Technical Contents

Engineering Guide: 1008 Vs 1018 Steel

Engineering Insight: 1008 vs 1018 Steel – The Role of Precision in Material Selection

In high-precision metal manufacturing, the distinction between seemingly similar low-carbon steels such as 1008 and 1018 can significantly impact performance, manufacturability, and final product integrity. At Wuxi Lead Precision Machinery, we understand that material selection is not merely a matter of chemical composition—it is a strategic engineering decision that must align with dimensional tolerances, end-use requirements, and production scalability. Our experience delivering components for Olympic-grade equipment and military-grade applications has reinforced the necessity of precision at every stage, beginning with the correct steel grade.

Both 1008 and 1018 steels fall under the AISI-SAE 10xx series, indicating plain carbon steel with minimal alloying elements. However, subtle differences in carbon content and manganese levels lead to divergent mechanical behaviors. 1008 steel contains approximately 0.08% carbon, making it one of the most formable low-carbon steels available. It is ideal for applications requiring deep drawing, cold heading, or complex bending without cracking. In contrast, 1018 steel, with a carbon content of around 0.18%, offers improved strength and hardness, making it more suitable for machined parts, pins, shafts, and components requiring moderate wear resistance.

The choice between these materials must be guided by precision engineering principles. For instance, in automated stamping or CNC turning environments, even minor variations in material hardness or ductility can affect tool life, surface finish, and dimensional consistency. 1018 steel, while stronger, may require more robust tooling and tighter process controls due to increased work hardening tendencies. Conversely, 1008’s superior ductility allows for high-speed forming but may present challenges in maintaining tight tolerances during secondary machining operations.

At Wuxi Lead Precision Machinery, our decades of experience in custom metal manufacturing have taught us that precision begins with material understanding. We leverage advanced metrology, in-process inspection, and statistical process control to ensure that whether a client selects 1008 for its formability or 1018 for its machinability, the final component meets exacting specifications. Our work on Olympic timing mechanisms and military deployment systems demanded micron-level accuracy and full traceability—standards we now apply to every client project.

Below is a comparative overview of key specifications for 1008 and 1018 steel to guide engineering decisions.

| Property | 1008 Steel | 1018 Steel |

|---|---|---|

| Carbon Content (%) | 0.05–0.10 | 0.14–0.20 |

| Manganese Content (%) | 0.30–0.50 | 0.60–0.90 |

| Tensile Strength (MPa) | 340–420 | 440–530 |

| Yield Strength (MPa) | 280–350 | 370–450 |

| Elongation at 2″ (%) | 20–30 | 15–20 |

| Typical Applications | Cold-formed parts, fasteners, enclosures | Shafts, pins, machined components, hardware |

| Machinability Rating | 50% | 70% |

| Weldability | Excellent | Good |

Selecting between 1008 and 1018 steel is not a matter of superiority, but of suitability. At Wuxi Lead, we partner with engineers to ensure material choice aligns with design intent, production method, and performance demands—proving that precision is not just measured in microns, but in informed decisions.

Precision Specs & Tolerances

Precision Engineering Capabilities for Low Carbon Steel Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom manufacturing of low carbon steel components, specializing in 1008 and 1018 alloys. Our technical expertise ensures optimal material utilization while meeting stringent dimensional and functional requirements. The subtle differences between these steels—1008’s ultra-low carbon content (0.08% max) enabling superior cold formability versus 1018’s slightly higher carbon (0.18%) and manganese for enhanced machinability and weldability—dictate precise process calibration. We leverage this metallurgical understanding to eliminate burring, tool wear, and dimensional drift during high-volume production.

Our facility deploys state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and MAZAK INTEGREX i-200S systems. These platforms execute complex geometries in a single setup, reducing cumulative error and secondary operations. Advanced high-pressure coolant delivery and rigid tooling strategies mitigate thermal deformation in both 1008’s soft annealed state and 1018’s free-machining variants. All equipment undergoes quarterly laser interferometer calibration to maintain volumetric accuracy below ISO 230-2 standards.

Quality assurance is anchored in Zeiss CONTURA and GLOBAL S CMM inspection systems, providing traceable metrology to ±0.0001″ (2.5 µm). Every critical dimension undergoes first-article and in-process verification against GD&T callouts, with real-time SPC data analysis ensuring process stability. Surface roughness is validated via Mitutoyo SJ-410 profilometers, guaranteeing Ra values down to 0.4 µm where required. This closed-loop QC framework prevents non-conformances before shipment.

Tolerance capabilities for low carbon steel machining are summarized below:

| Material | Typical Machining Tolerance | Critical Dimension Tolerance | Surface Roughness (Ra) |

|---|---|---|---|

| 1008 Steel | ±0.005″ (0.13 mm) | ±0.001″ (0.025 mm) | 1.6–3.2 µm |

| 1018 Steel | ±0.003″ (0.08 mm) | ±0.0005″ (0.013 mm) | 0.8–1.6 µm |

Note: Tolerances achieved under controlled environmental conditions (20±1°C). Critical dimensions require dedicated CMM validation per ASME B89.4.1030 standards.

Wuxi Lead integrates material science with precision engineering to transform design intent into flawless components. Our 5-axis CNC mastery and metrology-driven quality control ensure 1008 and 1018 steel parts consistently meet aerospace, medical, and automotive sector demands. Partner with us for technically complex builds where dimensional integrity directly impacts product performance and regulatory compliance. All processes adhere to ISO 9001:2015 and IATF 16949 frameworks, providing global supply chain confidence.

Material & Finish Options

When selecting materials for precision manufacturing applications, understanding the mechanical and chemical properties of common steels such as 1008 and 1018 is essential. At Wuxi Lead Precision Machinery, we specialize in custom metal components where material choice directly impacts performance, machinability, and cost-efficiency. Both 1008 and 1018 steels are low-carbon, mild steels widely used in industrial applications, but their subtle differences influence suitability for specific manufacturing needs.

1008 steel contains approximately 0.08% carbon, making it one of the lowest carbon content steels available. This composition provides excellent formability and weldability, ideal for applications requiring deep drawing or cold forming. Due to its low hardness and high ductility, 1008 is frequently used in wire, tubing, and stamped components. However, its lower strength limits its use in high-stress environments. It is typically supplied in cold-drawn or hot-rolled forms and responds well to case hardening when surface durability is required.

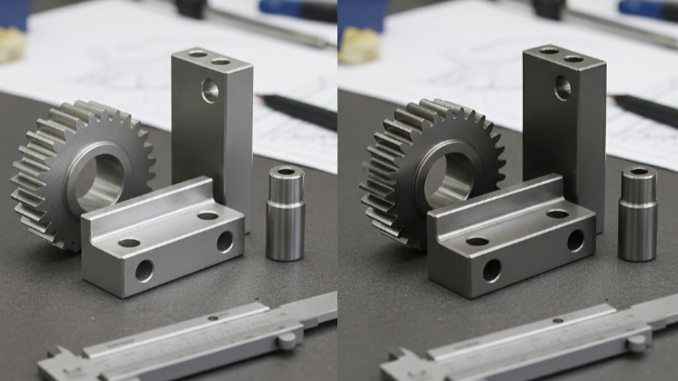

In contrast, 1018 steel contains slightly more carbon—approximately 0.18%—which increases its tensile strength and hardness while maintaining good machinability and weldability. This balance makes 1018 a preferred choice for shafts, pins, gears, and other mechanical parts requiring moderate strength and reliable performance under load. It is also commonly used in CNC-machined prototypes and production parts due to its consistent grain structure and dimensional stability.

When comparing these materials alongside other common manufacturing metals such as aluminum and titanium, the selection depends on application-specific demands. Aluminum offers high strength-to-weight ratio and corrosion resistance, ideal for aerospace and lightweight structural components. Titanium provides exceptional strength, corrosion resistance, and performance at elevated temperatures, though at a higher cost and more complex machining requirements. Steel remains the optimal choice for applications requiring durability, cost control, and ease of fabrication.

Surface finish selection further enhances material performance. For aluminum, anodizing provides a hard, wear-resistant oxide layer that improves corrosion resistance and allows for color coding. Steel components benefit from zinc plating, powder coating, or passivation depending on environmental exposure. While 1008 and 1018 steels are not typically anodized, they can be plated or coated to extend service life in harsh conditions.

Below is a comparative overview of key properties:

| Material | Carbon Content (%) | Tensile Strength (MPa) | Yield Strength (MPa) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| 1008 Steel | 0.08 | 340 | 285 | Wire, tubing, stampings | Excellent |

| 1018 Steel | 0.18 | 440 | 370 | Shafts, pins, gears | Good |

| Aluminum 6061 | – | 310 | 276 | Aerospace, structural | Excellent |

| Titanium Grade 5 (Ti-6Al-4V) | – | 900 | 830 | Medical, aerospace | Fair |

Material selection is a critical step in precision manufacturing. At Wuxi Lead, we support clients in choosing the optimal material and finish based on functional requirements, production volume, and environmental conditions.

Manufacturing Process & QC

Material Selection as the Foundation of Defect-Free Production

At Wuxi Lead Precision Machinery, the production journey for components requiring low-carbon steel begins with rigorous material specification. Selecting between 1008 and 1018 steel is not merely a cost decision but a critical engineering choice impacting every downstream process. Our engineers analyze the component’s functional requirements—tensile strength needs, weldability constraints, surface finish expectations, and dimensional stability under load—to determine which grade optimizes manufacturability and end-use performance. This phase integrates CAD/CAM simulations with material science data, ensuring the chosen steel aligns with the final part’s tolerance stack-up and fatigue resistance criteria.

Prototyping: Validating Material Behavior Under Real Conditions

We execute rapid in-house prototyping using the exact steel grade designated for production. CNC milling and turning operations replicate mass production toolpaths on small batches, allowing us to observe chip formation, tool wear rates, and thermal deformation specific to 1008 or 1018. Coordinate Measuring Machine (CMM) inspections validate dimensional accuracy against the digital twin, while destructive testing checks weld integrity and hardness uniformity. This phase identifies subtle material inconsistencies—such as 1018’s slightly higher carbon content improving machinability but requiring adjusted feed rates—and refines process parameters before full-scale commitment.

Mass Production: Enforcing Zero Defects Through Closed-Loop Control

Transitioning to volume manufacturing, Wuxi Lead implements our Zero Defects protocol through integrated process monitoring. Each 1008 or 1018 billet undergoes certified mill test report verification before machining. CNC cells operate with real-time force sensors and thermal compensation systems, automatically adjusting for material batch variations. Statistical Process Control (SPC) charts track critical dimensions from every 20th part, triggering immediate machine recalibration if trends approach tolerance limits. Final inspection employs automated optical comparators and 100% hardness testing, with traceability linking each component to its specific steel heat number. This closed-loop system ensures defects are physically impossible to propagate downstream.

Key Steel Property Comparison for Precision Manufacturing

| Property | 1008 Steel | 1018 Steel | Production Impact |

|---|---|---|---|

| Carbon Content (wt%) | 0.05–0.10 | 0.13–0.18 | 1018 offers better machinability; 1008 superior cold forming |

| Tensile Strength (MPa) | 325–410 | 400–500 | 1018 supports higher-stress applications |

| Machinability Rating | 50% (Fair) | 70% (Good) | 1018 reduces tool wear in high-volume CNC operations |

| Weldability | Excellent | Good | 1008 preferred for complex welded assemblies |

| Typical Applications | Nuts, bolts, stampings | Shafts, pins, spindles | Dictates process sequence and fixturing complexity |

This disciplined progression—from material-aware design through empirical prototyping to sensor-driven mass production—eliminates guesswork. At Wuxi Lead, we treat 1008 and 1018 not as interchangeable commodities but as engineered solutions, where process control tailored to their metallurgical profiles delivers certified zero-defect output for aerospace, medical, and automation clients demanding absolute reliability.

Why Choose Wuxi Lead Precision

When it comes to precision metal manufacturing, selecting the right material is only half the equation. The expertise, consistency, and technical capability of your manufacturing partner determine the final performance, durability, and value of your components. At Wuxi Lead Precision Machinery, we specialize in transforming raw materials like 1008 and 1018 steel into high-precision, mission-critical parts for industries ranging from automotive and aerospace to industrial automation and energy systems.

Our engineering team understands that while 1008 and 1018 steels may appear similar in composition, their mechanical behaviors under machining, forming, and welding conditions differ significantly. That distinction demands not just experience, but a data-driven approach to material selection and process optimization. We go beyond standard fabrication—we analyze your application requirements, load conditions, environmental exposure, and lifecycle expectations to recommend and deliver the optimal solution.

At Lead Precision, we operate under ISO 9001-certified quality management systems, utilizing state-of-the-art CNC machining centers, robotic welding cells, and in-line metrology to ensure repeatability and accuracy down to ±0.005 mm. Whether you require low-volume prototypes or high-volume production runs, our scalable manufacturing model supports rapid turnaround without compromising quality.

Below is a comparative overview of the key mechanical and chemical properties of 1008 and 1018 steel to guide your initial evaluation:

| Property | 1008 Steel | 1018 Steel |

|---|---|---|

| Carbon Content (%) | 0.08–0.13 | 0.14–0.20 |

| Tensile Strength (MPa) | ~340 | ~440 |

| Yield Strength (MPa) | ~285 | ~370 |

| Elongation at Break (%) | ~20 | ~15 |

| Hardness (Brinell) | ~105 | ~126 |

| Machinability Rating | 50% | 70% |

| Common Forms | Sheet, bar, wire | Bar, rod, cold-finished |

| Typical Applications | Formed parts, fasteners | Shafts, pins, machined components |

This data serves as a foundation, but real-world performance depends on precise process control. Our engineers apply this knowledge daily, adjusting feed rates, tooling strategies, and heat treatment protocols to match the nuances of each alloy.

Partnering with Wuxi Lead Precision Machinery means gaining a technical extension of your own team. We don’t just fulfill orders—we co-engineer solutions. From material sourcing and DFMA analysis to final inspection and global logistics, we manage every stage with transparency and accountability.

For your next project involving 1008, 1018, or any precision steel application, contact us today. Let our expertise ensure your components meet the highest standards of performance and reliability.

Email us at [email protected] to initiate a technical consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.