Technical Contents

Engineering Guide: 1018 Steel Material Properties

Engineering Insight: 1018 Steel Material Properties

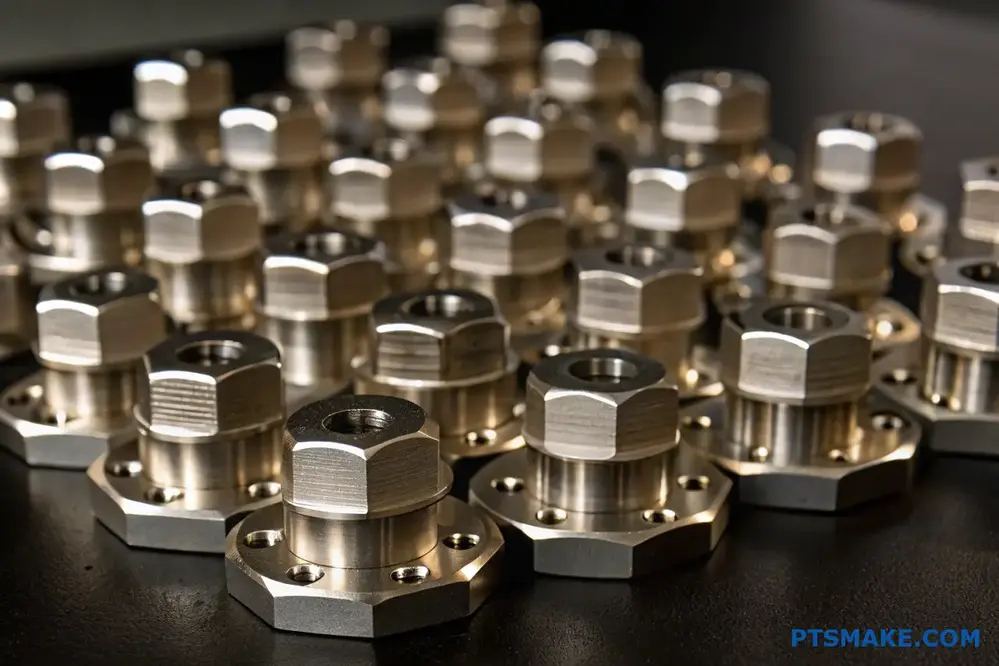

In the realm of custom metal manufacturing, precision is not merely a goal—it is a requirement. Nowhere is this more evident than in the selection and application of materials such as 1018 steel, a low-carbon steel widely used for its excellent machinability, weldability, and mechanical consistency. At Wuxi Lead Precision Machinery, we understand that mastering the nuances of 1018 steel is critical for delivering components that meet the exacting standards of industries ranging from aerospace to defense and high-performance industrial equipment.

1018 steel, also known as AISI 1018, contains approximately 0.18% carbon, which places it in the mild steel category. This low carbon content ensures that the material remains ductile and easily formed, yet strong enough for a wide range of structural and mechanical applications. Its balanced composition allows for uniformity in machining processes, minimizing tool wear and enabling tight tolerances—often within ±0.005 mm—essential for high-integrity parts. At Lead Precision, our CNC machining centers are calibrated to exploit these characteristics, ensuring repeatability and dimensional accuracy across high-volume production runs.

One of the defining advantages of 1018 steel is its response to case hardening. While it does not achieve the same through-hardening capability as higher-carbon steels, it responds exceptionally well to carburizing, allowing for a hard, wear-resistant surface while maintaining a tough, ductile core. This makes it ideal for gears, pins, shafts, and other components subjected to surface stress. Our engineering team leverages this property in custom solutions developed for clients in the military and Olympic-grade equipment sectors, where reliability under dynamic loading is non-negotiable.

Our experience with 1018 steel extends beyond routine fabrication. We have contributed to projects demanding extreme precision, including components for national defense systems and motion-critical assemblies used in Olympic training facilities. These applications require not only adherence to material specifications but also rigorous in-process inspection and post-machining validation. Our ISO-certified quality control systems ensure that every 1018 steel part we produce meets or exceeds ASTM A29 and SAE J403 standards.

The following table outlines key mechanical and physical properties of 1018 steel in the cold-drawn condition, the most commonly used form in precision manufacturing:

| Property | Value |

|---|---|

| Carbon Content | 0.15–0.20% |

| Tensile Strength | 440–550 MPa |

| Yield Strength | 370 MPa (min) |

| Elongation (in 2″) | 15% (min) |

| Hardness (Brinell) | 126–143 HB |

| Density | 7.87 g/cm³ |

| Modulus of Elasticity | 205 GPa |

| Machinability Rating | 72% (relative to B1112) |

| Weldability | Excellent (with proper techniques) |

At Wuxi Lead Precision Machinery, our mastery of 1018 steel is rooted in over a decade of delivering mission-critical components where failure is not an option. Precision begins with material understanding—and we engineer every part with that principle in mind.

Precision Specs & Tolerances

Precision Machining of 1018 Steel: Capabilities at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers exceptional value in custom components utilizing AISI 1018 low-carbon steel, leveraging its favorable balance of machinability, weldability, and cost-effectiveness for demanding industrial applications. Understanding the specific properties of 1018 steel is fundamental to achieving optimal results. This material exhibits good ductility and relatively low hardness in its cold-drawn or hot-rolled condition, making it highly suitable for complex geometries but requiring precise process control to manage its tendency towards work hardening and potential for dimensional instability if not stress-relieved post-machining. Its low carbon content minimizes hardening response, ensuring consistent machinability without the need for pre-heat treatment in most scenarios, though final stress relief is often recommended for critical precision components.

Our advanced manufacturing capabilities are specifically tuned to maximize the potential of 1018 steel. Utilizing state-of-the-art 5-axis CNC machining centers, we achieve intricate contours, tight tolerances, and superior surface finishes in a single setup, significantly reducing handling errors and cycle times inherent in multi-operation processes for this material. The dynamic capabilities of our 5-axis platforms allow for optimal tool engagement angles, mitigating the gummy chip formation characteristic of low-carbon steels like 1018, thereby enhancing tool life and dimensional consistency. Complex features such as undercuts, deep cavities, and organic shapes are executed with the highest fidelity directly from CAD models.

Rigorous quality control is non-negotiable for 1018 steel components where dimensional stability is paramount. Every critical feature undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMMs) operating within our ISO 17025 accredited metrology lab. This ensures conformance to print specifications, validates geometric dimensioning and tolerancing (GD&T), and provides traceable data for material batches and process parameters. Our inspection protocols specifically account for 1018’s properties, including verification after potential stress-relief operations to confirm final dimensions meet stringent requirements.

The achievable precision for 1018 steel components at Wuxi Lead is defined by our integrated process and equipment capabilities. The following table outlines typical tolerance ranges we consistently maintain for critical features, reflecting real-world production conditions on our 5-axis CNC systems with full CMM validation:

| Feature Type | Standard Tolerance (mm) | Precision Capability (mm) |

|---|---|---|

| Linear Dimensions | ±0.05 | ±0.0125 |

| Hole Diameter | ±0.03 | ±0.005 |

| Positional Tolerance | ±0.05 | ±0.0125 |

| Flatness | 0.05 | 0.0125 |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

These capabilities are not theoretical ideals but represent the consistent output achieved through our optimized machining strategies, stringent environmental controls, and expert operator knowledge of 1018 steel’s behavior. We partner with clients from the design phase to recommend optimal material condition (e.g., cold-drawn for tighter initial tolerances), machining sequences, and post-processing steps to ensure the final 1018 component meets the most exacting functional and dimensional requirements. Contact our engineering team to discuss how our precision 5-axis CNC machining and metrology expertise can be applied to your specific 1018 steel application.

Material & Finish Options

Material Selection Guide: Understanding 1018 Steel and Alternatives for Precision Manufacturing

In custom metal manufacturing, selecting the right material is critical to balancing performance, cost, and manufacturability. Among carbon steels, 1018 steel stands out as a widely used low-carbon option, particularly suited for applications requiring moderate strength, excellent machinability, and weldability. At Wuxi Lead Precision Machinery, we recommend 1018 steel for components such as shafts, pins, spacers, and structural parts where tight tolerances and consistent quality are essential.

1018 steel contains approximately 0.18% carbon, which contributes to its ductility and ease of cold working. It is typically supplied in cold-drawn or hot-rolled forms, with cold drawing enhancing its surface finish and dimensional accuracy. This material responds well to carburizing, allowing surface hardening for improved wear resistance while maintaining a tough core. However, it is not ideal for high-stress or high-temperature environments due to its relatively low tensile strength compared to alloy steels or materials like titanium.

When comparing 1018 steel to alternative metals such as aluminum and titanium, key differences emerge in weight, strength, and corrosion resistance. Aluminum offers a significant weight advantage and natural corrosion resistance, making it ideal for aerospace and transportation applications. Titanium provides exceptional strength-to-density ratio and outstanding resistance to corrosion, particularly in marine and medical environments, though at a higher cost and more challenging machining requirements.

For finishing, 1018 steel is commonly treated with zinc plating, black oxide, or powder coating to enhance corrosion resistance. Unlike aluminum, it is not suitable for anodizing, which is an electrochemical process specific to aluminum and its alloys. Anodizing increases surface hardness and allows for color customization, making it a preferred finish for aluminum components in consumer and industrial equipment.

Below is a comparative overview of key material properties to assist in selection for precision manufacturing projects.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Machinability Rating | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|---|

| 1018 Steel | 440 | 370 | 7.87 | 70% | Low (requires coating) | Zinc plating, black oxide |

| Aluminum 6061 | 310 | 276 | 2.70 | 90% | High | Anodizing, powder coating |

| Titanium Gr2 | 480 | 340 | 4.51 | 30% | Excellent | Passivation, bead blasting |

Selecting between 1018 steel, aluminum, and titanium depends on the operational environment, mechanical demands, and budget constraints of the final application. At Wuxi Lead Precision Machinery, we support clients in making informed decisions by providing material certifications, prototyping services, and expert consultation to ensure optimal performance in every manufactured component.

Manufacturing Process & QC

Production Process: Precision Manufacturing with 1018 Steel

At Wuxi Lead Precision Machinery, mastering the production lifecycle for 1018 steel components is fundamental to delivering zero-defect outcomes for demanding industrial applications. This low-carbon steel offers an optimal balance of machinability, weldability, and cost-effectiveness, making it a cornerstone material for custom shafts, pins, brackets, and structural elements. Our rigorous three-phase process ensures every part meets exacting specifications from concept to volume shipment.

The Design phase begins with deep material integration. Our engineering team leverages 1018 steel’s specific properties during CAD modeling and tolerance definition. Understanding its moderate strength, excellent cold-forming characteristics, and predictable chip formation allows us to optimize geometries for manufacturability while maintaining structural integrity. Finite Element Analysis (FEA) validates stress points under load, ensuring the inherent ductility of 1018 steel is fully utilized without compromising dimensional stability. Material certifications (ASTM A29) are specified upfront, guaranteeing traceability and compliance.

Prototyping transitions design into physical validation under real-world conditions. Utilizing our high-precision CNC milling and turning centers, we produce functional prototypes directly from the approved CAD data. Critical dimensions are verified against first-article inspection (FAI) requirements using calibrated CMMs and optical comparators. This phase rigorously tests 1018 steel’s response to our specific cutting parameters, tooling, and fixturing. Any micro-defects related to material grain flow or residual stress are identified and resolved here, long before tooling is committed for production. Customer sign-off on the prototype is mandatory, confirming both form and function meet expectations.

Mass Production executes at scale with embedded zero-defect protocols. Our automated CNC cells, running optimized G-code validated during prototyping, maintain consistent cutting speeds and feeds tailored to 1018 steel’s machinability. Real-time Statistical Process Control (SPC) monitors critical dimensions on every batch, with immediate feedback loops halting production if trends approach tolerance limits. 100% in-process inspection of key features, combined with rigorous final inspection against the FAI report and customer prints, ensures absolute conformance. Material lot traceability is maintained throughout, linking each component back to its certified 1018 steel heat number. This closed-loop system, powered by our engineering expertise and advanced metrology, guarantees that every part shipped meets the stringent quality standards required for critical industrial machinery.

Key 1018 Steel Material Properties for Precision Manufacturing

| Property | Value | Relevance to Production Process |

|---|---|---|

| Carbon Content | 0.15-0.20% | Enables excellent machinability and weldability |

| Tensile Strength | 440 MPa (63.8 ksi) min | Defines load-bearing capacity for design validation |

| Yield Strength | 325 MPa (47.1 ksi) min | Critical for FEA and structural integrity checks |

| Brinell Hardness (HB) | 121-131 | Impacts tool wear rates and surface finish quality |

| Machinability Rating | 72% (160 SFM) | Directly informs CNC speed/feed optimization |

| Elongation in 2″ | 25% min | Essential for cold-forming and bending operations |

| ASTM Standard | A29/A29M | Mandatory for material certification and traceability |

This disciplined approach, rooted in material science and process control, transforms the inherent advantages of 1018 steel into flawless, high-reliability components for global industrial clients. Wuxi Lead Precision Machinery guarantees performance through precision.

Why Choose Wuxi Lead Precision

When it comes to precision manufacturing with materials like 1018 steel, selecting the right partner is as critical as understanding the material itself. At Wuxi Lead Precision Machinery, we bring together deep metallurgical expertise, advanced CNC capabilities, and rigorous quality control to deliver custom metal components that meet exacting industrial standards. Our experience in machining low-carbon steels such as 1018 ensures optimal performance in applications ranging from automotive shafts and gears to structural components and fasteners.

1018 steel is widely valued for its excellent machinability, weldability, and surface finish characteristics. As a low-carbon steel, it offers good ductility and is often chosen for parts requiring moderate strength and high dimensional stability. While not typically hardened through heat treatment, 1018 steel responds well to carburizing and case hardening, making it ideal for wear-resistant surfaces with a tough core. At Wuxi Lead, we leverage these properties to produce components with tight tolerances, consistent microstructure, and repeatable quality across batch sizes.

Our manufacturing process begins with certified raw materials and integrates precision turning, milling, drilling, and grinding operations on state-of-the-art CNC equipment. We apply in-process inspections and final quality verification using coordinate measuring machines (CMM) and metallurgical analysis to ensure compliance with international standards, including ASTM A29 and SAE J403. Whether you require prototype development or high-volume production, our team provides scalable solutions tailored to your design and performance requirements.

Below are the key material properties of 1018 steel that inform our machining strategies and quality assurance protocols.

| Property | Value |

|---|---|

| Material Standard | ASTM A29 / SAE J403 |

| Carbon Content | 0.15–0.20% |

| Tensile Strength | 440–590 MPa (63–85 ksi) |

| Yield Strength | 370 MPa (54 ksi) min |

| Elongation | 15% min in 2″ |

| Hardness (Brinell) | 121–131 HB |

| Density | 7.87 g/cm³ |

| Modulus of Elasticity | 205 GPa (30 x 10⁶ psi) |

| Machinability Rating | 70% (relative to B1112) |

| Typical Applications | Shafts, pins, studs, machine parts, hardware |

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem backed by ISO 9001-certified processes and over 15 years of experience in serving global industrial clients. We specialize in transforming engineering specifications into high-integrity metal components with on-time delivery and full documentation traceability.

For your next project involving 1018 steel or other engineered metals, contact us today. Our engineering team is ready to review your prints, provide DFM feedback, and support your supply chain with precision-manufactured parts you can trust.

Email us at [email protected] to begin the conversation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.