Technical Contents

Engineering Guide: 1 4 Sheet Metal

Engineering Insight: 1/4″ Sheet Metal Fabrication Demands Absolute Precision

In high-stakes industrial applications, the specification of 1/4 inch (6.35 mm) sheet metal is far more than a dimensional choice; it represents a critical balance of structural integrity, weight, and manufacturability. This thickness is frequently mandated in aerospace substructures, heavy-duty machinery guards, defense vehicle components, and precision fixtures where failure is not an option. Achieving true dimensional accuracy and geometric consistency in 1/4″ material presents unique engineering challenges distinct from thinner gauges. Material springback during bending is significantly more pronounced, requiring sophisticated compensation algorithms in CNC press brakes. Thermal distortion during laser or plasma cutting must be meticulously controlled to prevent warpage in this substantial cross-section. Surface finish requirements for weld preparation or final coating adherence also become exponentially harder to maintain uniformly across the increased mass. Tolerances that might be acceptable in lighter sheet metal become critical failure points here, directly impacting assembly fit, load distribution, and long-term fatigue resistance.

The consequences of imprecision are severe. A deviation of even ±0.005 inches in critical bend angles or hole locations within a 1/4″ structural bracket can cascade into misaligned assemblies, compromised load paths, and accelerated wear in high-vibration environments. This necessitates fabrication processes governed by rigorous statistical process control (SPC) and advanced metrology protocols far exceeding standard industry practices. Material certification and traceability become non-negotiable, especially when working with high-strength alloys like 4130 steel or 6061-T6 aluminum common at this thickness.

Our experience fabricating 1/4″ components for Olympic venue infrastructure and classified military programs provides definitive proof of capability under extreme scrutiny. These projects demanded first-article certifications adhering to AS9100 and MIL-STD-883 standards, where geometric dimensioning and tolerancing (GD&T) callouts were measured in thousandths of an inch across multi-axis assemblies. The zero-defect mandate inherent in such work directly translates to the reliability our commercial clients expect.

Understanding the precise behavior of 1/4″ material under stress and during fabrication is paramount. The following table outlines critical specifications and achievable tolerances for this thickness under controlled production conditions:

| Parameter | Standard Tolerance | Lead Precision Achievable Tolerance | Critical Application Impact |

|---|---|---|---|

| Thickness (Nominal) | ±0.005″ (±0.13mm) | ±0.002″ (±0.05mm) | Affects bend allowance calculations and final part strength |

| Bend Angle | ±1.0° | ±0.25° | Critical for assembly fit; prevents gapping in structural joints |

| Hole Location (Dia ≤1″) | ±0.010″ (±0.25mm) | ±0.003″ (±0.08mm) | Ensures bolt pattern alignment in load-bearing connections |

| Flatness (per sq ft) | 0.015″ (0.38mm) | 0.005″ (0.13mm) | Vital for sealing surfaces and precision mounting |

Wuxi Lead Precision Machinery applies this depth of process understanding and military-grade quality discipline to every 1/4″ sheet metal project. We transform the inherent challenges of this thickness into a guarantee of performance, ensuring your critical components meet the uncompromising demands of modern engineering. Precision here isn’t a feature; it’s the absolute foundation of functional reliability.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Sheet Metal Fabrication

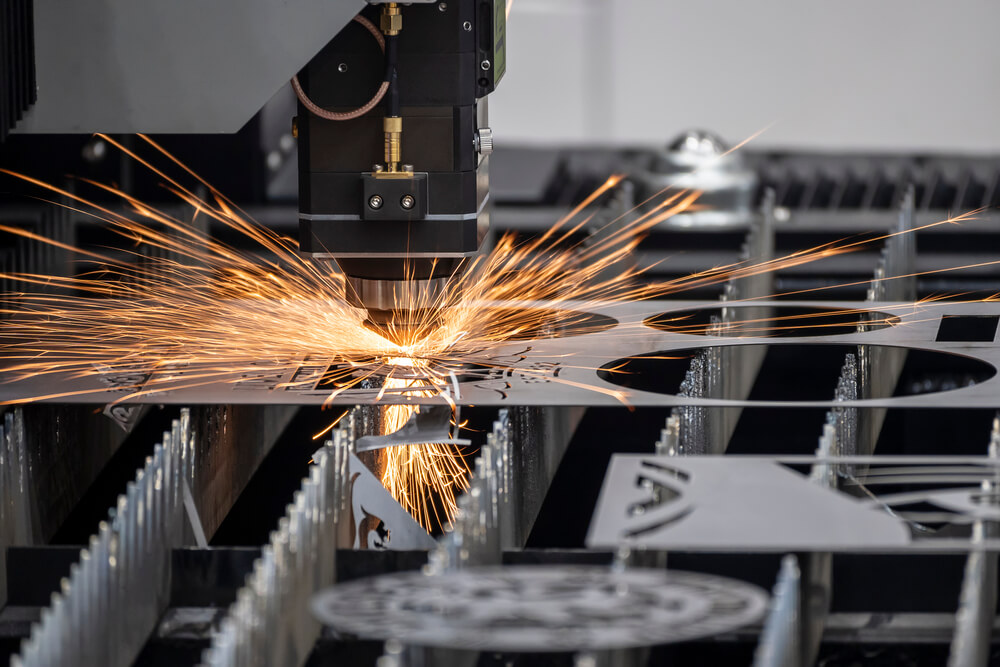

Wuxi Lead Precision Machinery delivers industry-leading technical expertise in the fabrication of 1 4 sheet metal components, combining state-of-the-art equipment with rigorous quality assurance protocols. Our advanced manufacturing ecosystem is engineered to support high-complexity projects requiring tight tolerances, repeatable accuracy, and superior surface integrity. At the core of our production capability is a fleet of 5-axis CNC machining centers, enabling multi-directional precision cutting, drilling, and contouring in a single setup. This eliminates cumulative alignment errors typical in multi-step processes and ensures optimal geometric consistency across both prototypes and high-volume production runs.

Our 5-axis CNC systems are optimized for processing a wide range of sheet metal alloys, including stainless steel, aluminum, carbon steel, and specialty materials used in aerospace, medical, and high-end industrial applications. The dynamic toolpath control allows for intricate feature machining on 1 4 sheet metal stock, supporting complex geometries such as compound curves, deep pockets, and asymmetrical cutouts with minimal material waste. Integrated high-speed spindles and adaptive feed-rate algorithms ensure superior surface finishes and reduced cycle times, enhancing both quality and throughput.

Complementing our machining capabilities is a full-scale metrology laboratory equipped with Coordinate Measuring Machines (CMM) for non-contact and tactile 3D inspection. Every critical component undergoes comprehensive dimensional verification against CAD-defined tolerances, ensuring compliance with ISO 2768 and customer-specific standards. Our CMM inspection process provides full traceability, with digital reports generated for each batch, supporting AS9100, ISO 13485, and other regulated industry requirements.

Material handling and fixturing are designed to minimize deformation during processing, particularly important when maintaining flatness and positional accuracy in thin or large-format 1 4 sheet metal panels. We employ vacuum tables, low-stress clamping systems, and in-process probing to maintain workpiece stability and verify alignment in real time. This holistic approach to precision manufacturing ensures that every part meets the highest standards of dimensional integrity and functional performance.

The following table outlines the standard tolerance capabilities achievable across common fabrication operations:

| Operation | Dimensional Tolerance | Angular Tolerance | Surface Finish (Ra) | Feature Positioning |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.1° | 0.8 – 3.2 µm | ±0.01 mm |

| Laser Cutting | ±0.05 mm | ±0.2° | 3.2 – 6.3 µm | ±0.05 mm |

| Forming / Bending | ±0.1 mm | ±0.5° | N/A | ±0.15 mm |

| Drilling / Tapping | ±0.02 mm | ±0.2° | 1.6 – 6.3 µm | ±0.03 mm |

| CMM Inspection Accuracy | ±0.002 mm (probe) | ±0.02° | N/A | Full 3D reporting |

These technical capabilities position Wuxi Lead Precision Machinery as a trusted partner for OEMs and engineering firms requiring precision-crafted 1 4 sheet metal solutions where performance, reliability, and compliance are non-negotiable.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material choice fundamentally dictates the performance, manufacturability, and lifecycle cost of sheet metal components. At Wuxi Lead Precision Machinery, we guide clients through this critical decision by aligning material properties with application demands, production complexity, and environmental exposure. Understanding the nuances between aluminum, steel, and titanium ensures optimal part functionality and cost efficiency.

Aluminum alloys dominate aerospace, electronics, and transportation sectors due to their exceptional strength-to-weight ratio and inherent corrosion resistance. Grade 5052 excels in marine environments and complex forming operations, while 6061-T6 offers superior weldability and moderate strength for structural frames. Its natural oxide layer provides baseline protection, but anodizing significantly enhances surface durability and aesthetic control. Steel remains indispensable for structural integrity and cost-sensitive applications. Austenitic stainless steel 304 delivers broad corrosion resistance for food processing and medical equipment, whereas 410 stainless provides higher strength and moderate corrosion resistance for cutlery or fasteners. Carbon steel SAE 1008 is ideal for painted or powder-coated enclosures where raw material cost is paramount. Titanium Grade 2 is reserved for extreme environments demanding unparalleled strength-to-weight ratio, biocompatibility, and resistance to seawater, chlorides, and high temperatures, common in aerospace and medical implants. Its high cost and challenging machinability necessitate careful justification.

Surface finishing, particularly anodizing for aluminum, is not merely cosmetic. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and dye receptivity for consumer products. Type III (Hardcoat) anodizing creates a significantly thicker, harder, and more wear-resistant surface essential for aerospace hydraulic components or military hardware, though it requires precise dimensional control during machining. Selecting the wrong finish can lead to premature failure or costly rework.

The following table summarizes critical properties for common sheet metal fabrication materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Weldability | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 5052-H32 | 190-225 | 2.68 | Excellent | Good | Medium |

| Aluminum 6061-T6 | 310 | 2.70 | Good | Very Good | Medium-High |

| Stainless 304 | 515 | 8.00 | Excellent | Good | High |

| Stainless 410 | 517 | 7.75 | Moderate | Fair | Medium |

| Carbon Steel 1008 | 340 | 7.87 | Poor (Requires Coating) | Excellent | Low |

| Titanium Gr 2 | 345 | 4.51 | Exceptional | Good | Very High |

Material selection requires balancing mechanical requirements, environmental factors, fabrication constraints, and total project economics. Wuxi Lead Precision Machinery leverages decades of CNC fabrication expertise and rigorous DFM analysis to validate your material and finish choices. We ensure seamless transition from design intent to high-integrity production, minimizing risk and maximizing component value. Partner with us to transform your sheet metal specifications into precision-engineered reality.

Manufacturing Process & QC

Design Phase: Precision Engineering as the Foundation

At Wuxi Lead Precision Machinery, the sheet metal fabrication process begins with meticulous design engineering. Our team collaborates closely with clients to transform conceptual requirements into detailed 3D models using advanced CAD software such as SolidWorks and AutoCAD. Every dimension, bend, and tolerance is optimized for manufacturability, ensuring compliance with international standards including ISO 2768 and GD&T specifications. Material selection is evaluated at this stage, considering factors such as mechanical strength, corrosion resistance, and thermal stability. For 1.4 mm sheet metal components—commonly used in industrial enclosures, control panels, and precision housings—we recommend materials like cold-rolled steel (SPCC), stainless steel (SUS304), or aluminum (AL5052), depending on application demands. Finite Element Analysis (FEA) is applied where necessary to validate structural integrity under operational loads.

Prototyping: Validating Design in Practice

Once the digital model is finalized, we proceed to prototyping using high-accuracy CNC punching and laser cutting machines. This stage is critical for verifying form, fit, and function before mass production. Prototypes are produced on the same equipment used in full-scale runs, ensuring consistency in quality and dimensional accuracy. Each prototype undergoes rigorous inspection via Coordinate Measuring Machine (CMM) and optical comparators to confirm tolerances within ±0.1 mm. Functional testing, including assembly trials and environmental exposure (if required), is conducted to identify potential design flaws early. Client feedback is integrated swiftly, with design iterations completed in under 72 hours. This agile approach minimizes downstream risks and accelerates time-to-market.

Mass Production: Zero Defects Through Process Control

With prototype approval, we transition to mass production under a fully documented Quality Management System compliant with ISO 9001:2015. Our production line integrates automated material handling, CNC turret punching, fiber laser cutting, press braking, and robotic welding to ensure repeatability and efficiency. Each 1.4 mm sheet metal part is tracked through a digital work order system, enabling full traceability from raw material to finished product. In-process inspections occur at every critical stage—after cutting, bending, welding, and surface treatment—using calibrated gauges and visual checklists. Final inspection includes dimensional verification, surface finish assessment, and packaging review to meet IPC-610 or client-specific acceptance criteria.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness | 1.4 mm (±0.08 mm) |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2° / ±0.1 mm |

| Minimum Bend Radius | 1.0 t (material thickness) |

| Surface Roughness (Ra) | ≤3.2 μm (after laser cutting) |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Prod.) | 10–20 days (after prototype approval) |

| Quality Standard | ISO 9001:2015, ISO 2768, client-specific |

Through integrated design validation, precision prototyping, and disciplined production controls, Wuxi Lead ensures zero-defect delivery for every 1.4 mm sheet metal component.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising 1/4 Inch Sheet Metal Fabrication

Stop compromising on precision, speed, or reliability for your 1/4 inch sheet metal projects. At Wuxi Lead Precision Machinery, we engineer solutions where tolerances matter and deadlines are non-negotiable. As your dedicated manufacturing partner, we eliminate the guesswork in high-stakes fabrication—transforming complex 1/4 inch steel, aluminum, and stainless steel components into repeatable successes. Our integrated CNC ecosystem, certified to ISO 9001 and AS9100 standards, ensures every bend, cut, and assembly meets aerospace, medical, and industrial benchmarks. We don’t just meet specifications; we redefine what’s achievable in sheet metal at this critical thickness.

Our technical mastery is quantifiable. Below are core capabilities for 1/4 inch material processing, reflecting our machinery’s precision and scalability. These specs are not theoretical targets—they are daily deliverables across 500+ client projects annually.

| Capability | Specification | Industry Impact |

|---|---|---|

| Material Thickness Range | 0.06″ – 0.25″ (1.5mm – 6.35mm) | Optimized for 1/4 inch without retooling |

| Laser Cutting Tolerance | ±0.003″ (±0.08mm) | Eliminates secondary finishing |

| CNC Bending Accuracy | ±0.1° angular / ±0.004″ linear | Ensures perfect sub-assembly alignment |

| Kerf Width Control | 0.008″ – 0.012″ (0.2mm – 0.3mm) | Maximizes material yield, minimizes waste |

| Lead Time (Prototype) | As fast as 15 days | Accelerates time-to-market by 30%+ |

Why do global innovators trust Lead Precision for 1/4 inch sheet metal? We merge Chinese manufacturing scale with German-engineered precision. Our 22,000 sqm facility houses 36 state-of-the-art Amada and Bystronic systems, operated by technicians with 10+ years’ average experience. We solve hidden pain points: reducing scrap rates by up to 22% through dynamic nesting software, preventing weld distortion via in-process metrology, and guaranteeing batch consistency even at 10,000+ units. When your design demands perfect edge quality on 1/4 inch stainless or burr-free aluminum brackets, our process validation protocols catch errors before they reach your assembly line.

This isn’t just fabrication—it’s risk mitigation. We absorb supply chain volatility through strategic raw material partnerships and dual-sourcing critical components. Your engineering team gains direct access to our DFM experts during quoting, ensuring manufacturability without redesign delays. For projects where 0.005″ deviations cascade into field failures, partnering with Lead Precision isn’t an option—it’s your quality insurance.

Ready to transform your 1/4 inch sheet metal challenges into competitive advantages? Contact our engineering sales team today. Email [email protected] with your CAD files or specifications. We’ll respond within 4 business hours with a detailed capability analysis and actionable timeline—not a generic brochure. Let’s build what others can’t. Your precision-engineered future starts here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.