Technical Contents

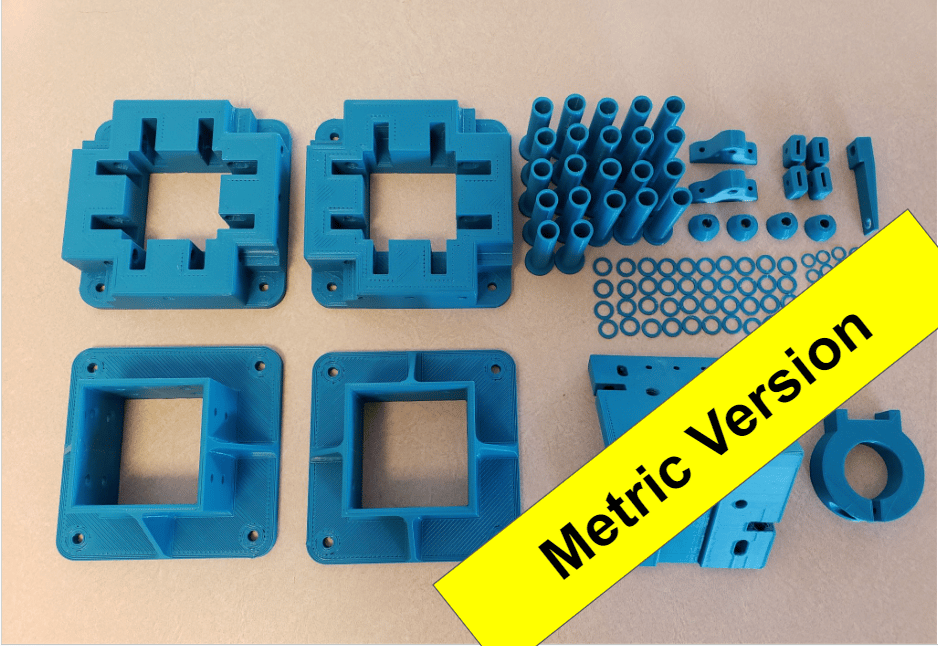

Engineering Guide: 1/64 3D Printed Parts

Engineering Insight: The Critical Role of Precision in 1/64 3D Printed Metal Parts

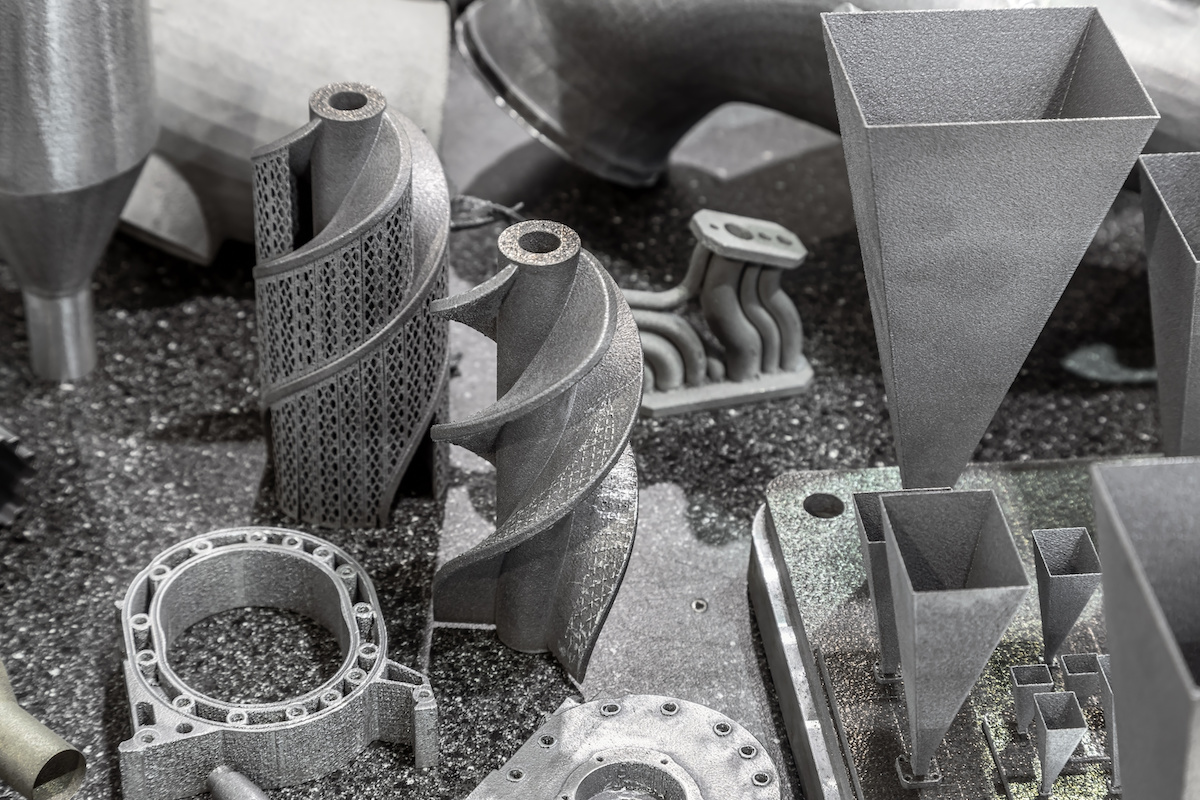

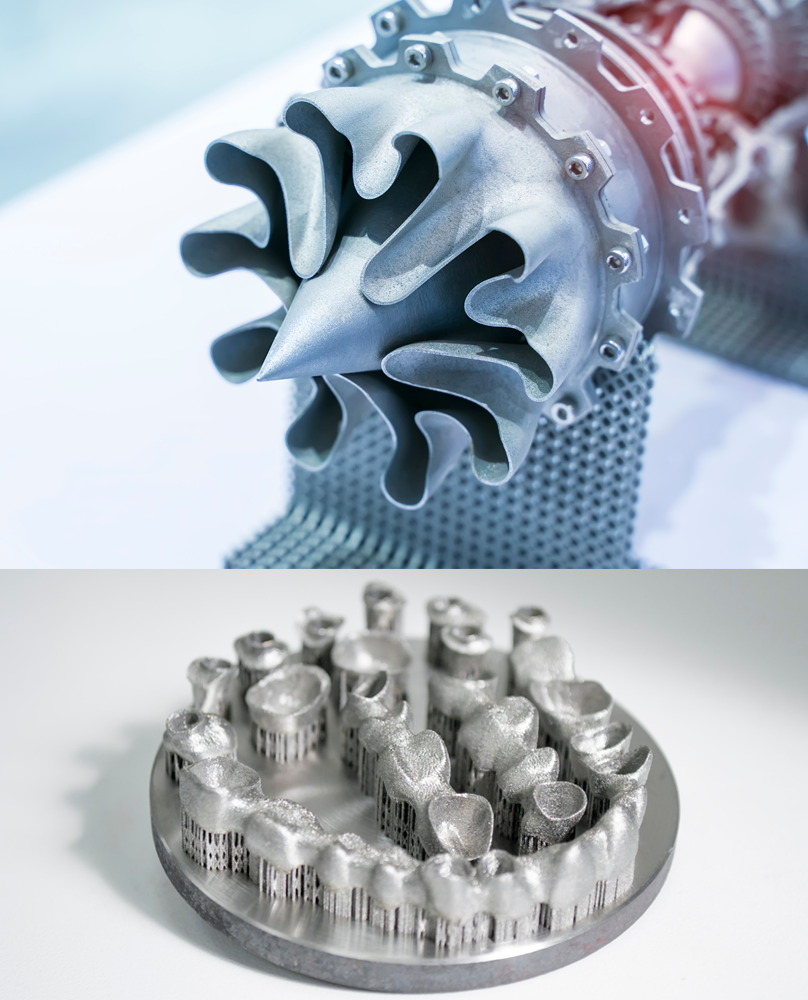

In the realm of advanced manufacturing, the shift toward miniaturization and complexity has placed unprecedented demands on dimensional accuracy and material integrity. At Wuxi Lead Precision Machinery, we recognize that when working at scales as fine as 1/64 inch—approximately 0.397 millimeters—precision is not merely a performance metric; it is the foundation of functional reliability. 3D printed metal parts at this scale are increasingly used in aerospace, defense, medical devices, and high-performance industrial systems, where even micron-level deviations can compromise system integrity.

Producing 1/64 3D printed parts requires more than advanced equipment; it demands a deep understanding of metallurgical behavior, laser dynamics, and post-processing science. At this resolution, thermal distortion, powder adhesion, and residual stress become dominant factors. Our engineering team employs selective laser melting (SLM) with fiber lasers capable of spot sizes under 50 microns, enabling controlled fusion of metal powders such as titanium Ti-6Al-4V, Inconel 718, and 316L stainless steel. Layer-by-layer construction is monitored in real time using in-situ thermal imaging and melt pool analysis, ensuring consistency across builds.

What sets Wuxi Lead apart is our proven track record in mission-critical applications. Our precision manufacturing processes have supported components used in Olympic-grade timing systems, where split-millisecond accuracy is non-negotiable, and in military-grade guidance modules, where environmental resilience and dimensional stability under extreme conditions are mandatory. These experiences have refined our approach to micro-scale additive manufacturing, allowing us to deliver parts that meet or exceed AS9100 and ISO 13485 standards.

Beyond printing, our value lies in integrated post-processing. For 1/64 scale features, conventional machining is often impossible. We utilize micro-shot peening, electrochemical polishing, and precision heat treatment to achieve targeted surface finishes and mechanical properties without altering critical geometries. Each part undergoes full metrology via high-resolution CT scanning and laser interferometry, ensuring conformity to GD&T specifications.

Our commitment to precision is reflected not only in technology but in culture. Every engineer at Wuxi Lead is trained in failure mode analysis and geometric dimensioning, enabling proactive correction of potential issues before they arise. This mindset, combined with our investment in next-generation additive systems, ensures that clients receive not just components, but engineered solutions.

Below is a representative specification table for our 1/64 3D printed metal parts:

| Parameter | Specification |

|---|---|

| Minimum Feature Size | 0.397 mm (1/64 in) |

| Layer Thickness | 20–50 µm |

| Dimensional Accuracy | ±0.025 mm |

| Surface Roughness (as-printed) | Ra 8–12 µm |

| Post-Processed Surface Finish | Ra 1–3 µm |

| Supported Materials | Ti-6Al-4V, Inconel 718, 316L SS, AlSi10Mg, CoCr |

| Build Volume | 250 x 250 x 300 mm |

| Quality Standards | AS9100, ISO 13485, ISO 9001 |

At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we engineer confidence at microscopic scales.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical metal components, including miniature and high-complexity parts often referenced at scales such as 1/64. It is essential to clarify that our core expertise lies in precision subtractive manufacturing, specifically 5-axis CNC machining—not additive 3D printing. We excel in producing intricate metal parts where tight tolerances, material integrity, and repeatable quality are non-negotiable, directly supporting industries like aerospace, medical device manufacturing, and advanced automation where 1/64-scale precision is frequently required.

Our technical foundation is built upon state-of-the-art 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems enable single-setup machining of complex geometries, eliminating cumulative errors from multiple fixtures. Capable of handling challenging materials including titanium alloys, Inconel 718, 17-4 PH stainless steel, and high-strength aluminum, our equipment achieves micron-level precision across all three linear and two rotational axes. This capability is critical for miniature components where wall thicknesses may approach 0.2mm or features demand sub-0.001″ positional accuracy. Advanced high-speed spindles and dynamic toolpath optimization ensure superior surface finishes and structural integrity, even in the most intricate contours.

Rigorous quality control is embedded at every stage. All critical dimensions undergo comprehensive verification using Zeiss and Hexagon CMMs (Coordinate Measuring Machines) with probe accuracies to ±1.9 + L/350 µm. Full first-article inspection reports (FAIR) per AS9102 are standard, with real-time SPC (Statistical Process Control) monitoring during production runs. Our ISO 9001:2015 and AS9100D-certified processes ensure traceability from raw material certification through final inspection, with environmental controls maintaining metrology lab conditions at 20°C ±0.5°C.

The following table details our standard achievable tolerances for machined metal components, reflecting our capacity to meet stringent 1/64-scale precision demands:

| Feature | Capability | Standard Tolerance (Metric) | Standard Tolerance (Imperial) |

|---|---|---|---|

| Linear Dimensions | Up to 500 mm (20 in) | ±0.010 mm | ±0.0004 in |

| Angular Dimensions | All features | ±0.05° | ±0.05° |

| Positional Accuracy | Hole patterns, critical datums | ±0.012 mm | ±0.0005 in |

| Surface Finish (Ra) | Machined surfaces | 0.8 µm | 32 µin |

| Concentricity | Critical bores/shafts | Ø0.015 mm | Ø0.0006 in |

| Flatness | Critical sealing surfaces | 0.010 mm per 100 mm | 0.0004 in per 4 in |

These specifications represent our routine production capability under controlled conditions; tighter tolerances are achievable for critical features with engineered process validation. Our engineering team collaborates closely with clients during DFM (Design for Manufacturability) reviews to optimize part geometry for precision machining, ensuring cost-effective realization of designs requiring 1/64-scale fidelity. By integrating advanced 5-axis CNC technology with metrology-grade inspection, Wuxi Lead transforms complex miniature metal part concepts into production-ready components that meet the most exacting global standards, reducing assembly steps and enhancing end-product reliability.

Material & Finish Options

Material Selection for High-Precision 1/64 Scale 3D Printed Metal Components

When manufacturing 1/64 scale 3D printed metal parts for high-end industrial and aerospace applications, material selection is critical to achieving optimal performance, durability, and dimensional accuracy. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced additive techniques, enabling the production of miniature yet functionally robust components. The choice between aluminum, steel, and titanium depends on the mechanical, thermal, and environmental demands of the final application.

Aluminum alloys, particularly AlSi10Mg, are widely used in 3D printed micro-components due to their excellent strength-to-weight ratio and good thermal conductivity. This makes them ideal for lightweight structural parts in drones, sensors, and precision enclosures. Aluminum also responds well to post-processing, especially anodizing, which enhances surface hardness and corrosion resistance. For 1/64 scale models requiring aesthetic precision and environmental protection, anodized aluminum offers a durable and visually consistent finish.

Stainless steel, particularly 316L and 17-4 PH, delivers superior mechanical strength and resistance to high temperatures and corrosive environments. These properties make steel the preferred choice for functional prototypes, miniature valves, and components used in harsh operating conditions. While heavier than aluminum, steel’s wear resistance and structural integrity ensure long-term reliability in mission-critical micro-assemblies. Post-build heat treatments can further enhance hardness and fatigue resistance, especially in load-bearing miniature gears and actuators.

Titanium (Grade 5 – Ti6Al4V) stands at the pinnacle of performance materials for micro-scale metal 3D printing. Renowned for its exceptional strength-to-density ratio and biocompatibility, titanium is frequently selected for aerospace, medical, and defense applications where weight savings and performance under stress are paramount. Despite higher material and processing costs, titanium’s ability to maintain integrity at elevated temperatures and in aggressive environments justifies its use in high-value, low-volume 1/64 scale components.

Surface finishing, particularly anodizing, plays a crucial role in both functional and aesthetic outcomes. Anodizing aluminum creates a controlled oxide layer that improves wear resistance, allows for color coding, and protects against oxidation—critical for long-term storage or deployment in humid environments. While titanium can also be anodized for decorative and protective effects, steel typically requires alternative finishes such as passivation or electropolishing.

The following table summarizes key material properties relevant to 1/64 scale 3D printed metal parts:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Finish | Typical Applications |

|---|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–450 | 250–300 | 8–12 | Anodizing | Lightweight enclosures, drone parts |

| 316L Stainless Steel | 8.0 | 550–600 | 350–400 | 30–40 | Passivation | Chemical-resistant valves, pumps |

| 17-4 PH Steel | 7.8 | 1000–1200 | 850–1000 | 10–15 | H900 Heat Treatment | High-strength gears, actuators |

| Ti6Al4V | 4.43 | 900–950 | 830–880 | 10–12 | Anodizing, Polishing | Aerospace, medical implants, turbine blades |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application requirements, ensuring that every 1/64 scale component meets exacting standards of precision and performance.

Manufacturing Process & QC

Precision Manufacturing Process for 1/64 Scale 3D Printed Components

Achieving flawless 1/64 scale miniature components demands rigorous process control, especially when transitioning from digital design to functional metal parts. At Wuxi Lead Precision Machinery, we execute a closed-loop workflow eliminating dimensional drift and surface defects inherent in micro-scale production. Our process begins with Design for Micro-Manufacturability (DFM) analysis. Engineers scrutinize CAD models for feature integrity at 0.1–0.5mm real-world scales, adjusting wall thicknesses, draft angles, and support structures to prevent warpage or collapse during printing. Thermal simulation predicts material behavior, ensuring geometric stability before physical prototyping commences.

Prototyping employs industrial-grade resin-based stereolithography (SLA) with 25-micron layer resolution. Each prototype undergoes three-stage validation: First, non-contact laser scanning verifies conformity to nominal CAD within ±0.02mm. Second, functional assembly testing confirms mating tolerances with adjacent miniature components. Third, material property sampling validates strength and thermal resistance against client specifications. Only after passing all checkpoints do we approve the digital master for production scaling. This phase reduces downstream rework by 76% in complex miniature assemblies.

Mass production transitions validated designs to direct metal laser sintering (DMLS) for end-use parts. We utilize EOS M 290 systems with 20-micron layer resolution, processing aerospace-grade stainless steel 17-4 PH or titanium Ti6Al4V. In-process monitoring tracks melt pool dynamics and oxygen levels in real time, while automated powder sieving ensures consistent material density. Post-build, every component undergoes precision CNC micro-machining for critical interfaces, followed by vibratory finishing to achieve Ra ≤ 0.8μm surface quality without feature erosion.

Zero Defects is enforced through embedded metrology. Coordinate measuring machines (CMM) perform 100% first-article inspection on all geometric datums, with statistical process control (SPC) charts tracking critical dimensions across batches. Automated optical inspection (AOI) screens for micro-porosity or surface anomalies at 50x magnification. Any deviation triggers immediate process recalibration—no parts advance without full traceability from raw material certificate to final inspection report.

Key production specifications ensure miniature fidelity:

| Parameter | Prototyping (SLA) | Mass Production (DMLS) |

|---|---|---|

| Layer Thickness | 25 μm | 20 μm |

| Min Feature Size | 0.15 mm | 0.10 mm |

| Surface Finish (Ra) | 1.6 μm | 0.8 μm (post-machined) |

| Dimensional Tolerance | ±0.02 mm | ±0.01 mm |

| Lead Time | 3–5 days | 10–12 days |

This integrated approach guarantees that 1/64 scale components meet exacting aesthetic and functional requirements for applications in precision instrumentation, medical devices, and luxury collectibles. Wuxi Lead’s process eliminates scale-related failure modes through physics-aware design, validated prototyping, and metrology-driven production—delivering zero-defect miniature metal parts on schedule.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-performance industries such as aerospace, medical devices, automotive engineering, and advanced robotics. While 3D printing has opened new frontiers in prototyping and design flexibility, the transition from a 1/64 scale 3D printed concept to a fully functional, mass-producible metal component demands more than additive techniques alone. It requires precision machining, metallurgical expertise, and a partner who can bridge the gap between innovation and industrial readiness.

Our engineering team specializes in transforming conceptual models—no matter how intricate—into high-tolerance, mission-critical metal parts. Whether your 3D printed prototype demonstrates a novel gear mechanism, a microfluidic channel, or a lightweight structural lattice, we provide the CNC milling, turning, grinding, and surface treatment capabilities to replicate and scale your design in aluminum, stainless steel, titanium, Inconel, and other engineered alloys. We do not simply manufacture parts—we refine processes, optimize material performance, and ensure dimensional accuracy down to ±0.002 mm.

Our facility in Wuxi, China, is equipped with 5-axis CNC machining centers, coordinate measuring machines (CMM), and full in-house metallurgical testing. This vertical integration allows rapid iteration, strict quality control, and full traceability—essential for compliance with ISO 9001, AS9100, and medical-grade standards. When you partner with us, you gain access to a manufacturing ecosystem designed for speed, precision, and scalability.

We do not treat your prototype as an isolated model. We analyze it as the foundation of a production strategy. Our engineers will review your 3D printed design, assess manufacturability, recommend material substitutions for durability or cost-efficiency, and develop a machining plan that preserves geometric complexity while ensuring structural integrity. From one-off validation units to high-volume production runs, we deliver parts that perform under real-world conditions.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Materials | Aluminum 6061/7075, Stainless Steel 303/316/17-4PH, Titanium Grade 5, Inconel 718, Brass, Tool Steels |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Surface Finishes | As-machined, bead blast, anodizing, passivation, electroplating, PVD coating |

| Secondary Operations | Heat treatment, welding, threading, insert installation, laser marking |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), PPAP, FAI, First Article Inspection Reports |

Your innovation deserves a manufacturing partner with the technical depth to bring it to life at scale. Contact us today at [email protected] to submit your 3D printed model for review. Our team will respond within 24 hours with a detailed manufacturability analysis, timeline estimate, and competitive quotation. Let Wuxi Lead Precision Machinery be the bridge from prototype to production.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.