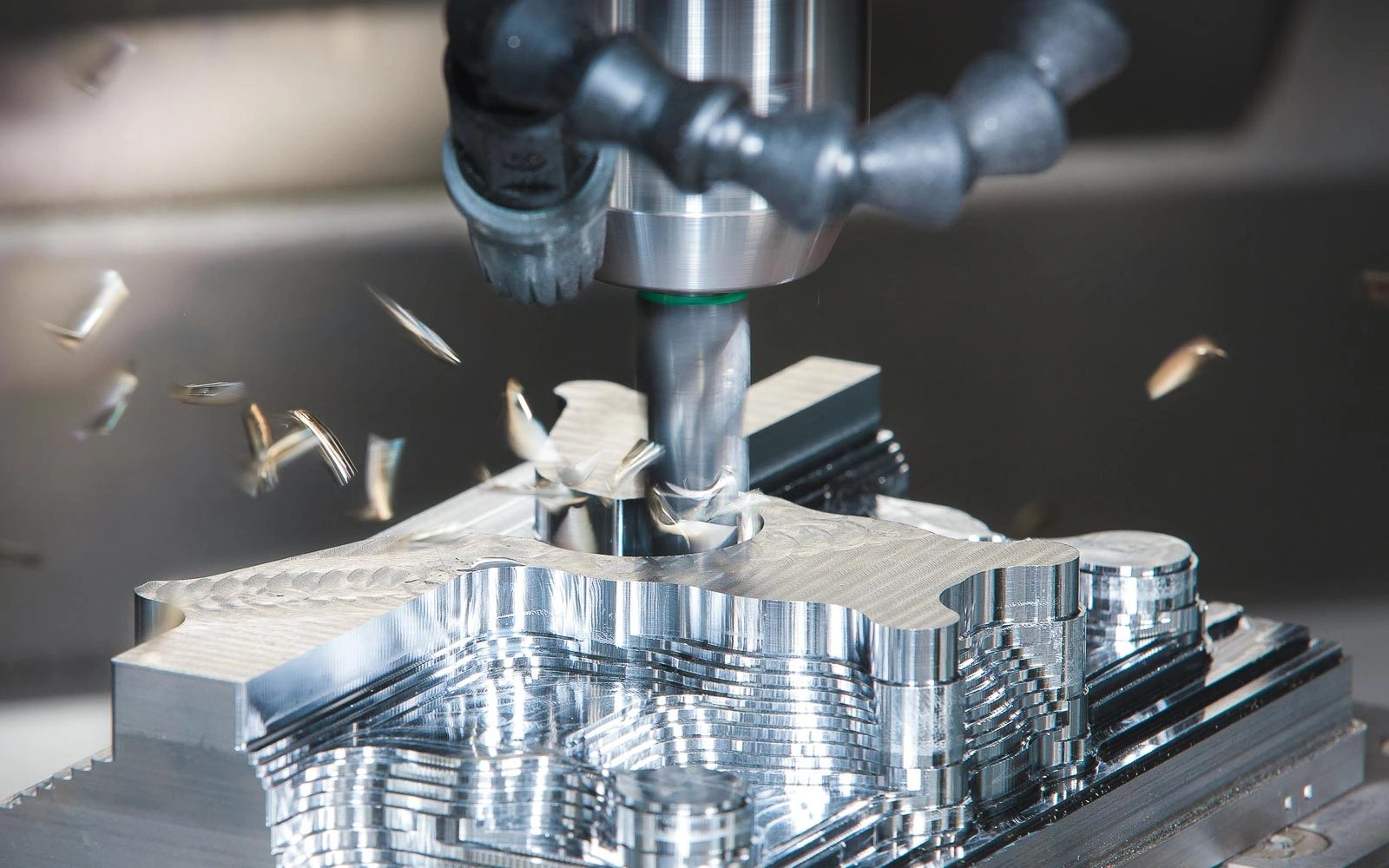

While 3D printers build layer by layer, the motion systems, structural frames, cooling manifolds, and bearing supports within these machines must be produced with micron-level accuracy. Even minor deviations in components such as linear rails, motor mounts, or heat sink bases can result in layer misalignment, reduced print resolution, and mechanical failure. This is where high-precision CNC machining becomes non-negotiable. At Lead Precision, we specialize in manufacturing mission-critical metal components where tolerances are measured in microns, not millimeters.

Our expertise in precision engineering is validated through our involvement in projects demanding the highest standards of reliability and repeatability. We have supplied components for systems used in Olympic athletic training equipment, where consistency directly impacts performance outcomes, and for military-grade portable 3D printing units deployed in extreme environments. These applications demand not only dimensional accuracy but also material integrity, thermal stability, and long-term durability—qualities we engineer into every part.

For 3D printer manufacturers, partnering with a precision machining provider that understands dynamic loads, thermal expansion, and vibration resistance is essential. Aluminum alloys such as 6061-T6 and 7075-T6 are commonly used in printer frames and moving parts due to their strength-to-weight ratio and machinability. Stainless steel is preferred for high-wear components like nozzles and fasteners, while brass and titanium may be used for specialized nozzles or aerospace-grade structural elements.

Below are typical specifications we achieve for 3D printer components:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.2 µm (polished) |

| Materials | Aluminum 6061-T6, 7075-T6, Stainless Steel 303/304/316, Brass C360, Titanium Grade 5 |

| Max Part Size | 800 × 500 × 400 mm |

| Positional Accuracy | ±0.003 mm (via laser calibration) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reporting |

Every component we produce undergoes rigorous in-process and final inspection using coordinate measuring machines (CMM) and optical comparators. This ensures full compliance with engineering drawings and long-term functional reliability.

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer performance. For OEMs developing next-generation 3D printers, precision is not an option. It’s the foundation.

Precision Specs & Tolerances

Technical Capabilities for Precision 3D Printer Component Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical metal components engineered specifically for high-performance additive manufacturing systems. Our technical foundation addresses the stringent geometric, thermal, and material demands inherent in advanced 3D printer subsystems. We specialize in producing complex geometries such as high-flow nozzles, precision heat blocks, kinematic coupling elements, rotary build plates, and structural frame components where micron-level accuracy directly impacts print fidelity, thermal stability, and system longevity. Standard manufacturing approaches often fail to meet the thermal management requirements and dynamic load tolerances essential for reliable printer operation; our integrated processes eliminate these failure points.

Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers, including Makino a61nx-5 and DMG MORI CTX beta 1250 models. These platforms enable single-setup machining of intricate organic shapes and deep cavities common in optimized thermal pathways and lightweight structural elements. Simultaneous 5-axis movement ensures superior surface finish on critical sealing surfaces and bearing journals while minimizing cumulative error from multiple fixtures. We routinely machine challenging materials including Inconel 625, Titanium Grade 5, Oxygen-Free Copper, and tool steels to net-shape or near-net-shape configurations, significantly reducing post-processing requirements and material waste versus traditional methods. Advanced high-speed milling strategies maintain tight thermal control during cutting, preventing distortion in thin-walled features like heater cartridges and sensor housings.

Quality verification is non-negotiable for components operating under extreme thermal cycling and mechanical stress. Every critical dimension undergoes validation via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with calibrated accuracy to ISO 10360-2 standards. Our inspection protocols extend beyond basic dimensional checks to include geometric dimensioning and tolerancing (GD&T) analysis, surface roughness profiling per ISO 4287, and material verification through spectrographic testing. This comprehensive metrology suite guarantees functional interchangeability and long-term reliability in demanding printer environments. All inspection data is traceable and provided in detailed first-article inspection reports (FAIR), enabling seamless integration into our clients’ quality management systems.

The following table details achievable tolerance capabilities for critical features in 3D printer components:

| Feature Category | Standard Capability | Precision Capability | Typical Application Example |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | Nozzle outer diameter, shaft lengths |

| Geometric Tolerances | 0.020 mm | 0.005 mm | Concentricity of heater bore, flatness of build plate mounts |

| Hole Diameters | +0.010/-0.000 mm | +0.003/-0.000 mm | Thermistor pockets, screw threads |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Sealing faces, bearing surfaces |

| Angular Features | ±0.05° | ±0.01° | Kinematic coupling facets, mounting interfaces |

These capabilities are consistently achieved across production runs from prototype to high-volume batches. Our engineering team collaborates early in the design phase to optimize manufacturability, ensuring thermal expansion coefficients, stress concentrations, and assembly sequences are addressed before metal cutting begins. This proactive approach minimizes costly iterations and accelerates time-to-market for next-generation printer platforms requiring uncompromised component integrity.

Material & Finish Options

Material Selection for High-Performance 3D Printer Components

In the precision-driven world of additive manufacturing, the performance and reliability of 3D printer parts are directly influenced by material selection and surface treatment. At Wuxi Lead Precision Machinery, we specialize in custom metal components engineered for durability, thermal stability, and dimensional accuracy. For critical 3D printer elements—such as heat sinks, structural frames, guide rails, and nozzle mounts—aluminum, steel, and titanium represent the most effective material choices, each offering distinct mechanical and thermal advantages.

Aluminum, particularly grades 6061 and 7075, is widely used for lightweight structural components due to its excellent strength-to-weight ratio and thermal conductivity. It is ideal for heat dissipation applications such as hotend mounts and cooling shrouds. When paired with anodizing, aluminum gains enhanced surface hardness, corrosion resistance, and electrical insulation—critical for long-term reliability in high-cycle printing environments.

Steel, especially stainless steel 304 and 316, delivers superior strength, wear resistance, and dimensional stability. It is best suited for high-stress components such as lead screw nuts, fasteners, and build plate supports. While heavier than aluminum, steel maintains rigidity under thermal cycling and mechanical load, ensuring consistent print accuracy over time. For applications requiring extreme durability, tool steels like H13 can be considered for custom tooling and inserts used in hybrid manufacturing setups.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the premium choice for high-stress, high-temperature environments. Its exceptional strength-to-density ratio and resistance to oxidation make it ideal for aerospace and medical-grade 3D printer components where weight savings and performance are paramount. Though more costly and challenging to machine, titanium offers unparalleled longevity in corrosive or elevated-temperature applications.

Surface finish plays a pivotal role in component functionality. Anodizing, especially Type II and Type III (hardcoat), is the preferred finish for aluminum parts. Type II anodizing provides moderate wear and corrosion resistance with aesthetic versatility, while Type III delivers a thicker, harder oxide layer suitable for high-abrasion environments. Both processes improve adhesion for coatings and reduce galling in threaded interfaces.

Material selection must align with functional requirements, environmental exposure, and cost targets. Our engineering team at Wuxi Lead Precision Machinery supports clients in optimizing material and finish combinations tailored to their specific 3D printing applications.

Mechanical and Thermal Properties of Common Materials

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 276 | 2.70 | 167 | Frames, heat sinks, brackets |

| Aluminum 7075 | 572 | 503 | 2.81 | 130 | High-stress mounts, couplings |

| Stainless Steel 304 | 580 | 290 | 8.00 | 16.2 | Fasteners, build plates, supports |

| Stainless Steel 316 | 580 | 290 | 8.00 | 15.1 | Corrosion-resistant components |

| Titanium Ti-6Al-4V | 900 | 830 | 4.43 | 6.7 | Aerospace, medical printer parts |

Manufacturing Process & QC

Precision Manufacturing Process for Critical 3D Printer Components

Achieving flawless performance in industrial 3D printer systems demands absolute precision in every metal component. At Wuxi Lead Precision Machinery, our Zero Defects philosophy governs a rigorously controlled production sequence: Design Finalization, Precision Prototyping, and Scalable Mass Production. This integrated approach ensures components meet the extreme demands of additive manufacturing environments, eliminating field failures and safeguarding our clients’ operational uptime.

The Design Phase transcends basic CAD modeling. Our engineering team collaborates deeply with the client to validate functional requirements against material science and manufacturability constraints. Finite Element Analysis (FEA) simulates thermal cycling, mechanical stress, and vibration inherent in high-speed printing. This proactive validation identifies potential fatigue points or thermal distortion risks before metal is cut, ensuring the design is inherently robust and optimized for our precision machining capabilities. Critical geometries and interfaces are locked down with unambiguous GD&T specifications.

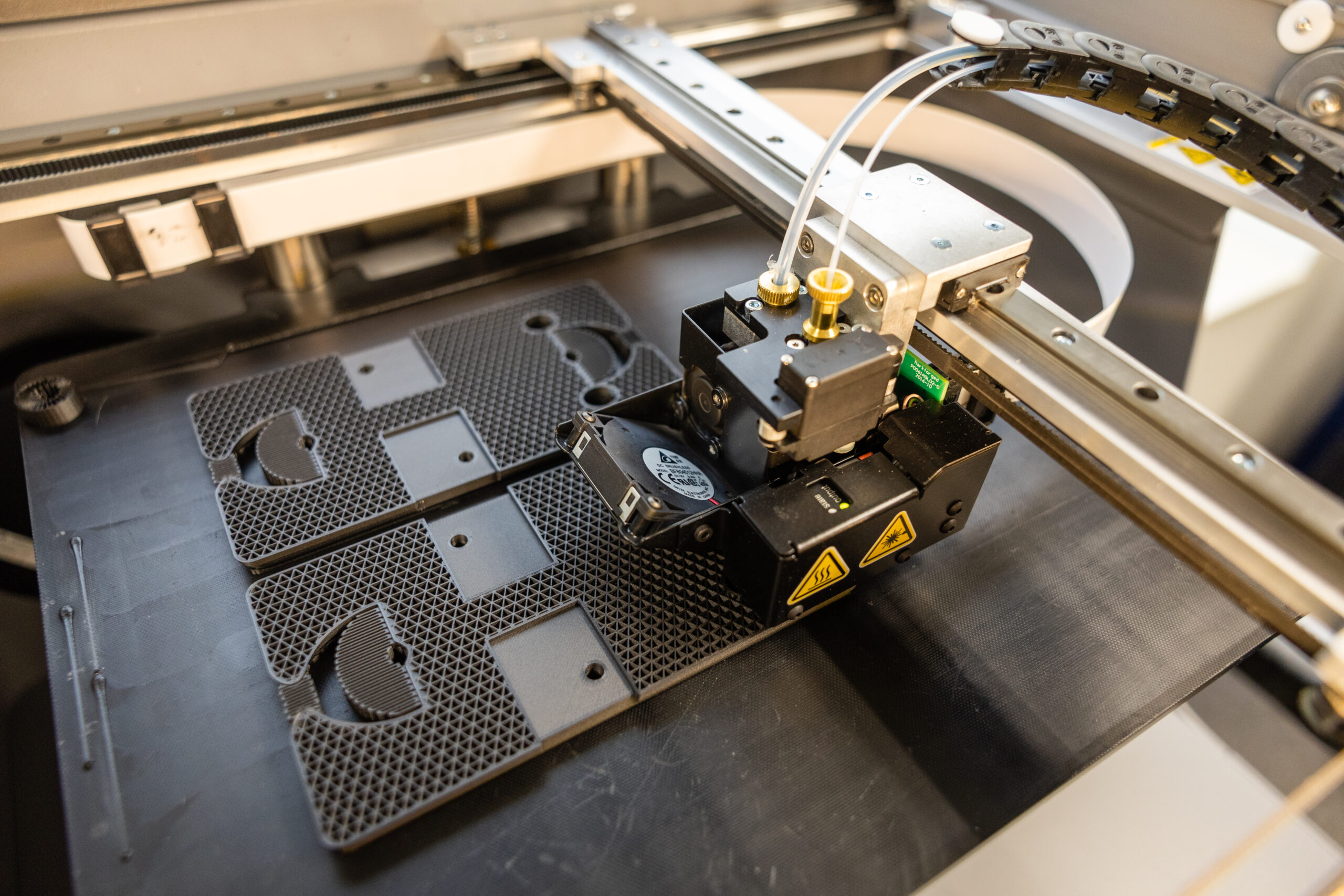

Prototyping is not merely a form check; it is full functional validation under simulated operational conditions. Using the exact production-grade alloys and processes intended for volume, we manufacture initial units. These undergo comprehensive metrology: Coordinate Measuring Machine (CMM) scans verify all critical dimensions against the validated design model, while surface profilometry confirms finish requirements. Functional testing within representative printer assemblies validates thermal stability, dimensional integrity under load, and interface compatibility. Any deviation triggers immediate root cause analysis and corrective action within the design or process parameters, preventing defect propagation.

Mass Production leverages the perfected process blueprint. Our CNC machining centers, operating under strict environmental controls, execute the program with sub-micron repeatability. Statistical Process Control (SPC) monitors key parameters in real-time, with automated data logging ensuring traceability for every component. 100% in-process dimensional checks occur at critical stages, supplemented by rigorous final inspection protocols. Material certifications, heat treatment records, and full inspection reports accompany every shipment, providing auditable proof of conformance to the Zero Defects standard. This systematic execution guarantees consistent output meeting the most stringent requirements.

The following table summarizes critical production specifications achievable for high-performance 3D printer metal parts:

| Parameter | Capability | Measurement Standard |

|---|---|---|

| Material Options | Ti-6Al-4V, SS 17-4PH, Inconel 718, Al 7075-T73 | ASTM/AMS Specifications |

| Dimensional Tolerance | ±0.005 mm (critical features) | ISO 2768-mK / Custom GD&T |

| Surface Finish | Ra 0.4 µm (machined), Ra 0.2 µm (polished) | ISO 1302 |

| Geometric Accuracy | Flatness < 0.01 mm / 100 mm | ASME Y14.5 |

| Inspection Method | CMM (0.0005 mm probe), Optical Comparator, Surface Roughness Tester | ISO 9001:2015 Compliant |

This disciplined progression from validated design through rigorously tested prototyping to statistically controlled mass production is the cornerstone of our Zero Defects commitment. It transforms complex 3D printer component requirements into reliably delivered precision hardware, directly protecting our clients’ manufacturing yield and brand reputation. Wuxi Lead delivers not just parts, but guaranteed performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision-Engineered 3D Printer Components

In the rapidly evolving world of additive manufacturing, the performance of 3D printers hinges on the precision, durability, and consistency of their core metal components. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing tailored specifically for the high-demand requirements of industrial 3D printing systems. As a trusted partner to OEMs and engineering firms worldwide, we deliver mission-critical parts that meet exacting tolerances, material specifications, and performance standards.

Our expertise lies in producing complex, high-precision components such as build plates, Z-axis guide rails, laser mounting brackets, heat sink assemblies, and motion system housings. These parts are essential to ensuring dimensional accuracy, thermal stability, and long-term reliability in metal and polymer 3D printers. Leveraging advanced CNC machining, multi-axis milling, precision turning, and surface treatment technologies, we manufacture components with tolerances as tight as ±0.002 mm and surface finishes down to Ra 0.4 µm.

We understand that every 3D printer design presents unique engineering challenges. That’s why we adopt a collaborative approach—working closely with your engineering team from prototype to full-scale production. Whether you require low-volume batches for R&D or high-volume runs for global deployment, our flexible manufacturing ecosystem ensures rapid turnaround, full traceability, and consistent quality. All components are inspected using coordinate measuring machines (CMM), optical comparators, and laser scanning to guarantee compliance with ISO 9001:2015 standards.

Material selection is critical in 3D printer applications, where thermal conductivity, rigidity, and wear resistance are paramount. We routinely work with aerospace-grade aluminum alloys (7075-T6, 6061-T6), stainless steels (304, 316L), titanium (Ti-6Al-4V), and specialty materials such as Invar and copper alloys. Surface treatments including anodizing, hard coating, passivation, and precision lapping are applied to enhance performance under dynamic operating conditions.

Below are typical specifications we support for 3D printer component manufacturing:

| Specification | Capability |

|---|---|

| Tolerance | ±0.002 mm |

| Surface Finish | As fine as Ra 0.4 µm |

| Maximum Part Size | 800 × 600 × 500 mm |

| Materials | Aluminum, Stainless Steel, Titanium, Copper, Invar, Brass |

| Machining Processes | 3- to 5-axis CNC milling, CNC turning, Wire EDM |

| Secondary Operations | Anodizing, Passivation, Heat Treatment, Laser Marking |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to advancing the capabilities of your 3D printing systems. Our team is ready to support your next-generation designs with responsive engineering feedback, competitive pricing, and on-time global delivery.

Contact us today at [email protected] to discuss your 3D printer component requirements. Let Lead Precision become your trusted partner in high-performance metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.