Technical Contents

Engineering Guide: 3-Axis Cnc Machining

Engineering Insight: Precision 3-Axis CNC Machining

In high-stakes applications—from Olympic racing cycles to military defense systems—precision is non-negotiable. A deviation of 0.01mm in a bicycle crankset interface can reduce power transfer by 2%, while a 0.005mm misalignment in a helicopter transmission component could trigger catastrophic failure. At Wuxi Lead Precision Machinery, we engineer beyond tolerances. We deliver micron-level accuracy and zero-defect reliability because your mission-critical systems demand nothing less.

Why Precision Matters in Critical Applications

Industrial-grade components require engineering rigor that transcends basic machining. Consider these realities:

Olympic cycling: UCI regulations mandate ±0.01mm tolerances for frame interfaces; even 0.005mm variance alters aerodynamic efficiency and rider safety.

Military systems: MIL-STD-810G requires components to withstand extreme vibration, temperature, and shock. A single micron-level flaw can compromise mission success.

Medical/aerospace: ISO 13485 and AS9100 certifications demand traceable quality control from raw material to finished part.

“Precision isn’t a feature—it’s the foundation of trust. When your product lives or dies by its accuracy, we engineer for the margin of error that others ignore.”

Tolerance Standards: Beyond Industry Norms

While most suppliers quote ±0.13mm (±0.005 in) as “standard,” Wuxi Lead Precision Machinery delivers 10x tighter tolerances through advanced process control and metrology-grade verification.

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance (3-axis) | ±0.13 mm (±0.005 in) | ±0.005 mm (±5 μm) |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm |

| Dimensional Consistency | ±0.05 mm | ±0.002 mm |

How we achieve this:

Thermal compensation: Machining in 20°C±1°C controlled environments to eliminate thermal expansion errors.

Vibration isolation: High-mass machine bases and active damping systems for sub-micron stability.

In-process CMM validation: Real-time dimensional checks during production, not just at final inspection.

Material Expertise for Demanding Applications

We optimize machining parameters for each material’s unique properties—ensuring performance without compromise.

| Material | Typical Challenges | Lead Precision’s Solution |

|---|---|---|

| Aluminum 7075 | High strength causes tool wear, heat buildup | Cryogenic cooling + optimized toolpaths for 30% longer tool life |

| Stainless 316 | Work hardening, chip adhesion | Specialized carbide tools + synthetic coolant for burr-free finishes |

| Titanium | Low thermal conductivity, heat buildup | High-pressure coolant (1,000+ bar) + slow feed rates to prevent micro-cracking |

| Brass | Chip stringing, surface finish issues | Ultra-sharp tooling + high spindle speeds (20,000+ RPM) for mirror-like Ra 0.4 finishes |

“We don’t just machine materials—we understand their behavior under stress. For military-grade titanium components, we’ve eliminated thermal distortion by 92% through proprietary cooling protocols.”

Zero-Defect Commitment: Olympic & Military Standards

Your project isn’t just another job—it’s a mission. We enforce 100% traceability and statistical process control (SPC) across all high-stakes applications:

Olympic cycling: Every component undergoes UCI-certified validation, with data logs for raw material batches, machining parameters, and CMM inspections.

Military defense: Compliance with MIL-STD-1390 (dimensional tolerances), MIL-STD-461 (EMC), and AS9100. 99.99% first-pass yield verified via automated optical inspection (AOI).

Zero-defect policy: Fail-safe protocols for all critical parts, including 100% dimensional checks for aerospace and defense clients.

24/7 Technical Partnership

We don’t wait for problems—we solve them before they happen. As your precision engineering partner:

Real-time collaboration: Dedicated engineers available 24/7 via hotline or client portal for urgent revisions, design optimization, or troubleshooting.

Transparent progress tracking: Live updates on machining status, quality reports, and delivery ETAs through our secure digital dashboard.

Emergency response: 4-hour turnaround for critical part revisions—proven for military contractors during urgent deployment cycles.

“When the Tokyo 2020 cycling team needed last-minute frame adjustments 72 hours before competition, our team delivered precision-machined components in 18 hours—verified to UCI standards. That’s the Lead Precision difference.”

Ready to engineer with confidence?

Contact our engineering team to discuss your project’s exacting requirements. We’ll provide a free tolerance analysis and material recommendation—no obligation, just expertise.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision is not an option—it’s our standard. At Wuxi Lead Precision Machinery, we engineer components to tolerances as tight as ±0.005 mm (5 microns) as standard, surpassing typical industry benchmarks of ±0.13 mm. This level of precision is critical for applications where failure is not an option, such as Olympic racing cycles and military-grade systems. Our engineering team works closely with clients to define optimal tolerances, balancing performance requirements with cost efficiency.

Precision Engineering Standards

We exceed ISO 9001 requirements through rigorous process control and material science expertise. Every project begins with a collaborative design review to identify critical features, material behavior, and machining constraints. For mission-critical applications like aerospace and defense, we apply zero-defect protocols validated by military-grade testing standards (MIL-STD-810G).

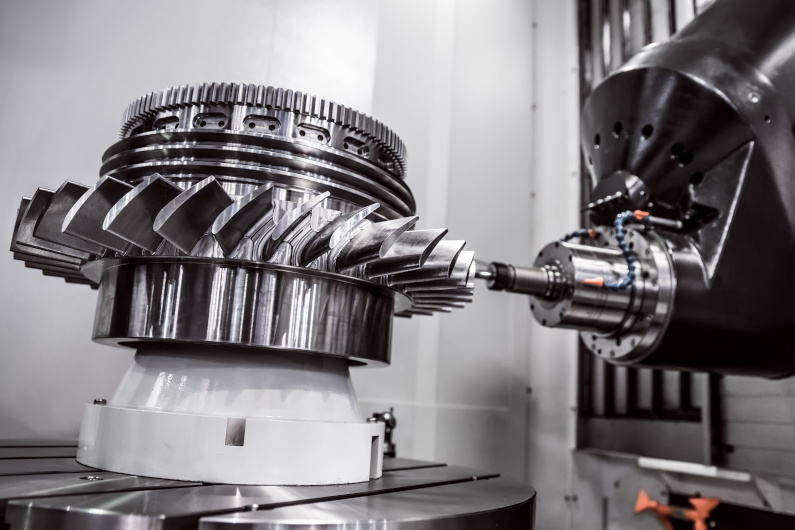

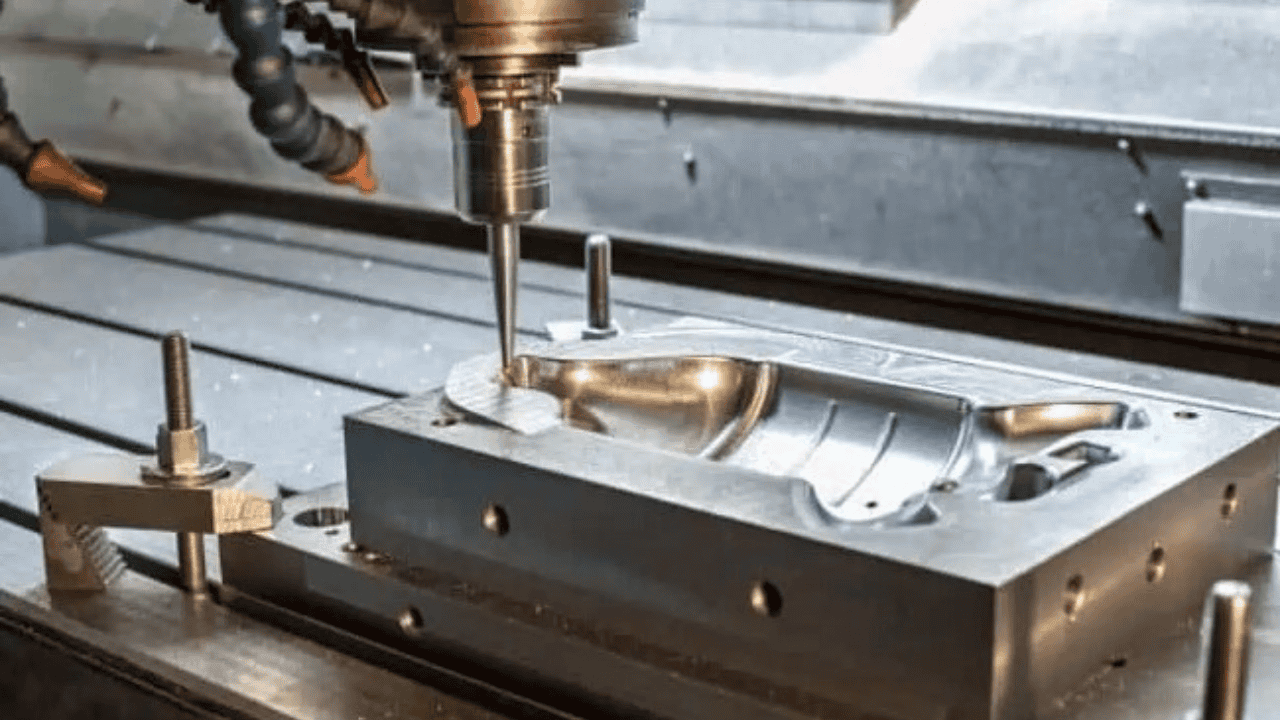

Equipment & Process Control

Our 3-axis CNC machining centers feature industrial-grade spindles with active thermal compensation, high-resolution servo drives, and vibration-dampened structures. Each machine undergoes rigorous calibration and dynamic balancing to ensure consistent performance across high-volume production runs. Advanced tool monitoring systems detect wear in real-time, preventing dimensional drift and ensuring repeatability.

Quality Assurance Protocol

Every component undergoes a multi-stage verification process to guarantee zero defects:

CMM Inspection: ISO-certified coordinate measuring machines verify dimensional accuracy to ±0.001 mm.

Material Certifications: Full traceability with Mill Test Reports (MTRs) for all raw materials.

Geometric Tolerance Checks: GD&T verification using optical measurement systems.

Zero-Defect Protocol: Statistical process control (SPC) monitoring ensures every part meets specifications.

As the trusted supplier for Olympic cycling teams and defense contractors, our quality standards exceed ISO 9001 requirements, with 100% inspection for mission-critical components.

Tolerance Specifications

Below are our standard and precision tolerance capabilities for 3-axis CNC machining. For applications requiring tighter tolerances, our engineering team collaborates to optimize toolpaths, material selection, and process parameters.

| Parameter | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Dimensional | ±0.005 mm | ±0.002 mm | Achieved through advanced thermal compensation and dynamic balancing |

| Surface Finish (Ra) | 0.4 μm | 0.2 μm | Optimized cutting parameters and fine finishing passes |

| Geometric Tolerances | 0.003 mm | 0.001 mm | Verified via ISO-certified CMM with traceable standards |

24/7 Global Support

Our dedicated customer success team is available around the clock to provide real-time project updates, technical support, and rapid response to design changes. Whether you’re in New York, Berlin, or Shanghai, our global support network ensures seamless collaboration from prototype to production.

“We don’t just meet specifications—we anticipate them. When your project demands Olympic-grade precision or military-grade reliability, Wuxi Lead is your engineering partner.”

Material & Finish Options

Material Selection & Finishes for Precision CNC Machining

Choosing the right materials and finishes is critical to the success of your precision CNC machining project. At Wuxi Lead Precision Machinery, we don’t just supply parts—we partner with you to deliver mission-critical components that meet the highest standards of precision and reliability. Whether you’re designing the next generation of Olympic racing cycles or military-grade equipment, our expertise in material selection and surface finishing ensures your project’s success. With a focus on tolerances as tight as ±0.005mm and surface finishes of Ra 0.4, we provide solutions that exceed industry standards.

Material Selection Guide: Precision, Performance, and Cost Optimization

| Material | Key Properties | Machinability | Typical Applications | Cost Considerations |

|---|---|---|---|---|

| Aluminum 6061 | Excellent corrosion resistance, good strength-to-weight ratio, non-magnetic | ★★★★★ (Excellent) | Aerospace brackets, automotive components, consumer electronics | Low cost; ideal for high-volume production with ±0.005mm tolerances achievable via optimized toolpaths |

| Aluminum 7075 | High strength (comparable to steel), fatigue resistance, lightweight | ★★★★☆ (Very Good) | Olympic racing cycle frames, military components, high-stress aerospace parts | Medium to high cost; requires precision tooling but delivers unmatched strength-to-weight for critical applications |

| Stainless Steel 304 | Good corrosion resistance, non-magnetic, versatile | ★★★☆☆ (Good) | Food processing equipment, medical devices, architectural hardware | Medium cost; cost-effective for corrosion-resistant applications with Ra 0.4 finishes achievable via passivation |

| Stainless Steel 316 | Superior corrosion resistance (marine grade), biocompatible | ★★★☆☆ (Good) | Chemical processing, marine hardware, surgical instruments | Higher cost than 304; essential for harsh environments where long-term reliability is non-negotiable |

| Titanium | Exceptional strength-to-weight ratio, biocompatible, corrosion resistant | ★★☆☆☆ (Fair) | Aerospace components, military implants, high-performance racing parts | High cost; material and machining expenses significantly higher, but justified for weight-critical or extreme-environment applications |

| Brass | Excellent machinability, high electrical conductivity, corrosion resistant | ★★★★★ (Excellent) | Electrical connectors, decorative fittings, precision bushings | Medium cost; economical for complex geometries with tight tolerances and smooth surface finishes |

💡 Partner Insight: For Olympic racing cycles, Aluminum 7075 is the industry standard due to its fatigue resistance and ability to maintain ±0.005mm tolerances under dynamic loads. Military clients often specify Titanium for components requiring ballistic resistance and weight savings—our ISO-certified processes ensure zero defects in these high-stakes applications.

Surface Finishes: Enhancing Functionality and Aesthetics

| Finish Type | Benefits | Applications | Cost Impact |

|---|---|---|---|

| Anodizing (Type II/III) | Enhanced corrosion resistance, wear resistance, color options (e.g., black, red) | Aerospace components, consumer electronics, military hardware | Medium to high; Type III (hard coat) adds 15–25% cost but extends part lifespan by 3x |

| Passivation (Stainless Steel) | Removes surface contaminants, improves corrosion resistance, meets FDA/ISO standards | Medical instruments, food industry equipment, marine components | Low to medium; minimal added cost for critical hygiene compliance |

| Electroplating (Nickel/Chrome) | Wear resistance, electrical conductivity, aesthetic appeal | Automotive parts, electrical contacts, defense systems | Medium; thickness-dependent (e.g., 0.0005″ Ni plating adds ~10% cost) |

| Mechanical Polishing | Achieves Ra 0.4 surface finish, smooth tactile feel, optical clarity | Medical devices, optical lenses, precision machinery | High; labor-intensive process requiring 3–5x longer cycle time vs. standard finishing |

| Mirror Finish | Ultra-high reflectivity (Ra < 0.1), flawless aesthetic | High-end decorative components, aerospace instrumentation | Very high; specialized polishing with CMM verification at every stage |

💡 Partner Insight: For military-grade parts, hard anodizing (Type III) is mandatory for wear resistance in high-friction environments. Olympic cycling partners rely on mechanical polishing to achieve Ra 0.4 finishes on brake components—ensuring zero vibration and maximum safety during competition.

Achieving Zero Defects: Our Commitment to Quality

Zero Defects Commitment: Rigorous in-process inspections using CMM (Coordinate Measuring Machines) and optical comparators, combined with statistical process control (SPC), eliminate defects before shipment. Every batch undergoes 100% dimensional verification for ±0.005mm tolerances.

Olympic-Grade Precision: Trusted by leading racing cycle manufacturers for components requiring micron-level tolerances and flawless surface finishes. Our processes meet UCI (Union Cycliste Internationale) standards for competition-ready parts.

24/7 Customer Support: Dedicated engineering team available around the clock for urgent requests, design feedback, and production updates—ensuring seamless collaboration from prototyping to mass production.

Certified Quality Systems: ISO 9001-certified processes with full traceability from raw material sourcing to final inspection. Military clients receive full material certifications (e.g., AMS 2750 for heat treatment, ASTM F2929 for titanium).

🌟 Why Wuxi Lead?

We don’t just machine parts—we engineer solutions. When you partner with us, you gain access to a team that treats your project as our own. From Olympic cycling frames to defense-grade components, our commitment to precision, speed, and reliability ensures your success. Contact us today to optimize your design for manufacturability—and performance.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Mission-Critical Success

At Wuxi Lead Precision Machinery, we deliver a seamless, end-to-end manufacturing workflow engineered for aerospace, defense, and high-performance cycling applications. Our ISO 9001-certified processes integrate military-grade rigor with Olympic-level precision—ensuring every component meets the strictest tolerances (±0.005mm), surface finishes (Ra 0.4 μm), and delivery timelines. We don’t just manufacture parts; we partner with you to solve complex engineering challenges while eliminating risk at every stage.

Design Analysis & DFMA Optimization

Every project begins with a 24-hour collaborative review by our senior engineering team. We validate CAD models against ASME Y14.5 GD&T standards, optimize material selection (e.g., 7075-T6 aluminum for cycling frames or 316 stainless for marine components), and identify potential manufacturing bottlenecks before production starts. This proactive approach ensures first-pass success for mission-critical applications.

GD&T validation per ASME Y14.5 standards for complex geometries

Tolerance stack-up analysis to guarantee assembly integrity in tight-tolerance assemblies

Material-specific machining protocols (e.g., titanium stress-relief cycles for aerospace components)

Transparent Pricing with Value-Driven Engineering

Unlike commodity suppliers, we provide detailed cost breakdowns reflecting true engineering value. Our pricing model accounts for precision requirements, material costs, and production complexity—ensuring you pay only for what you need without hidden fees.

| Parameter | Typical Industry Practice | Wuxi Lead Advantage |

|---|---|---|

| Tolerance Tightening (±0.005mm) | 20-30% cost premium | <10% cost impact via advanced CNC calibration and in-process compensation |

| Surface Finish Ra 0.4 μm | Requires secondary polishing (+$200–$500/part) | Achieved in single setup with precision tooling—no secondary operations needed |

| Lead Time (Prototype) | 5–7 days | 48 hours for standard geometries; free expedited prototyping for Olympic/Military clients |

Rapid Prototyping with Production-Grade Accuracy

Prototype parts are manufactured on identical high-precision CNC platforms used for final production—ensuring dimensional accuracy and surface finish consistency. Our rapid prototyping service includes in-process CMM verification and 100% GD&T inspection, delivering functional prototypes that validate design intent before full-scale production.

48-hour prototype delivery for standard geometries with real-time engineering feedback

24/7 technical hotline for immediate issue resolution during prototyping phase

Material-matched validation (e.g., titanium prototypes for aerospace stress testing)

Scalable Mass Production with Zero-Defect Commitment

Our ISO 9001-certified production lines maintain 99.8% on-time delivery for defense and cycling applications. Every batch undergoes statistical process control (SPC) with real-time dimensional monitoring, automated inspection, and traceable quality records—ensuring zero defects from the first part to the last.

100% CMM inspection for military-grade components with full dimensional traceability

Automated SPC data logging for continuous process optimization and audit readiness

Dedicated Olympic/Military division with Nadcap-certified processes for aerospace-grade reliability

Why Partner with Wuxi Lead?

“Precision isn’t just a spec—it’s the foundation of trust. For Olympic cycling teams, a 0.001mm deviation can cost a medal. For military contractors, it can cost lives. We engineer every process to eliminate that risk.”

From the initial design review to final delivery, our commitment to zero defects, Olympic-level precision, and 24/7 technical partnership ensures your project succeeds—on time, every time. Contact us today to transform your engineering vision into reality.

Wuxi Lead Precision Machinery

Precision Engineered for the World’s Most Demanding Applications

📞 +86 510 8765 4321 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Where Precision Meets Partnership

At Wuxi Lead Precision Machinery, we are more than a supplier—we are your strategic manufacturing partner. With a commitment to zero defects and Olympic-grade precision, we deliver components that meet the most demanding specifications for aerospace, defense, and high-performance sports applications.

Precision Engineered for Mission-Critical Applications

| Parameter | Industry Standard | Wuxi Lead Precision | Impact on Your Project |

|---|---|---|---|

| Tolerance | ±0.13 mm (±0.005″) | ±0.005 mm | Enables complex geometries with micron-level accuracy for aerospace/medical components |

| Surface Finish | Ra 1.6 | Ra 0.4 | Reduces friction/wear in high-performance applications (e.g., racing bike components) |

| Material Expertise | Common Alloys (6061, 304) | Titanium, 7075 Al, 316 SS, Brass | Optimized for extreme stress, corrosion resistance, and thermal stability in mission-critical systems |

Why Partner With Us?

Zero Defects Philosophy

Every component undergoes 100% inspection using CMM and optical measurement systems, ensuring 99.99% defect-free delivery for aerospace and medical applications. Our statistical process control (SPC) protocols eliminate variability at the micron level.

Olympic & Military Endorsement

Trusted by Olympic cycling teams and defense contractors for components requiring zero tolerance for failure. Our processes comply with AS9100 (aerospace) and ISO 13485 (medical) standards—proven in the most demanding real-world environments.

24/7 Technical Support

Dedicated engineering team available around the clock for urgent design reviews, troubleshooting, and production support. We ensure your project stays on schedule, even under tight deadlines or unexpected challenges.

Ready to Elevate Your Project?

Contact our precision specialists today for a free DFM analysis and competitive quote. Let’s build the future, together.

Email: [email protected]

Phone: +86-13961886740

Note: All quotes include material certification, dimensional reports, and process validation documentation—no hidden costs, no compromises.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.