Technical Contents

Engineering Guide: 1000 Steel Machined Parts

Engineering Insight: 1000 Steel Machined Parts – The Imperative of Precision

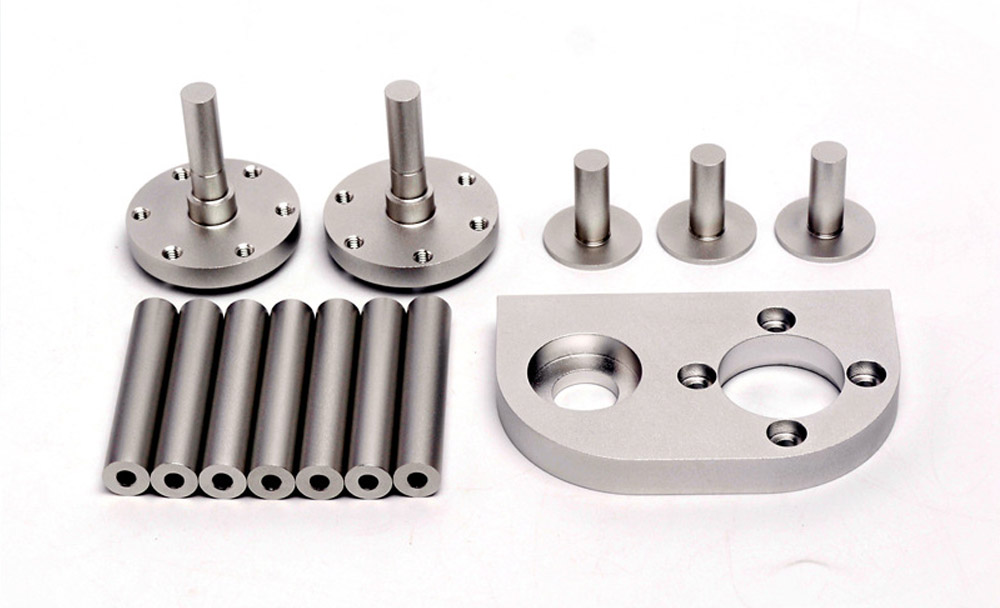

In the realm of high-volume precision manufacturing, producing 1000 steel machined parts is not merely a matter of replication—it is an exercise in consistency, accuracy, and engineering excellence. Each component must meet exacting dimensional tolerances, surface finish requirements, and material integrity standards, ensuring that every part performs identically in its final application. At Wuxi Lead Precision Machinery, we understand that mass production does not compromise precision; rather, it demands a higher level of process control, tooling stability, and quality assurance.

Steel, as a material, presents unique challenges in machining due to its hardness, thermal resistance, and tendency to work-harden during cutting. When scaling to 1000 units, even minor inconsistencies—such as tool deflection, thermal expansion, or feed rate variation—can compound into significant deviations. Our approach integrates advanced CNC machining centers with real-time monitoring systems, ensuring that each part adheres to tolerances as tight as ±0.005 mm. This level of precision is not theoretical—it is a standard we uphold across every production batch.

Our experience in delivering mission-critical components for Olympic-grade equipment and military-grade systems has honed our ability to manage complexity at scale. These applications leave no margin for error. A single failure can compromise performance, safety, or structural integrity. This discipline directly informs our methodology for high-volume steel machining. From initial material selection to final inspection, every phase is governed by ISO 9001-certified protocols and in-process quality checks.

We utilize hardened tooling optimized for steel alloys, coupled with high-pressure coolant systems to manage heat and extend tool life. Our CNC lathes and milling centers operate under closed-loop feedback, allowing for automatic compensation of wear and drift. Additionally, first-article inspection (FAI) and statistical process control (SPC) are employed throughout the run to validate consistency across all 1000 units.

The result is a batch of steel machined parts that are not only dimensionally identical but also functionally interchangeable—essential for assembly-line integration and long-term reliability.

| Specification | Detail |

|---|---|

| Material Options | 4140, 4340, 1045, Stainless Steel 304/316, Tool Steels |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry) |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (customizable) |

| Max Part Size | 600 mm x 400 mm x 300 mm |

| Production Capacity | 1000+ units with full traceability and batch documentation |

| Quality Standards | ISO 9001:2015, FAI, SPC, CMM inspection reports |

Precision at scale is not achieved by automation alone—it is the product of experience, engineering rigor, and an unwavering commitment to quality. At Wuxi Lead Precision Machinery, we bring decades of expertise to every high-volume steel machining project, ensuring that your 1000 parts perform as one.

Precision Specs & Tolerances

Technical Capabilities for Precision Steel Machined Components

Wuxi Lead Precision Machinery delivers uncompromising quality and complexity for demanding steel machined part applications. Our core strength lies in integrating advanced multi-axis CNC technology with rigorous metrology, specifically engineered for the stringent requirements of aerospace, energy, and industrial equipment sectors where 1000+ part batches demand absolute consistency. We specialize in machining high-strength alloy steels including 4140, 4340, 17-4PH, and tool steels, ensuring material integrity and dimensional stability throughout production.

Our primary machining platform consists of state-of-the-art 5-axis CNC milling and turning centers, predominantly DMG MORI and Makino models. These machines enable the complete machining of complex geometries in a single setup, eliminating cumulative errors inherent in multi-operation processes. Simultaneous 5-axis interpolation allows precise contouring of intricate features, deep cavities, and compound angles common in structural brackets, hydraulic manifolds, and turbine components. This capability significantly reduces lead times for complex steel parts while enhancing positional accuracy between critical features. High-torque spindles and rigid machine structures ensure optimal metal removal rates and surface finishes on challenging steel alloys, maintaining process stability even during extended unmanned production runs essential for 1000-part quantities.

Quality assurance is non-negotiable. Every critical dimension on steel components undergoes verification using Zeiss and Hexagon Coordinate Measuring Machines (CMMs). Our AS9100-certified inspection process utilizes calibrated probes and advanced software for comprehensive geometric dimensioning and tolerancing (GD&T) analysis. Full first-article inspection reports (FAIRs) and periodic in-process CMM checks are standard protocol, providing traceable data to validate conformance against your engineering specifications. This systematic approach ensures zero-defect delivery for high-volume steel part programs, mitigating scrap risk and guaranteeing fit/function in final assembly.

The following table details our standard achievable tolerance capabilities for machined steel components, reflecting the precision delivered across production batches:

| Feature Category | Capability | Typical Tolerance Range (mm) |

|---|---|---|

| Linear Dimensions | General Machining | ±0.01 to ±0.05 |

| Critical Features | ±0.005 to ±0.01 | |

| Geometric Tolerances | Positional Accuracy | ±0.01 to ±0.025 |

| Flatness / Parallelism | 0.01 to 0.03 per 100mm | |

| Concentricity / Runout | 0.005 to 0.015 | |

| Surface Finish | Machined Surfaces (Ra) | 0.8 µm to 3.2 µm |

| Critical Bearing Seals (Ra) | 0.4 µm to 1.6 µm |

This combination of 5-axis machining mastery and metrology-driven quality control forms the foundation of Wuxi Lead’s capability to produce 1000+ precision steel machined parts per order with exceptional repeatability. We translate complex engineering requirements into reliable, high-integrity components, ensuring your assembly lines operate without disruption. Partner with us for steel machining where tolerance adherence and batch consistency are mission-critical.

Material & Finish Options

Material selection is a critical step in the precision CNC machining of high-performance steel components, particularly when producing large-volume runs such as 1000 machined parts. At Wuxi Lead Precision Machinery, we emphasize the importance of aligning material properties with application requirements to ensure longevity, performance, and cost-efficiency. The three primary materials used in such applications—aluminum, steel, and titanium—each offer distinct advantages depending on the operational environment, mechanical demands, and weight considerations.

Aluminum is widely selected for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, automotive, and consumer electronics applications where weight reduction is a priority. Grade 6061-T6 and 7075-T6 are among the most commonly used aluminum alloys due to their balanced mechanical properties and suitability for post-machining treatments such as anodizing. Anodizing enhances surface hardness and wear resistance while providing a clean, aesthetically pleasing finish, which is especially valuable in visible components.

Steel remains the preferred choice for applications requiring high tensile strength, durability, and resistance to deformation under load. Alloy steels such as 4140 and 4340, as well as stainless steels like 304 and 316, are frequently used in industrial machinery, tooling, and structural components. Stainless steel variants offer additional corrosion resistance, making them suitable for medical devices and marine environments. While steel is heavier than aluminum, its mechanical robustness and cost-effectiveness in high-wear scenarios make it indispensable in precision manufacturing.

Titanium, though more expensive and challenging to machine, delivers unmatched performance in extreme conditions. Its high strength-to-density ratio, combined with exceptional resistance to corrosion and elevated temperatures, makes it ideal for aerospace, defense, and medical implant applications. Grade 5 (Ti-6Al-4V) is the most widely used titanium alloy in CNC machining due to its weldability and thermal stability. Despite slower machining speeds and higher tool wear, the long-term performance benefits often justify its use in mission-critical components.

Surface finishing, particularly anodizing for aluminum, plays a vital role in enhancing functional and cosmetic properties. Anodizing creates a controlled oxide layer that improves wear resistance, allows for color coding, and increases adhesion for paint primers. For steel and titanium, alternative finishes such as passivation, powder coating, or bead blasting may be recommended based on environmental exposure and design requirements.

The following table summarizes key mechanical and machining characteristics of commonly used materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Excellent | Anodizing, Powder Coat | Aerospace, Electronics, Automotive |

| Steel 4140 | 655 | 7.85 | Good | Passivation, Plating | Industrial Machinery, Tooling |

| Stainless 316 | 570 | 8.0 | Moderate | Passivation, Bead Blast | Medical, Marine, Food Processing |

| Titanium Ti-6Al-4V | 900 | 4.43 | Fair | Anodizing, Shot Peening | Aerospace, Defense, Medical |

Selecting the optimal material and finish ensures that each of the 1000 machined parts meets stringent performance standards while maintaining production efficiency and cost control. Wuxi Lead Precision Machinery provides expert consultation to guide clients through these decisions, ensuring precision, repeatability, and long-term reliability in every component delivered.

Manufacturing Process & QC

Precision Steel Machining: From Design to Zero-Defect Mass Production

Achieving flawless delivery of 1000 precision steel machined parts demands a rigorously controlled, integrated process. At Wuxi Lead Precision Machinery, we eliminate traditional production gaps by synchronizing engineering, prototyping, and manufacturing under one roof. This unified approach ensures dimensional accuracy, material integrity, and absolute compliance with your specifications from the first prototype to the thousandth component. Our Zero Defects philosophy is not aspirational; it is engineered into every phase through systematic validation and real-time process control.

The journey begins with collaborative design validation. Our engineering team conducts a comprehensive Design for Manufacturability (DFM) review, scrutinizing CAD models for optimal machinability, fixture strategy, and tolerance stack-up analysis specific to steel alloys. We identify potential stress points, thin-wall challenges, or complex geometries early, proposing refinements that maintain functional intent while enhancing producibility and reducing cycle time. This proactive step prevents costly errors before metal is cut, ensuring the design is inherently robust for high-volume steel machining.

Prototyping transitions directly into our controlled production environment using the exact CNC equipment and tooling designated for the final run. We produce functional prototypes on HAAS, DMG MORI, or Makino centers matching the mass production cell. Rigorous first-article inspection follows, employing Zeiss CMMs, optical comparators, and surface roughness testers to validate all critical dimensions against your print. Material certification and hardness testing confirm steel grade compliance. Only after full dimensional and material verification, with documented approval, do we authorize the production sequence. This phase validates not just the part, but the entire manufacturing process capability.

Mass production leverages the validated process with unwavering discipline. Each of the 1000 parts undergoes in-process Statistical Process Control (SPC), with real-time monitoring of critical dimensions via automated probes on the CNC machines. Final inspection employs 100% verification of key features using calibrated CMMs and selective full-spectrum checks per AS9102 standards. Our closed-loop system instantly detects any deviation, triggering immediate corrective action to prevent non-conforming parts from progressing. Traceability is absolute, with individual part data linked to machine parameters, tooling batches, and operator logs.

This seamless integration guarantees consistency. Below are core specifications maintained throughout the 1000-part run:

| Parameter | Specification | Verification Method |

|---|---|---|

| Material | Per spec (e.g., 304SS, 4140, 17-4PH) | Mill Cert + In-house Hardness Test |

| Dimensional Tolerance | ±0.005 mm (typical) | CMM + In-Process Probing |

| Surface Finish | Ra 0.8 µm (typical) | Surface Roughness Tester |

| Geometric Tolerance | GD&T Per Print | CMM + Optical Comparator |

| Process Control | SPC on Critical Features | Real-time CNC Monitoring |

Delivering 1000 identical, defect-free steel components requires more than advanced machinery; it demands process ownership. Wuxi Lead embeds quality into the production DNA, transforming your design intent into guaranteed reality. Partner with us for risk-mitigated, precision steel machining where every part meets the standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Steel Machined Components

When your project demands 1,000 precision steel machined parts, the success of your final product hinges on consistency, accuracy, and reliability. At Wuxi Lead Precision Machinery, we specialize in high-volume CNC machining of steel components with tight tolerances, complex geometries, and uncompromising quality standards. Our advanced manufacturing capabilities, combined with decades of engineering expertise, position us as the ideal partner for OEMs, industrial equipment manufacturers, and high-tech enterprises worldwide.

We understand that scaling production to 1,000 units introduces critical challenges—material consistency, dimensional repeatability, process validation, and delivery timelines. Our ISO 9001-certified facility in Wuxi, China, is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, allowing us to maintain ±0.005 mm tolerances across all parts. Whether your application requires alloy steel, stainless steel, or tool steel, we source certified materials with full traceability and perform in-process and final inspections using CMM, optical comparators, and surface roughness testers.

Our engineering team collaborates closely with your design and procurement departments from the outset. We conduct Design for Manufacturability (DFM) reviews to optimize part geometry, reduce cycle times, and eliminate unnecessary costs—all while preserving functional integrity. This proactive approach ensures faster time-to-market and reduces the risk of rework or non-conformance.

Beyond precision, we offer end-to-end project management, including first-article inspection reports (FAIR), production run documentation, and packaging tailored to your logistics requirements. Our lean manufacturing systems support batch traceability, real-time production tracking, and on-time delivery—critical for integration into your assembly line or supply chain.

For 1,000 steel machined parts, consistency is not assumed—it is engineered. At Wuxi Lead Precision Machinery, we don’t just meet specifications; we ensure every component performs to the highest industrial standards, batch after batch.

Explore how our precision CNC machining services can elevate your manufacturing outcomes. Contact us today to submit your RFQ, share CAD models, or schedule a technical consultation with our engineering team.

Contact Information

Email: [email protected]

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Material Types | Carbon Steel, Alloy Steel, Stainless Steel (300/400 Series), Tool Steel |

| Tolerance | Up to ±0.005 mm |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Machining Types | 3-axis, 4-axis, 5-axis CNC Milling, CNC Turning, Mill-Turn |

| Quality Standards | ISO 9001:2015, FAIR, PPAP, CMM Inspection, Material Traceability |

| Batch Sizes | Prototypes to 10,000+ units |

| Lead Time (1,000 pcs) | 12–20 working days (varies by complexity) |

Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing. Reach out to us at [email protected] and experience the difference that engineering excellence makes.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.