Technical Contents

Engineering Guide: 3 Axis Vs 5 Axis Cnc

Engineering Insight: 3 Axis vs 5 Axis CNC – The Precision Imperative

In the realm of high-precision CNC machining, the distinction between 3-axis and 5-axis machining centers is not merely technical—it is foundational to the quality, efficiency, and complexity of manufactured components. At Wuxi Lead Precision Machinery, we understand that precision is not an outcome but a design principle embedded in every process, machine, and decision. With over a decade of experience delivering mission-critical components for Olympic-grade equipment and military-grade systems, our engineering team has consistently leveraged advanced CNC technologies to meet the most stringent tolerances and surface finish requirements.

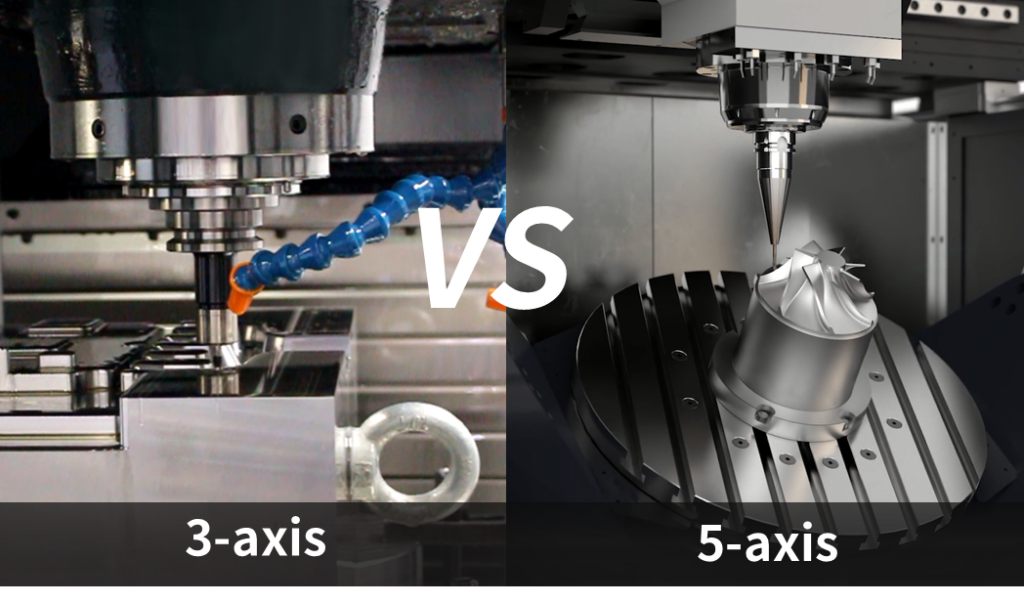

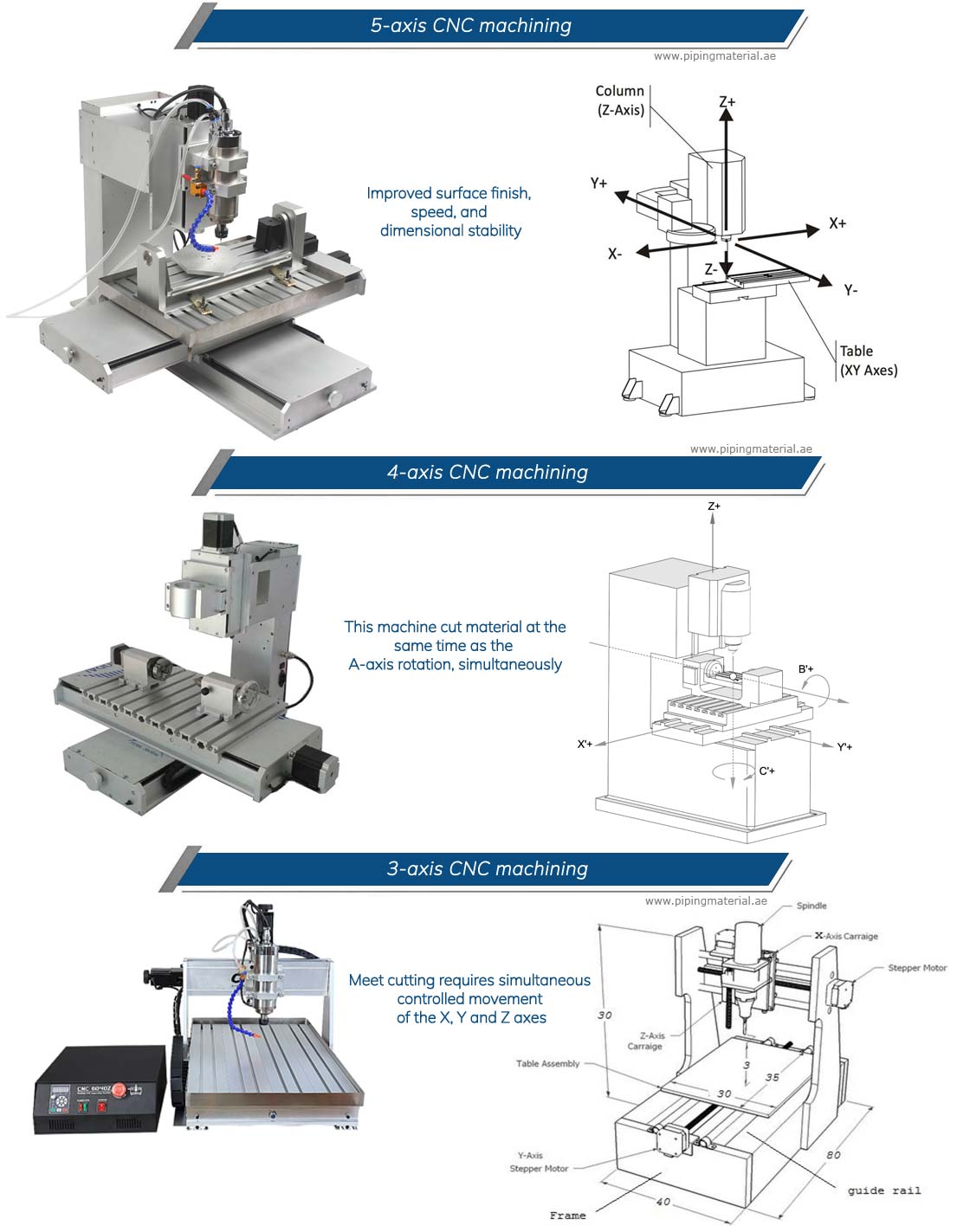

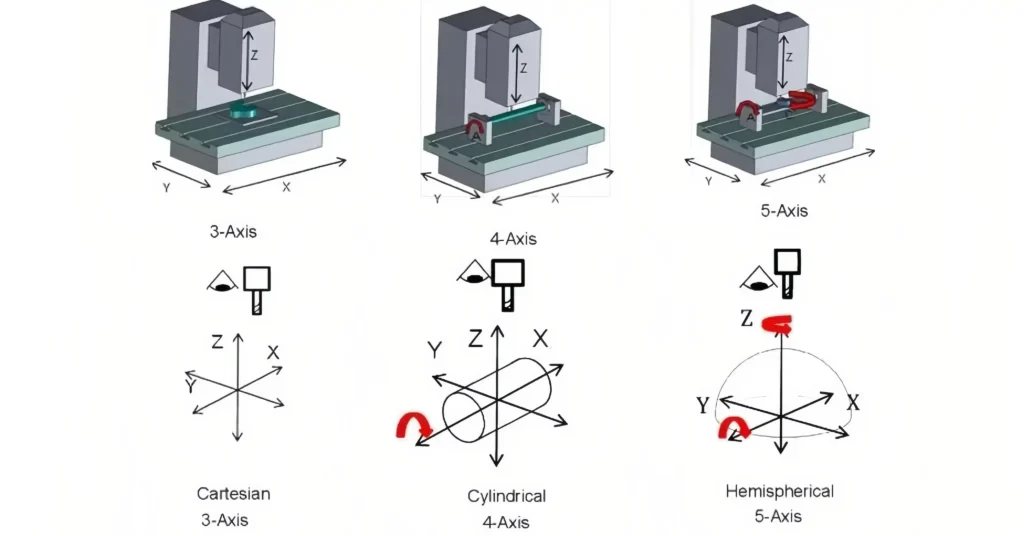

3-axis CNC machining remains a cornerstone of traditional manufacturing, offering reliable performance for parts with simple geometries. In this setup, the cutting tool moves along the X, Y, and Z linear axes, allowing material removal from the top and sides of the workpiece. While effective for flat-surfaced or prismatic parts, 3-axis systems require multiple setups for complex features, increasing the risk of alignment errors and reducing overall precision. For industries where micron-level accuracy is non-negotiable, such limitations can compromise both performance and reliability.

In contrast, 5-axis CNC machining introduces two additional rotational axes—typically A (rotation around X) and B (rotation around Y)—enabling the cutting tool to approach the workpiece from virtually any angle. This dynamic capability eliminates the need for repositioning, significantly enhancing geometric accuracy and surface integrity. Complex contours, deep cavities, and organic shapes can be machined in a single setup, reducing cumulative tolerances and thermal drift. At Lead Precision, our 5-axis platforms are equipped with high-resolution encoders, thermal compensation systems, and real-time tool monitoring—ensuring repeatability within ±0.002 mm across production runs.

The decision between 3-axis and 5-axis is not solely about complexity—it is about precision under demand. For aerospace impellers, medical implants, or defense actuators, where failure is not an option, 5-axis machining is the definitive solution. Our work on precision components for Olympic bobsled chassis and military-grade communication housings exemplifies this commitment. These projects demanded not only exacting dimensional control but also superior surface finishes to reduce drag and ensure electromagnetic shielding—achievements only possible through 5-axis synchronization and advanced toolpath optimization.

Below is a comparative overview of key technical specifications between standard 3-axis and high-end 5-axis CNC systems as deployed at Wuxi Lead Precision Machinery.

| Parameter | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Axes of Motion | X, Y, Z (linear) | X, Y, Z, A, B (linear + rotational) |

| Typical Positioning Accuracy | ±0.010 mm | ±0.002 mm |

| Surface Finish (Ra) | 1.6 – 3.2 µm | 0.4 – 0.8 µm |

| Setup Requirements | Multiple clamping cycles | Single setup for complex geometry |

| Tool Life Efficiency | Moderate | High (optimized tool engagement) |

| Ideal Applications | Plates, brackets, housings | Impellers, molds, aerospace parts |

At Wuxi Lead Precision Machinery, we do not merely choose between 3-axis and 5-axis—we engineer the optimal solution based on precision, performance, and purpose.

Precision Specs & Tolerances

Advanced Multi-Axis Machining Capabilities at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers uncompromising precision for complex aerospace, medical, and energy sector components through state-of-the-art 5-axis CNC machining. While 3-axis CNC remains suitable for prismatic geometries with sequential operations, our 5-axis simultaneous machining technology eliminates critical limitations inherent in traditional setups. By integrating rotational motion around the A and B axes with linear X, Y, and Z movement, we achieve uninterrupted tool access to complex contours—reducing part handling, minimizing datum errors, and maintaining geometric integrity across intricate features. This capability is essential for monolithic structural components, organic turbine blades, and implant geometries where cumulative tolerance stack-up from multiple setups would otherwise compromise functionality.

Our DMG MORI CTX beta 1250 5-axis machining centers feature high-torque spindle systems (15,000 RPM) and thermal compensation algorithms ensuring micron-level stability during extended production runs. Crucially, every component undergoes rigorous validation via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), certified to ISO 10360-2 standards. This closed-loop quality control process verifies critical dimensions against CAD models, capturing deviations in real-time to guarantee compliance with AS9100 and ISO 13485 requirements. Unlike 3-axis workflows requiring manual repositioning, our 5-axis methodology sustains ±0.005 mm positional accuracy across all features in a single setup—directly translating to enhanced part reliability and reduced scrap rates for clients.

The following table details achievable tolerances under controlled production conditions, reflecting our integrated machining and inspection protocols:

| Feature Type | 3-Axis CNC Tolerance Range | 5-Axis CNC Tolerance Range | Surface Finish (Ra) |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm to ±0.025 mm | ±0.005 mm to ±0.010 mm | 0.8–1.6 µm |

| Angular Features | ±0.05° | ±0.02° | 0.4–0.8 µm |

| Complex Contours | ±0.025 mm (multi-setup) | ±0.008 mm (single setup) | 0.2–0.4 µm |

| Hole Position Accuracy | ±0.015 mm | ±0.005 mm | 0.8–1.6 µm |

Material selection and part geometry influence final tolerances; our engineering team collaborates with clients during DFM analysis to optimize designs for 5-axis efficiency. The elimination of secondary operations not only achieves tighter tolerances but also reduces lead times by up to 40% compared to multi-setup 3-axis alternatives—critical for time-sensitive defense and medical device programs. All inspection reports include full CMM traceability data, providing auditable proof of conformance for regulatory submissions.

Wuxi Lead’s commitment to 5-axis excellence ensures geometric complexity never compromises precision. By merging advanced motion control with metrology-grade verification, we deliver components that meet the most stringent performance demands—proving that in high-value manufacturing, the capability to maintain tolerances across complex surfaces defines true engineering excellence. Partner with us to transform intricate designs into production-ready realities without compromise.

Material & Finish Options

Material selection is a critical factor in determining the performance, durability, and cost-efficiency of CNC-machined components. At Wuxi Lead Precision Machinery, we understand that the choice between aluminum, steel, and titanium directly impacts machining strategy, tool life, and final part functionality—especially when comparing 3-axis versus 5-axis CNC capabilities. Each material presents unique challenges and advantages, and selecting the appropriate one depends on the application’s mechanical, thermal, and environmental requirements.

Aluminum is widely used in aerospace, automotive, and electronics due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grades such as 6061 and 7075 are commonly processed on both 3-axis and 5-axis machines. Aluminum’s softness allows for high-speed cutting, reduced tool wear, and shorter cycle times. However, its lower hardness makes it more prone to deformation under high stress, limiting its use in high-load applications. For enhanced surface protection and aesthetic appeal, aluminum components are often finished with anodizing—a process that increases corrosion and wear resistance while allowing for color customization.

Steel, particularly alloy and stainless variants like 4140 and 304/316, offers superior strength, hardness, and resistance to wear and deformation. These properties make steel ideal for industrial tooling, medical devices, and heavy machinery components. However, steel is significantly harder to machine than aluminum, requiring more robust tooling, slower feed rates, and increased power—factors that benefit from the precision and multi-angle access of 5-axis CNC systems. While steel does not anodize, alternative surface treatments such as passivation, plating, or powder coating are typically applied to improve corrosion resistance.

Titanium, especially Grade 5 (Ti-6Al-4V), is favored in aerospace, defense, and medical implants due to its exceptional strength-to-density ratio and biocompatibility. It maintains structural integrity at high temperatures and resists corrosion in harsh environments. However, titanium’s low thermal conductivity leads to heat concentration at the cutting zone, accelerating tool wear. Its high chemical reactivity with tool materials also demands specialized cutters and precise coolant application. These challenges are more effectively managed on 5-axis machines, which minimize repositioning and optimize tool engagement angles.

Below is a comparative overview of key material properties and machining considerations:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Typical CNC Axis Preference | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Excellent | 3-axis or 5-axis | Anodizing, bead blasting |

| Steel 4140 | 655 | 7.85 | Moderate | 5-axis preferred | Passivation, plating, coating |

| Titanium Ti-6Al-4V | 900 | 4.43 | Poor | 5-axis recommended | Anodizing (Type II/III), polishing |

Selecting the right material involves balancing performance needs with manufacturability. At Wuxi Lead Precision Machinery, our expertise in both 3-axis and 5-axis CNC machining ensures optimal material utilization, tight tolerances, and superior surface finishes—delivering precision components tailored to your industry demands.

Manufacturing Process & QC

Precision Axis Selection: Optimizing Production Flow from Design to Zero-Defect Output

At Wuxi Lead Precision Machinery, geometric complexity dictates machine selection, directly impacting our zero-defect production flow. Choosing between 3-axis and 5-axis CNC machining begins at the design phase, where manufacturability analysis determines the optimal path. Our engineers evaluate part geometry, tolerance stack-ups, and surface finish requirements against axis capabilities. Complex organic shapes or parts requiring features on multiple faces inherently demand 5-axis processing to avoid costly, error-prone secondary operations. Simpler prismatic components often achieve superior cost-efficiency on precision 3-axis platforms. This early-stage decision prevents downstream rework, embedding quality at the source.

During prototyping, 5-axis CNC proves indispensable for validating intricate designs. Single-setup machining eliminates cumulative alignment errors inherent in multi-vise 3-axis processes, delivering true-to-CAD prototypes that accurately reflect final part behavior. This capability allows our clients to verify form, fit, and function with absolute confidence before committing to mass production tooling. The reduced handling also accelerates iteration cycles, compressing time-to-market without compromising dimensional integrity. For less complex prototypes, 3-axis machining provides rapid, economical validation where multi-axis capability offers no functional advantage.

Mass production execution leverages our axis selection to institutionalize zero defects. 5-axis systems excel in high-mix, low-volume runs of complex components like aerospace impellers or medical implants. Continuous five-axis contouring maintains micron-level tolerances across compound surfaces within a single clamping, eliminating fixture-induced variation. For high-volume commodity parts such as hydraulic manifolds or brackets, optimized 3-axis cells deliver unmatched throughput and cost control. Our integrated metrology—featuring in-process probes and post-machining CMM validation—ensures every part, regardless of axis configuration, meets stringent ±0.001mm tolerances. Rigorous SPC monitoring on critical dimensions prevents drift, guaranteeing batch consistency.

The table below summarizes key production considerations guiding our axis selection strategy:

| Parameter | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Typical Applications | Prismatic parts, simple geometries | Complex contours, multi-faceted components |

| Setup Time per Part | Higher (multiple fixtures) | Minimal (single setup) |

| Achievable Tolerance | ±0.005 mm | ±0.001 mm |

| Surface Finish Quality | Good on primary faces | Exceptional on all surfaces |

| Defect Risk Factor | Moderate (fixture errors) | Very Low (single setup) |

Wuxi Lead’s production philosophy centers on matching axis capability to phase-specific requirements. By rigorously applying this methodology—design validation, prototype fidelity, and production control—we systematically eliminate defect opportunities. Our process engineering team selects the optimal configuration not based on machine availability, but on demonstrable impact to your yield rate and total cost of quality. This disciplined approach ensures every component leaving our facility meets the uncompromising standards demanded by aerospace, medical, and energy sector leaders. Partner with us to transform your precision manufacturing challenges into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced CNC Machining Solutions

At Wuxi Lead Precision Machinery, we understand that selecting the right CNC machining strategy—whether 3-axis or 5-axis—is not just a technical decision, but a strategic one that impacts your production efficiency, part quality, and time-to-market. As a leading provider of precision CNC machining services in China, we specialize in delivering tailored manufacturing solutions that align with your unique engineering and commercial requirements. Our expertise spans industries including aerospace, automotive, medical devices, and industrial automation, where precision, repeatability, and reliability are non-negotiable.

Choosing between 3-axis and 5-axis CNC machining depends on complexity, tolerance, volume, and surface finish demands. While 3-axis machining remains ideal for simpler geometries and high-volume production runs, 5-axis CNC offers unparalleled flexibility for complex, organic, or highly detailed components. At Lead Precision, we operate state-of-the-art 3-axis and 5-axis CNC centers equipped with advanced tooling, real-time monitoring, and rigorous quality control protocols. Our engineering team collaborates closely with clients to evaluate part geometry, material properties, and production goals, ensuring optimal process selection and cost-efficient manufacturing.

We go beyond machining—we are your strategic partner in precision. From initial design consultation and DFM analysis to prototyping, production, and post-processing, our integrated workflow reduces lead times and eliminates bottlenecks. Our facility in Wuxi is ISO 9001 certified, featuring climate-controlled environments and in-house CMM inspection to guarantee dimensional accuracy down to ±0.005 mm. Whether you require rapid prototyping or high-mix, low-volume production, our scalable infrastructure supports your growth.

Below is a comparison of our core CNC machining capabilities:

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Axis Movement | X, Y, Z linear axes | X, Y, Z linear + A, B rotary axes |

| Typical Applications | Flat surfaces, prismatic parts, drilled holes | Complex contours, turbine blades, molds, organic shapes |

| Setup Frequency | Multiple setups often required | Single setup for multi-sided machining |

| Surface Finish | Good for standard geometries | Superior finish on complex surfaces |

| Production Speed | High for simple parts | Optimized for intricate parts, reduced cycle time |

| Tolerance | ±0.01 mm | ±0.005 mm |

| Materials Supported | Aluminum, steel, plastics, brass | Titanium, Inconel, hardened steels, composites |

Our commitment to innovation, quality, and customer success drives every project. When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally with deep technical insight and global delivery capability.

Contact us today to discuss your next project. Let our experts guide you in selecting the optimal CNC solution for your application. Reach out to our engineering team at [email protected] and experience the Lead Precision advantage—where accuracy meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.